TigerStop TigerCrossCut User manual

2

Quick Reference

Cards

Nut Pack Power Cable

Controller

Cable

Controller

Stand

Controller

Serial Number

Extension

Motor

Cover

F-45 End Plate End Plate Bar

F-45 Middle Plate

F-45 Hardware

Pack

3

Safety First!

WARNING: Installation of your TigerStop Product must be done by a person trained in the safe

design and installation of automation products, and in the safe operation of power equipment. Ensure

that such installation meets all legally required safety requirements and guidelines, and that proper

guarding and safety devices are provided on all sides of the equipment to preclude unintended access

during operation. Consult with and follow the recommendations of a qualifi ed safety engineer.

WARNING: TigerStop Products are components intended for use in conjunction with potentially

dangerous machinery. The use of TigerStop Products does not make other machinery safe. TigerStop

Products are not intended to substitute, in any manner, for safe operating practices in general, or for

safety features present in other machines designed to make those machines as safe as possible.

TIGERSTOP PRODUCTS, IF USED OR INSTALLED IMPROPERLY, MAY CAUSE PERSONAL

INJURY OR DEATH AND SHOULD ONLY BE OPERATED BY PERSONS TRAINED IN THEIR

SAFE OPERATING PROCEDURES. Illustrations of TigerStop Products in use do not show, and are

not intended to show, all safety features and practices necessary for their safe operation.

GENERAL

WARNINGS

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

WARNING: TigerStop Products must be installed in accordance with all local, state, and federal

regulations. Only personnel properly trained in the safe design and installation of automation

machinery and related power equipment should install TigerStop Products onto other equipment, to

ensure a safe and proper work station. TigerStop Products should not be operated without proper

training, both in the operation of TigerStop Products, and in the operation of related equipment.

INSTALLATION

WARNINGS

IMPORTANT CAUTION:

The motor box (compartment) contains DC voltage with potentially FATAL amperage. NEVER attempt

any unauthorized actions inside the motor box.

WARNING: Using a TigerStop interconnect does not relieve you of the responsibility for making sure

that your saw or other tool has all the necessary safety equipment in place. All installations must

meet all legally required safety requirements and guidelines. Installation and training should be done

following the recommendations of a qualifi ed safety engineer.

INTERCONNECTS

DANGER: This machine can start, move and stop automatically. Keep hands and loose clothing

clear of moving parts while operating. Moving parts can crush and cut. When used with a saw or

other cutting equipment, bodily injury and death may result if operated without safety guards on

all machines. Do not operate with guards removed. Operators must wear adequate eye and ear

protection.

OPERATION

DANGER! Don’t get pinched by the push feeder. Keep your hands away when in motion!

4

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

Do not use TigerStop machines in a dangerous environment. Using power tools in damp or wet

locations or in rain can cause shock or electrocution.

Do not operate near fl ammable liquids or in gaseous or explosive atmospheres!

Wear proper apparel, no loose clothes, long hair or jewelry which could get pulled into moving

machinery or materials.

Wear non slip footwear, safety glasses, ear protection and a dust mask.

Use only 3- wire extension cords that have 3-prong grounding type plugs and 3-pole receptacles that

accept the tools plug for 120VAC. Use only 5-wire cords and plugs when using 3 phase.

DO NOT operate this or any machine under the infl uence of drugs or alcohol!

Do not open motor compartment or controller keypad. DC Voltage with potentially FATAL amperage!

Disconnect power before servicing. No user-serviceable parts inside.

No one should operate this machine except for fully qualifi ed personnel.

Read the manual!

Keep the work area clean and well lighted to avoid accidental injury.

5

Table of Contents

Table of Contents

Installation Requirements ...................................................................................... 6

TigerCrossCut Installation...................................................................................... 7

TigerCrossCut Anatomy

Installation

Altendorf F45 Installation

Install Extension

Install Controller

Install Motor Cover

Final Connections

Enable Code......................................................................................................... 15

First Power Up...................................................................................................... 16

Calibration Settings

Find the End Limits

Calibrate TigerCrossCut

Set Kerf

Set CrossCut Offset

Set CrossCut Alarm

Set Units

Basic TigerCrossCut Functions................................................................................ 20

Entering Decimals

Entering Fractions

Calculator Mode

Jog

Increment

PreSet

Quick Calibration

Working with Part Lists ......................................................................................... 24

Maintenance Schedule .......................................................................................... 26

IMPORTANT SAFETY INFORMATION. READ ALL WARNINGS BEFORE OPERATING THIS PRODUCT.

Do not use TigerStop machines in a dangerous environment. Using power tools in damp or wet

locations or in rain can cause shock or electrocution.

Do not operate near fl ammable liquids or in gaseous or explosive atmospheres!

Wear proper apparel, no loose clothes, long hair or jewelry which could get pulled into moving

machinery or materials.

Wear non slip footwear, safety glasses, ear protection and a dust mask.

Use only 3- wire extension cords that have 3-prong grounding type plugs and 3-pole receptacles that

accept the tools plug for 120VAC. Use only 5-wire cords and plugs when using 3 phase.

DO NOT operate this or any machine under the infl uence of drugs or alcohol!

Do not open motor compartment or controller keypad. DC Voltage with potentially FATAL amperage!

Disconnect power before servicing. No user-serviceable parts inside.

No one should operate this machine except for fully qualifi ed personnel.

Read the manual!

Keep the work area clean and well lighted to avoid accidental injury.

6

Installation Requirements

Installation Requirements

Do NOT drill or tap into the TigerCrossCut beam!

Drilling holes into the TigerCrossCut beam may damage the drive system. All fastening or

attachment to the fence beam must be made by inserting T-bolts or T-nuts with washers.

Do NOT over tighten mounting hardware!

It is critical that the bolts are prevented from over tightening and driving into the fence beam.

Always use washers.

ALWAYS evenly tighten mounting hardware!

Uneven tightening of mounting hardware can introduce a slight twist or other deformation in the beam.

This will result in inaccurate measurement and premature failure of the drive or other components.

NEVER open TigerCrossCut Motor Box!

The motor box compartment contains DC voltage with potentially FATAL amperage.

NEVER attempt any unauthorized actions inside the motor box!

110 VAC 15 Amps

208 VAC 20 Amps

240 VAC 20 Amps

TigerCrossCut Power Requirements

TigerCrossCut must have a dedicated circuit. No other equipment or devices should be on the same

circuit.

WARNING! Do NOT use a high leg delta circuit to power TigerCrossCut.

If you are not sure what kind of circuit you are using, STOP! Have a qualified electrician confirm the main power circuit.

7

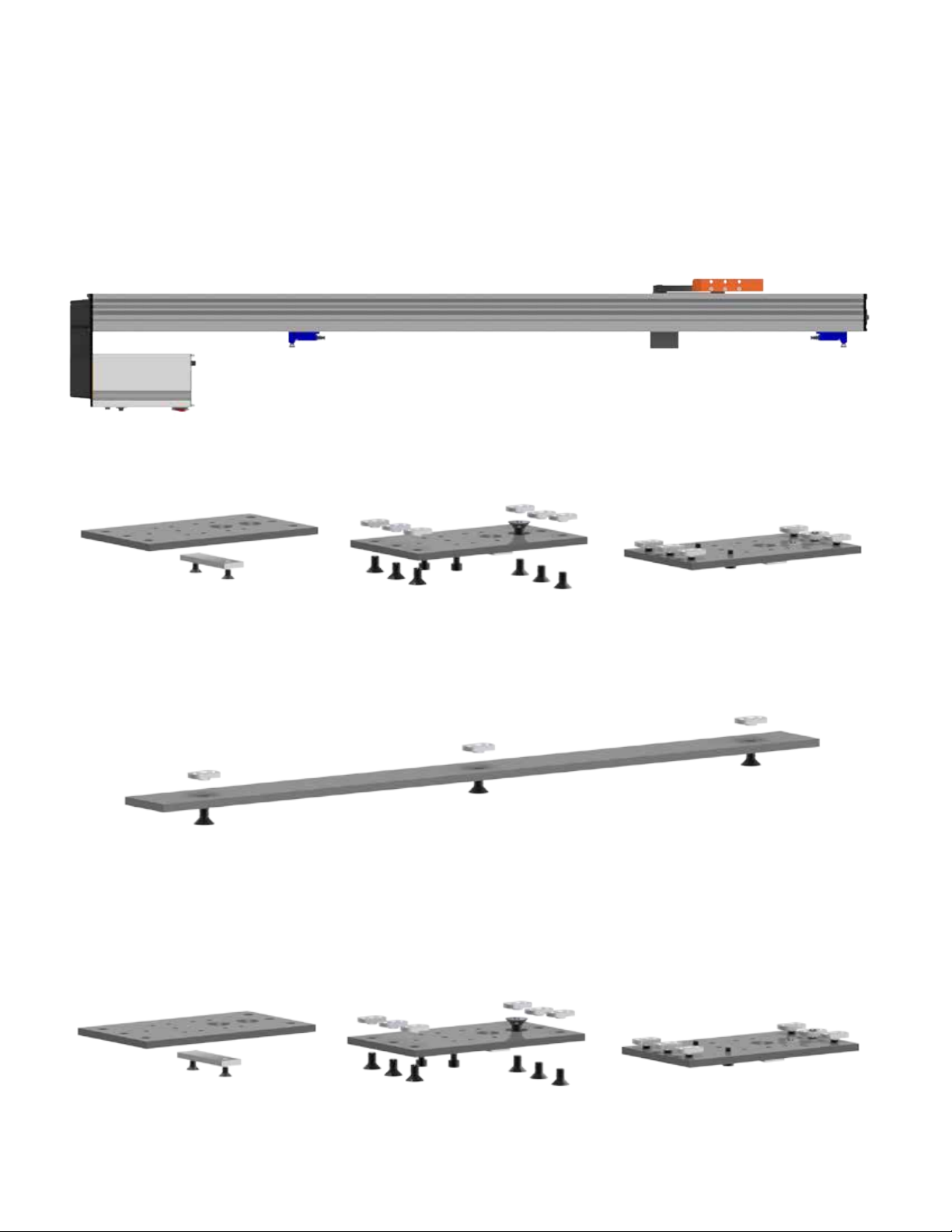

TigerCrossCut Installation

TigerCrossCut Installation

TigerCrossCut Anatomy

Controller

Controller

Stand

Extension

Flip Stop 1

TigerCrossCut

Serial Number

Motor Box

Flip Stop 2

Mounting Slots

(Underside)

Sacrificial

Wood Block

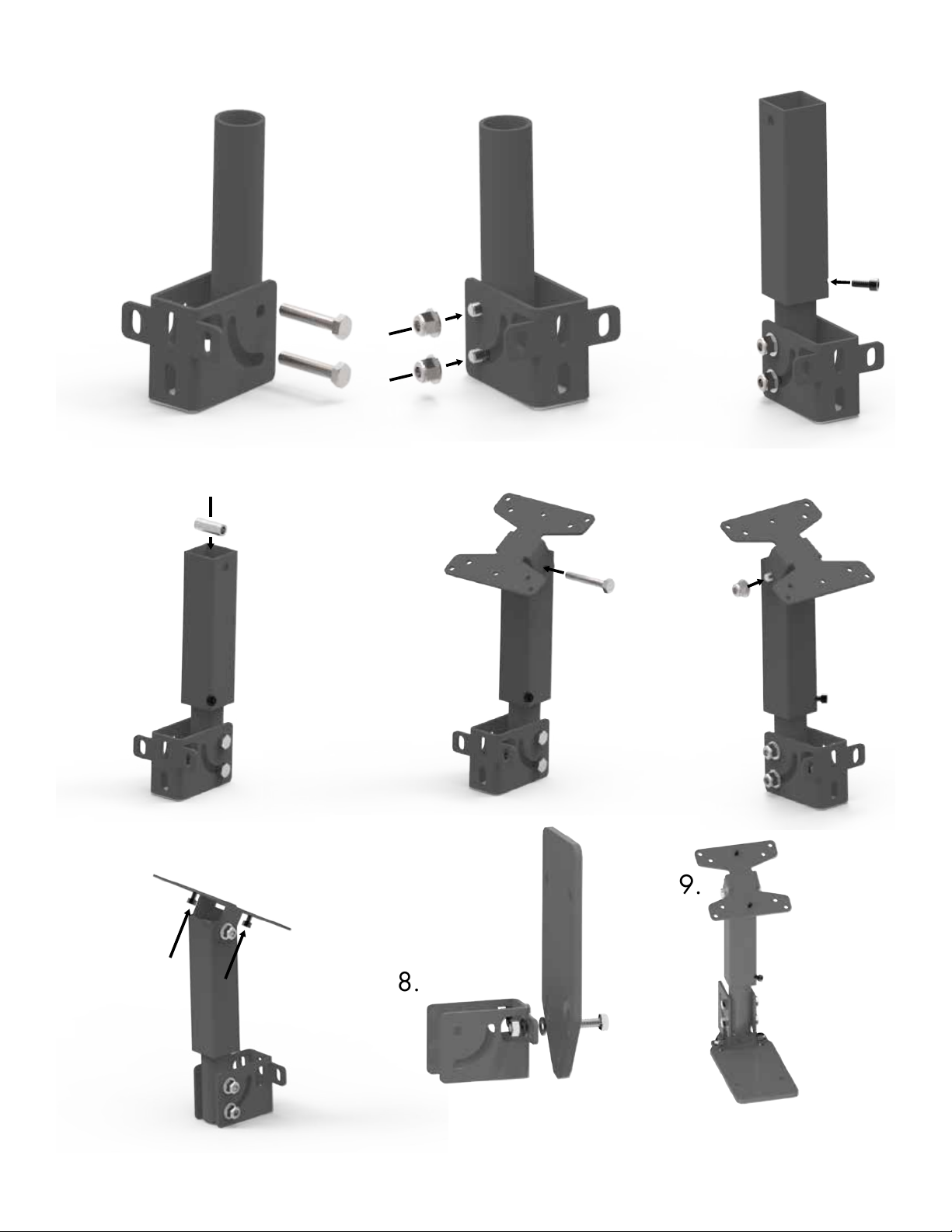

Installation

1. Install the TigerCrossCut Controller Stand. Continued on page 8.

Note: The TigerCrossCut controller stand will hold the TigerCrossCut controller at a comfortable angle and height. The stand

is attached to the bottom of the TigerCrossCut beam before being installed to the table saw.

8

1. 2. 3.

4. 5. 6.

7.

8.

9.

9

2. Slide two T-Bolts into one of the mounting slots.

3. Set the controller stand base onto the T-bolts and thread mounting hardware.

4. Insert the sacrificial wood block into the end of TigerCrossCut. Tighten the set screws.

Note: This block should stick out past your saw blade once TigerCrossCut is mounted.

10

-OR-

For Eccentric Pin

Style Saws

If you are installing TigerCrossCut to an Altendorf F45, skip to page 12 for installation instructions.

5. Perform lock out/tag out procedures on your table saw.

6. Remove the existing crosscut fence from your saw.

Note: Ensure the mounting surface is clean and smooth. Nothing should prevent a tight fit.

7. There will now be two empty mounting holes where the existing crosscut fence was mounted.

Note: You may have only one empty hole and an eccentric pin. This is OK as well. If you don’t have any empty mounting

holes, you may need to modify your sliding bed.

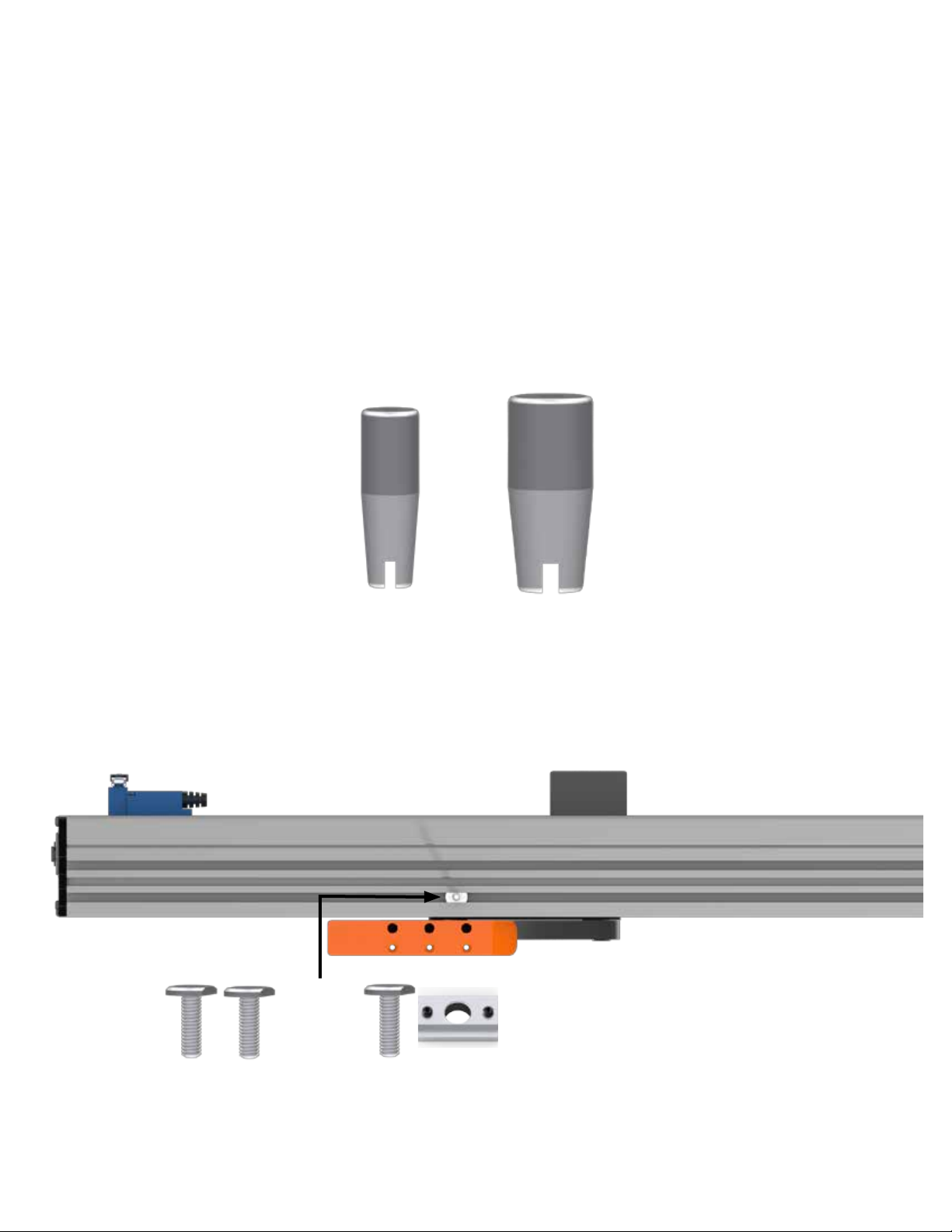

8. Locate the two sets of alignment cones. Test each set to find the size that fits best in your empty

mounting holes.

Note: TigerStop sends a 15 mm set and a 20 mm set. Modification of the cones may be necessary for other size holes.

15 mm 20 mm

-OR-

9. Set TigerCrossCut on your sliding bed, face down, so the mounting slots are exposed.

Note: Place TigerCrossCut with the motor box away from the saw blade.

10. Insert two T-bolts into the mounting slot of TigerCrossCut and align them with the empty holes.

Note: If you have one empty hole and an eccentric pin, use one T-bolt and the included custom T-nut.

11

11. Thread alignment cones onto each of the T- bolts.

12. Rotate TigerCrossCut so that the alignment cones go into the empty mounting holes.

Note: Once TigerCrossCut is upright, hold it in place and ensure that TigerCrossCut is tight against the mounting surface.

13. Thread a long set screw onto the open side of each cone. Thread a knob on each screw.

Note: If you are installing TigerCrossCut on an Altendorf F45, skip to page 12.

12

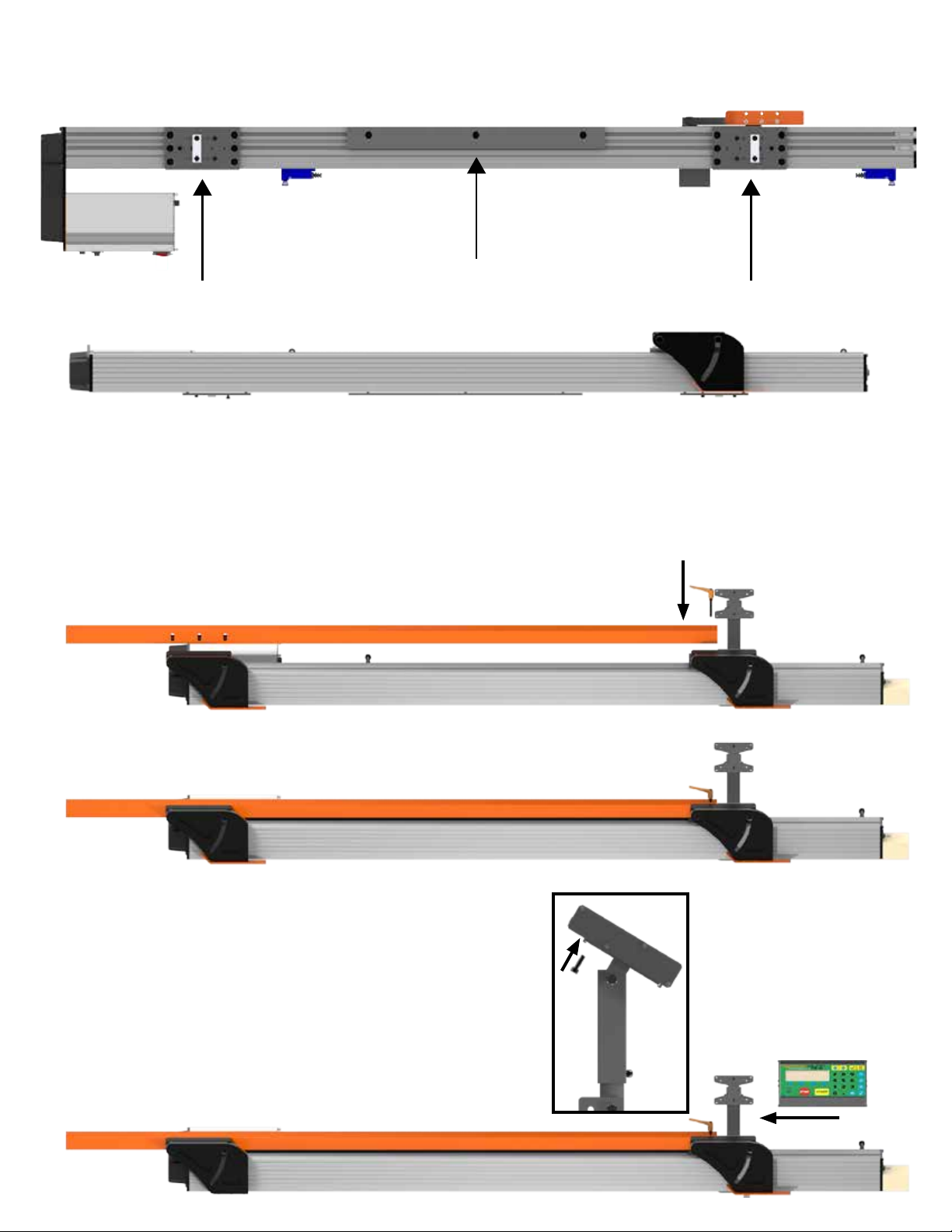

Altendorf F45 Installation

1. Perform lock out/tag out procedures on your table saw.

2. Remove the existing crosscut fence from your saw.

Note: Ensure the mounting surface is clean and smooth. Nothing should prevent a tight fit.

3. Set TigerCrossCut on your sliding bed, face down, so the mounting slots are exposed.

Note: Place TigerCrossCut with the motor box away from the saw blade.

4. Assemble each of the 3 F45 adapter plates.

13

5. Slide each adapter bracket into the TigerCrosscut mounting slots. Each bracket is offset so that the

edge of the bracket is flush with the face of the fence.

6. Line up the end plates with the Altendorf F45 locking cams.

7. Join the locking cams to the end plates.

8. Attach the cams to the end plates and tighten the end plate hardware.

End Plate End Plate

Middle Plate

Install Extension

Install Controller

14

Install Motor Cover

Install the motor cover over the exposed drive pulleys on the motor end of TigerCrossCut using 3

supplied screws.

Once TigerCrossCut and all accessories are installed, its time to make the final connections.

1. Connect the TigerCrossCut Controller Cable to the Controller and to the Motor Box.

Note: The TigerCrossCut Controller Cable is a proprietary cable. DO NOT use an “off the shelf” cable. Doing so can cause

damage to TigerCrossCut.

Final Connections

Controller TigerCrossCut Motor Box 15 Pin

White End (Motor Box)

Black End (Controller)

2. Connect the TigerCrossCut power cable from your power outlet to the TigerCrossCut power plug.

Power Outlet TigerCrossCut Motor Box Power Cable

Black TigerStop

Power Cable

15

Enable Code

Enable Code

Your new TigerCrossCut will not function until you enter the enable code, which is supplied by TigerStop

Customer Service.

The enable code notifies TigerStop, LLC when your new TigerCrossCut is about to be put into service.

This lets us start the warranty on the exact day you turn it on. The enable code also allows TigerStop to

turn on any upgrades you have purchased.

How to Enable TigerCrossCut

1. Fill out the TigerStop Warranty Registration sheet that is shipped

with your TigerCrossCut controller.

Fax or email the registration to:

(360) 260-0755

You may also register your warranty by phone:

TigerStop Customer Service

(360) 254-0661

TigerStop Customer Service will contact you by phone to give you the

enable code, within the hour during regular business hours, Monday

through Friday 6:00 am - 4:00 pm PST.

2. When you have received your enable code, power up TigerCrossCut using the power switch on the

motor box.

3. TigerCrossCut will ask you to enter your enable code. Enter the code received from TigerStop and

press .

Your TigerCrossCut has now been enabled.

16

First Power Up

First Power Up

After entering the enable code, TigerCrossCut will ask to run the ‘Home Routine’.

Home Routine Explained

Every time TigerCrossCut is powered up, it performs the ‘Home Routine’. The home routine is a 3 step

process where TigerCrossCut will move to its farthest position.

1. Press START to run the Home Routine.

2. When movement stops, TigerCrossCut will display the Ready Screen.

The Ready Screen is the starting point for all TigerCrossCut functions. Let’s take a look at the screen, line

by line.

Line 1 displays the “heartbeat”. The heartbeat is a line that rotates and

lets you know that TigerCrossCut is functioning normally. The letter next

to the heartbeat is the drive indicator. This tells you what the motor is

doing. TigerCrossCut also displays which stop you should be using.

Drive Indicator Meaning

H Holding Still

A Accelerating

C Moving at Constant Speed

D Decelerating

W Waiting

S Stopping

T Waiting for Text Entry

X E-stop Error

N Communication Error

Line 2 shows the current position of TigerCrossCut. The position will

show with ‘in’ when in inches mode and ‘mm’ when in metric mode.

17

Line 3 shows the next position of TigerCrossCut. This is where user

input is shown.

Line 4 displays the soft key prompts. These prompts tell you what the

soft key button below it does. These can change when you access

different screens.

Calibration Settings

Once homed, we will need to set a few settings to ensure TigerCrossCut is measuring properly.

Find the End Limits

1. From the Ready Screen, press the [Show] soft key to show the menu

options.

2. Press the [Menu] soft key to display the Menu Select screen.

3. TigerCrossCut requires a password to access all menu options.

Enter your TigerCrossCut password and press .

Note: By default, the TigerCrossCut password is set to the serial number.

4. At the Menu Select screen, press the [Setup] soft key to access the

Setup Menu.

5. Press to scroll through the settings. Stop when you see FindLim.

6. Press START to run the Find End Limit routine.

Note: Ensure TigerCrossCut can move its entire length without obstruction.

TigerCrossCut will move once START is pressed.

18

Calibrate TigerCrossCut

1. Press to scroll through the settings until you get to the Calib

setting.

2. Measure how far the TigerCrossCut is from your saw blade.

3. Press to save the parameter.

Set Kerf

The kerf is the measure of how much material is destroyed by the saw blade during a cut.

1. Press to scroll through the settings. Stop when you get to the

Kerf setting.

To measure kerf...

1. Cut a sample piece and measure it with a caliper. Record your measurement.

2. Cut this piece in half.

3. Put the two pieces together as if they were one piece and re-measure with a caliper.

4. The difference between the measurement on step 1 and the measurement on step 3 will be your kerf

value.

5. Enter your kerf value and press .

Note: It is important to check and reset the kerf every time the saw blade is changed or sharpened.

Set CrossCut Offset

The CrossCut Offset tells TigerCrossCut where Stop 2 is in relation to Stop 1.

1. Flip up Stop 1.

2. Put material against Stop 2 and make a cut.

3. Measure the cut piece between the saw blade and Stop 2.

4. Flip down Stop 1 and cut the piece again.

5. Measure the cut piece.

6. The difference between the two cut pieces is your new CrossCut Offset.

7. Press to scroll through the settings. Stop when you get to the

CrossCut Offset setting.

8. Enter your Crosscut Offset calculated in step 6.

9. Press the [Done] soft key to save the parameter.

19

Set CrossCut Alarm

The CrossCut Alarm setting alerts the user when a flip stop change is required.

1. From the Ready Screen, press the [Show] soft key to show the menu

options.

2. Press the [Menu] soft key to display the Menu Select screen.

3. TigerCrossCut requires a password to access all menu options.

Enter your TigerCrossCut password and press .

Note: By default, the TigerCrossCut password is set to the serial number.

4. At the Menu Select screen, press the [Options] soft key to access the

Options menu.

5. Press to scroll through the settings. Stop when you get to the

CrossCut Alarm setting.

6. Press [B] or [C].

7. Enter your TigerCrossCut password and press .

Note: By default, the TigerCrossCut password is set to the serial number.

8. Press [B] or [C] to toggle the setting.

9. Press to save the parameter.

1. Press to scroll through the settings. Stop when you get to Units.

2. Press [B] to toggle between inches and metric.

3. Press the [Done] soft key when finished.

Set Units

TigerCrossCut can display its position in inches or metric.

TigerCrossCut is now ready to use. To view the complete TigerStop users guide, visit the

support section of www.tigerstop.com.

20

Basic TigerCrossCut Functions

Basic TigerCrossCut Functions

Manual Movement

To manually move TigerCrossCut to a position, you must enter the length you want TigerCrossCut to go

to. This length can be entered as a decimal or a fractional value.

Entering Decimals

1. Start at the Ready Screen.

2. Enter a length at the controller.

Example: To enter 24 1/2 as a decimal, enter .

3. Press START to move TigerCrossCut.

Entering Fractions

4. Start at the Ready Screen.

5. Enter a length at the controller.

Example: To enter 24 1/2 as a fraction, enter .

6. Press START to move TigerCrossCut.

Notice that even though you entered a fraction, TigerCrossCut will

display the position as a decimal once it has moved. TigerCrossCut

cannot display fractions in the ‘Position’ field.

Calculator Mode

1. Start at the Ready Screen.

TigerCrossCut has a calculator function that can be used to do simple math problems.

Table of contents

Other TigerStop Industrial Equipment manuals

TigerStop

TigerStop TigerScan User manual

TigerStop

TigerStop TigerSPC User manual

TigerStop

TigerStop TigerSaw 1000 User manual

TigerStop

TigerStop SAWGEAR User manual

TigerStop

TigerStop TigerAngle 2D System manual

TigerStop

TigerStop HeavyDuty2 User manual

TigerStop

TigerStop TigerRack User manual

TigerStop

TigerStop TigerSPC User manual

TigerStop

TigerStop AutoLoader User manual

TigerStop

TigerStop TigerGauge User manual