TFP1510

Page 3 of 4

Installation

The Model BFV-N Grooved End Butter-

fly Valves may be installed with flow in

either direction and can be positioned

either horizontally or vertically.

The grooved end pipe couplings used

with the Model BFV-N must be listed or

approved for fire protection service and

installed in accordance with the manu-

facturers instructions.

The Model BFV-N Butterfly Valve may

be installed with any schedule of pres-

sure class of pipe or tubing that is listed

or approved for fire protection.

As applicable, refer to Figure 2 for the

internal switch wiring diagram.

Conduit and electrical connections

are to be made in accordance with

the authority having jurisdiction and/

or the National Electrical Code. With

reference to Figure 2, the supervisory

switch is intended for connection to

the supervisory circuit of a fire alarm

control panel in accordance with NFPA

72. The auxiliary switch is intended for

the unsupervised connection to aux-

iliary equipment in accordance with

NFPA 70, National Electric Code.

NOTE: For outdoor applications with

internal supervisory switches, it is rec-

ommended that wiring connections

be made at a temperature above 15°F

(-9°C), in order to insure sufficient flex-

ibility of the wire lead insulation.

Stop

Adjustment

Procedure

The gear operator’s OPEN and SHUT

position have been factory set. The

following procedure should be used if

slight adjustments are needed. Refer to

Figure 3.

Step 1. Turn the Handwheel until the

valve is fully closed.

Step 2. Remove two lockscrews (A)

from the gear operator body.

Step 3. Turn the Shut Stop Screw (B)

clockwise until snug.

Step 4. Turn the Handwheel until the

valve is fully open.

Step 5. Turn the Open Stop Screw (C)

clockwise until snug.

Step 6. Close the valve by turning the

Handwheel until the valve is fully in

the closed position. Ensure the disc

has returned to the fully closed posi-

tion and the disc is centered in the seat

area. Readjust the Shut Stop Screw if

necessary.

Step 7. Replace two lockscrews (A)

into the gear Operator body locking

the stops into position.

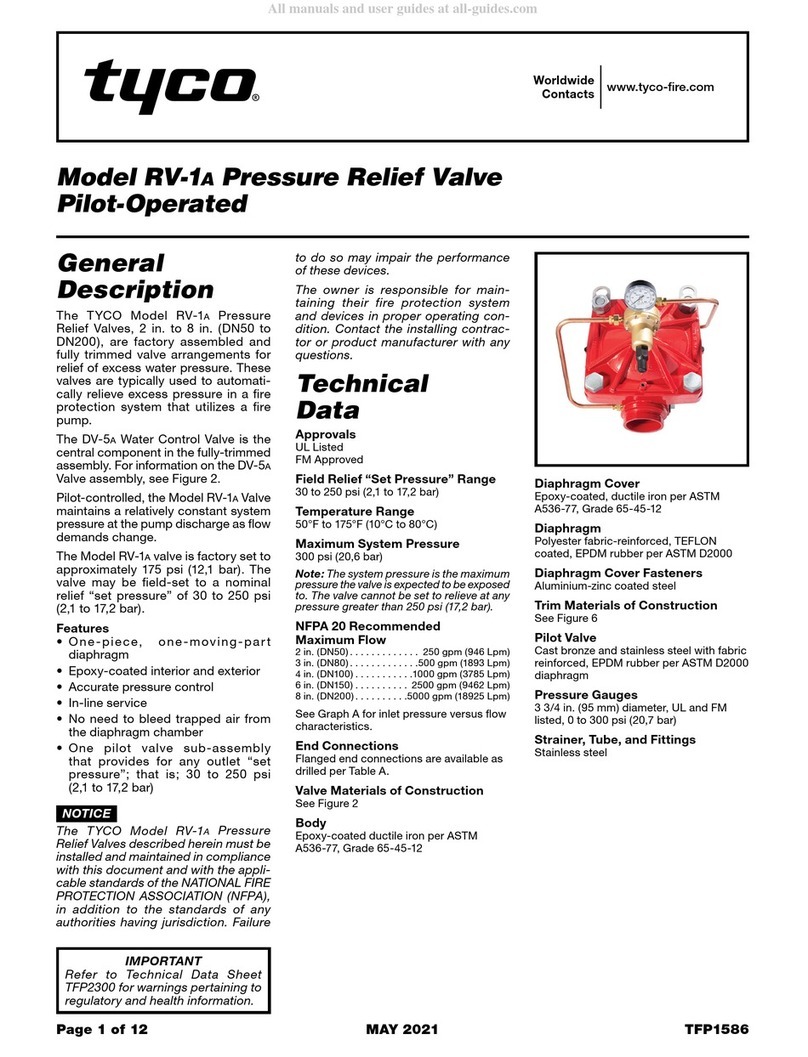

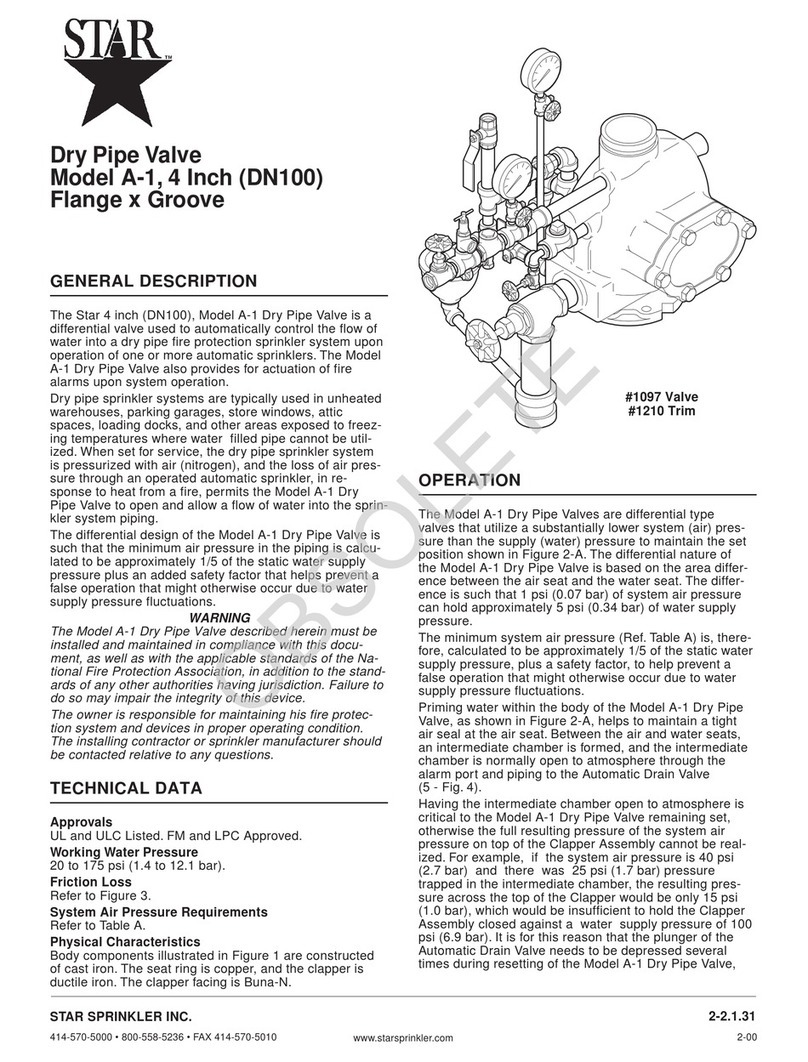

10 INCH (DN250)

8 INCH (DN200)

6 INCH (DN150)

5 INCH (DN125)

4 INCH (DN100)

3 INCH (DN80)

2-1/2 INCH (DN65)

2.0

0.4

0.1

0.2

0.3

0.6

0.5

0.8

1.0

3.0

4.0

5.0

60 100 200 600400 1000 2000 1000060004000

600 1000060001000 2000 4000 20000 40000400

0,30

0,20

0,08

0,10

0,06

0,04

0,05

0,03

0,02

0,01

FLOW RATE IN LITRES PER MINUTE (LPM)

FLOW RATE IN GALLONS PER MINUTE (GPM)

NOMINAL PRESSURE DROP

IN POUNDS PER SQUARE INCH (PSI)

NOMINAL PRESSURE DROP IN BAR

(1 GPM = 3,785 LPM)

15000

300

AC

A

B

OPEN

GRAPH A

DN65 THROUGH DN250 MODEL BFV-N BUTTERFLY VALVE

NOMINAL PRESSURE DROP VERSUS FLOW

FIGURE 3

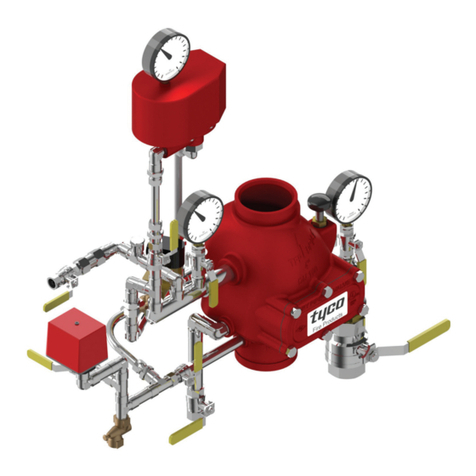

MODEL BFV-N GROOVED END

BUTTERFLY VALVE

OPERATOR ADJUSTMENT