www.cmp-products.com

UNION TYPE PX780REX FOR CONNECTING CONDUITS TO ENCLOSURES OR

CONDUITS TO EACH OTHER USING RAPIDEX RESIN IN EXPLOSIVE ATMOSPHERES.

TECHNICAL DATA

EXPLOSIVE ATMOSPHERES CLASSIFICATION

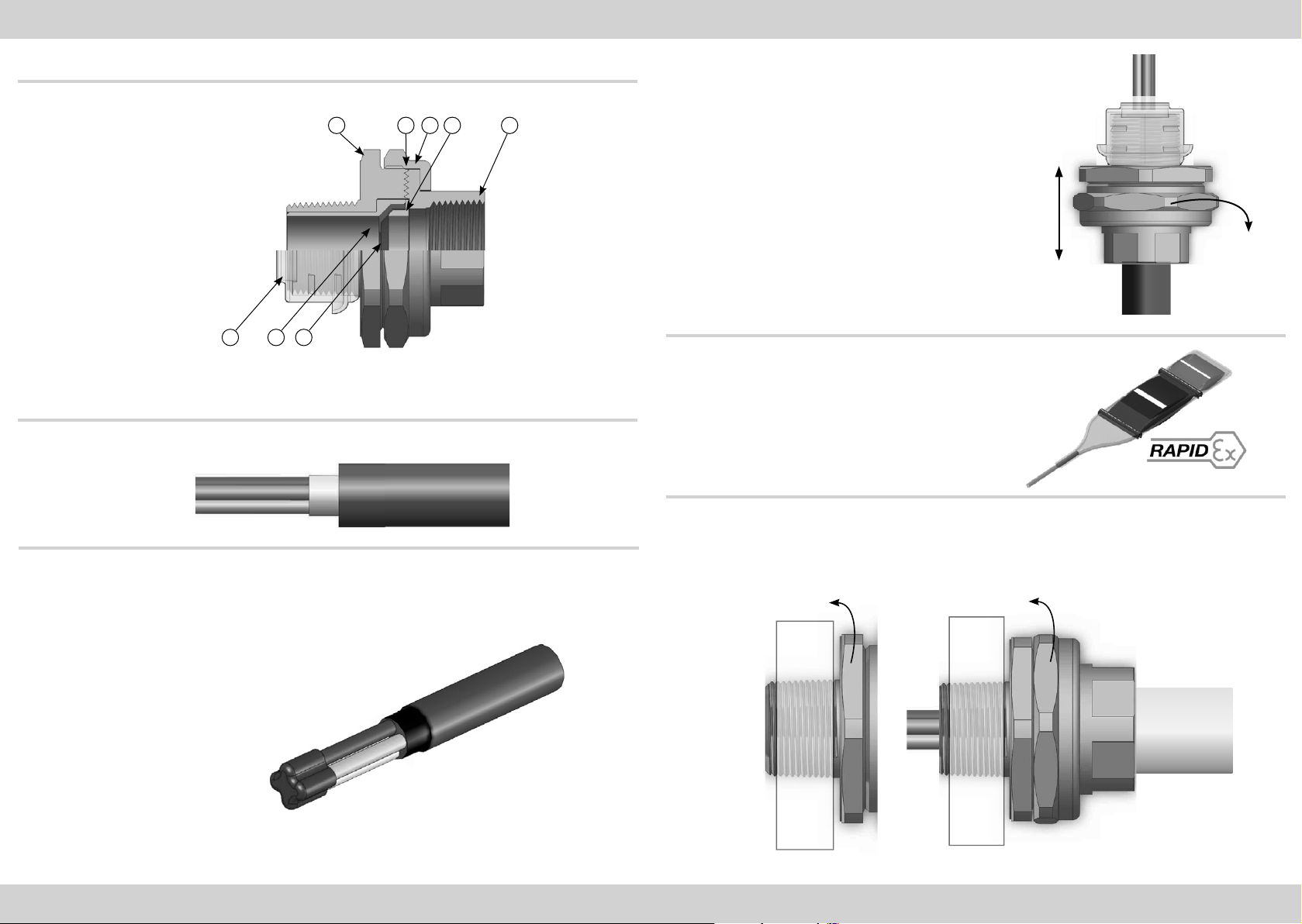

INSTALLATION INSTRUCTIONS

1. Installation should only be performed by a competent person using the correct tools. Spanners should be used for tightening. Read all instructions before beginning installation.

2. The interface between a cable entry device and its associated enclosure / cable entry will require additional sealing to achieve ingress protection (IP) ratings higher than IP54.The

minimum protection level is IP54 for explosive gas atmospheres and IP6X for explosive dust atmospheres. Parallel threads (and tapered threads when using a non-threaded entry)

require a CMP sealing washer or integral O-ring face seal (where available) to maintain IP66, 67 and 68 (when applicable). It is the installer’s responsibility to ensure the IP rating

is maintained at the interface.

Note: When fitted to a threaded entry, all tapered threads will automatically provide an ingress protection rating of IP68.

3. A CMP earth tag should be used when it is necessary to provide an earth bond connection. CMP earth tags have been independently tested to comply with Category B rating

specified in IEC 62444 (there are no ratings stated in IEC 60079-0). Ratings are shown in the associated table. CMP earth tags slip over the cable gland or accessory entry thread

from inside/outside the enclosure and must be secured with a locknut (if fitted internally).

ACCESSORIES

The following accessories are available from CMP Products, as optional extras, to assist with fixing, sealing and earthing :-

Locknut | Earth Tag | Serrated Washer | Entry Thread (I.P.) Sealing Washer

INSTALLATION INSTRUCTIONS

FOR UNION TYPE PX780REX

SPECIFIC CONDITIONS OF USE

Only one union is to be used with any single cable entry on the associated equipment.

Glasshouse Street • St. Peters • Newcastle upon Tyne • NE6 1BS

Tel: +44 191 265 7411 • Fax: +44 191 715 464

PRODUCT TYPE : PX780REX

INGRESS PROTECTION : IP66 when used with CMP sealing accessories

PROCESS CONTROL SYSTEM : ISO 9001

: ISO/IEC 80079-34:2011

ATEX CERTIFICATION No : CML 18ATEX1327X

ATEX CERTIFICATION CODE : ^II 2G 1D Ex db IIC Gb, Ex eb IIC Gb, Ex ta IIIC Da IP6X

: ^IM2 Ex db I Mb / Ex eb I Mb

IECEx CERTIFICATION No : IECEx CML 18.0190X

IECEx CERTIFICATION CODE : Ex db IIC Gb, Ex eb IIC Gb, Ex db I Mb, Ex eb I Mb, Ex ta IIIC Da IP6X

cCSAus CERTIFICATION No : 1055233

CODE OF PROTECTION : Class I, Div 1 and 2, Groups A,B,C and D; Enclosure Type 4X: Class I Zone 1, AEx de II; Ex de II

INMETRO CERTIFICATION No : TÜV 18.2088X

INMETRO CERTIFICATION CODE : Ex db IIC Gb, Ex eb IIC Gb, Ex db I Mb, Ex eb I Mb, Ex ta IIIC Da IP6X

CMP Products Limited on its sole responsibility declares that the equipment referred to herein conforms to the requirements of the ATEX Directive 2014/34/EU and the following standards:

EN 60079-0:2018, EN 60079-1:2014, EN 60079-7:2015, EN 60079-31:2014

David Willcock – Certification Engineer (Authorised Person)

CMP Products Limited, Cramlington, NE23 1WH, UK

15 April 2019

SCAN FOR INSTALLATION VIDEOS

FI471

Certicate Revision Date

IFS 9 05/19

ATEX / IECEx 6 04/19

cCSAus 5 05/16

Alternate thread types available

Can be supplied with mixed thread types e.g. PX780REXDM10T10 - M100 male thread, 4”NPT female thread, please contact CMP for more information

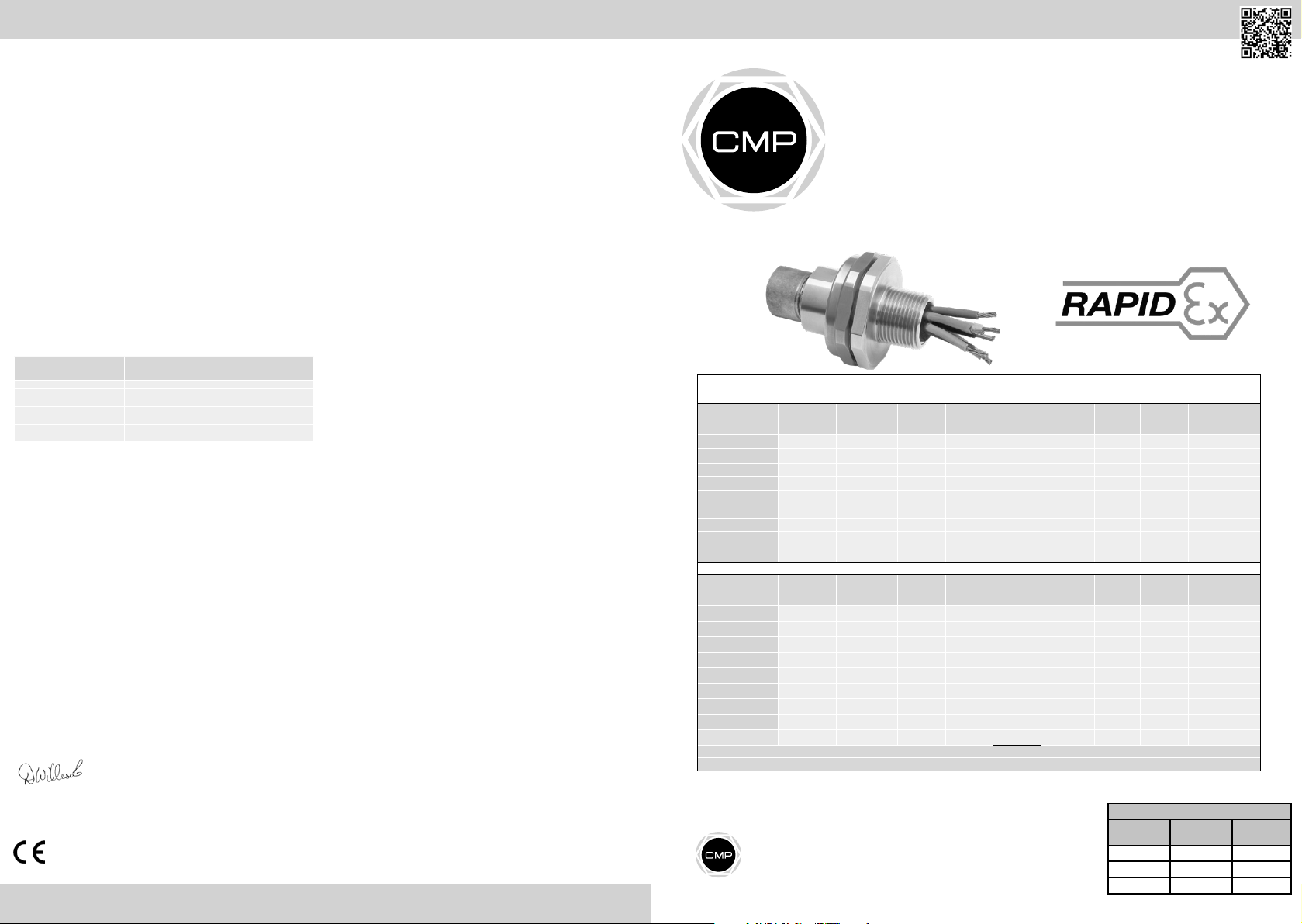

Product Selection Table

METRIC

Ordering Reference

(Brass, Metric)

Male Forward

Thread Size

Minimum

Thread Length

Female Rear

Thread Size

Diameter

Over Cores

Max.

Number of

Cores

Protrusion

Length

Across

Flats Hex

Across

Corners Ø

‘D’

Installation

Torque (Nm)

PX780REXDM2M2 M20 X 1.5 15.0 M20 X 1.5 12.6 21 36.1 46.0 50.3 7

PX780REXDM3M3 M25 X 1.5 15.0 M25 X 1.5 17.5 30 36.1 50.0 54.7 10

PX780REXDM4M4 M32 X 1.5 15.0 M32 X 1.5 23.6 50 35.2 60.0 65.7 15

PX780REXDM5M5 M40 X 1.5 15.0 M40 X 1.5 30.0 59 35.2 65.0 71.2 25

PX780REXDM6M6 M50 X 1.5 15.0 M50 X 1.5 41.0 115 35.3 75.0 82.2 30

PX780REXDM7M7 M63 X 1.5 15.0 M63 X 1.5 53.7 115 35.3 90.0 98.7 45

PX780REXDM8M8 M75 X 1.5 15.0 M75 X 1.5 64.2 140 38.8 100.0 109.7 45

PX780REXDM9M9 M90 X 2.0 24.0 M90 X 2.0 75.3 140 45.0 120.0 131.7 45

PX780REXDM10M10 M100 x 2.0 24.0 M100 x 2.0 83.6 200 83.9 145.0 159.2 45

NPT

Ordering Reference

(Brass, NPT)

Male Forward

Thread Size

Minimum

Thread Length

Female Rear

Thread Size

Diameter

Over Cores

Max.

Number of

Cores

Protrusion

Length

Across

Flats Hex

Across

Corners Ø

‘D’

Installation

Torque (Nm)

PX780REXDT1T1 1/2” 0.79 1/2” 12.6 21 35.4 46.0 50.3 7

PX780REXDT2T2 3/4” 0.80 3/4” 17.5 30 35.0 50.0 54.7 10

PX780REXDT3T3 1” 0.98 1” 23.6 50 33.7 60.0 65.7 15

PX780REXDT4T4 1-1/4” 1.01 1-1/4” 30.0 59 37.0 65.0 71.2 25

PX780REXDT5T5 1-1/2” 1.03 1-1/2” 36.6 115 38.2 75.0 82.2 30

PX780REXDT6T6 2” 1.06 2” 47.9 115 39.1 90.0 98.7 45

PX780REXDT7T7 2-1/2” 1.57 2-1/2” 59.9 140 54.1 100.0 109.7 45

PX780REXDT8T8 3” 1.63 3” 75.3 140 52.5 120.0 131.7 45

PX780REXDT9T9 3-1/2” 1.69 3-1/2” 83.6 200 80.0 145.0 159.2 45

All dimensions shown are in millimetres unless otherwise stated

For material options please add the following suffix to the Ordering Reference; Brass (no suffix required), Nickel Plated Brass “5”, 316 Grade Stainless Steel “4”, Copper Free Aluminium “1”

CMP Earth Tag Size Short Circuit Ratings Symmetrical Fault Current

(kA) for 1 second

20 3.06

25 4.06

32 5.40

40 7.20

50 10.40

63 10.40

75 10.40

2776

INCORPORATING EU DECLARATION OF CONFORMITY TO DIRECTIVE [2014/34/EU]