TOLOMA

TIC

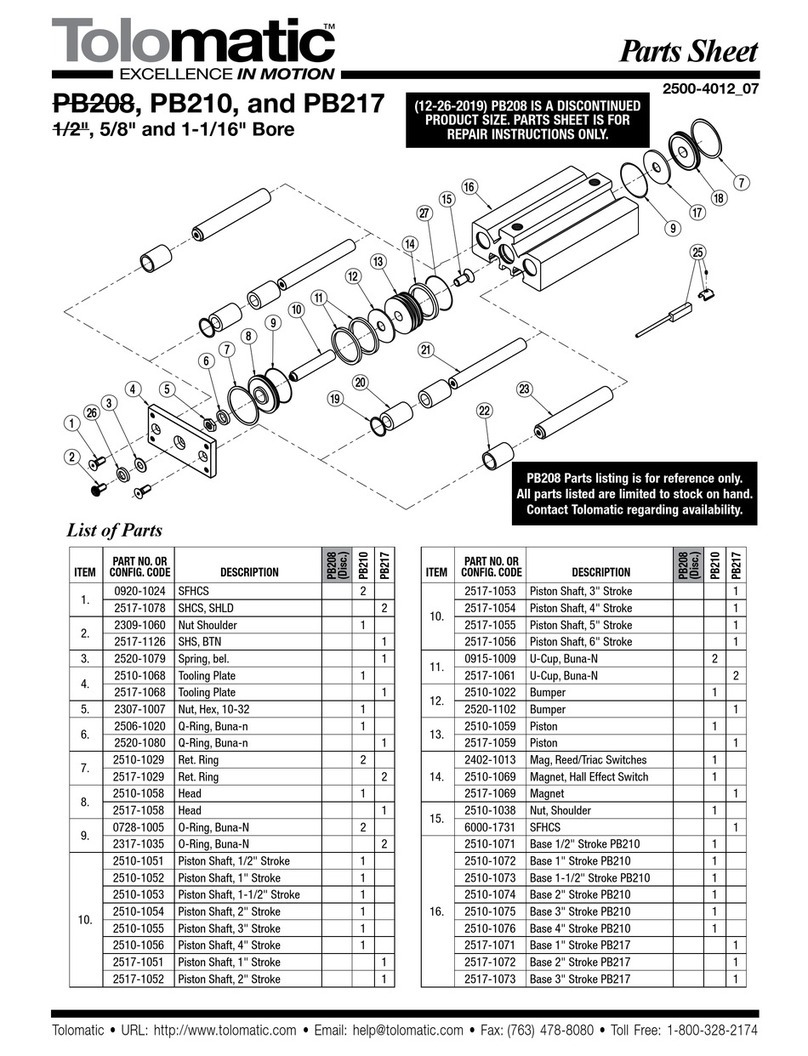

•

URL:

http://www

.tolomatic.com

•

Email:

[email protected] •

Fax:

(763)

478-8080

•

T

oll

Free:

1-800-328-2174

Parts Sheet #3420-4005_11_BC320ps

4 – Instructions BC320, BC3M20

CYLINDER DISASSEMBLY INSTRUCTIONS FOR INSTALLATION OF

REPAIR KITS ONLY

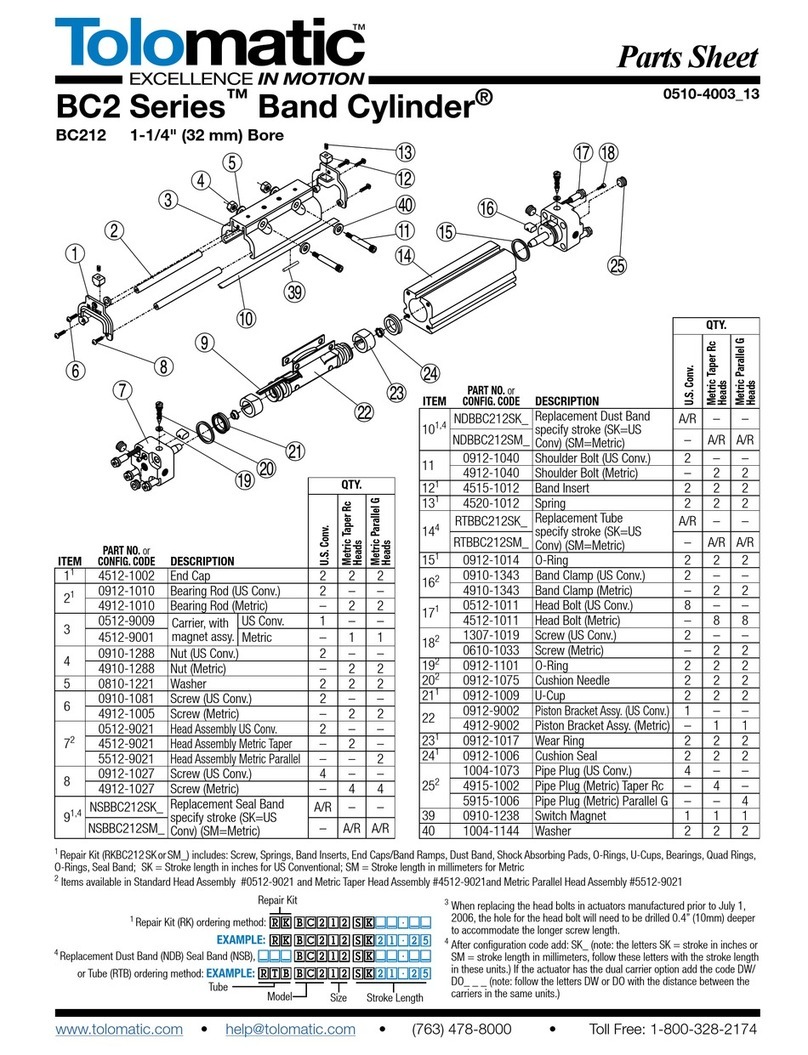

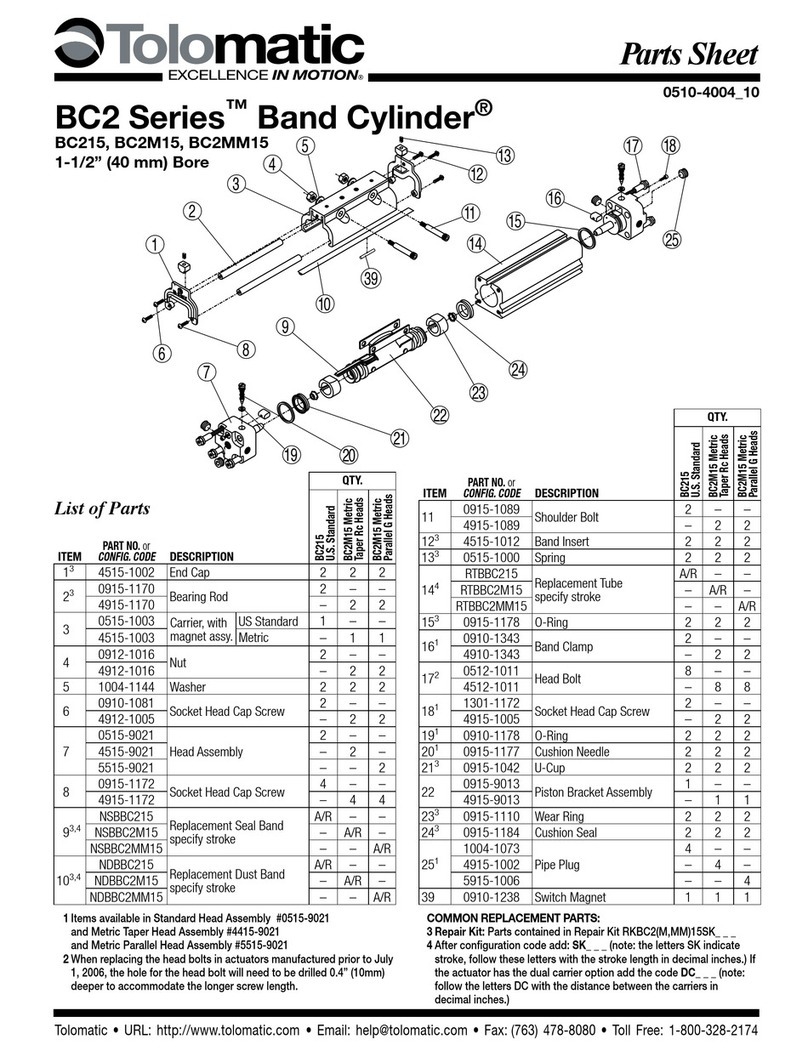

1. Remove Band Cylinder from machinery.

2.

Remove any foot mounting hardware external shock absorbers or

switches if present. Remove the four Head Screws(13) and the two

Set Screws(6) from each cylinder Head(8). Remove the Upper Clamp

Pad(4), Upper Clamp(5) and Lower Clamp(3). Remove Heads.

3. Remove Screws(42) from End Caps(26) and slide End Caps off

Carrier(33). Slide off Carrier Cover(27). Remove top Dust Band(2).

Remove Screws(29) to release Piston Blocks(38). Slide Carrier(33)

slightly either direction to remove Piston Blocks(38) and release

Piston Bracket Assembly(18). Slide Piston Bracket Assembly out

end of tube.

CAUTION: DO NOT remove the Carrier or the rails. Ball Bearings

will fall out as a result.

4. Dislodge the inner Sealing Band(1) from its groove by gently press-

ing down on the band with an O-ring Pick or similar tool.(When

doing so, take care that NO SCRATCHES are made in the tube

bore slot.) Remove Sealing Band.

CYLINDER ASSEMBLY INSTRUCTIONS

1. CLEAN AND LUBRICATE

Thoroughly clean all components, particularly the tube bore slot and

bands. Thoroughly lubricate the tube with Magnalube®-G grease.

2. READY INNER SEALING BAND

Lubricate rubber strip on both sides of new Sealing Band(1) with

Magnalube®-G grease. Slide Sealing Band(1) into cylinder

Tube(22) with rubber portion facing up. Center band in Tube so

equal lengths of Band extend out both ends.

CAUTION: Metal edges of Sealing Band are sharp. Exercise caution

to avoid injury to yourself of the Band and Tube when inserting.

3. INSTALL PISTON ASSEMBLY

Lubricate and install new U-Cups(12)(lip seals facing out) onto

Piston ends(18). Lubricate and install new Cushion

Seals(20)(small end facing out) into Piston ends and rotate to seat

them in their grooves.

NOTE: If the cylinder will be used with optional shock absorber

packages, do not install the Cushion Seals. Doing so will adversely

affect shock performance.

Lubricate and install new Wear Rings(17) onto the piston with the

thinner edge and widest part of the flat inward, lining up the wider

flat portion with the band ramp and the narrower flat portion with

the flat on the Piston. Place a small amount of grease into the

Cushion Seals on each end of the Piston. Fill indentations on both

sides of the Piston Bracket Assembly(18) completely with grease

and install into the cylinder Tube(22) feeding the Sealing Band(1)

between the Piston and Bracket. If the cylinder is equipped for

switches, it is important to note which side of the Piston Bracket

Assembly(18) contains the Magnet, as switches must be attached

to that side of the Tube. Slide the Piston Bracket Assembly(18) to

the Carrier(33), slide the Carrier back over the Piston and continue

to move the Piston Bracket Assembly the length of the tube to seat

the sealing band in its groove. Wipe away excess grease.

NOTE: If Tube and Piston were greased properly, excess grease

should be present as Piston exits end of tube.

4. TRIM SEALING BAND

With a razor blade, remove rubber from extended band until flush

with the end of tube. With tin snips, trim band to length indicated.

Cylinder Size Trim Length From Tube

2"(50 mm) 1.200" (30.48 mm)(Tolerance of +/- .032")

CAUTION: Bands inaccurately cut too long may cause serious

injury to your hand when pressing the head onto the tube.

5. INSTALL HEADS

Lubricate and install new O-Rings(11) onto Head snouts. Lubricate

and install new O-rings(16) into cross ports on Heads(8). Remove

Cushion Needle Valve(10) and lubricate and install new O-Rings(9)

onto Cushion Needle Valves. Insert Cushion Needle Valves(10)

back into Heads(8). Insert heads into tube using a slight rocking

motion. DO NOT TWIST. Twisting the head during installation may

cut the O-ring resulting in excessive leakage during operation.

NOTE: When inserting heads, make sure band does not get

pushed backwards into tube. Rubber on band must remain flush to

the tube after head installation.

Install Head Bolts(13) into heads(8). Torque Head Bolts(13) to

180-195 in.-lbs(20.34-22.03 Nm).

6. LUBRICATE BALLWAYS

Before installing the top Dust Band(2) lubricate the ballways with

Mobil HP grease.

7. INSTALL CARRIER STOPS

Place a Piston Stop(38) on either side of the Piston Bracket

Assembly(18), notch on Stop to face bracket. Slide the Carrier(33)

over the Piston Bracket and Carrier Stops(38) until holes in the

Carrier line up with holes in Piston Stops. Apply Loctite #242 on the

Screws(29) and secure stops to the carrier. There should be no

slack between stops and bracket.

8. INSTALL DUST BAND

Install the top Dust Band(2) over the Carrier(33) centering it along

the length of the cylinder. Slide Carrier Cover(27) into slots on top

of Carrier. Apply Loctite #242 to Screws(42) and secure End

Caps(26) to ends of Carrier(33). With tin snips, cut ends of top

band 1/16" in from outside edge of Head(8). Place a Lower

Clamp(3) between the Sealing Band(1) and Dust Band(2). Place

Upper Clamp Pad(4) and Upper Clamp(5) in each Head(8). Apply

Loctite #242 to Set Screws(6) and insert in Upper Clamp(5).

Torque set screws to 20-30 in.-lbs. to secure bands.

9. CHECK ASSEMBLY

Run the Carrier(33) back and forth along the full stroke to make

certain the cylinder is properly assembled before applying air.

Before mounting cylinder back in application, check the cylinder’s

internal cushions.(If optional shock absorber kits are being used,

this step can be eliminated as Cushion Seals(20) were not

installed.) Push the Carrier(33) to one end. You should feel the

Cushion decelerate the Carrier before the Cushion bottoms out. If

the Carrier slams into the end of the cylinder, either the Cushion

Seals have not been properly installed or the Cushion Needle

Valve(10) is adjusted too far out.

10. REMOUNT

Before installing back in application, check your air lines to be sure

they are in good condition and free of leaks. Remount and apply air.

If external shock absorbers are not being used, readjustment of the

Cushions may be necessary. Start by screwing the Cushion Needle

Valve(10) all the way in but do not tighten, then back it out slightly.

Cycle the cylinder and back the Cushion Needle Valve out as nec-

essary to reduce the amount of cushion. This will prevent the load

from slamming into an under adjusted cushion and prevent band

damage caused from pressure spikes as a result of over tightening

the Cushion Needle Valve.