CMO VALVES GL Series Instructions for use

1manufacturing the valve you need

INSTRUCTIONS AND MAINTENANCE MANUAL - SERIES - GL

GL

Rev. 16-05-2019

KNIFE GATE VALVE - SERIE GL

2manufacturing the valve you need

KNIFE GATE VALVE - SERIE GL

Rev.08 22-11-2019

2

INSTRUCTIONS AND MAINTENANCE MANUAL - SERIES - GL

ASSEMBLY

APPLICATION OF EUROPEAN DIRECTIVES

See document of European Directives applicable to CMO Valves.

The GL Valve complies with the Directive on Equipment and Protective Systems

for Potentially ExplosiveAtmospheres. In these cases the logo will appear on the

identification label. This label shows the exactclassification of the zone in which

the valve can be used. The user is responsible for its use in any other zone.

HANDLING

When handling the equipment please pay special attention to the following points:

• SAFETY WARNING: Before handling the valve check that the crane to be used

is capable of bearing its weight.

• Do not lift the valve or hold it by the actuator. Lifting the valve by the actuator

can lead to operating problems as it is not designed to withstand the valve’s wei-

ght.

• Do not lift the valve by holding it in the flow passage area. The valve’s O-ring

seal is located in this area. If the valve is held and lifted by this area it can damage

the surface and the O-ring seal and lead to leakage problems whilst the valve is

operating.

• To prevent damage, especially to the anticorrosive protection, it is recommen-

ded to use soft straps to lift the knife gate valves. These straps must be fitted

around the top of body.

• Packing in wooden boxes: If the equipment is packed in wooden boxes these must be provided with clearly marked holding

areas where the slings will be placed when securing them. In the event that two or more valves are packed together, separation

and securing elements must be provided between them to prevent possible movements, knocks and friction during transport.

When storing two or more valves in the same box you must ensure they are correctly supported to prevent deformations. In the

case of dispatches by sea we recommend the use of vacuum bags inside the boxes to protect the equipment from contact with

sea water.

• Pay special attention to maintaining the correct levelling of the valves during loading and unloading as well as during transport

to prevent deformations in the equipment. For this purpose we recommend the use of mounts or trestles.

INSTALLATION

In order to avoid personal harm and other type of damage (to the facilities, the valve, etc.) please follow these instructions:

• The sta responsible for the installation or operation of the equipment must be qualified and trained.

• Use suitable Personal Protective Equipment (PPE) (gloves, safety boots, goggles…).

• Shut o all lines that aect the valve and put up a warning sign to inform about the work being performed.

• Completely isolate the valve from the whole process. Depressurise the process.

• Drain all the line’s fluid.

• Use hand tools not electric tools during the installation and maintenance, in accordance with EN13463-1 (15).

Before installation, inspect the valve to ensure no damage has occurred during transport or storage.

Make sure that the inside of the valve’s body and, in particular the seal area, are clean. Inspect the installation’s pipes and the

flanges to make sure they are clean.

IMPORTANT: The valve must always be installed in the OPEN position.

3

www.cmovalves.com

KNIFE GATE VALVE - SERIE GL

Rev.08 16-05-2019

VENTAJAS

• As the GL valve is bi-directional, the direction of the fluid does not matter, it works correctly in both directions.

• Special care must be taken to respect the correct distance (gap) between the flanges and ensure they are correctly aligned and

parallel (Fig. 1).

The incorrect position or installation of the flanges can cause deformations on the valve’s body and this could lead to operating

problems.

It is very important to make sure that the valve is correctly aligned and parallel to the flanges to prevent leakages and avoid

deformations. Ensure the valve is assembled in open position.

• The screws in the tapped blind holes will have a maximum depth (Fig. 2) and will never reach the bottom of the hole. The

following table (Table 1) shows the maximum thread depth in the holes and the maximum torque to be applied to the flange

screws:

• The equipment must be firmly installed in the pipe. It will be joined to the pipe with a screw joint.

• The screws and nuts to be fitted must also be suitable for the operating conditions and their measurements must in accordance

with the approved plans. The screws and nuts must be fitted diametrically.

To torque to apply to the fastening screws and nuts must be correct according to the applicable standard, we recommend the

initial assembly be carried out with a low tightening torque and after all the screws are in place, the final torque is applied.

• As regards scaolding, ladders and other auxiliary elements to be used during the assembly, follow the safety recommendations

indicated in this dossier.

• Once the equipment has been assembled make sure that there are no elements, whether interior or exterior, which can interfere

with the gate valve’s movement.

• Make the relevant connections (electrical, pneumatic, hydraulic) in the equipment’s drive system following the instructions and

wiring diagrams supplied it.

• The operation of the equipment must be coordinated with the site’s control and safety sta and no modifications are permitted

in the equipment’s external indication elements (limit switches, positioners, etc.).

• When operating the equipment follow the safety recommendations indicated in this dossier.

ASPECTS TO BE CONSIDERED DURING ASSEMBLY

Correct parallelism

and alignment

DN 50 65 80 100 125 150 200 250 300 350 400 450 500 600 700 800 900 1000 1200 1300 1400

P14 14 14 14 15 15 17 17 20 21 23 24 25 26 26 26 26 27 29 29 30

PAR 45 45 45 45 45 88 88 88 88 88 152 152 152 223 223 303 303 412 529 529 685

Table. 1

4manufacturing the valve you need

KNIFE GATE VALVE - SERIE GL

Rev.08 22-11-2019

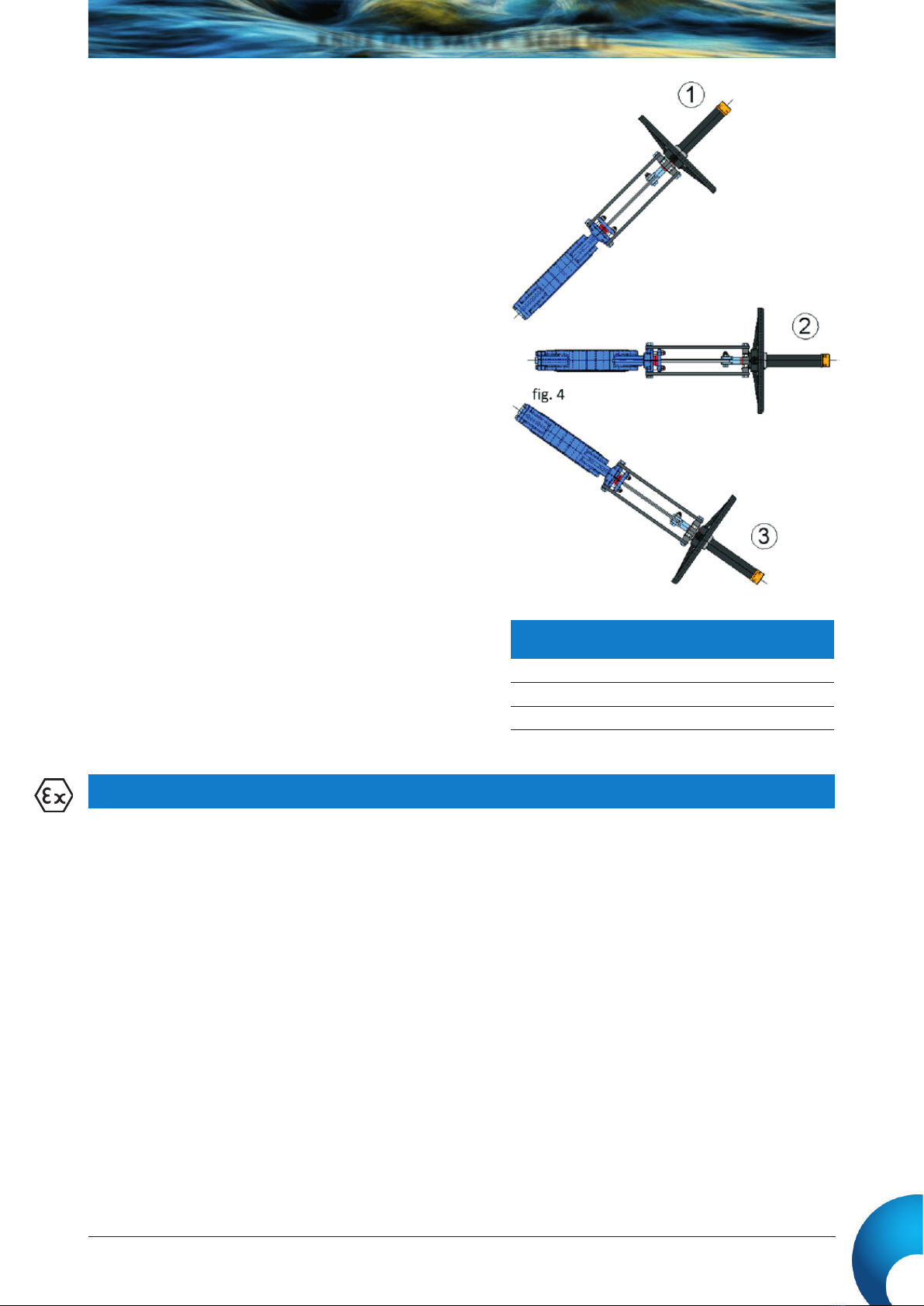

In horizontal pipes it is recommended that CMO valves be assembled in vertical position, although other assembly positions are

also possible.

Position 1: This is the most advisable position.

Position 8: The valve can be installed in this position but you are advised to contact CMO Valves if this is necessary.

Positions 2, 3, 6 y 7: For large valves (more than ND300), the maximum angle with the installation vertical is 30º. For smaller

sizes the angle can be increased up to 90º (positions 4 and 5).

When it is necessary to install large valves in any of these positions, it is recommended to consult CMO Valves, as in these cases,

due to the weight of the actuator, a suitable support must be made to prevent deformations and operating problems in the

valves.

Positions 4 y 5: For smaller sized valves, the valves can be installed in these positions.

To install larger valves (more than ND300) in any of these positions, please contact..

In these cases, due to the weight of the actuator, a suitable support must be made to prevent deformations and operating

problems in the valves.

ASSEMBLY POSITIONS (Horizontal Pipe)

fig 3.

30º MAX. 30º MAX.

5

www.cmovalves.com

KNIFE GATE VALVE - SERIE GL

Rev.08 16-05-2019

To operate the valve: Turn the handwheel clockwise to close or anticlockwise to open.

To operate the valve pull one of the chain’s vertical drops, taking into account that locking is carried out when the chainwheel

turns clockwise.

First loosen the position locking clamp located on the yoke. Once it is unlocked raise the lever to open or lower it to close. To

complete the operation lock the lever again.

CMO pneumatic actuators are designed to be connected to a 6 kg/cm pneumatic network, although these cylinders support up

to 10 kg/cm2. The pressurised air used for the pneumatic actuator must be correctly filtered and lubricated. This type of actuator

does not require any adjustment, due to the fact that the pneumatic cylinder is designed for the exact stroke required by the

valve

CMO hydraulic actuators are designed to work at a standard pressure of 170 kg/cm2. This type of actuator does not require any

adjustment, due to the fact that the hydraulic cylinder is designed for the exact stroke required by the valve.

If the valve incorporates a motorised actuator it will be accompanied with the electric actuator supplier’s instructions.

CMO valves can be assembled in all positions; however, certain

aspects must be taken into account:

Positions 1, 2 y 3: In these positions, it is recommended to make

a suitable support, because, due to the weight of the actuator,

deformations may arise and this can lead to operating problems in

the valves.

Once the valve has been installed, check that all the screws and

nuts have been correctly tightened and that the whole valve

action system has been correctly adjusted (electrical connections,

pneumatic connections, instruments…).

All CMO valves are tested at its facilities, however, during the

handling and transport the screws on the packing gland can come

loose and must be re-tightened. Once the valve is installed in the

pipeline and it has been pressurised, it is very important to check for

any leakages from the packing gland to the atmosphere.

In the event of a leakage, tighten the nuts on the packing gland

crosswise until the leakage stops, ensuring that there is no contact

between the packing gland and the gate.

A very high tightening torque on the packing gland’s nuts can lead

to problems, such as an increase in the valve’s torque, reduction in

the packing’s working life, or the breaking of the packing gland. The

tightening torques are indicated in Table 2

Once the valve is installed in its place, check that the flanges and

electrical and pneumatic connections are secure. If the valve has

electrical accessories or you are in an ATEX zone, earth connections

must be made before operating it.

If you are in an ATEX zone, check the continuity between the valve

and the pipeline (EN 12266-2, annex B, points B.2.2.2. and B.2.3.1.).

Check the pipeline’s earth connection and the conductivity between

the outlet and inlet pipelines

ASSEMBLY POSITIONS (Vertical/Inclined Pipe)

HANDWHEEL (Rising or Non-Rising Stem and Stem with Gear Box)

CHAINWHEEL

LEVER

PNEUMATIC (Double and Single Acting)

HIDRAULIC

MOTORISED (Rising or Non-Rising Stem)

TIGHTENING TORQUES FOR PACKING GLAND

SCREWS

ND50 a ND125 25 Nm

ND150 a ND300 30 Nm

ND350 a ND1400 55 Nm

ACTUATOR

Table. 2

6manufacturing the valve you need

KNIFE GATE VALVE - SERIE GL

Rev.08 22-11-2019

MAINTENANCE

If the valves suer any damage due to improper handling or without the proper authorisation, CMO Valves

will not be responsible. The valves must not be modified except under express authorisation.

• Use suitable Personal Protective Equipment (PPE) (gloves, safety boots, goggles…).

• Shut o all lines that aect the valve and put up a warning sign to inform about the work being performed.

• Completely isolate the valve from the whole process. Depressurise the process.

• Drain all the line’s fluid through the valve.

• Use hand tools not electric tools during the maintenance, in accordance with EN13463-1(15).

The only maintenance required in this type of valve is to change the packing’s rubber joint and the rubber seals. It is recommended

to carry out regular checks on the sleeves. The duration of these seals will depend on the valve’s working conditions, such as:

Pressure, temperature, number of operations, type of fluid and others.

In an ATEX zone, electrostatic charges may be present inside the valve, which can cause a risk of explosion. The user will be

responsible for carrying out the appropriate actions in order to minimise the risks.

The maintenance sta must be informed about the risks of explosion and ATEX training is recommended. If the fluid transported

constitutes an internal explosive atmosphere, the user must regularly check the installation’s correct watertight integrity. Regular

cleaning of the valve to prevent accumulation of dust. Assemblies not permitted at the end of the line. Avoid re-painting the

products supplied.

• In order to work under ideal safety conditions, the magnetic and electrical elements must be in idle mode and the air tanks

depressurised. The electrical control cabinets must also be out of service. The maintenance sta must be up to date with the

safety regulations and work can only start under orders from the site’s safety sta.

• The safety areas must be clearly marked and you must avoid placing auxiliary equipment (ladders, scaolding, etc.) on levers

or mobile parts which will lead to the movement of the gate valve.

• In equipment with spring return actuators, the gate must be mechanically locked and only unlocked when the actuator is

pressurised.

• In equipment with electrical actuator, it is recommended to disconnect it from the mains in order to access the mobile parts

without any risk.

• Due to its great importance, you must check that the valve’s axle has no load before disassembling the actuator system.

IMPORTANT SAFETY ASPECTS

Volante husillo

ascendente

Accionamiento

Neumático

Accionamiento

eléctrico

Accionamiento

hidraúlico

Volante

reductor

LUBRICATION

It is recommended to lubricate the stem twice a year by removing the protection cap and filling it with grease up to half its

volume.

After the maintenance and in an ATEX zone, you must check the electrical continuity between the pipe and the rest of the valve’s

components, such as the body, gate, stem… EN 12266-2 Standard, annex B, points B.2.2.2. and B.2.3.1.)

7

www.cmovalves.com

KNIFE GATE VALVE - SERIE GL

Rev.08 16-05-2019

Taking into account the recommendations indicated, below

we indicate the maintenance operations carried out in this

type of equipment: SLEEVES

1. Make sure there is absolutely no pressure and fluid in the

installation.

2. Remove the valve from the pipeline.

3. Place the gate (2) in open position

4. The sleeves (7) are replaced from outside the valve’s

body, it is a seat with two symmetrical parts, below we show

a diagram of the seat (fig.6)..

5. Once the sleeves have been removed, clean their

housing thoroughly.

6. Once they have been lubricated with Vaseline, insert the

new sleeves (7) of the same dimensions as those old ones..

7. Replace the valve between the flanges, taking special

care not to damage the sleeves.

8. Before starting up the installation, perform various

operations to open and close the valve.

1. Make sure there is absolutely no pressure and fluid in the

installation.

2. Place the valve in closed position.

3. Loosen the screws that connect the stem or rod to the

gate

4. Release the connection between the support plates (8)

and the body (1).

5. Release and remove the packing gland (3) and the safety

guards where present.

6. Remove the old packing seal (4) and greased packing

using a pointed tool, taking care not to damage the surface

of the gate (2)..

7. Carefully clean the packing and make sure that there are

no residues anywhere so that the new greased packing (5)

and the pacing seal (4) fit correctly.

8. Insert the new greased packing (5) and the new packing

seal (4) correctly lubricated, impregnating their inner

cavities with plenty of Vaseline.

9. Place the packing gland in its original position (step 5),

making sure it does not touch the gate, carefully tighten all

the nuts crosswise and make sure the same distance is left

between the gate and the packing gland on both sides

10. Screw down the support plates and the stem, in the

reverse order to what is described in steps 3 and 4.

11. Perform several manoeuvres with no load, checking the

correct operation of the valve and ensuring the packing

gland is correctly centred.

12. Pressurise the valve in the line and tighten the packing

gland crosswise, enough to prevent leakages to the

atmosphere

*Note: The numbers in brackets refer to the components list

in Table 5

*Note: During the assembly of the new sleeves it is

recommended to apply “Vaseline” to the seal to facilitate

the assembly process and the valve’s correct operation (do

not use oil or grease), below in Table 3 we show details of

the Vaseline used

REPLACING THE SEALING JOINT

REPLACING THE PACKING SEAL

WHITE PETROLEUM JELLY

Saybolt Colour ASTM D-156 15

Melting point (ºC) ASTM D-156 60

Viscosity at 100ºC ASTM D-156 5

Penetration 25ºC mm/10 ASTM D-156 165

Silicone content None

Pharmacopeia BP OK

fig. 6

Table. 3

fig. 7

8manufacturing the valve you need

KNIFE GATE VALVE - SERIE GL

Rev.08 22-11-2019

MAINTENANCE OF THE PNEUMATIC ACTUATOR

The maintenance of these cylinders is simple, if your need to replace any elements and you have any questions please consult

CMO Valves. Below is an exploded diagram of the pneumatic actuator and a list of the cylinder’s components. The top cover and

the support cover are usually made of aluminium, but from pneumatic cylinders greater than Ø200 mm, they are made of cast

iron GJS-400.

The maintenance kit normally includes: The socket and its joints and the scraper, and if the customer wishes the piston is also

supplied. Below we show the steps to follow to replace these parts.

1. Position the valve in closed position and shut o the pneumatic circuit. (depressurize)

2. Loosen the cylinder air input connections.

3. Release and remove the cylinder cap (5), the cylinder tube (4) and the tie rods (16).

4. Loosen the nut (14) which connects the piston (3) and the rod (1), remove the parts. Disassemble the cir-clip (10) and remove

socket (7) with its joints (8,9) .

5. Release and remove the cylinder head (2), in order to remove the scraper (6).

6. Replace the damaged parts with new ones and assemble the actuator in the opposite order to that described for the

disassembly.

To ensure the valve is in optimum conditions of use after long periods of storage, it should be stored in a well-ventilated place

at temperatures below 30ºC. It is not advisable, but if it is stored outside, the valve must be covered to protect it from heat and

direct sunlight, with good ventilation to prevent humidity

PNEUMATIC ACTUATOR

POS. DESCRIPTION MATERIAL

1 STEM AISI-304

2CYLINDER HEAD ALUMINIO

3 PISTON S275JR + EPDM

4CYLINDER ALUMINIO

5CYLINDER CAP ALUMINIO

6 SCRAPPER NITRILO

7 SLEEVE NYLON

8 OUTSIDE O-RING NITRILO

9 INSIDE O-RING NITRILO

10 CIR-CLIP ACERO

11 WASHER ST ZINC

12 O-RING NITRILO

13 WASHER ST ZINC

14 SELF-LOCKING NUT 5.6 ZINC

15 O-RING NITRILO

16 TIE RODS F-114 ZINC

17 WASHER ST ZINC

18 NUT 5.6 ZINC

19 SCREW 5.6 ZINC

20 WASHER ST ZINC

21 SCREW 5.6 ZINC

22 NUT A-2

23 SELF-LOCKING NUT A-2

24 PROTECTION S275JR

STORAGE

Table. 4

9

www.cmovalves.com

KNIFE GATE VALVE - SERIE GL

Rev.08 16-05-2019

The following aspects must be considered for storage purposes:

• The storage place must be dry and under cover.

• It is not recommended to store the equipment outdoors with direct exposure to adverse weather conditions, such as rain, wind,

etc. Even less so if the equipment is not protected with packaging.

• This recommendation is even more important in areas with high humidity and saline environments. Wind can carry dust and

particles which can come into contact with the valve’s mobile parts and this can lead to operating diculties. The actuator

system can also be damage due to the introduction of particles in the dierent elements.

• The equipment must be stored on a flat surface to avoid deformations.

• If the equipment is stored without suitable packaging it is important to keep the valve’s mobile parts lubricated, for this reason,

it is recommended to carry out regular checks and lubrication.

• Likewise, if there are any machined surfaces without surface protection it is important for some form of protection to be applied

to prevent the appearance of corrosion.

• Store the valves in open position to ensure that the sleeves are not deformed.

COMPONENTS LIST

POS. DESCRIPTION

1 BODY

2GATE

3 PACKING GLAND

4 JUNTA DE EMPAQUETADURA

5 PACKING SEAL

6 LOWER COVER

7 SLEEVES

8 SUPPORT PLATES

9 STEM

10 YOKE

11 STEM NUT

12 HANDWHEEL

13 STOP NUT

14 HOOD NUT

15 HOOD

16 CAP

17 GREASER (OPTIONAL)

*Note: The numbers in brack ets refer to the components list in Table 5.

Table. 3

Table. 5

NORTH AMERICA

SOUTH AMERICA

EUROPE

MIDDLE EAST

AFRICA

ASIA

AUSTRALIA

& OCEANIA

www.cmovalves.com

CMO HEADQUARTERS

MAIN OFFICES & FACTORY

Amategi Aldea, 142

20400 Tolosa

Guipuzcoa (Spain)

Tel.: (+34) 943 67 33 99

Fax: (+34) 943 67 24 40

cmo@cmovalves.com

www.cmovalves.com

CMO MADRID

C/ Rumania, 5 - D5 (P.E. Inbisa)

28802 Alcalá de Henares

Madrid (Spain)

Tel.: (+34) 91 877 11 80

Fax: (+34) 91 879 79 94

cmomadrid@cmovalves.com

www.cmovalves.com

Table of contents

Other CMO VALVES Control Unit manuals