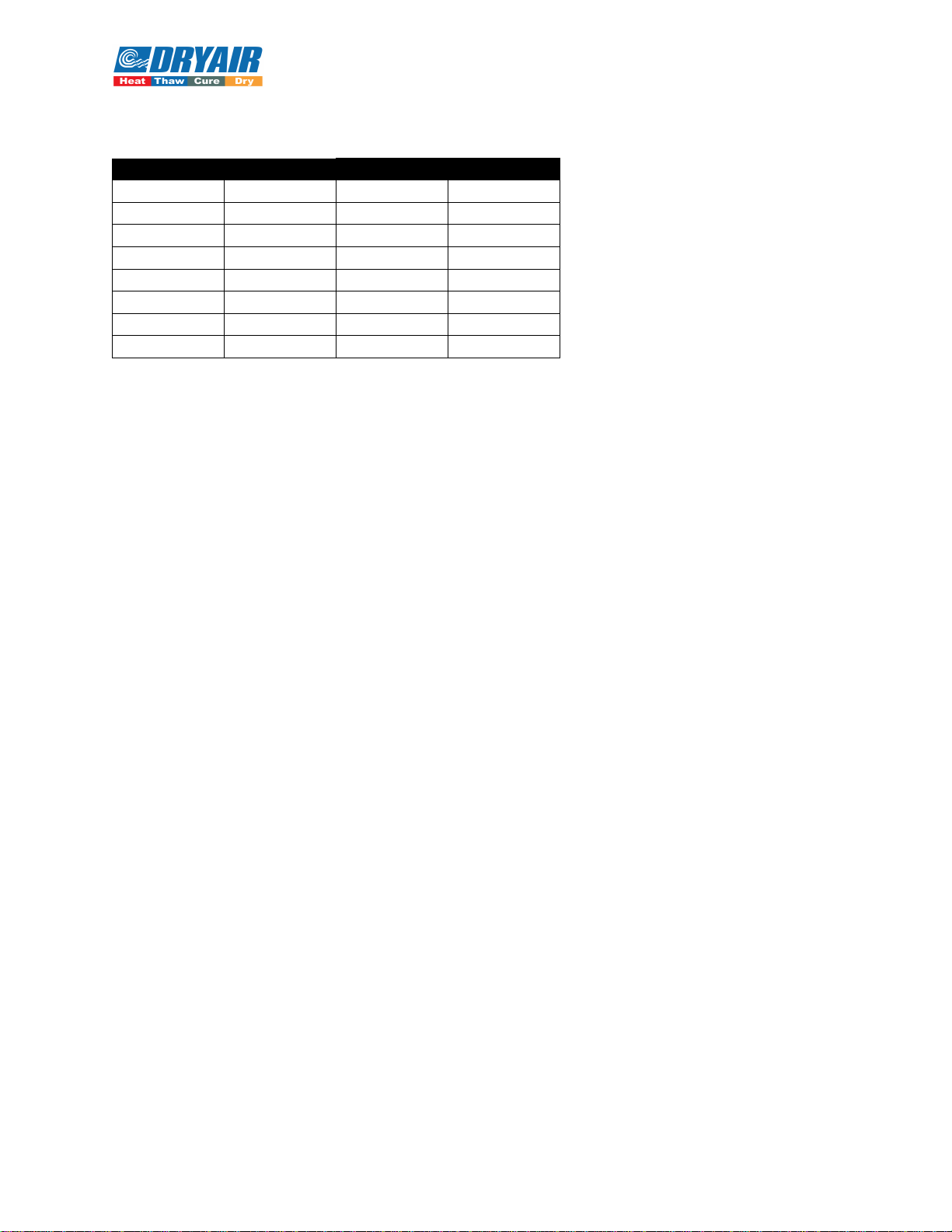

Table of Contents

1. Warranty Policies & Claim Procedures...................................................................................1-1

Warranty Policies ....................................................................................................................1-1

BasicWarranty Policy..........................................................................................................1-1

Extended Warranty Policy ...................................................................................................1-1

Exceptions to the Warranty Policies....................................................................................1-1

Owner Obligations...............................................................................................................1-2

Manufacturer Obligations ....................................................................................................1-2

Warranty Claim Procedure......................................................................................................1-3

2. Safety Concerns.......................................................................................................................2-1

General Safety Guidelines.......................................................................................................2-1

Heating Appliance...................................................................................................................2-1

HTF .........................................................................................................................................2-1

3. Introduction & Installation ......................................................................................................3-1

Positioning...............................................................................................................................3-1

Electrical Connections.............................................................................................................3-1

Fluid Connections....................................................................................................................3-1

4. Operation.................................................................................................................................4-1

Controls ...................................................................................................................................4-1

5. Troubleshooting.......................................................................................................................5-1

Fan Does Not Start ..................................................................................................................5-1

Fan is Running but No Heat....................................................................................................5-1

HTF is Leaking........................................................................................................................5-1

6. Maintenance ............................................................................................................................6-1

Daily Checklist........................................................................................................................6-1

Check the Heat Coil for Cleanliness or Clogging................................................................6-1

Check all Fluid Fittings and Connections Daily..................................................................6-1

Storage.....................................................................................................................................6-1

Hardware..............................................................................................................................6-1

Hose & Poly.........................................................................................................................6-1

HTF .........................................................................................................................................6-1

7. Appendix .................................................................................................................................7-1

Electrical Schematic................................................................................................................7-1

Product Dimensions ................................................................................................................7-2

Heat Transfer Fluid Information .............................................................................................7-3