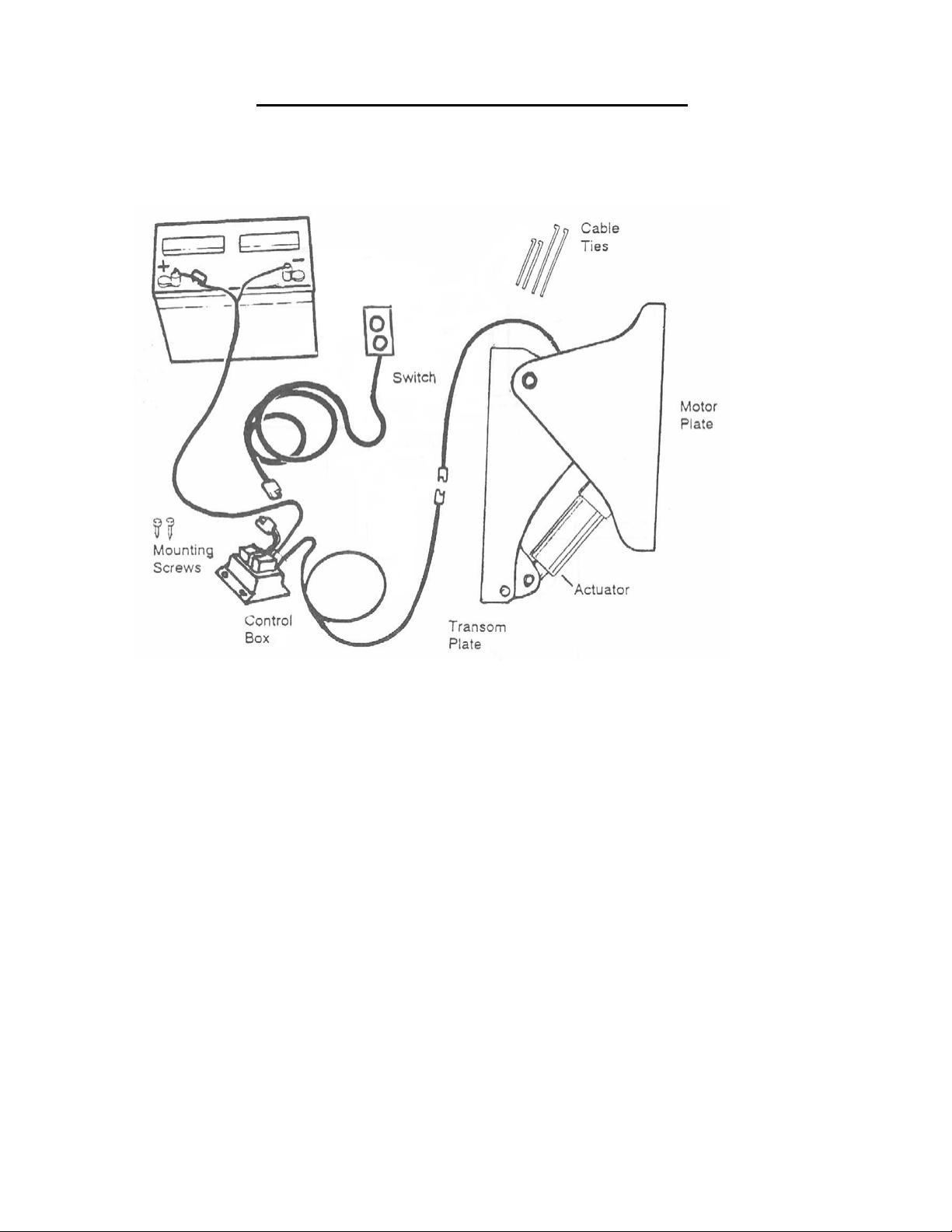

MOUNTING THE MOTOR LIFT BRACKET

1. Position the transom plate in the selected location of the transom. Check to make sure

that the hole placement will not interfere with any moldings, rivets, etc.

2. Once positioned, use a punch to mark the hole location.

3. Using a 3/16 bit, drill a pilot hole in each location to make sure the holes are properly

aligned and that there will be no interference with the mounting bolts. Then finish drill-

ing the holes with a ½ inch drill bit.

4. Before mounting the unit, apply a bead of RTV silicone sealant around the edge of each

hole to insure a watertight seal.

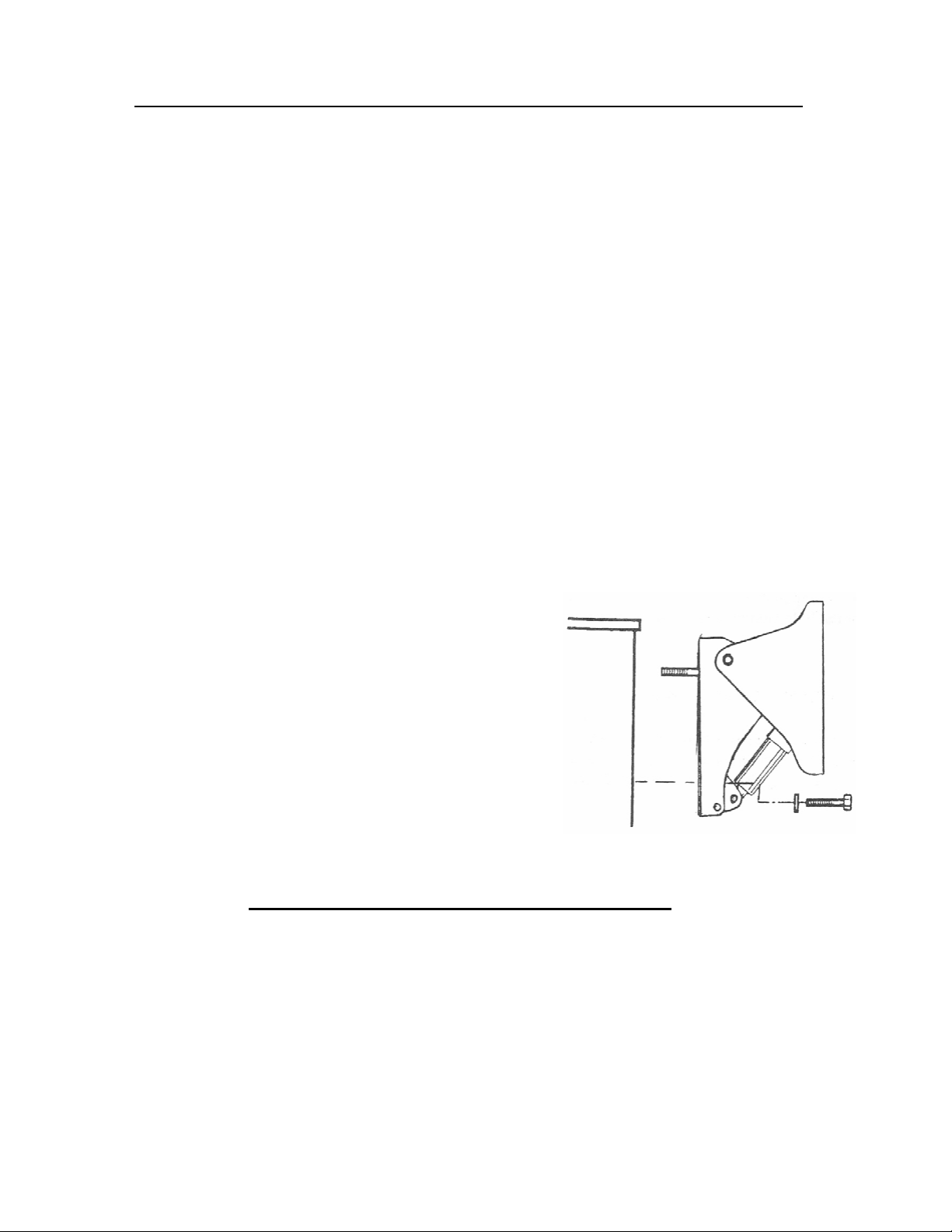

5. To mount the Motor Lift bracket to the transom use four ½ inch diameter stainless steel

bolts with washers and nylon locking nuts. Start by placing a bolt with a washer into each

of the upper mounting holes. Stick a piece of tape over the head of each bolt to hold

them in place, then lift the unit up to the transom, align the bolts and slide the unit into

place. Install the washers and the nuts inside the boat. Do not tighten the nuts com-

pletely until the lower bolts have been installed.

6. Complete the installation by inserting the two lower

mounting bolts, together with washer and the nyl

on locking nuts. Tighten each bolt evenly, taking

care not to over torque the nut to the point where

the transom or the bracket could be damaged.

MOUNTING THE MOTOR

1. Your motor lift bracket is supplied with a plastic 2 X 3 shim to help mount

the motor to the bracket.

2. Place the shim on the inside of the mounting plate and hold it in place while

placing the motor over the top edge of the bracket.