CMF Power Select User manual

CUSTOM METAL FABRICATORS, INC.

Installation / Operation Instructions

Power Select

Ver. 3.0

(For serial # 80396 and above)

(PLC VERSION 4.87)

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.31

Table of Contents

Chapter 1 Introduction......................................................................... 2

Chapter 2 Installation.......................................................................... 3

Chapter 3 Operation............................................................................ 8

Chapter 4 Advanced HMI Operations................................................. 11

Chapter 5 Integration ......................................................................... 13

Chapter 6 Maintenance...................................................................... 23

Chapter 7 Troubleshooting................................................................. 24

Chapter 8 Drawings ........................................................................... 27

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.32

1 Introduction

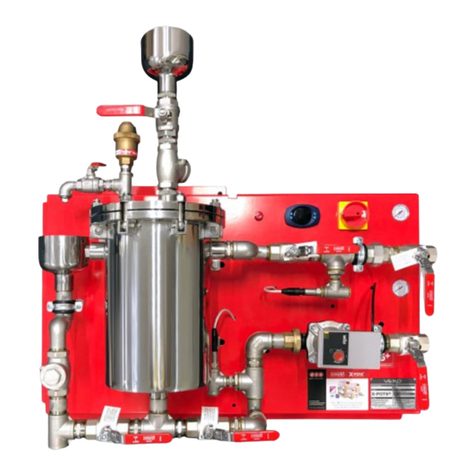

1.1 The CMF Power Select is a semi automatic hydro-electric positioning system for the CMF

"TH" (Turn Head), “HH” (Head House), and “Pendulum” series distributors. The heart of

this system is a micro PLC (Programmable Logic Controller) that controls and tracks the

movement and location of the inner spout. The PLC accepts input from the operator via

a 3.5” touch screen HMI (Human Machine Interface) at the operator panel.Once a

position is selected by the operator, the PLC compares the destination to the current

location and determines a direction of travel selecting the shortest route on full round

models. At this point, the PLC engages the hydraulic system and raises the inner spout.

Once the inner spout is raised, it then rotates to the position selected by the operator and

lowers into the outlet stub. The CMF Power Select incorporates several operation,

safety, and diagnostic routines into the programming to inform the operator of the current

status via the HMI at the operator panel.

1.2 From a controls standpoint, all of the CMF series distributors are identical. This allows

for simple integration of multiple units at the same facility.The following sections

describe how to install various configurations of the Power Select and how to operate and

maintain the system.

1.3 This version of the Power Select has multiple options for controlling and monitoring the

unit. The default setup uses a standard Ethernet connection directly from the HMI to the

Power Select. Other options include, but are not necessarily limited to:

•Controlling the Power Select without the HMI

•Connecting the Power Select and HMI to an Ethernet network for remote

monitoring / control

•Controlling more than one Power Select using only one HMI (the HMI can be

easily programmed for multiple units and scaled with the touch of a button)

•Other connections (see section 5)

Note: Any configuration other than the default 1:1 connection will require connections through

an Ethernet switch. The recommended max length of any single run of Ethernet is 320’

although it has been known to function without issues at longer distances. One way to easily

add more length to Ethernet is to install an unmanaged switch at the first 320’ and continue from

there.

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.33

2 Installation

2.1 The CMF Power Select can be ordered as a complete unit factory installed on a new

distributor, or by itself to be retrofit to an existing “TH” distributor installation in the field.

Section 2.2 details a factory prepared unit. Section 2.3 details a field installation.

2.2 Factory Installed Unit

2.2.1 Upon receipt of the distributor, check for visible signs of damage that may have

occurred during shipment. These include scratched paint, dented housing, oil

leaking from the unit, etc.

2.2.2 Hang the distributor making sure that all outlet spouts are adequately supported to

prevent distortion of the distributor housing.

2.2.3 Mount the operator panel in the desired location. Connect the communication wire

between the operator panel and the main panel (located on the Power Select).

Shielded CAT5e cable is recommended for this connection. See dwg 502950-E

for details. Observe all applicable codes for control installations.

2.2.4 Connect the power supply wires to the terminals provided in the main panel and

the operator panel.See electrical schematics for details.

2.2.5 Turn power on to the unit and the operator panel.

2.2.6 Installation is complete; proceed to section 3, Operation.

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.34

2.3 TH Series Field Installation

2.3.1 Upon receipt of the Power Select, check for visible signs of damage that may have

occurred during shipment. These include scratched paint, dented housing, oil

leaking from the unit, etc.

2.3.2 Remove the current distributor control device and install the provided adaptor into

the inner spout support pipe (dwg 503003-F). The adaptor MUST be welded to

the support pipe. DO NOT drill a hole through the adaptor and use a bolt to

attach the adaptor. A bolted adaptor would allow too much “play” in the inner

spout and the unit would not function properly. The existing hole in the support

pipe is for manual control only (i.e. cable control). If required, the inner spout

support pipe can be unbolted and removed from the distributor to weld the adaptor

in place.

2.3.3 Remove the access covers from the Power Select.

2.3.4 Locate and drill (4) 7/16” diameter holes in the bottom of the distributor using the

supplied dimensions (dwg 503003-F), or use the Power Select frame as a

template.

2.3.5 Raise the Power Select unit up to the bottom of the distributor, aligning the inner

spout support pipe adaptor shaft with the hollow bore and keyway in the gearbox,

making sure the square key is in place.Insert (4) 3/8 inch bolts through the holes

in the distributor bottom and through the holes located in the top of side frames on

the Power Select.

2.3.6 Thread the supplied “encoder bolt” assembly (dwg 503003-F) through the bottom

of the gear box into the support pipe adaptor and tighten.

2.3.7 Carefully slip the encoder shaft into the bolt with the flat area facing the setscrew

in the bolt head. Tighten the setscrew. Note: It is important that the encoder is

mounted properly so that it can’t slip, since this is how the PLC determines the

spout position.

2.3.8 Attach the “encoder tether” to the frame of the Power Select and to the encoder

bracket with ¼” bolts and tighten.

2.3.9 Connect the loose M12 cable to encoder. Note: This is a keyed connector. It

must be rotated properly or it will not plug in.

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.35

2.3.10 Mount the operator panel in the desired location. Connect the communication

wire between the operator panel and the main panel (located on the Power

Select). Shielded CAT5e cable is recommended for this connection. See dwg

502950-E for details. Observe all applicable codes for control installations.

2.3.11 Connect the power supply wires to the terminals provided in the main panel and

in the operator panel. See electrical schematics for details.

2.3.12 Turn on power to the main panel, and the operator panel.

2.3.13 In order to make the adjustments needed for the system to function properly, it

will be necessary to manually operate the unit. Manually moving (jogging) the

Power Select is accomplished by starting the hydraulic pump and then pushing or

pulling the red manual override disks located on the ends of the solenoid valves.

(Fig 1) Note: You will notice that it is much easier to push the valves than to pull

them. This is normal.

Fig. 1: Solenoid Valve Override

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.36

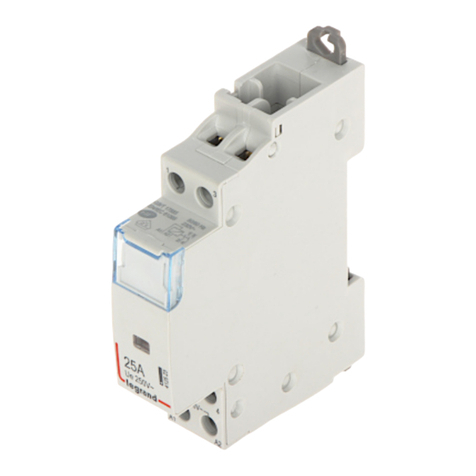

2.3.14 Remove the cover from the main electrical panel and locate the motor contactor

on the topmost terminal strip on the left side.In the center of the motor contactor

is a blue manual override switch. Slide this manual override to the left to engage

the contactor. (Fig 2) As long as this override is held, the hydraulic pump will run,

supplying hydraulic pressure to the system. With the pump running, use the

solenoid valve override controls to move the inner spout as outlined in the

previous section. Be sure that the inner spout is all the way UP before

rotating.

Fig. 2: Motor Contactor

2.3.15 With the lift cylinder retracted (down position), check the position of the down

proximity sensor. If needed, adjust the down proximity sensor block to a point

where the LED light on the sensor comes on and the block completely covers the

face of the sensor with a maximum 1/16” gap between the sensor and the block.

(Fig. 3) Note: Intrinsically safe sensors are opposite meaning the light will come

on when the sensor leaves the block, and the light will go off when the sensor is

in front of the block.

Fig. 3: Proximity Sensors

2.3.16 Jog the Power Select (UP) until the lift cylinder is fully extended (up position),

check the up proximity sensor as outlined above.

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.37

2.3.17 Jog the Power Select (ROTATING) until the inner spout is aligned with the

number one outlet (dwg 503003-G). Jog the inner spout (DOWN) until the lift

cylinder is fully retracted (down position). Ensure that the inner spout has

engaged the locator ring and the outlet stub.

2.3.18 It is now time to “teach” the PLC the position of each stub outlet. Section 4.1

describes this procedure. At this point it is recommended to read through section

3, Operation, before continuing the setup procedure.

2.3.19 After teaching the outlets, installation is complete; refer to section 3 for normal

operation.

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.38

3 Operation

3.1 Operator Panel

3.1.1 The operator panel consists of an electrical enclosure and the HMI

(Human Machine Interface). The HMI is a touch screen interface that allows the

operator to interact with the machine.

3.1.2 To navigate the HMI, there are buttons displayed on the screen. To activate a

button, simply touch it lightly. Some buttons have a built in delay. Delay-type

buttons must be touched and held for 1 second before the action will execute.

There are also textboxes to display and input data. Just like a button, touch the

textbox to edit the value. The “CMF” logo at the bottom of the screen with either

take you to the “MENU” screen, or back to the “HOME” screen depending on what

screen is currently displayed. Touch the banner at the top of the screen at any

time to view messages.

3.2 Power Up

3.2.1 After the unit is installed, and power is turned on to the main panel and the

operator panel, the HMI will boot to the “Welcome” screen.

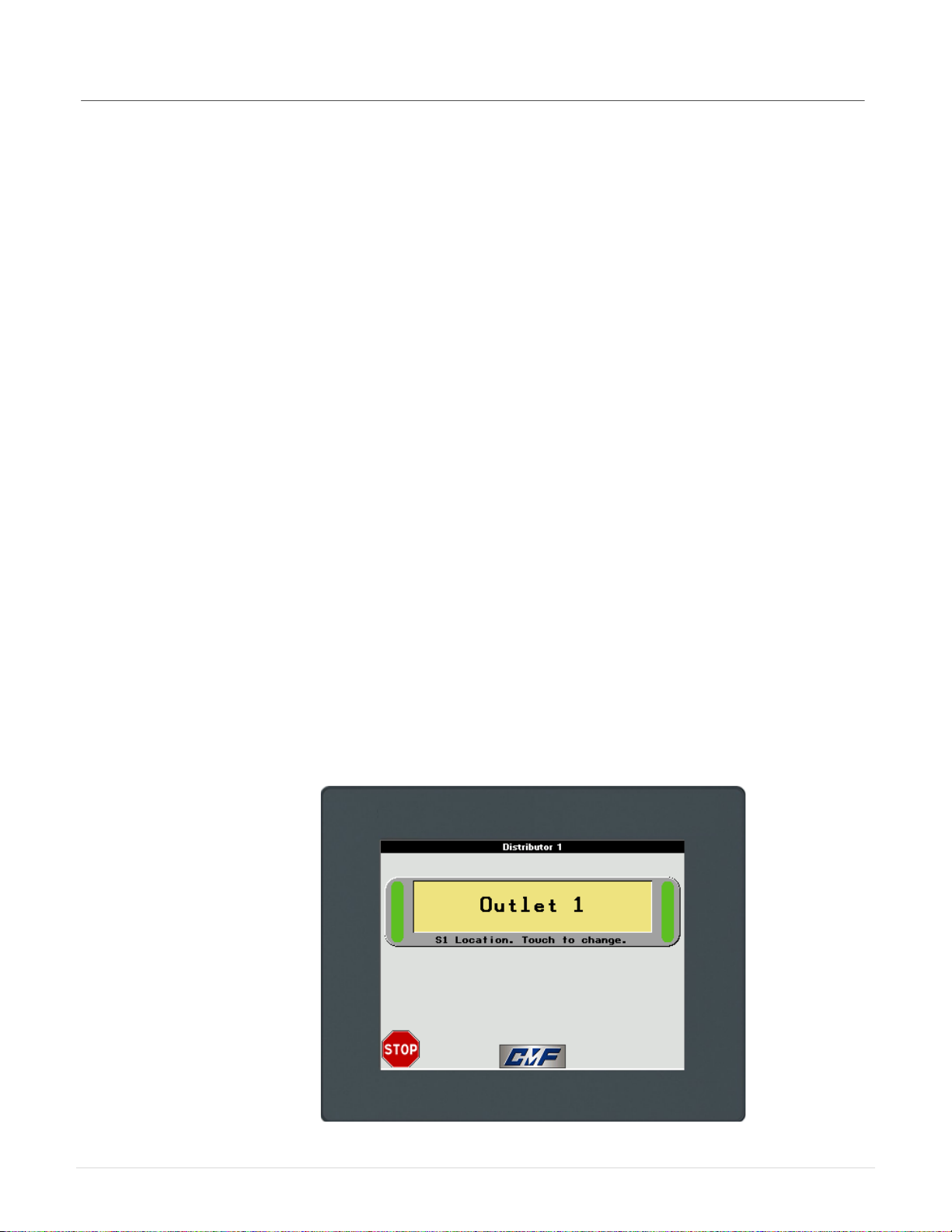

3.2.2 Once the operator closes the welcome screen, the HMI will display the “Home”

screen (Fig 4). From the “Home” screen, the operator can see the current position

of the inner spout(s) and access other screens by interacting with the buttons.

Fig. 4: Home screen

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.39

3.2.3 If the machine is booting up for the first time, or if any fault has occurred, the

operator may see the “Machine Stop” alarm banner and a popup window with

pertinent information about the fault. If the “Fault Code” popup is not visible, but

the alarm banner is being displayed at the top of the screen, the operator can

touch the banner to display the fault code.

Fig. 5: Alarm/Fault Code

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.310

3.3 Selecting an Outlet

3.3.1 To change the position of the spout, press the button on the “Home” screen that

corresponds to the spout you want to move.

3.3.2 From the “Outlet Selection” screen (Fig. 6), choose the outlet number that the

spout should move to and press the button for at least 1 second. This delay

acts as an interlock to keep from accidentally changing the outlet. After the button

is pressed, the “moving” indicator will appear on the screen. When the inner spout

has reached its destination, the button for the corresponding outlet will turn green

and the “moving” indicator will disappear.

Fig. 6: Outlet Selection screen

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.311

4 Advanced HMI operations

4.1 Logging In

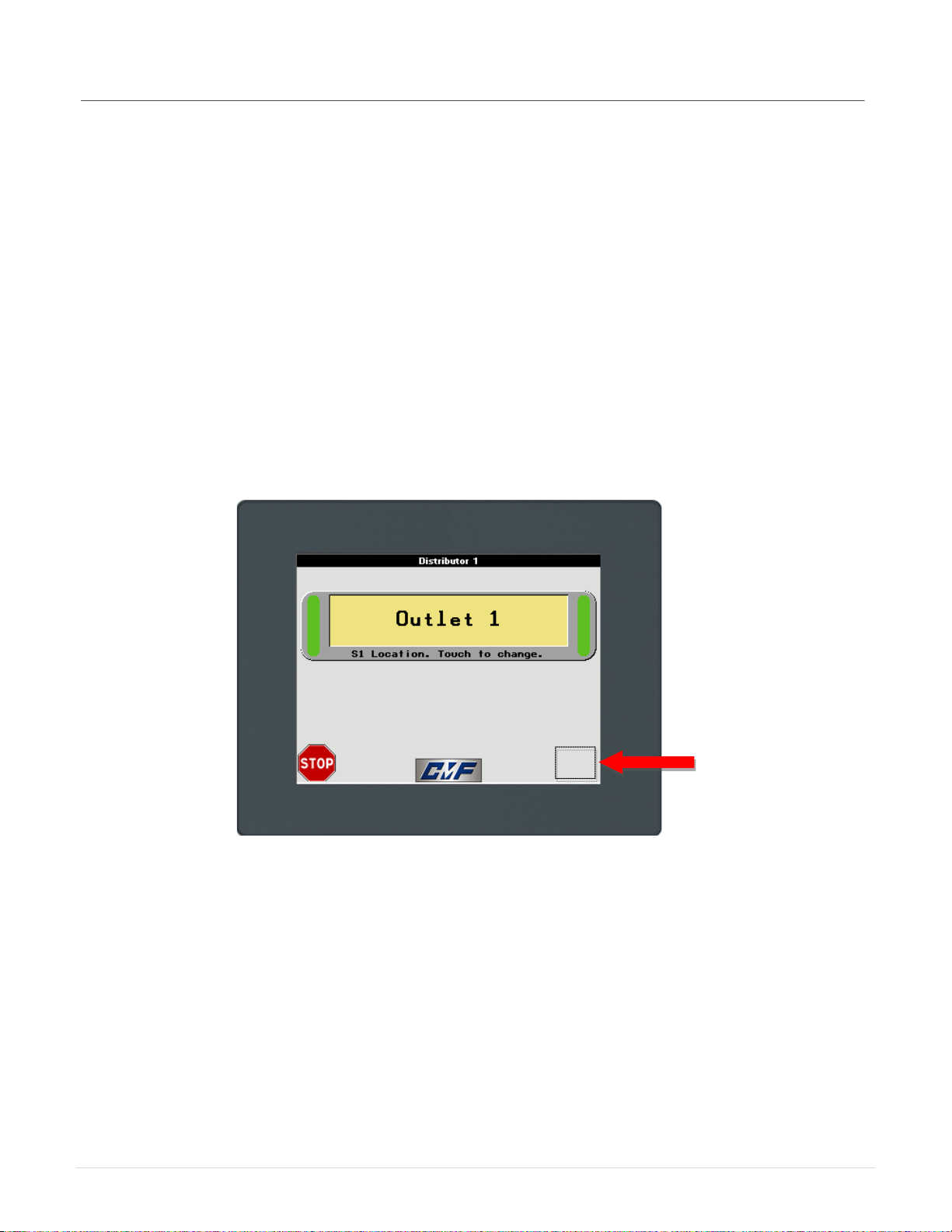

4.1.1 For advanced setup and maintenance, the operator must “Log In”. From the

“Home” screen, touch and hold in the lower right hand corner of the screen until

the “Login” screen is displayed (about 3 seconds). Touch the “Name” textbox and

type the word “MANAGER” in upper case, and then press the “Enter” button.

Touch the “Password” textbox and type the word “CMF” in upper case. Touch the

“padlock” icon to login and confirm that the “Current User” field has changed to

“MANAGER”. Touch the “home” icon to return.

Fig. 7: Invisible Button

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.312

Fig. 8: Login Screen

4.1.2 After successfully logging in, a button will show up on the “Home” screen. Use it

to enter the “Setup” screen.

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.313

4.2 Teaching Outlets

4.2.1 In order for the PLC to direct the spout to the proper outlet, it is required to “teach”

each position and store these set points into memory.

4.2.2 From within the “Setup” screen, touch the “Maintenance Mode” checkbox to

disable the machine automation.

4.2.3 Confirm that the “Number of Outlets” textbox matches the number of outlets on the

distributor.

4.2.4 Touch the setup button for the spout being configured. For example, on a single-

spout distributor, touch the “S1 Setup” button.

4.2.5 With the inner spout seated in the number one outlet as instructed in section

2.3.17. Touch and hold the “Set Home Position” button until the “Shaft Position”

textbox displays the new value. The default “home” position of the encoder is

“45”. This procedure changes the offset of the encoder so that the current inner

spout position is the starting point for all other positions.Note: The encoder reads

a value from 0-4096. The encoder shaft position is NOT the same thing as the

distributor outlet number. For example, with the inner spout at outlet #2, the

encoder shaft position might be at a value of 170.

4.2.6 Touch the “Teach Outlets” button.

4.2.7 Each outlet has a unique system identifier. For instance, (Inner Spout 1: Outlet 1)

is labeled “H101”. Or (Inner Spout 2: Outlet 10) is labeled “H210”.

4.2.8 In order to “teach” the current outlet as “position one”, either touch and hold the

“H101” button until the corresponding value changes or touch the textbox and

enter the value manually. Jog the inner spout to the next outlet as described in

section 2.3.

4.2.9 Repeat the procedure from section 4.2.8 for the remaining outlets, confirming that

each outlet has a unique value, and that these values increment from smallest to

largest. Note: The values must be in order with each one being larger than the

last. There can be no duplicate values. For example, (45, 170, 295, 420, 545,

670) is an acceptable range. None of the values should be “0”.

4.2.10 Touch the “Backup to HMI” button. This will store the data in the HMI in case the

PLC would ever need to be replaced. Touch the “Backup PLC” button. This will

store the data in the PLC persistent memory area.

4.2.11 Touch the “Log Out” button.

4.2.12 Configuration is complete. Refer to section 3 for normal operation.

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.314

5 Integration

5.1 If required, the power select can be controlled by 3rd party hardware. There are 4 options

available for communicating with the on board PLC.

1. Modbus RTU (serial)

2. Modbus TCP/IP (Ethernet)

3. Ethernet/IP (CIP)

4. Cam switch / Relay control (24vdc signals)

5.2 Modbus Parameters

•Baud rate: 19200

•Data Bits: 8 (RTU)

•Parity Bits: none

•Stop Bit: 2

•Response Timeout: 200ms

•Time Between Frames: 3ms

•@ node address 1

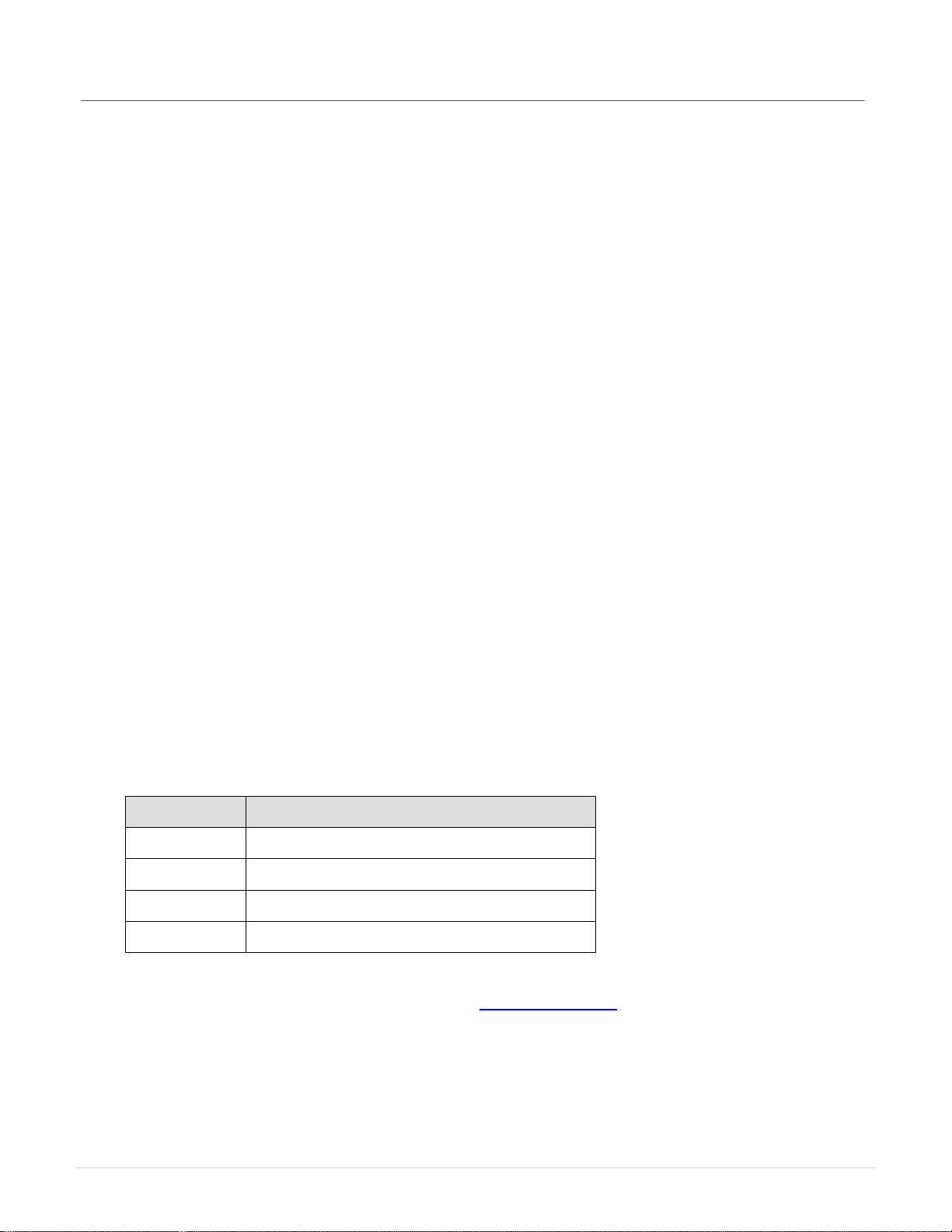

5.3 Supported Modbus Requests

5.3.1

Function

Description

3 (3h)

Read multiple internal registers %MW

6 (6h)

Write single holding register %MW

16 (10h)

Write multiple registers %MW

23 (17h)

Read/Write multiple registers %MW

For more information on Modbus, refer to www.modbus.org

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.315

5.4 Required Memory Objects

Address

Symbol

Description

Access

%MW1 S1_OUTLET_SELECT

Spout 1 outlet select. Set this MW to the corresponding

outlet position (101-130) to change the position of the

spout.

READ/WRITE

%MW30 FAULT_CODE

Fault code for diagnostics. Gets reset by the system

with “RESET”.

READ ONLY

%MW31

RESET

Set to “1” to reset the machine.

READ/WRITE

%MW33 MAINTENANCE_MODE

Set to “1” to bypass automation and allow for manually

moving the inner spouts. Gets reset by the system

with “RESET”.

READ/WRITE

%MW35 E_STOP

Set to “1” to disable the machine. Gets reset by the

system with “RESET”.

READ/WRITE

%MW43 S1_AT_DESTINATION

Spout 1 is at its destination and in the hole. Gets set

to “1” by the system when the condition is true.

READ ONLY

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.316

5.5 Optional/Advanced Memory Objects

*These values should only be modified during setup of the machine. Check all values before attempting to

run the machine.

Address

Symbol

Description

Access

%MW0 CONTROL_TYPE

Type of input control. 0, 1, or 2 Gets set by sending

“RESET” from respective device. Set to “3”

Manually for “Modbus / Other”.

(CMF / HMI = ”0”, Ethernet/IP = ”1”, Cam/Relay =

”2”, Modbus / Other = “3”).

READ/WRITE

%MW5

NUM_INNERSPOUTS

Total number of inner spouts.

READ/WRITE

%MW6 NUM_OUTLETS

Total number of outlets. Set this MW to match the

number of outlets on the distributor.

READ/WRITE

%MW7 DISTRIBUTOR_TYPE

Type of distributor. (Flat Back= ”1”, Full Round= ”2”,

Pendulum= ”3”, Head House= ”4”).

READ/WRITE

%MW32 MACHINE_STOP

Gets set to “1” by the system if a fault has occurred.

Gets reset by the system with “RESET”.

READ ONLY

%MW60 MOVING

Gets set to “1” by the system when machine is

moving.

READ ONLY

%MW67 HEARTBEAT

Toggles from “0” to “1” every 1 second. Can be

used with a timer to confirm the presence of the

machine on the bus.

READ ONLY

%MW101-n

H101-H1n (“n” = # of

outlets on the distributor)

Spout 1 outlet positions: Used to store the unique

position of each outlet. READ/WRITE

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.317

5.6 Ethernet

5.6.1 The default network parameters for the Ethernet connection are shown below.

These parameters can be changed by connecting the PLC to a switch/hub and

entering the IP address in a standard web browser such as Google Chrome or

Mozilla Firefox. If a switch is not available, a 1:1 connection can be established

with a computer provided the computers IP address is set to static and configured

to use the same subnet mask as the PLC.

5.6.2 Default network parameters

PLC IP address: 192.168.1.51

HMI IP address: 192.168.1.50

Subnet mask: 255.255.255.0

5.6.3 Changing the PLC network parameters

Enter the current IP address of the PLC in the web browser address bar. Enter

the username and password. Username: USER Password: USER. Once

logged in, browse to the “Maintenance” tab and click “Post Conf” on the left side of

the page. You can now edit the network parameters. Be very careful when editing

the post file and double check your entry before clicking on the “Save” button. For

the new settings to take effect, a power cycle of the PLC is required.

Fig. 9: PLC login

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.318

Fig. 10: PLC network settings

Note: Notice the parameters are separated by commas and NOT periods. The file will be

ignored if periods are used. For the new settings to take effect, a power cycle of

the PLC is required.

Installation / Operation Instructions

CMF Power Select Ver. 3.0

REV 6.319

5.6.4 Changing the HMI network parameters

In order to modify the HMI network parameters, the user must login as

“MANAGER” to the HMI. This process is described in section 4.1.1. After logging

in, from the “Home” screen of the HMI, touch the CMF logo at the bottom of the

screen to enter the “Menu” screen. Touch the “Network Settings” button. To

modify the local network settings for the HMI, touch the “This HMI Network

Settings” button. To modify which unit/s that this HMI can communicate with,

touch the “Equipment To Control” button. If you changed the IP address of the

PLC, you have to update this parameter in the HMI in order to establish

communication to the new PLC address. Note: You cannot change the actual

IP address of the PLC from the HMI. This must be done within the PLC web

interface as outlined in section 5.6.3, or with a script on an SD card.

Table of contents

Popular Industrial Equipment manuals by other brands

Meanwell

Meanwell UHP-200A Series manual

Alfalaval

Alfalaval T6 BZM instruction manual

TigerStop

TigerStop TigerCrossCut installation guide

Black Hawk Automotive

Black Hawk Automotive Porto-Power B65139 Operating instructions & parts manual

Strack

Strack PowerMax SN5650-PMU-0330 operating instructions

Haufftechnik

Haufftechnik HSD100 EW 1x24-44+4x7-12 b40 installation instructions

DryAIR

DryAIR MAXCOIL HEFA 600 MAX Operator's manual

woodmizer

woodmizer E10 Safety, Operation, Maintenance & Parts Manual

KEBCO

KEBCO COMBISTOP 28 Installation

Delta

Delta DVP-ES2 Operation manual

Ebmpapst

Ebmpapst W2E200-HK86-01 operating instructions

Wesco

Wesco DM-800-HR-MDT Operating instructions and parts manual