CNP INDUSTRIES PFA36SCG Installation guide

OCT06.0101

PFA42SCG

PFA36SCG

www.windcrestcnp.com

By CNP INDUSTRIES, INC.

All manuals and user guides at all-guides.com

All manuals and user guides at all-guides.com

PLEASE READ ENTIRE INSTRUCTIONS BEFORE PROCEEDING.

INSTALLATION MUST COMPLY WITH ALL LOCAL CODES.

IMPORTANT: Save these Instructions for the Local Electrical Inspector’s use.

INSTALLER: Please leave these Instructions with this unit for the owner.

OWNER: Please retain these instructions for future reference.

Safety Warning: Turn off power circuit at service panel and lock out panel, before wiring this appliance.

Requirement: 120 V AC, 60 Hz. 15 or 20 A Branch Circuit

APPROVED FOR RESIDENTIAL APPLIANCES

FOR RESIDENTIAL USE ONLY

READ AND SAVE THESE INSTRUCTIONS

Spanish page 3

English page 2

French page 20

9

2

All manuals and user guides at all-guides.com

Table of Contents

Installation Instruction..................................................................8

Before installing the hood......................................................................................5

Important safety Notice.................................................................4

Electrical requirements..........................................................................................5

Electrical & Installation requirements.......................................5Electrical & Installation requirements.......................................5Electrical & Installation requirements.......................................5

Preparation..............................................................................................................8

Part supplied...........................................................................................................6

List of Materials...............................................................................6

Description of the hood & Controls..........................................13

Part not supplied.....................................................................................................6

Dimension and clearances..........................................................7

Installation - Ductwork Calculation Sheet -..............................9

Electrical connection....................................................................10

List of Part and Accessories.....................................................19

Venting methods.....................................................................................................8

Controls: filter change indicator (metal filters)....................................................16

Controls: filter change indicator (carbon filters)..................................................15

Installation.......................................................................................11

Touch controls & features....................................................................................14

Cleaning.................................................................................................................17

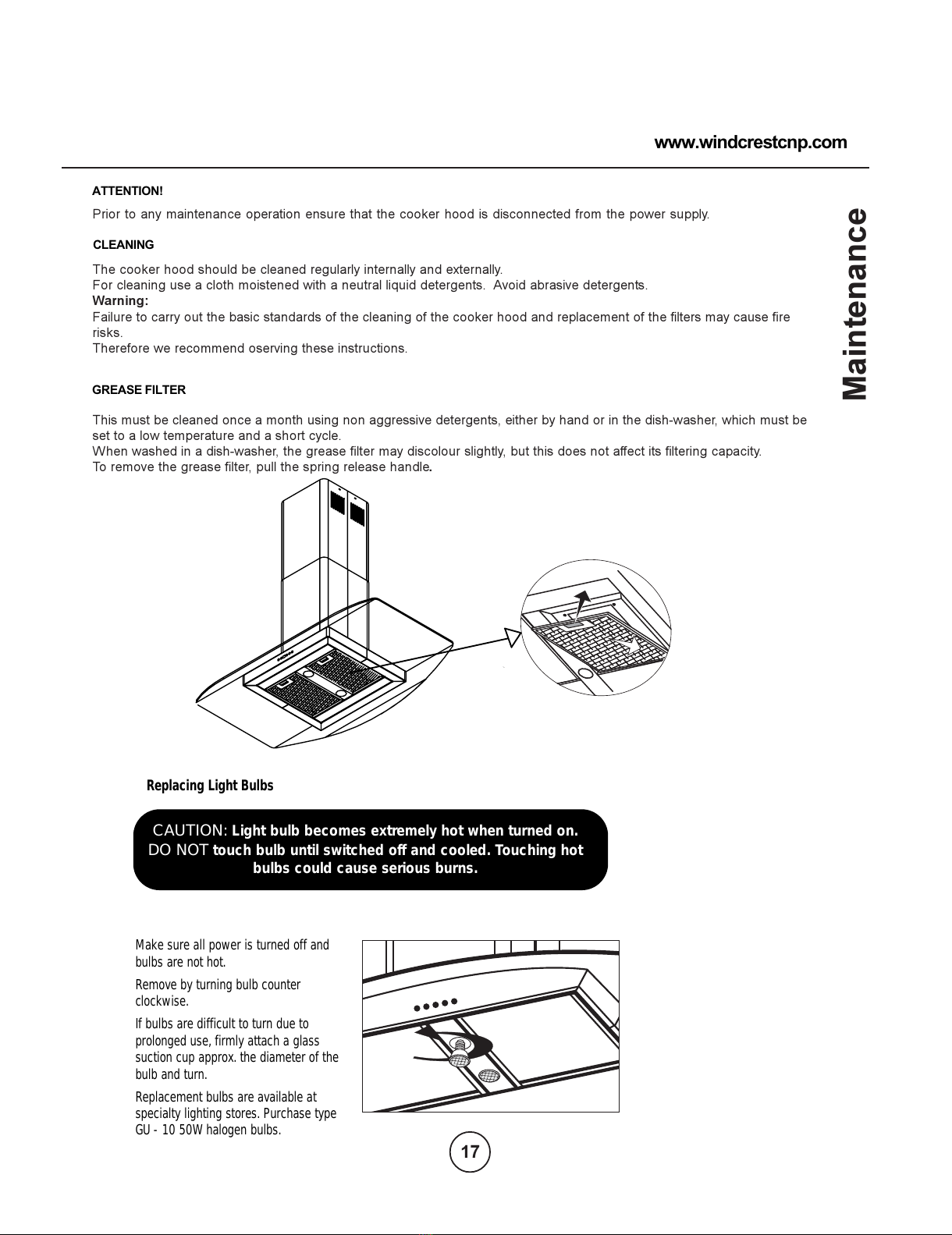

Grease filter...........................................................................................................17

Replacing the light bulb........................................................................................17

Maintenance......................................................................................17

Trouble Shooting......................................................................18

www.windcrestcnp.com

3

All manuals and user guides at all-guides.com

Important safety Notice

CAUTION:

FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS

OR VAPORS.

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

A. Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

B. Before servicing or cleaning the unit, switch power off at service panel and lock service panel disconnecting means to

prevent power from being switched on accidentally. When the service disconnecting means cannot be locked,

securely fasten a prominent warning device, such as a tag, to the service panel.

C. Installation Work and lectrical Wiring Must Be Done By Qualified Person(s) In Accordance With All Applicable Codes

& Standards, Including Fire-rated Construction.

D. Sufficient air is needed for proper combustion and exhausting of gases through the flue (chimney) of fuel burning

equipment to prevent back- drafting. Follow the heating equipment manufacturers guideline and safety standards such

as those published by the National Fire Protection Association (NFPA), the American Society for Heating, Refrigeration

and Air Conditioning ngineers (ASHRA ), and the local code authorities.

E. When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

F. Ducted systems must always be vented to the outdoors.

CAUTION:

To educe isk of fi e and to p ope ly exhaust ai , be su e to duct ai outside - do not vent exhaust ai into spaces

within walls, ceilings, attics, c awl spaces, o ga ages.

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCT WORK.

Install this hood in accordance with all requirements specified.

WARNING

To Reduce The Risk Of Fi e O Elect ic Shock, Do Not Use This Hood With Any Exte nal Solid State Speed

Cont ol Device.

WARNING

TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE.

a) Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite.

Heat oils slowly on low or medium settings.

b) Always turn hood ON when cooking at high heat or when flambeing food (i.e. Crepes Suzette, Cherries Jubilee,

Peppercorn Beef Flambe).

c) Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or filter.

d) Use proper pan size. Always use cookware appropriate for the size of the surface element.

WARNING

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:

a) SMOTH R FLAM S with a close-fitting lid, cookie sheet, or other metal tray, then turn off the gas burner or the electric

element. B CAR FUL TO PR V NT BURNS. If the flames do not go out immediately, VACUAT AND CALL TH

FIR D PARTM NT.

b) N V R PICK UP A FLAMING PAN - you may be burned.

c) DO NOT US WAT R, including wet dishcloths or towels - a violent steam explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a class ABC extinguisher, and you already know how to operate it.

2) The fire is small and contained in the area where it started.

3) The fire department is being called.

4) You can fight the fire with your back to an exit.

OPERATION

a. Always leave safety grills and filters in place. Without these components, operating blowers could catch onto hair,

fingers and loose clothing.

The manufacturer declines all responsibility in the event of failure to observe the instructions given here for installation,

maintenance and suitable use of the product. The manufacturer further declines all responsibility for injury due to

negligence and the warranty of the unit automatically expires due to improper maintenance.

* NOT : Please check our website for revisions before doing any custom work.

READ AND SAVE THESE INSTRUCTIONS

4

All manuals and user guides at all-guides.com

Electrical & Installation requirements

ELECTRICAL REQUIREMENTS

Important:

Observe all governing codes and ordinances.

It is the customers responsibility:

To contact a qualified electrical installer.

To assure that the electrical installation is adequate and in conformance with National lectrical Code, ANSI/NFPA 70

latest edition*, or CSA Standards C22.1-94, Canadian lectrical Code, Part 1 and C22.2 No.0-M91 - latest edition**

and all local codes and ordinances.

If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the

ground path is adequate.

Do not ground to a gas pipe.

Check with a qualified electrician if you are not sure range hood is properly grounded.

Do not have a fuse in the neutral or ground circuit.

IMPORTANT:

Save Installation Instructions for electrical inspectors use.

The range hood must be connected with copper wire only.

The range hood should be connected directly to the fused disconnect (or circuit breaker) box through metal electrical

conduit.

Wire sizes must conform to the requirements of the National lectrical Code ANSI/NFPA 70 latest edition*, or CSA

Standards C22.1-94, Canadian lectrical Code Part 1 and C22.2 No. 0-M91 - latest edition** and all local codes and

ordinances.

A U.L.- or C.S.A.-listed conduit connector must be provided at each end of the power supply conduit (at the range hood

and at the junction box).

Copies of the standards listed may be obtained from:

* National Fire Protection Association Batterymarch Park Quincy, assachusetts 02269

** CSA International 8501 East Pleasant Valley Road Cleveland, Ohio 44131-5575

BEFORE INSTALLING THE HOOD

1. For the most efficient air flow exhaust, use a straight run or as few elbows as possible.

CAUTION: Vent unit to outside of building, only.

2. Almost two people are necessary for installation.

3. The hood is fitted with Screws and Drywall Anchors suitable for most surfaces, consult a Qualified Installer, check if

they perfectly fit with your cabinet/wall.

4. Do not use flex ducting.

5. COLD W ATH R installations should have an additional backdraft damper installed to minimize backward cold air

flow and a nonmetallic thermal break to minimize conduction of outside temperatures as part of the ductwork. The

damper should be on the cold air side of the thermal break.

The break should be as close as possible to where the ducting enters the heated portion of the house.

6. Make up air: Local building codes may require the use of Make-Up Air Systems when using Ducted Ventilation

Systems greater than specified CFM of air movement.

The specified CFM varies from locale to locale. Consult your HVAC professional for specific requirements in your area.

www.windcrestcnp.com

5

All manuals and user guides at all-guides.com

List of Materials

PART SUPPLIED

PART NOT SUPPLIED

- Duct, conduit all tools required for installation

To be used only in the

- Glass canopy.

- Hood canopy assembly with blower.

- Duct Convers.

- Use Care and Installation Guide.

- Hardware Packet

46 screw 3.5x9.5 to assemble chimmey structure and to fix the duct convers under ceiling

4 washer 4x16 to assemble chimmey structure to ceiling

- Grease filters (2p.) and lamps (2p.), already installed.

- Chimmey structure.

4 anchors to assemble chimmey structure to ceiling

4 screw 5x50 to assemble chimmey structure to ceiling

includes: charcoal filter, charcoal filter support and fixing bracket, deflector

- Ductless Recirculating Kit

Ductless (Recirculating)version

- Warranty.

6

All manuals and user guides at all-guides.com

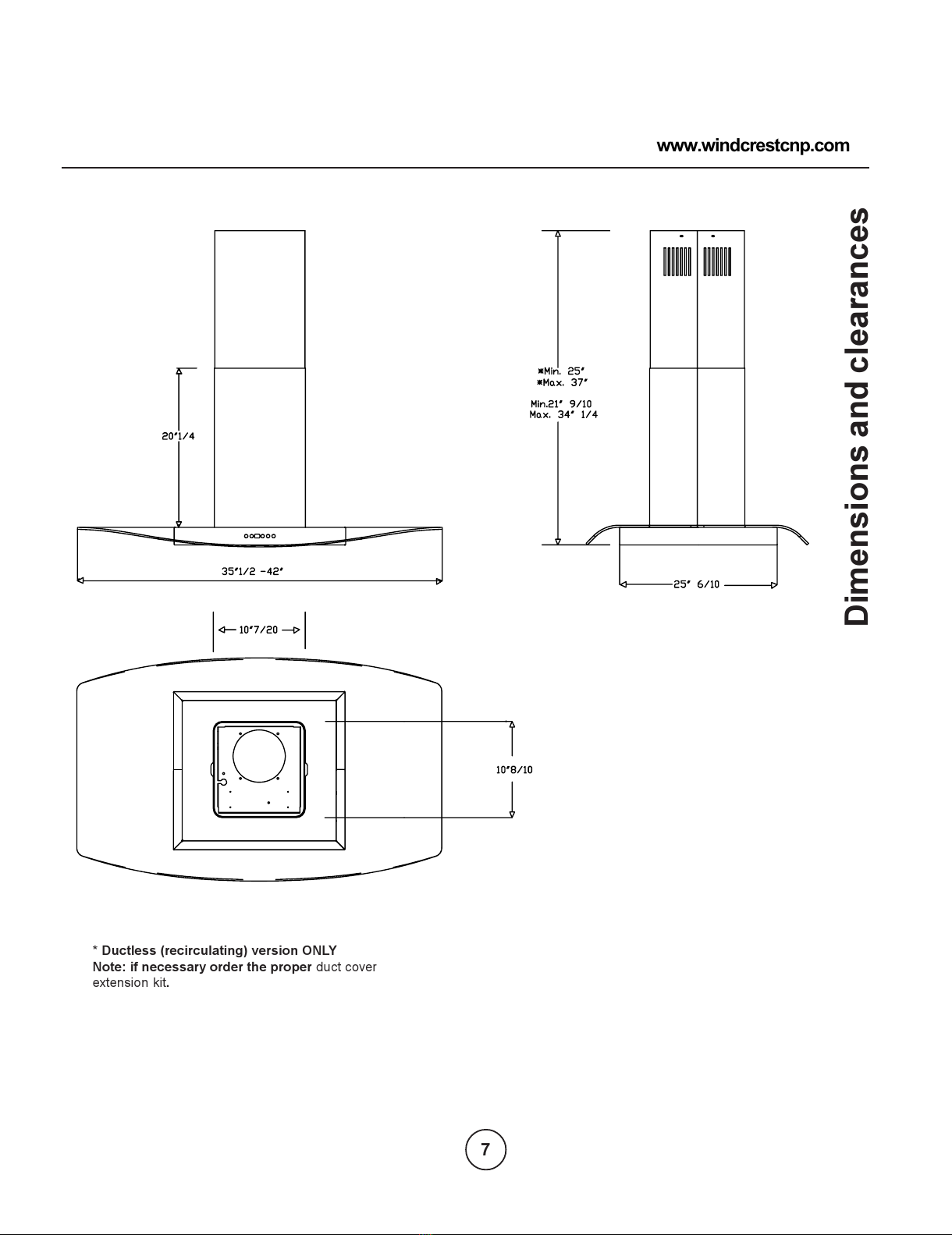

Dimensions and clearances

* Ductless ( eci culating) ve sion ONLY

Note: if necessa y o de the p ope duct cover

extension kit.

www.windcrestcnp.com

7

All manuals and user guides at all-guides.com

Installation Instructions

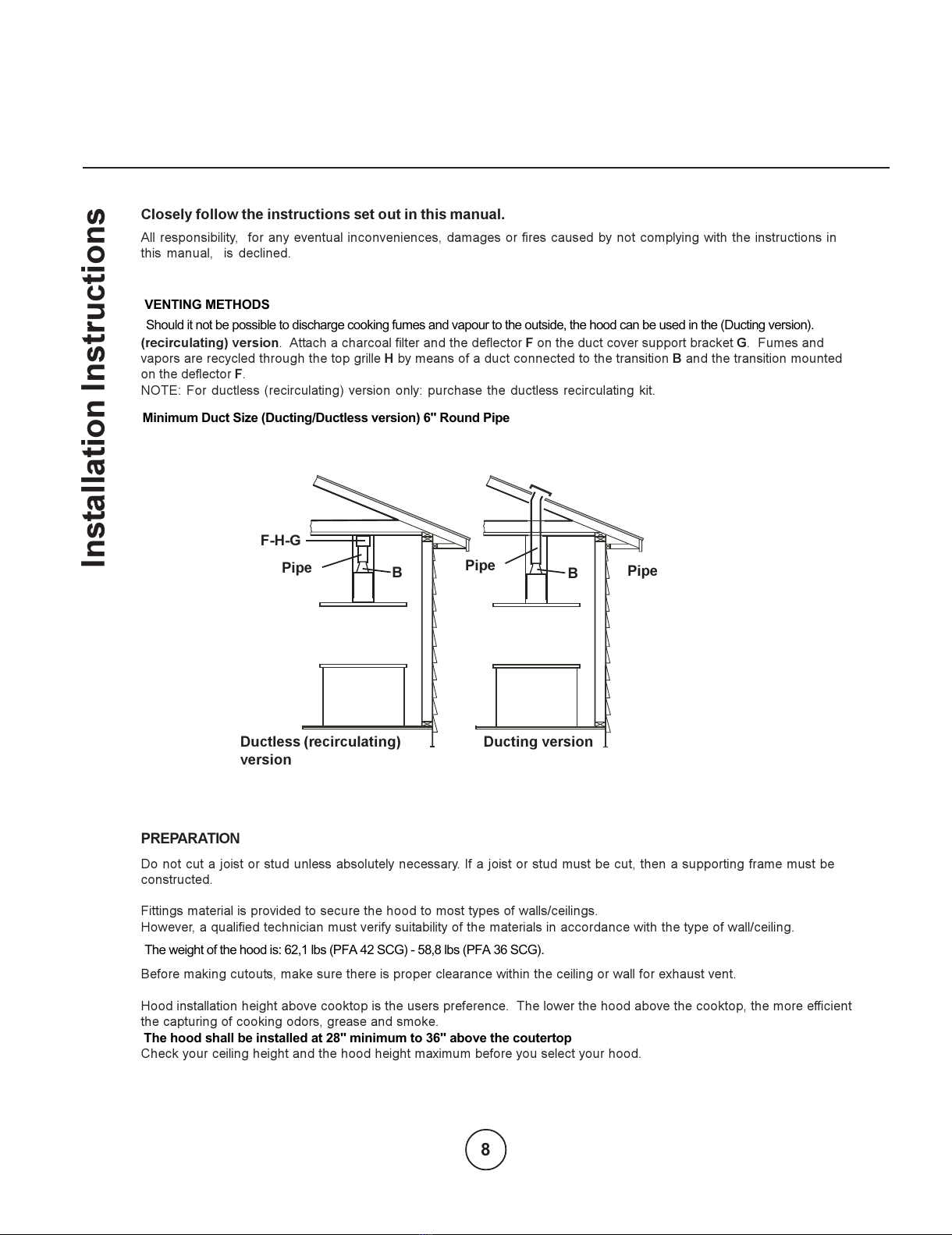

Clo ely follow the in truction et out in thi manual.

All responsibility, for any eventual inconveniences, damages or fires caused by not complying with the instructions in

this manual, is declined.

( eci culating) ve sion. Attach a charcoal filter and the deflector F on the duct cover support bracket G. Fumes and

vapors are recycled through the top grille H by means of a duct connected to the transition B and the transition mounted

on the deflector F.

NOT : For ductless (recirculating) version only: purchase the ductless recirculating kit.

PREPARATION

Do not cut a joist or stud unless absolutely necessary. If a joist or stud must be cut, then a supporting frame must be

constructed.

Fittings material is provided to secure the hood to most types of walls/ceilings.

However, a qualified technician must verify suitability of the materials in accordance with the type of wall/ceiling.

Before making cutouts, make sure there is proper clearance within the ceiling or wall for exhaust vent.

Hood installation height above cooktop is the users preference. The lower the hood above the cooktop, the more efficient

the capturing of cooking odors, grease and smoke.

Check your ceiling height and the hood height maximum before you select your hood.

F-H-G

B

B

Ducting ver ionDuctle (recirculating)

ver ion

Pipe

Pipe

Pipe

The hood shall be installed at 28" minimum to 36" above the coutertop

VENTING METHODS

Should it not be possible to discharge cooking fumes and vapour to the outside, the hood can be used in the (Ducting version).

The weight of the hood is: 62,1 lbs (PFA 42 SCG) - 58,8 lbs (PFA 36 SCG).

Minimum Duct Size (Ducting/Ductless version) 6" Round Pipe

8

All manuals and user guides at all-guides.com

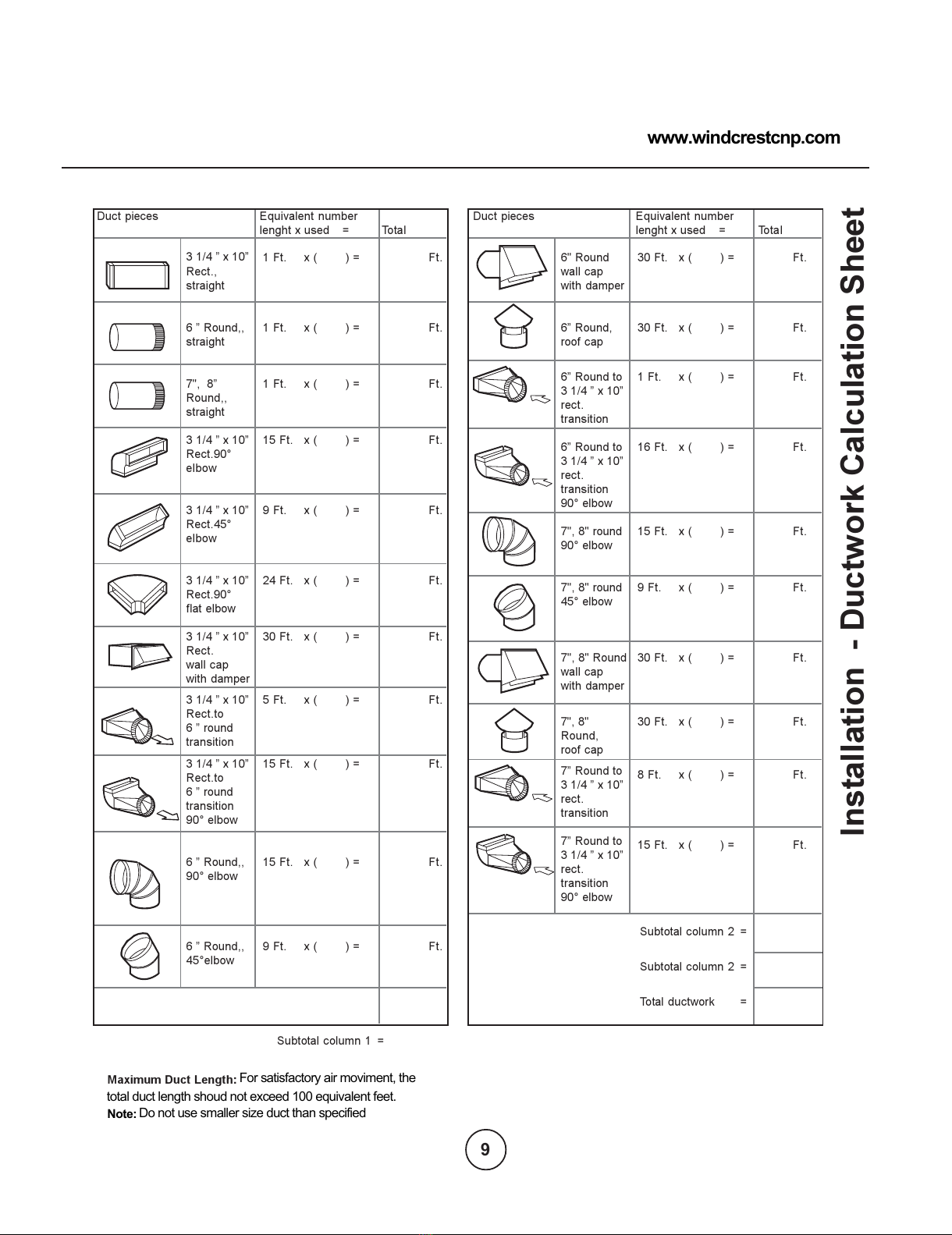

Installation - Ductwor Calculation Sheet

3 1/4 x 10

Rect.,

straight

6 Round,,

straight

7", 8

Round,,

straight

3 1/4 x 10

Rect.90°

elbow

3 1/4 x 10

Rect.45°

elbow

3 1/4 x 10

Rect.90°

flat elbow

3 1/4 x 10

Rect.

wall cap

with damper

3 1/4 x 10

Rect.to

6 round

transition

3 1/4 x 10

Rect.to

6 round

transition

90° elbow

6 Round,,

90° elbow

6 Round,,

45°elbow

1 Ft. x ( ) =

1 Ft. x ( ) =

1 Ft. x ( ) =

15 Ft. x ( ) =

9 Ft. x ( ) =

24 Ft. x ( ) =

30 Ft. x ( ) =

5 Ft. x ( ) =

15 Ft. x ( ) =

15 Ft. x ( ) =

9 Ft. x ( ) =

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

6" Round

wall cap

with damper

6 Round,

roof cap

6 Round to

3 1/4 x 10

rect.

transition

6 Round to

3 1/4 x 10

rect.

transition

90° elbow

7", 8" round

90° elbow

7", 8" round

45° elbow

7", 8" Round

wall cap

with damper

7", 8"

Round,

roof cap

7 Round to

3 1/4 x 10

rect.

transition

7 Round to

3 1/4 x 10

rect.

transition

90° elbow

30 Ft. x ( ) =

30 Ft. x ( ) =

1 Ft. x ( ) =

16 Ft. x ( ) =

15 Ft. x ( ) =

9 Ft. x ( ) =

30 Ft. x ( ) =

30 Ft. x ( ) =

8 Ft. x ( ) =

15 Ft. x ( ) =

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Ft.

Duct pieces Equivalent number

lenght x used = Total

Duct pieces Equivalent number

lenght x used = Total

Subtotal column 2 =

Subtotal column 2 =

Total ductwork =

Subtotal column 1 =

Maximum Duct Length:

Note: Do not use smaller size duct than specified

total duct length shoud not exceed 100 equivalent feet.

For satisfactory air moviment, the

www.windcrestcnp.com

9

All manuals and user guides at all-guides.com

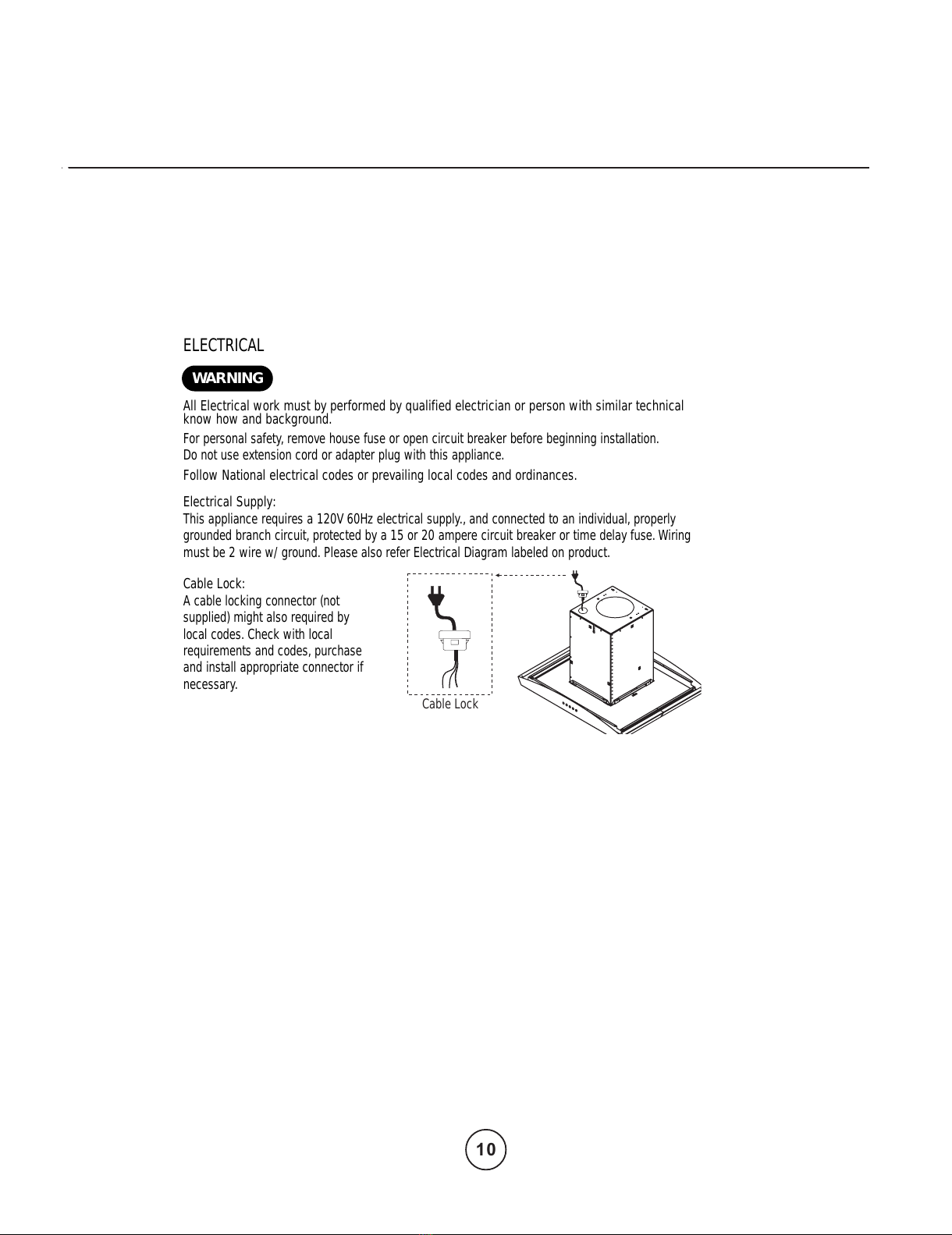

ELECTRICAL

All Electrical work must by performed by qualified electrician or person with similar technical

know how and background.

For personal safety, remove house fuse or open circuit breaker before beginning installation.

Do not use extension cord or adapter plug with this appliance.

Follow National electrical codes or prevailing local codes and ordinances.

Electrical Supply:

This appliance requires a 120V 60Hz electrical supply., and connected to an individual, properly

grounded branch circuit, protected by a 15 or 20 ampere circuit breaker or time delay fuse.Wiring

must be 2 wire w/ ground. Please also refer Electrical Diagram labeled on product.

Cable Lock:

A cable locking connector (not

supplied) might also required by

local codes. Check with local

requirements and codes, purchase

and install appropriate connector if

necessary. Cable Lock

WARNING

10

All manuals and user guides at all-guides.com

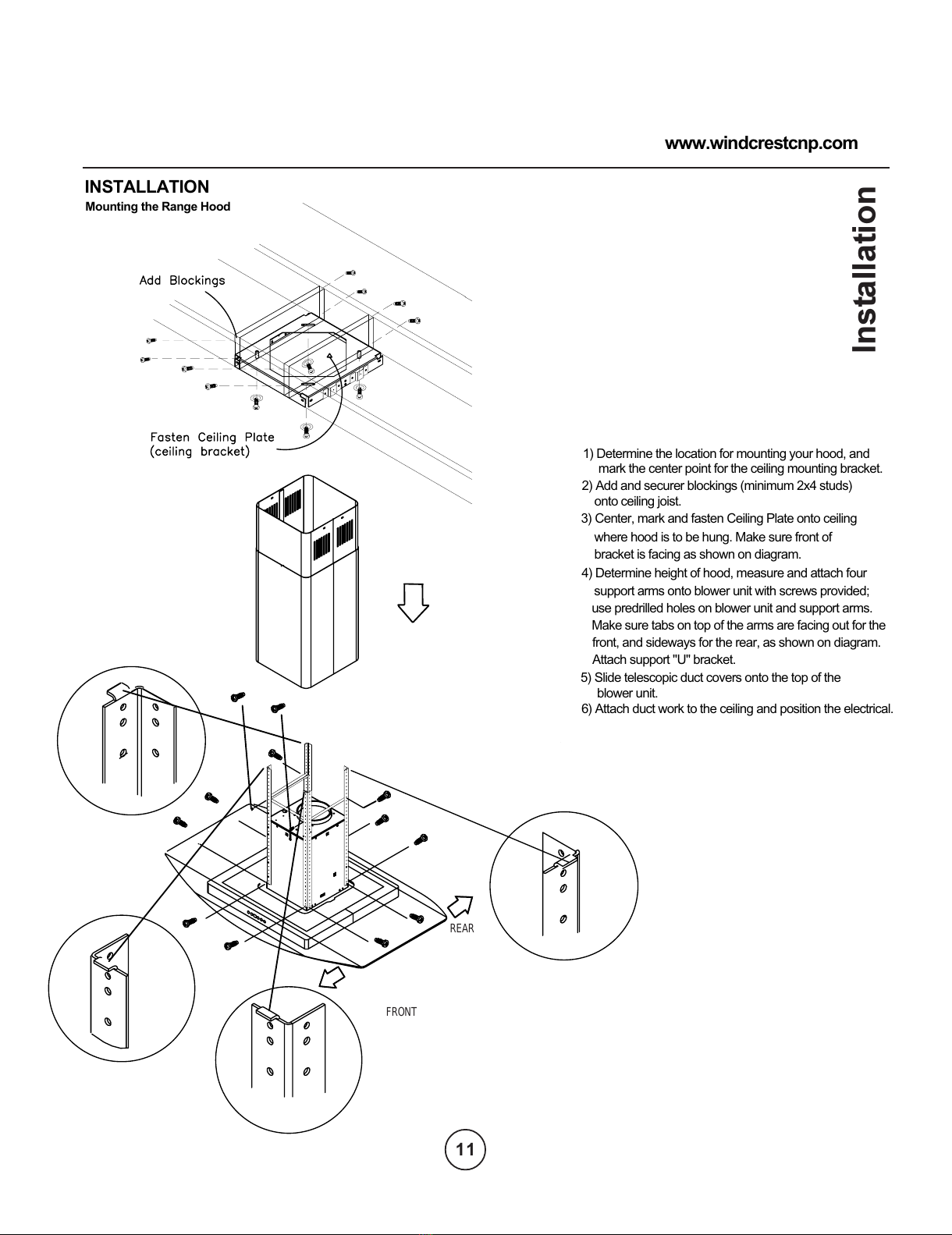

Installation

REAR

FRONT

onto ceiling joist.

2) Add and securer blockings (minimum 2x4 studs)

3) Center, mark and fasten Ceiling Plate onto ceiling

bracket is facing as shown on diagram.

where hood is to be hung. Make sure front of

use predrilled holes on blower unit and support arms.

4) Determine height of hood, measure and attach four

support arms onto blower unit with screws provided;

Attach support "U" bracket.

Make sure tabs on top of the arms are facing out for the

front, and sideways for the rear, as shown on diagram.

11

www.windcrestcnp.com

INSTALLATION

Mounting the Range Hood

blower unit.

mark the center point for the ceiling mounting bracket.

1) Determine the location for mounting your hood, and

5) Slide telescopic duct covers onto the top of the

6) Attach duct work to the ceiling and position the electrical.

11

All manuals and user guides at all-guides.com

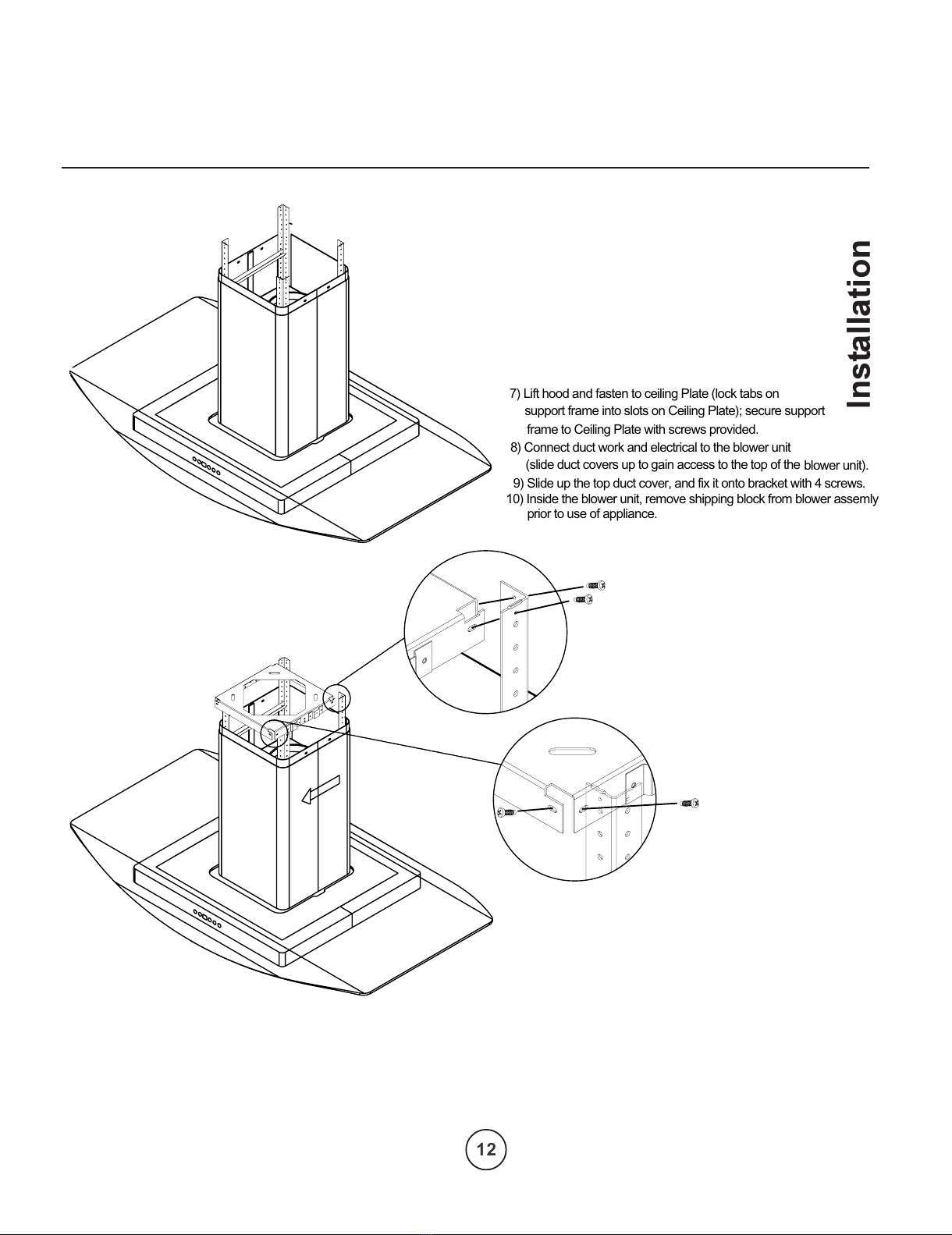

Installation

support frame into slots on Ceiling Plate); secure support

7) Lift hood and fasten to ceiling Plate (lock tabs on

frame to Ceiling Plate with screws provided.

12

10) Inside the blower unit, remove shipping block from blower assemly

blower unit).

(slide duct covers up to gain access to the top of the

8) Connect duct work and electrical to the blower unit

prior to use of appliance.

9) Slide up the top duct cover, and fix it onto bracket with 4 screws.

12

All manuals and user guides at all-guides.com

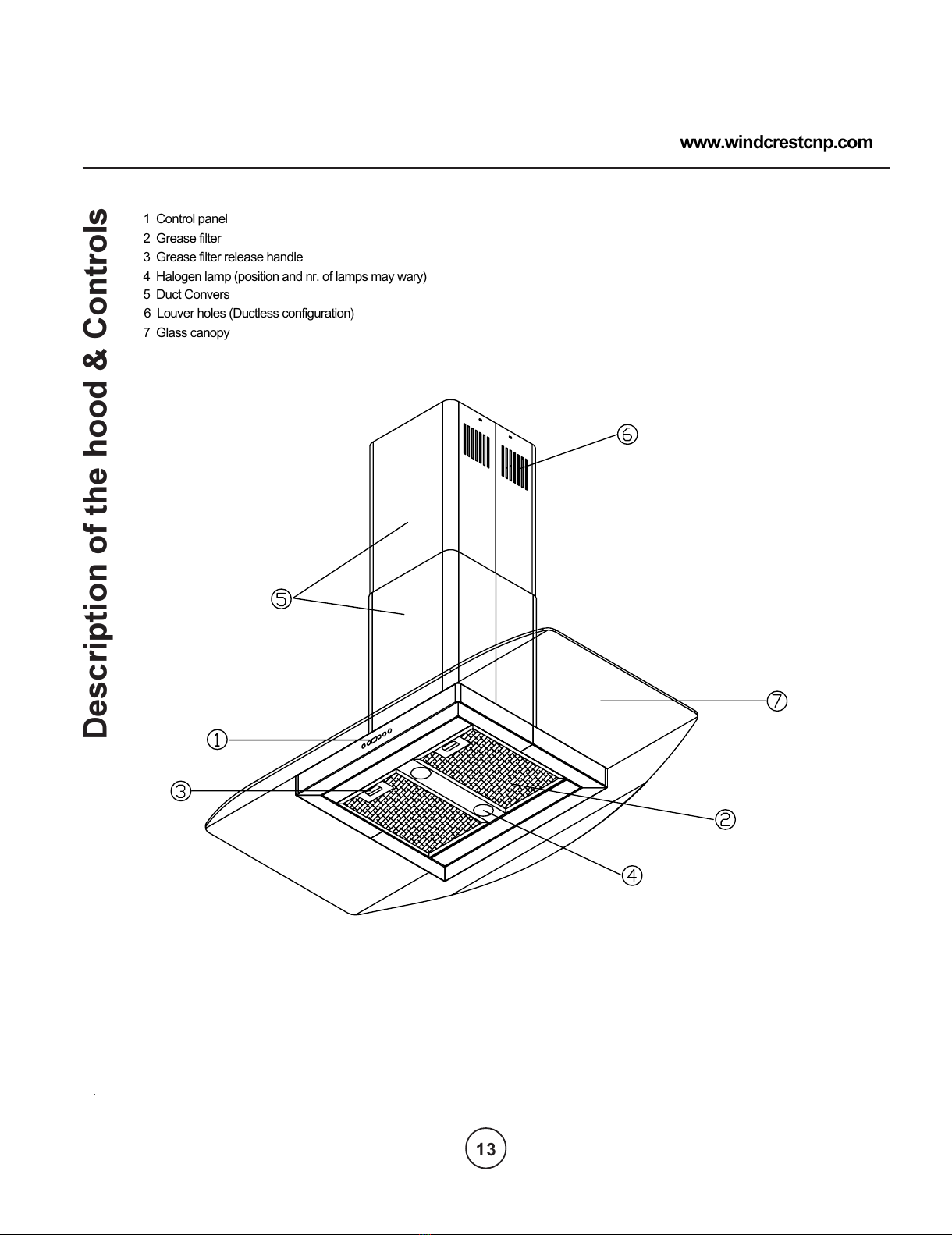

Description of the hood & Controls

..

2 Grease filter

3 Grease filter release handle

4 Halogen lamp (position and nr. of lamps may wary)

5 Duct Convers

6 Louver holes (Ductless configuration)

7 Glass canopy

1 Control panel

www.windcrestcnp.com

13

All manuals and user guides at all-guides.com

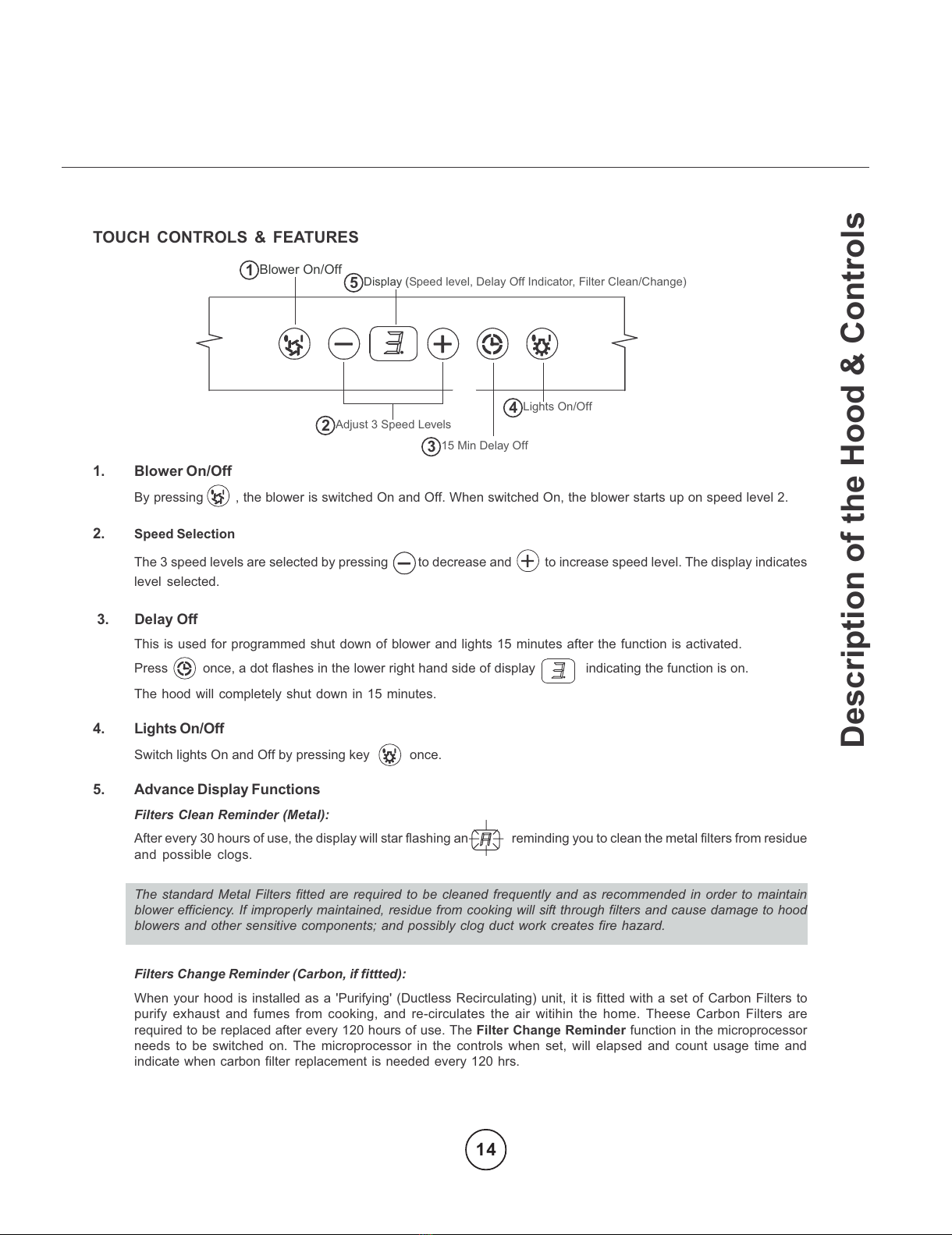

TOUCH CONTROLS & FEATURES

1. Blower On/Off

By pressing , the blower is switched On and Off. When switched On, the blower starts up on speed level 2.

2. Speed Selection

The 3 speed levels are selected by pressing to decrease and to increase speed level. The display indicates

level selected.

3. Delay Off

This is used for programmed shut down of blower and lights 15 minutes after the function is activated.

Press once, a dot flashes in the lower right hand side of display indicating the function is on.

The hood will completely shut down in 15 minutes.

4. Lights On/Off

Switch lights On and Off by pressing key once.

5. Advance Display Functions

Filters Clean Reminder (Metal):

After every 30 hours of use, the display will star flashing an reminding you to clean the metal filters from residue

and possible clogs.

The standard Metal Filters fitted are required to be cleaned frequently and as recommended in order to maintain

blower efficiency. If improperly maintained, residue from cooking will sift through filters and cause damage to hood

blowers and other sensitive components; and possibly clog duct work creates fire hazard.

Filters Change Reminder (Carbon, if fittted):

When your hood is installed as a 'Purifying' (Ductless Recirculating) unit, it is fitted with a set of Carbon Filters to

purify exhaust and fumes from cooking, and re-circulates the air witihin the home. Theese Carbon Filters are

required to be replaced after every 120 hours of use. The Filter Change Reminder function in the microprocessor

needs to be switched on. The microprocessor in the controls when set, will elapsed and count usage time and

indicate when carbon filter replacement is needed every 120 hrs.

Description of the Hood & Controls

15

2

3

4

Blower On/Off

Display (Speed level, Delay Off Indicator, Filter Clean/Change)

Adjust 3 Speed Levels

15 Min Delay Off

Lig ts On/Off

14

All manuals and user guides at all-guides.com

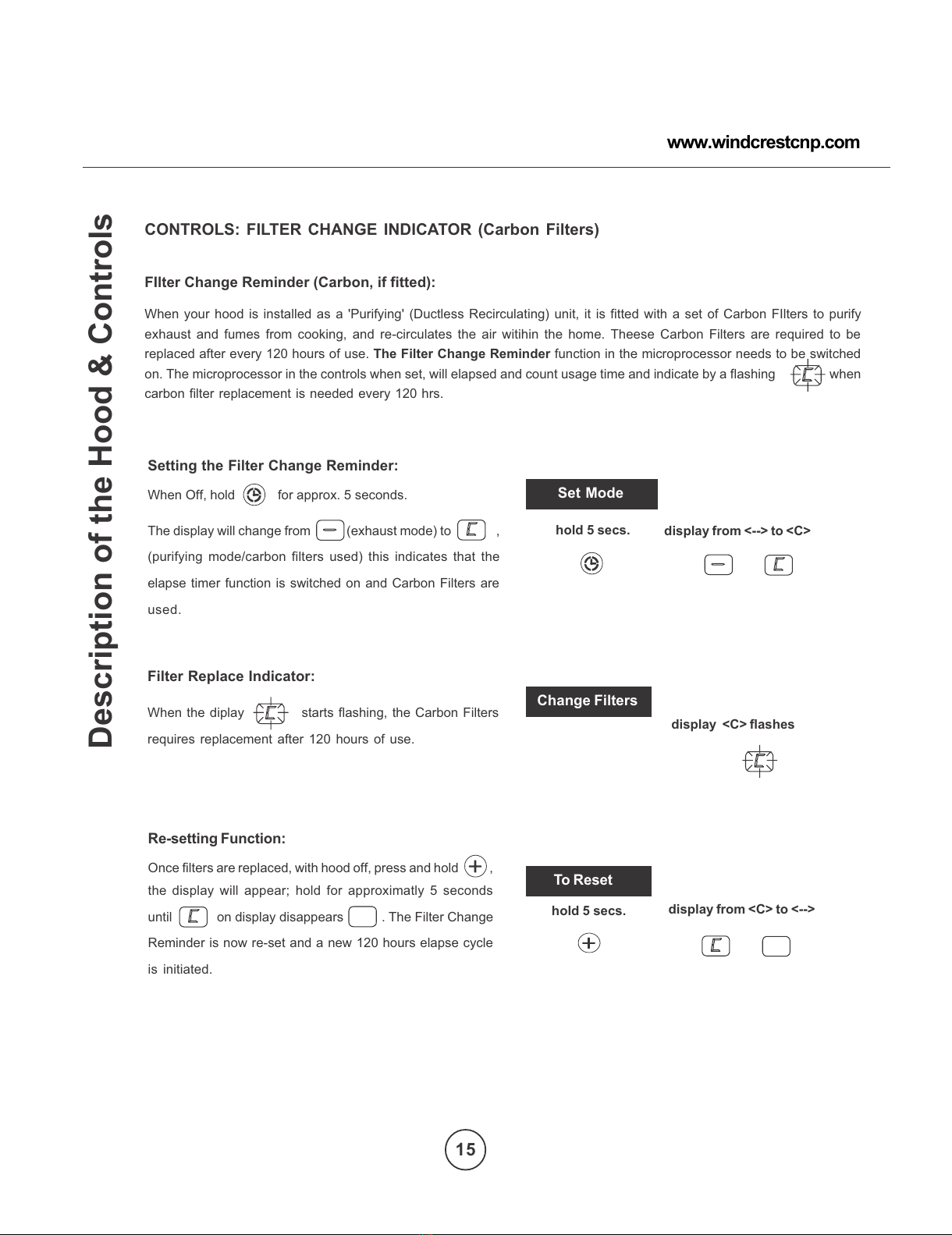

CONTROLS: FILTER CHANGE INDICATOR (Carbon Filters)

FIlter Change Reminder (Carbon, if fitted):

When your hood is installed as a 'Purifying' (Ductless Recirculating) unit, it is fitted with a set of Carbon FIlters to purify

exhaust and fumes from cooking, and re-circulates the air witihin the home. Theese Carbon Filters are required to be

replaced after every 120 hours of use. The Filter Change Reminder function in the microprocessor needs to be switched

on. The microprocessor in the controls when set, will elapsed and count usage time and indicate by a flashing when

carbon filter replacement is needed every 120 hrs.

Setting the Filter Change Reminder:

When Off, hold for approx. 5 seconds.

The display will change from (exhaust mode) to ,

(purifying mode/carbon filters used) this indicates that the

elapse timer function is switched on and Carbon Filters are

used.

Filter Replace Indicator:

When the diplay starts flashing, the Carbon Filters

requires replacement after 120 hours of use.

Re-setting Function:

Once filters are replaced, with hood off, press and hold ,

the display will appear; hold for approximatly 5 seconds

until on display disappears . The Filter Change

Reminder is now re-set and a new 120 hours elapse cycle

is initiated.

Set Mode

Change Filters

To Reset

hold 5 secs. display from <--> to <C>

hold 5 secs. display from <C> to <-->

display <C> flashes

Description of the Hood & Controls

15

www.windcrestcnp.com

All manuals and user guides at all-guides.com

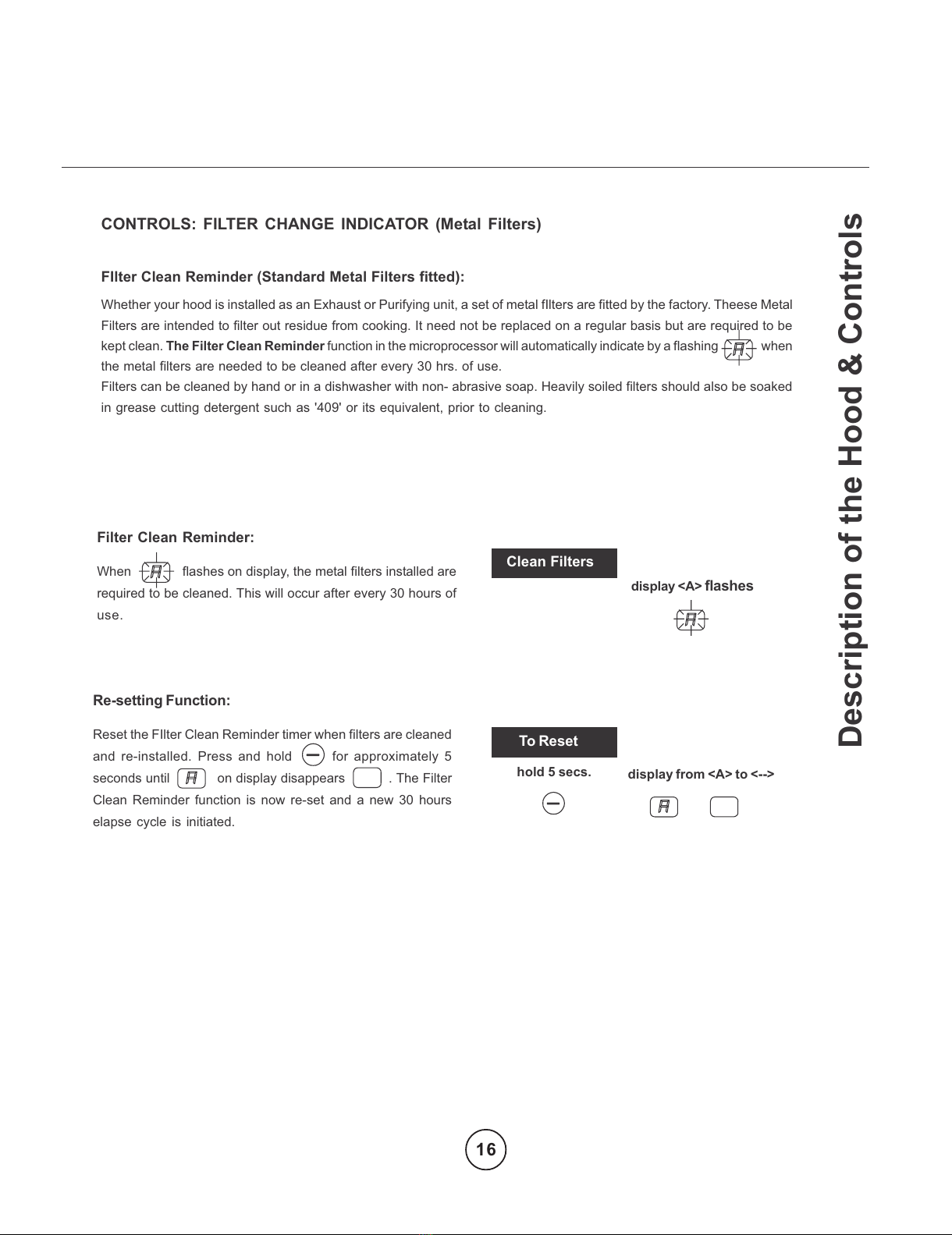

Filter Clean Reminder:

When flashes on display, the metal filters installed are

required to be cleaned. This will occur after every 30 hours of

use.

Re-setting Function:

Reset the FIlter Clean Reminder timer when filters are cleaned

and re-installed. Press and hold for approximately 5

seconds until on display disappears . The Filter

Clean Reminder function is now re-set and a new 30 hours

elapse cycle is initiated.

Set Mode

Clean Filters

To Reset

hold 5 secs. display from <A> to <-->

display <A>

flashes

CONTROLS: FILTER CHANGE INDICATOR (Metal Filters)

FIlter Clean Reminder (Standard Metal Filters fitted):

Whether your hood is installed as an Exhaust or Purifying unit, a set of metal fIlters are fitted by the factory. Theese Metal

Filters are intended to filter out residue from cooking. It need not be replaced on a regular basis but are required to be

kept clean. The Filter Clean Reminder function in the microprocessor will automatically indicate by a flashing when

the metal filters are needed to be cleaned after every 30 hrs. of use.

Filters can be cleaned by hand or in a dishwasher with non- abrasive soap. Heavily soiled filters should also be soaked

in grease cutting detergent such as '409' or its equivalent, prior to cleaning.

Description of the Hood & Controls

16

All manuals and user guides at all-guides.com

Maintenance

Prior to any maintenance operation ensure that the cooker hood is disconnected from the power supply.

The cooker hood should be cleaned regularly internally and externally.

For cleaning use a cloth moistened with a neutral liquid detergents. Avoid abrasive detergents.

Wa ning:

Failure to carry out the basic standards of the cleaning of the cooker hood and replacement of the filters may cause fire

risks.

Therefore we recommend oserving these instructions.

This must be cleaned once a month using non aggressive detergents, either by hand or in the dish-washer, which must be

set to a low temperature and a short cycle.

When washed in a dish-washer, the grease filter may discolour slightly, but this does not affect its filtering capacity.

To remove the grease filter, pull the spring release handle.

ATTENTION!

GREASE FILTER

CLEANING

17

www.windcrestcnp.com

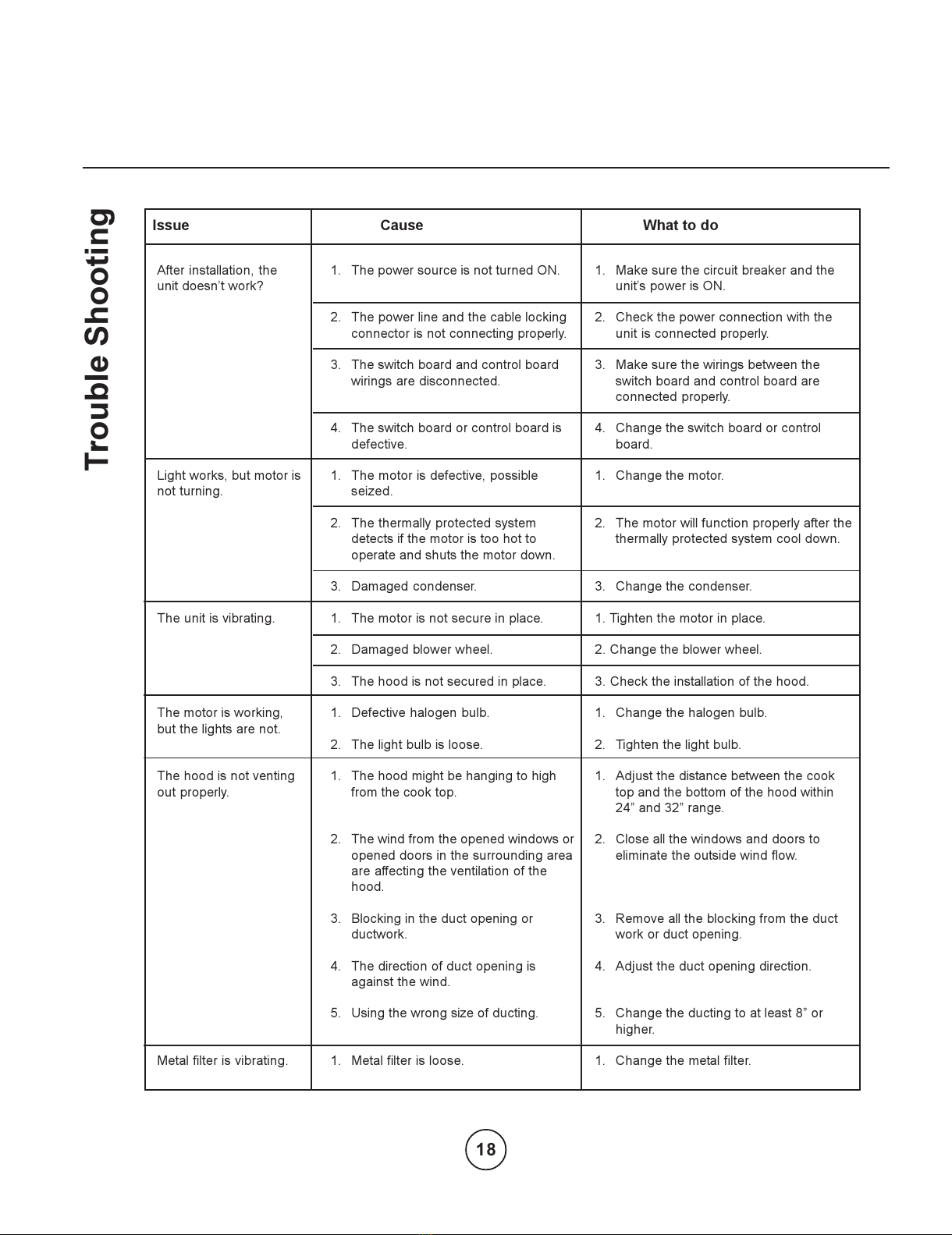

Replacing Light Bulbs

Make sure all power is turned off and

bulbs are not hot.

Remove by turning bulb counter

clockwise.

If bulbs are difficult to turn due to

prolonged use, firmly attach a glass

suction cup approx. the diameter of the

bulb and turn.

Replacement bulbs are available at

specialty lighting stores. Purchase type

GU - 10 50W halogen bulbs.

CAUTION: Light bulb becomes extremely hot when turned on.

DO NOT touch bulb until switched off and cooled. Touching hot

bulbs could cause serious burns.

All manuals and user guides at all-guides.com

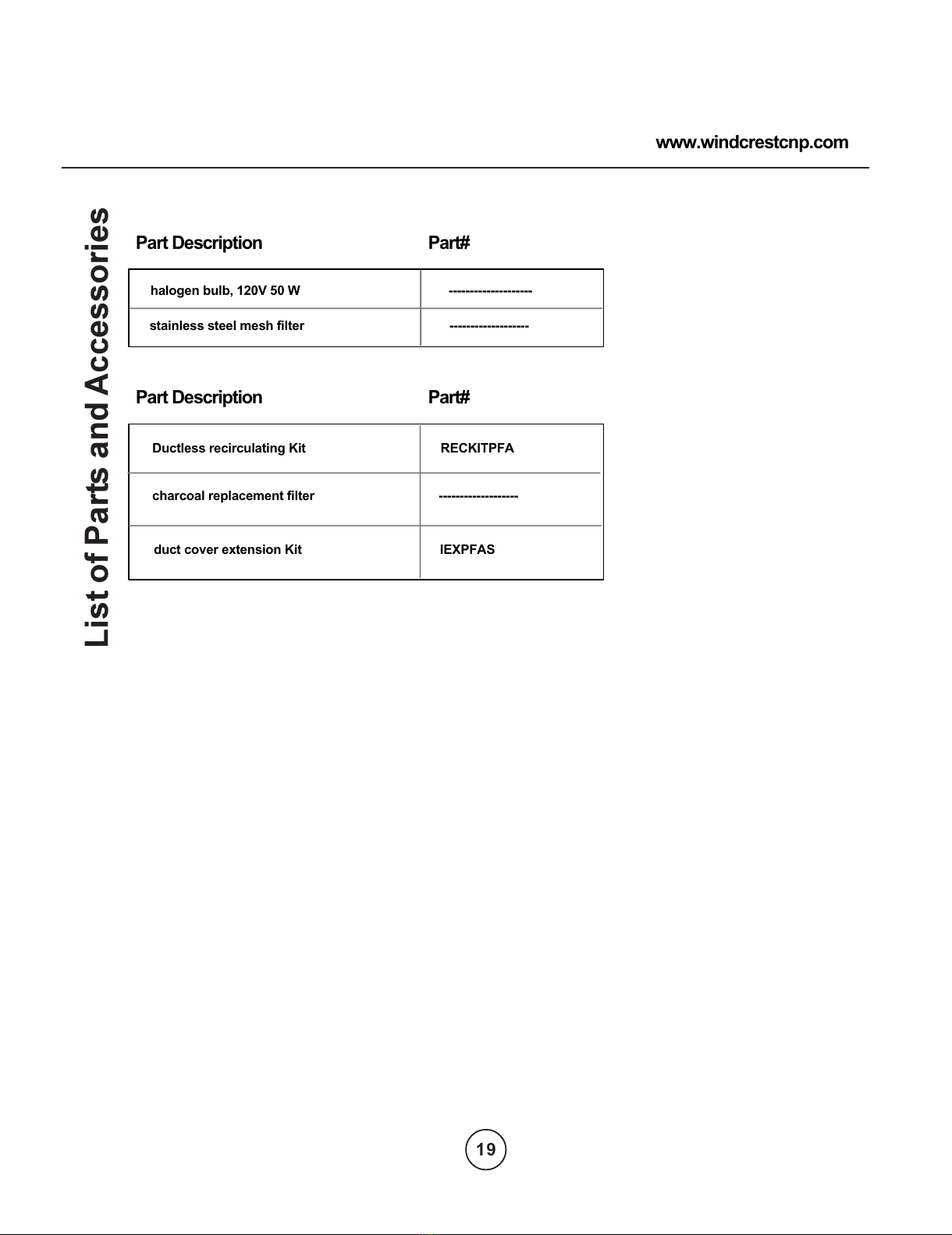

Trouble Shooting

After installation, the

unit doesnt work?

Light works, but motor is

not turning.

The unit is vibrating.

The motor is working,

but the lights are not.

The hood is not venting

out properly.

Metal filter is vibrating.

1. The power source is not turned ON.

2. The power line and the cable locking

connector is not connecting properly.

3. The switch board and control board

wirings are disconnected.

4. The switch board or control board is

defective.

1. The motor is defective, possible

seized.

2. The thermally protected system

detects if the motor is too hot to

operate and shuts the motor down.

3. Damaged condenser.

1. The motor is not secure in place.

2. Damaged blower wheel.

3. The hood is not secured in place.

1. Defective halogen bulb.

2. The light bulb is loose.

1. The hood might be hanging to high

from the cook top.

2. The wind from the opened windows or

opened doors in the surrounding area

are affecting the ventilation of the

hood.

3. Blocking in the duct opening or

ductwork.

4. The direction of duct opening is

against the wind.

5. Using the wrong size of ducting.

1. Metal filter is loose.

I ue Cau e What to do

1. Make sure the circuit breaker and the

units power is ON.

2. Check the power connection with the

unit is connected properly.

3. Make sure the wirings between the

switch board and control board are

connected properly.

4. Change the switch board or control

board.

1. Change the motor.

2. The motor will function properly after the

thermally protected system cool down.

3. Change the condenser.

1. Tighten the motor in place.

2. Change the blower wheel.

3. Check the installation of the hood.

1. Change the halogen bulb.

2. Tighten the light bulb.

1. Adjust the distance between the cook

top and the bottom of the hood within

24 and 32 range.

2. Close all the windows and doors to

eliminate the outside wind flow.

3. Remove all the blocking from the duct

work or duct opening.

4. Adjust the duct opening direction.

5. Change the ducting to at least 8 or

higher.

1. Change the metal filter.

18

All manuals and user guides at all-guides.com

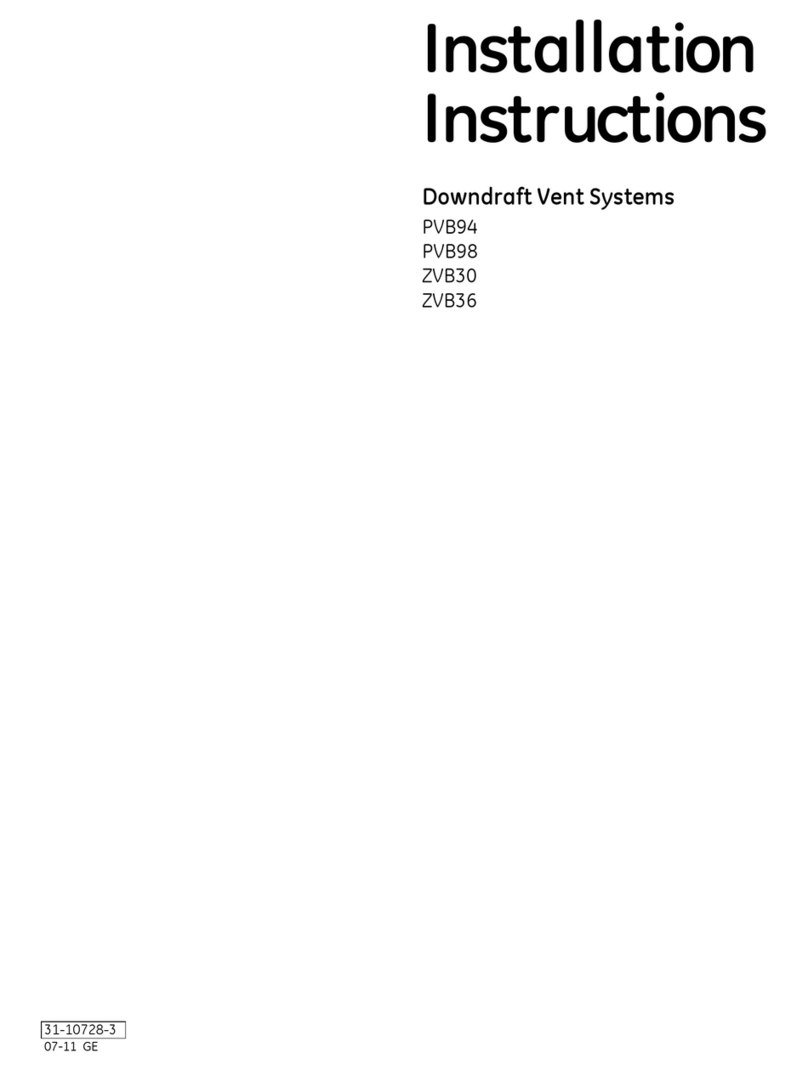

List of Parts and Accessories

stainless steel mesh filter -------------------

duct cover extension Kit IEXPFAS

Part Description Part#

Part Description Part#

halogen bulb, 120V 50 W --------------------

Ductless recirculating Kit RECKITPFA

charcoal replacement filter -------------------

www.windcrestcnp.com

19

All manuals and user guides at all-guides.com

This manual suits for next models

1

Table of contents

Languages:

Other CNP INDUSTRIES Ventilation Hood manuals

Popular Ventilation Hood manuals by other brands

ELICA

ELICA Horizonte Island Series Use, care and installation guide

Gorenje

Gorenje ONE DVG65W Instructions for use

AIRFORCE

AIRFORCE F162 90 D2 Glass Instruction on mounting and use

GE

GE PVB94DTBB installation instructions

Omega

Omega ORU90XL quick start guide

Howdens

Howdens Lamona LAM2400 User's installation guide

Whirlpool

Whirlpool 30 " Eye-Level Gas Range installation instructions

Xo

Xo XOI27S User instructions

Amica

Amica OWS 451 O instruction manual

Bosch

Bosch DHI665VGB Operating and installation instructions

Brillia

Brillia RAX9430SQB Installation instructions and operation manual

Novy

Novy 650 installation instructions