Cobod BOD2-444 User manual

Instruction Manual

Original Version

BOD2-444

3D Construction Printer

Generation: 02

Instruction Manual - Original Version

Page 2 of 50

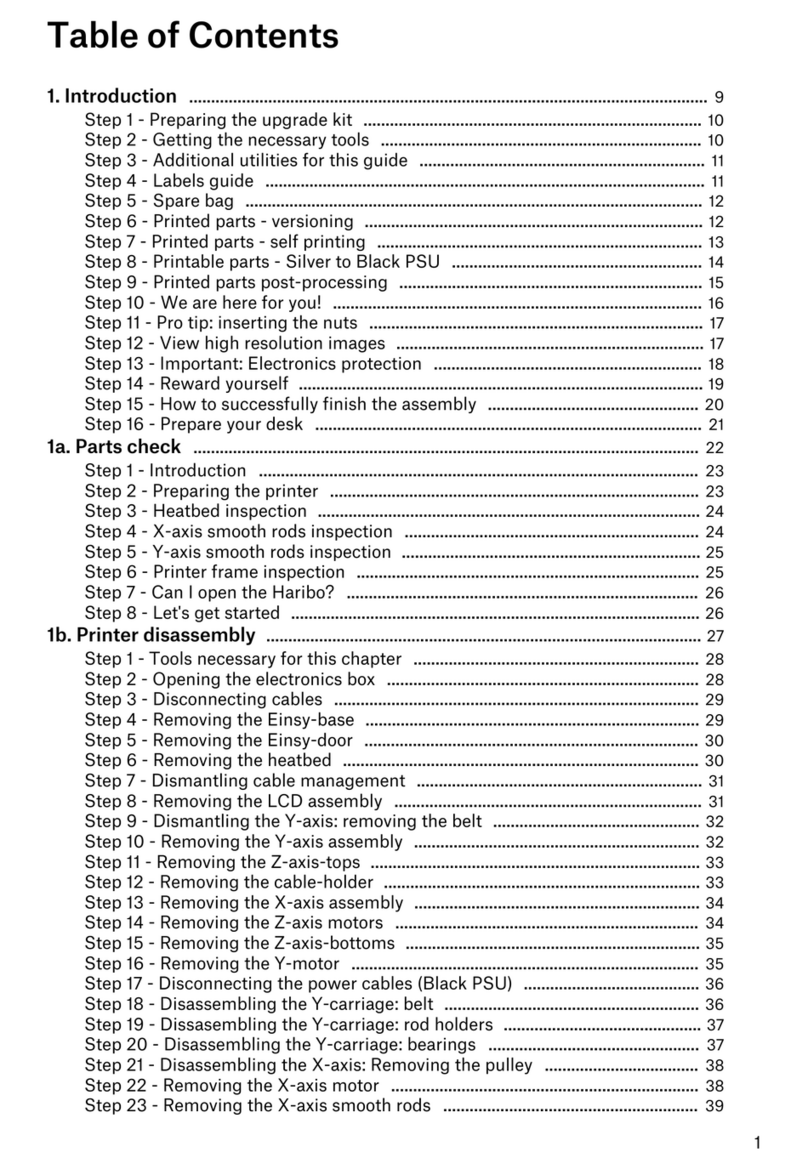

1Contents

1.1 Document version ............................................................................................................................. 4

2 Identification ............................................................................................................................................. 5

2.1 Supplier information.......................................................................................................................... 5

2.2 Declaration of Conformity................................................................................................................. 6

3 Product description ................................................................................................................................... 7

3.1 General .............................................................................................................................................. 7

3.1.1 Function description.................................................................................................................. 7

3.1.2 Machine construction................................................................................................................ 7

3.1.3 Process description.................................................................................................................. 10

3.1.4 Proper use................................................................................................................................ 10

3.1.5 Improper use ........................................................................................................................... 10

3.1.6 Modification ............................................................................................................................ 10

3.1.7 Before the commissioning....................................................................................................... 11

3.1.8 Limits of machinery ................................................................................................................. 11

3.2 Machine information....................................................................................................................... 12

3.3 Safety information........................................................................................................................... 13

3.3.1 Signs......................................................................................................................................... 13

3.3.2 Safety functions....................................................................................................................... 14

4 Definitions ............................................................................................................................................... 18

4.1 Technical terms and abbreviations ................................................................................................. 18

4.2 References....................................................................................................................................... 18

5 Handling................................................................................................................................................... 19

5.1 Transport and storage ..................................................................................................................... 19

5.2 Precautionary measures before the operation...................................Error! Bookmark not defined.

5.3 Unpacking........................................................................................................................................ 19

5.4 Safe disposal of packing material .................................................................................................... 19

5.5 Installation and assembly of the machine....................................................................................... 19

5.5.1 Mechanical assembly............................................................................................................... 19

5.5.2 Electrical installation................................................................................................................ 25

5.5.3 Connections............................................................................................................................. 26

5.6 Storage............................................................................................................................................. 26

5.7 Repacking......................................................................................................................................... 27

Instruction Manual - Original Version

Page 3 of 50

5.8 Placing of instructions ..................................................................................................................... 27

6 Operating manual.................................................................................................................................... 28

6.1 Normal function............................................................................................................................... 28

6.1.1 Connection to computer ......................................................................................................... 28

6.1.2 Manual operation.................................................................................................................... 29

6.1.3 Automatic operation ............................................................................................................... 31

6.1.4 User interface .......................................................................................................................... 31

6.2 Error situations................................................................................................................................ 37

6.3 Signals to be observed..................................................................................................................... 38

6.4 Accessories ...................................................................................................................................... 38

6.5 Disposal of waste materials............................................................................................................. 38

7 Maintenance and cleaning ...................................................................................................................... 39

7.1 Precautionary measures.................................................................................................................. 39

7.2 Maintenance made by the operator ............................................................................................... 39

7.2.1 1 –Test axis movement........................................................................................................... 40

7.2.2 2 –Test end-stops.................................................................................................................... 40

7.2.3 3 –Test Load cells.................................................................................................................... 40

7.2.4 4 –Test pump controller (OPTIONAL: only if pump controller is attached) ........................... 41

7.2.5 5 –Test all E-stops................................................................................................................... 41

7.2.6 6 –Test downwards pinch safety............................................................................................ 41

7.2.7 7 –Test safety door (Optional, if safety door is installed and connected).............................. 42

7.2.8 8 –Inspect Extruder pump ...................................................................................................... 42

7.2.9 9 –Inspect hoses ..................................................................................................................... 43

7.2.10 10 –Inspect mixing shaft......................................................................................................... 43

7.2.11 11 –Inspect cables .................................................................................................................. 43

7.2.12 12 –Grease tooth rack ............................................................................................................ 43

7.3 Maintenance and cleaning made by the cleaning personnel.......................................................... 43

7.3.1 1 –All parts of the printhead................................................................................................... 44

7.3.2 2 –Material hose..................................................................................................................... 44

7.3.3 3 –Mixer pump ....................................................................................................................... 44

7.3.4 4 –Printing area....................................................................................................................... 45

7.3.5 5 –Other equipment ............................................................................................................... 45

7.3.6 6 –Excess / waste material ..................................................................................................... 45

Instruction Manual - Original Version

Page 4 of 50

7.3.7 7 –Extruder inner parts........................................................................................................... 45

7.4 Alarm list..............................................................................................Error! Bookmark not defined.

8 Service ..................................................................................................................................................... 47

8.1 Service intervals............................................................................................................................... 47

8.1.1 1 –Maintenance task No. 1.........................................................Error! Bookmark not defined.

8.1.2 2 –Maintenance task No. 2.........................................................Error! Bookmark not defined.

8.1.3 3 –Maintenance task No. 3.........................................................Error! Bookmark not defined.

8.1.4 4 –Maintenance task No. 4.........................................................Error! Bookmark not defined.

8.1.5 5 –Maintenance task No. 5.........................................................Error! Bookmark not defined.

8.2 Customer service............................................................................................................................. 47

9 List of spare parts and consumables ...........................................................Error! Bookmark not defined.

10 Disposal of the machine ...................................................................................................................... 49

11 Logbook ............................................................................................................................................... 50

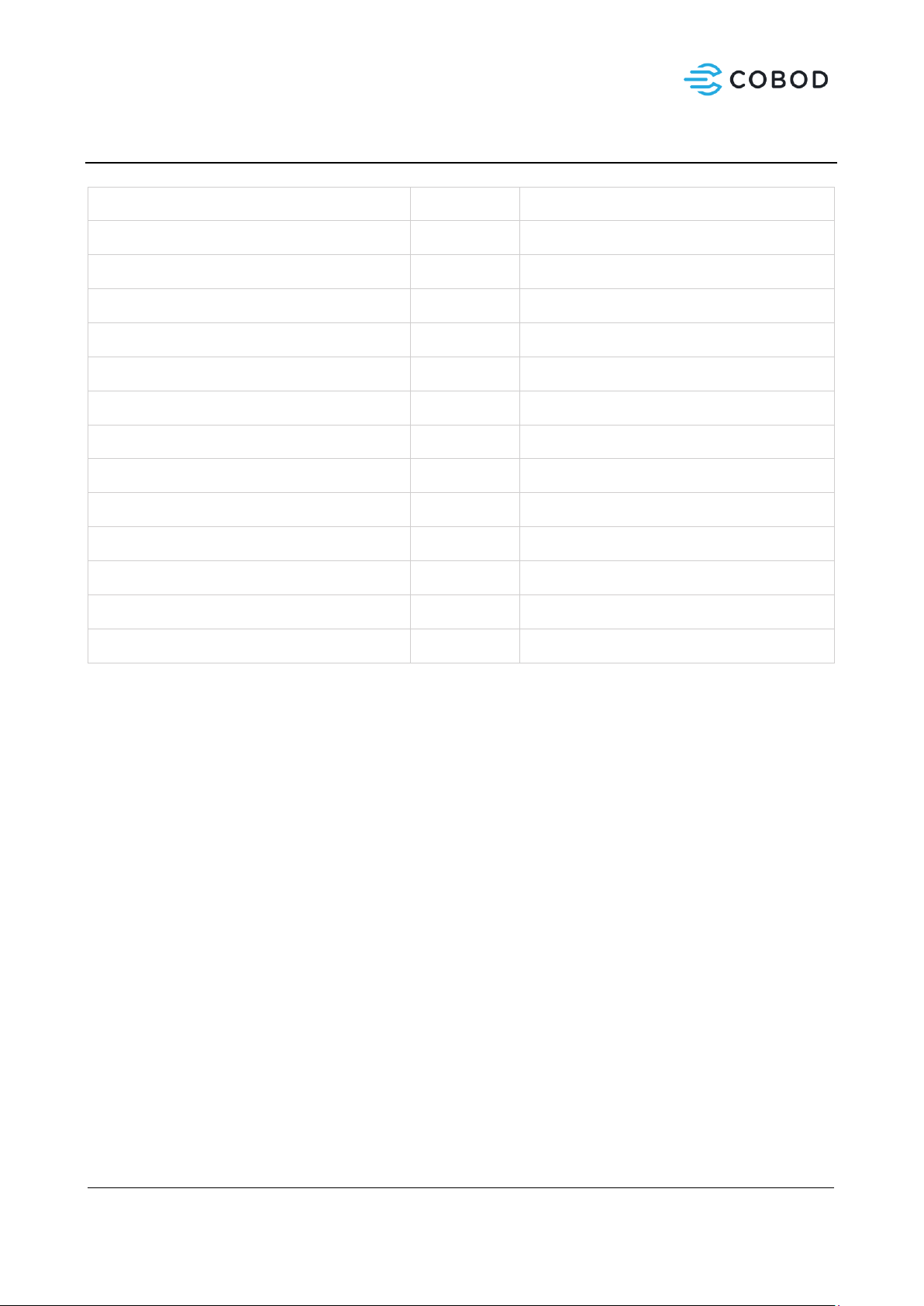

1.1 Document version

Version

Description

Date of issue

UK01

First version

November, 2018

Instruction Manual - Original Version

Page 5 of 50

2Identification

2.1 Supplier information

Manufacturer:

COBOD International A/S

Address:

Dronningens Tværgade 26

DK - 1302 København K

Phone

+45 70 60 55 33

E-Mail:

Instruction Manual - Original Version

Page 6 of 50

2.2 Declaration of Conformity

Instruction Manual - Original Version

Page 7 of 50

3Product description

3.1 General

Before the machine is commissioned, this instruction manual must be thoroughly read and

understood!

This warning symbol indicates that special precautionary measures must be taken.

If the safety precautions are not observed, it may lead to hazardous conditions and result

in personal injury or damage to property.

This symbol indicates that the following information is important.

3.1.1 Function description

This instruction manual describes the proper use of the machine.

The BOD2 is a modular gantry-based 3D construction printer. The BOD 2 printer is built from 2.5m modules

and can be built to customer specifications.

The BOD2 printer works in 3 dimensions, with the print head moving on the X-axis, the X-axis bar moving

on the Y-axis and the whole XY-group moving up and down on the 4 Z-columns. The gantry principle allows

the printer to access any position within the print envelope and gives complete freedom of movement

within the volume.

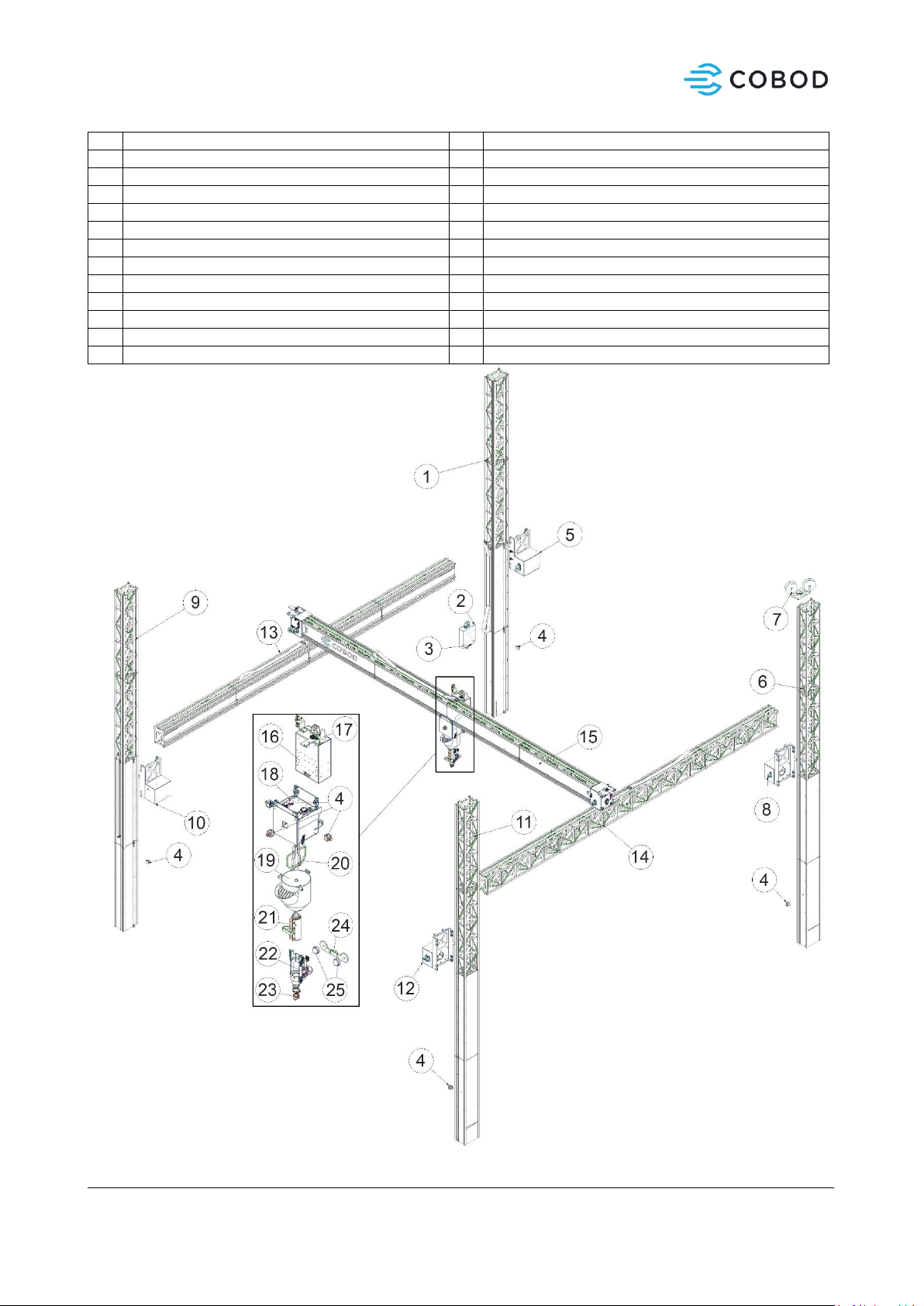

3.1.2 Machine construction

The BOD2 is designed as a stand-alone unit consisting of several integrated units and components:

• Four Z-columns (legs), height = 10 m, 4 servomotors, drivers included.

• Two Y-axis, length = 10 m, 2 servomotors, drivers included.

• One X-axes, width = 10 m, 1 servomotor, drivers included.

• One print head, 2 servomotors, drivers included.

(One for turning the nozzle and one for controlling the material flow)

• Control cabinet with supply disconnector, electrical equipment, 3D print controller and safety PLCs.

Instruction Manual - Original Version

Page 8 of 50

Figure 1: Model of printer

Instruction Manual - Original Version

Page 9 of 50

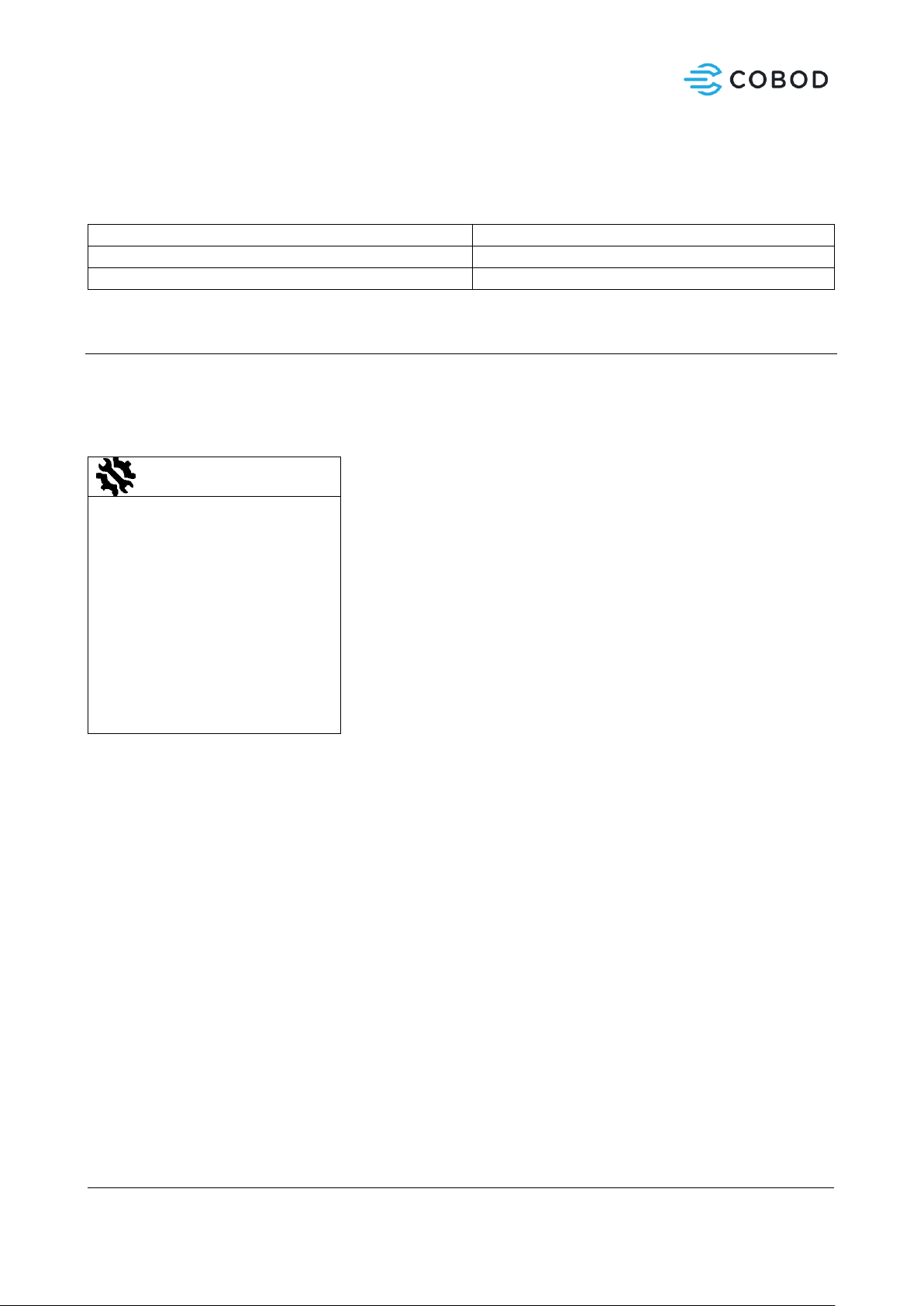

Figure 2: Exploded view, printer parts

1

Z1-axis

14

Y2-axis

2

Main E-box

15

X-axis

3

Power connection and circuit breaker

16

X-carriage E-Box

4

Emergency stop

17

Status lamp

5

Z1-carriage

18

X-carriage

6

Z2-axis

19

Material hopper

7

Hose management

20

Mixing shaft

8

Z2-Carriage

21

PCP

9

Z3-axis

22

U Axis

10

Z3-carriage

23

Nozzle

11

Z4-axis

24

Camera Mount

12

Z4-carriage

25

IP Cameras

13

Y1-axis

Instruction Manual - Original Version

Page 10 of 50

3.1.3 Process description

The machine is intended for automated extrusion of concrete materials in layers. The shape of the layers is

directed by a predefined digital model.

•Fresh concrete or mortar is fed to the hopper. Either manually or by an external pumping device.

•From the hopper, the concrete is extruded through a nozzle, and placed in a predefined layer

pattern.

•Layers are applied on top continuously until the desired geometry is printed.

•The machine can be controlled manually or automatically.

3.1.4 Proper use

The machine may only be used under the operating conditions foreseen in this instructions manual.Any

other use beyond such operating conditions is deemed not conform to the instructions manual and the

manufacturer cannot accept any liability what-so-ever for subsequent loss or damage.

Proper use shall be deemed to include:

•The observance of all references of this instruction manual.

•The observance of service intervals and maintenance routines.

3.1.5 Improper use

The manufacturer / supplier will not be liable for any subsequent loss or damage resulting from improper

use of the machine.

Improper use shall be deemed to include:

•The use of substances that may damage machine parts. Including substances that may create

explosive or poisonous gases posing a risk to personnel or property.

•Improper or missing maintenance of the machine.

•Improper installation of machine or its sub-components.

•Use of the machine for other operations than the stated purpose.

3.1.6 Modification

Any alterations or additions to the machine must be filed in the technical documentation of the machine. If

necessary, the Declaration of Conformity must be updated and signed again. The responsibility for this rests

with the owner of the machine.

Instruction Manual - Original Version

Page 11 of 50

3.1.7 Before the commissioning

Before the commissioning of the machine, it must be checked that all parts have been installed according

to the documentation and instructions from COBOD International A/S.

Before the commissioning of the machine, all relevant personnel must be instructed in the documentation

of the machine –including instruction manual, maintenance instructions, diagrams etc.

3.1.8 Limits of machinery

3.1.8.1 Use limits

The BOD2 is intended for use on construction sites and will be

installed inside (typically in a tent).

•3D print of objects within the dimensions of the machine.

•Automatic mode used to move the machine based on G-code.

•The machine can be operated manually.

•The machine is operated from a web interface or from a touch panel.

•The supply disconnector is installed outside of the operating area of the machine.

•Energy supply: see Power Sources.

3.1.8.2 Space limits

The foot print of the BOD2 444 is:

•Length = 10.1 m.

•Width = 12.6 m

•Height = 10.5 m.

3.1.8.3 Time limits

The service life of the machine is 20 years of a daily 8-hour operation. This is based on the presumption that

all service and maintenance instructions described in this instruction manual are observed carefully.

3.1.8.4 Other limits

The BOD2 is intended for use on construction sites and must be installed inside (typically in a tent).

Printing material is a premix of concrete and cement-based mortars.

Temperature limits: 5 °C to +50 °C.

Instruction Manual - Original Version

Page 12 of 50

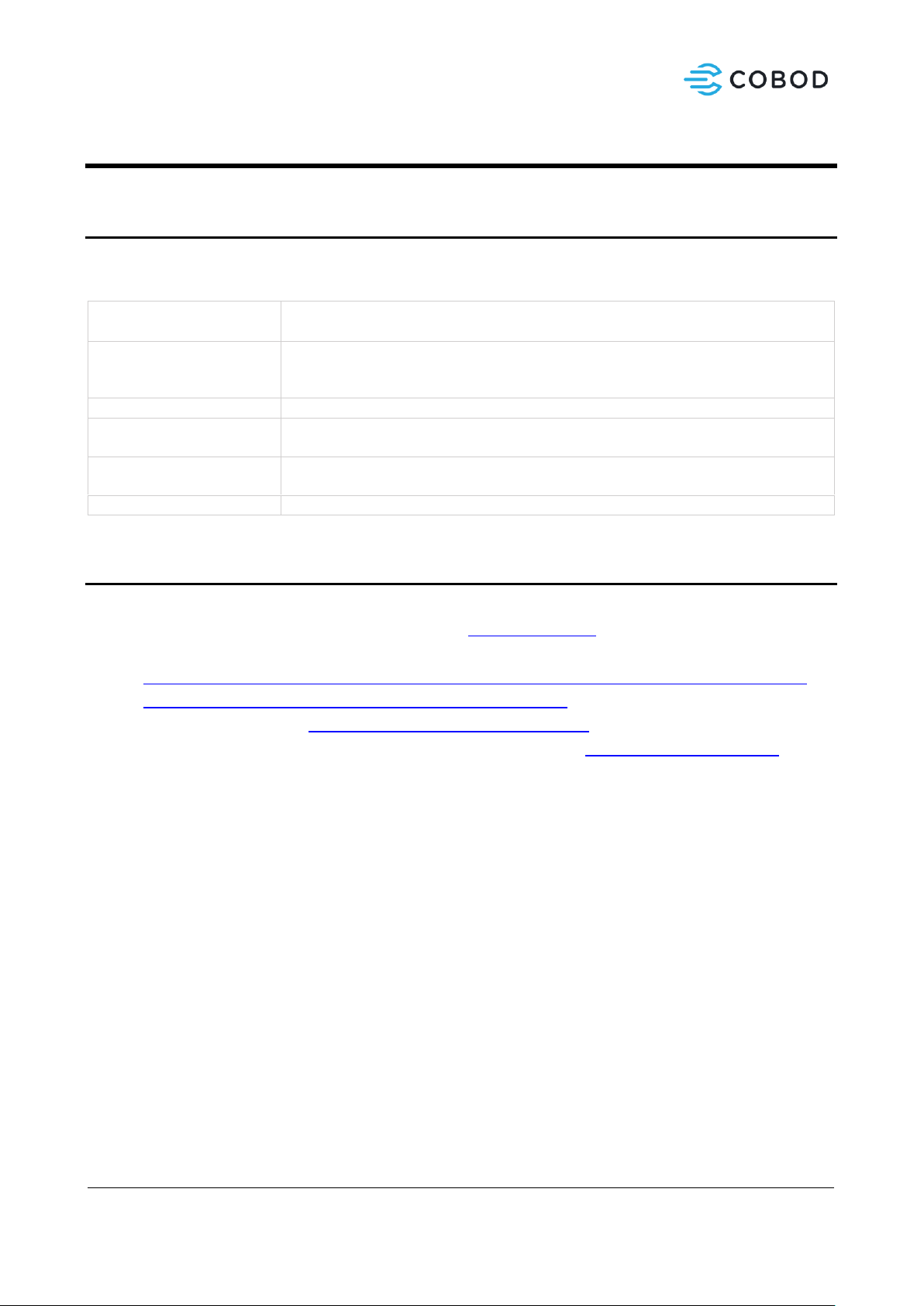

3.2 Machine information

Description

Unit

Value

Measurements (length x width x height)

[m]

10.1 x 12.6 x 10.5

Weight

[kg]

5023

Power consumption

[A]

32

Voltage

[V]

3x400VAC + PE

Frequency

[Hz]

50/60 Hz

Short circuit current, Ikmin

[A]

500

Short circuit current, Ikmax

[A]

1200

Max. speed (X –Axis)

[mm/s]

250

Max. speed (Y –Axis)

[mm/s]

250

Max. speed (Z –Axis)

[mm/s]

50

Sound level

[dB(A)]

Less than 70

Required bed plate flatness

[mm/m]

10 mm/m

Instruction Manual - Original Version

Page 13 of 50

3.3 Safety information

3.3.1 Signs

The machine is fitted with several mandatory and warning signs. The meaning of these is described in the

following.

Protection

Description

Symbol

Helmet

Mandatory:

When entering the printing area.

When working in the area, always wear approved

safety helmet.

Safety shoes

Mandatory:

When entering the printing area.

When working in the area, always wear approved

safety shoes

Safety glasses

Mandatory:

When working with fresh concrete or dry mix

concrete in- or outside printing area

Protective gloves

Mandatory:

When working with fresh concrete or dry mix

concrete in- or outside printing area

Respiratory protection

Mandatory:

When working with fresh concrete or dry mix

concrete in- or outside printing area

Electricity

Warning:

Control Cabinets.

Only experienced and skilled personnel may open

the control cabinets.

Crushing of hands

Warning:

Transmission parts, toothed rack on each axis.

Crushing

Warning:

When moving the X-, Y- axis and print head

downwards, between print head and floor.

When print head is moved towards one of the two

“end” positions on the X-axis.

Instruction Manual - Original Version

Page 14 of 50

3.3.2 Safety functions

Before operating the machine, the operator must seek information about the safety functions and

protection equipment of the machine.

The use and operation of the machine must only be initiated when all safety functions

are fully present and in an operable condition!

Defective safety functions and protection equipment may lead to loss of safety and

hazardous situations.

In case defective safety functions and protective equipment is found, do the following:

•Stop the machine immediately.

•Make sure the machine cannot restart by disconnecting the supply sources to the

machine.

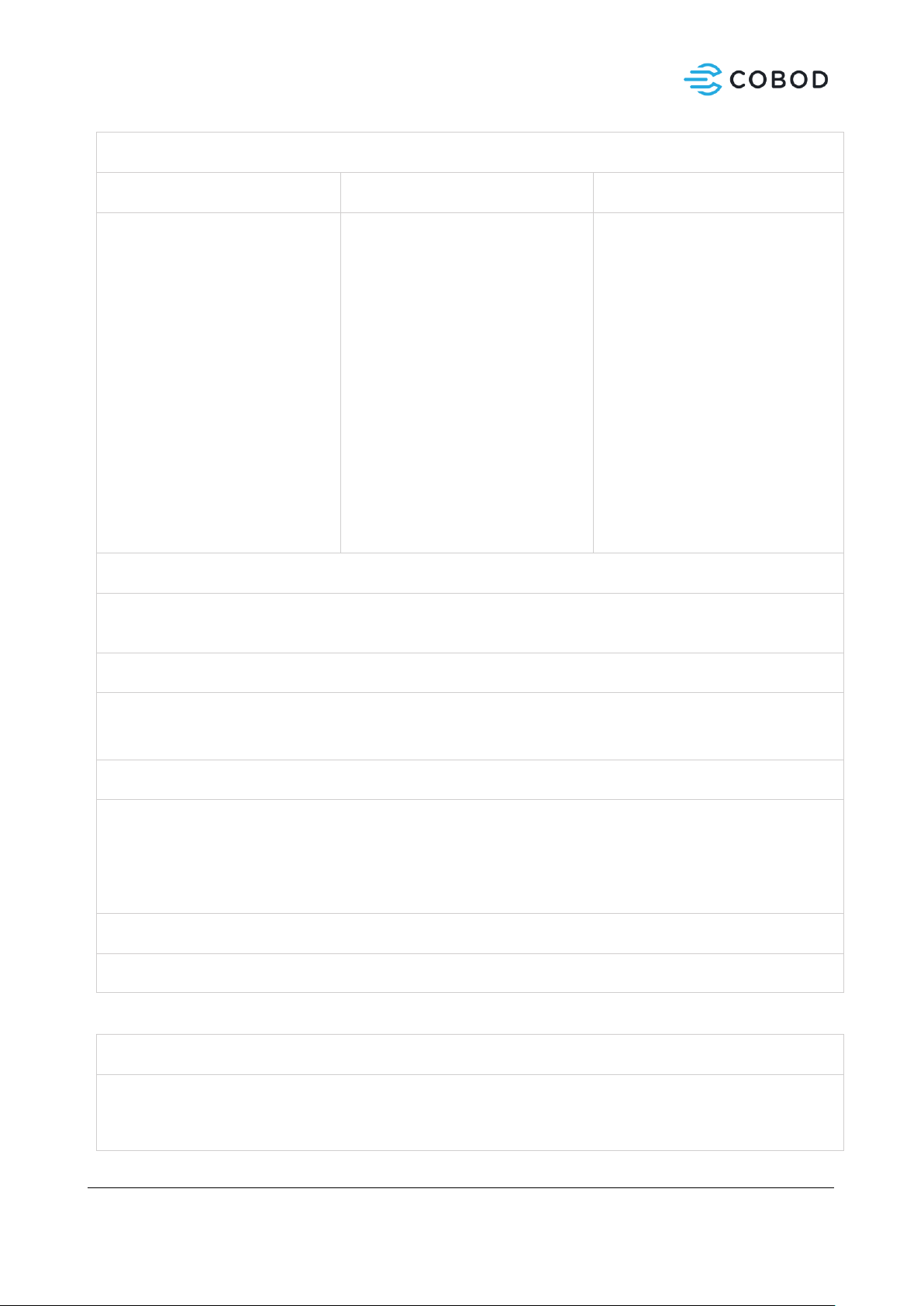

The following safety and protection devices are installed on the machine:

Emergency stop-function

The emergency stop function is a supplementary safety function, with the purpose of preventing a source of hazard

from arising caused by the improper use of the machine. As an example, a source of hazard could result in personal

injury, damage to the machine or ongoing work, or it may arise because another safety function is failing.

After actuation and before disengaging the E-stop devices, the machinery shall be inspected in order to detect the

reason for actuation.

Components included in the safety function.

Input part

Logical part

Output part

Emergency stop push-button

(E-stop)

The emergency stop push-button is

shaped like a red push-button

switch on a yellow background.

Emergency stop of the machine is

induced by activating the

emergency stop push-button.

The emergency stop push-buttons

are located at the following places

of the machine:

-One on each leg (Z-axis).

-Three on the print head.

-One at the control panel.

-One on safety door

Disengagement of the E-stop push

button:

-Turn the red push button

counter clockwise.

Safety controller.

Intelligent controller monitoring

the safety function.

The service life of the safety

controller is 20 years.

The safety function i.e. the

machine must not be used beyond

20 years. The use beyond 20 years

is conditional to the fact that the

relevant components are replaced

by new components of identical or

improved properties than the

original ones.

The safety controllers are located

in the control cabinets.

Servo drives.

Disconnects the power supply to the

moving parts.

-X-axis (front-, back- ward);

-Y-axes (up-, down-ward);

-Print head (Side wards);

-Mixer in the print head.

-Rotation of the print head.

The service life of the servo drives is

20 years.

The servo drives are located in the

control cabinet.

Instruction Manual - Original Version

Page 15 of 50

Displays and alarms

When activating an E-stop, the status will appear on the operator monitor:

”Emergency stop of the machine is activated”

Operating conditions

The work of the emergency function is unchanged throughout any operation modes of the machine.

Maintenance and test

The emergency stop function must be activated and tested before commissioning after each installation or

reinstallation of the machine.

Test: Activating the E-stop one at the time, must stop all servo drives.

As a minimum, the emergency stop function must be visually checked and activated at least every 6 months.

Also see section 7 of this instruction manual.

The safety function complies with EN ISO 13849-1:2015.

The emergency stop function is constructed as a Category 3, PL d.

Speed monitoring of the movement of the X –axis and the Print head (optional)

The speed monitoring of the movement of the X –axis and the print head is a safety function, with the purpose of

preventing them going faster than 250 mm/sec. If the limit is exceeded, the machine is stopped.

The speed monitoring is optional and comes together with the perimeter guarding which also is optional.

If the application requires a speed higher than 250 mm/sec. for the X-axis and print head, the perimeter guarding

together with an interlocked door must be installed. When entering the guarded zone, opening the interlocked

door, the speed of the X-axis and the print head is automatically reduced to 250mm/sec and is then monitored by

the speed monitoring as long as the door to the guarded zone is open. As soon as the door is closed the speed is

automatically increased. See also Interlocked door.

Instruction Manual - Original Version

Page 16 of 50

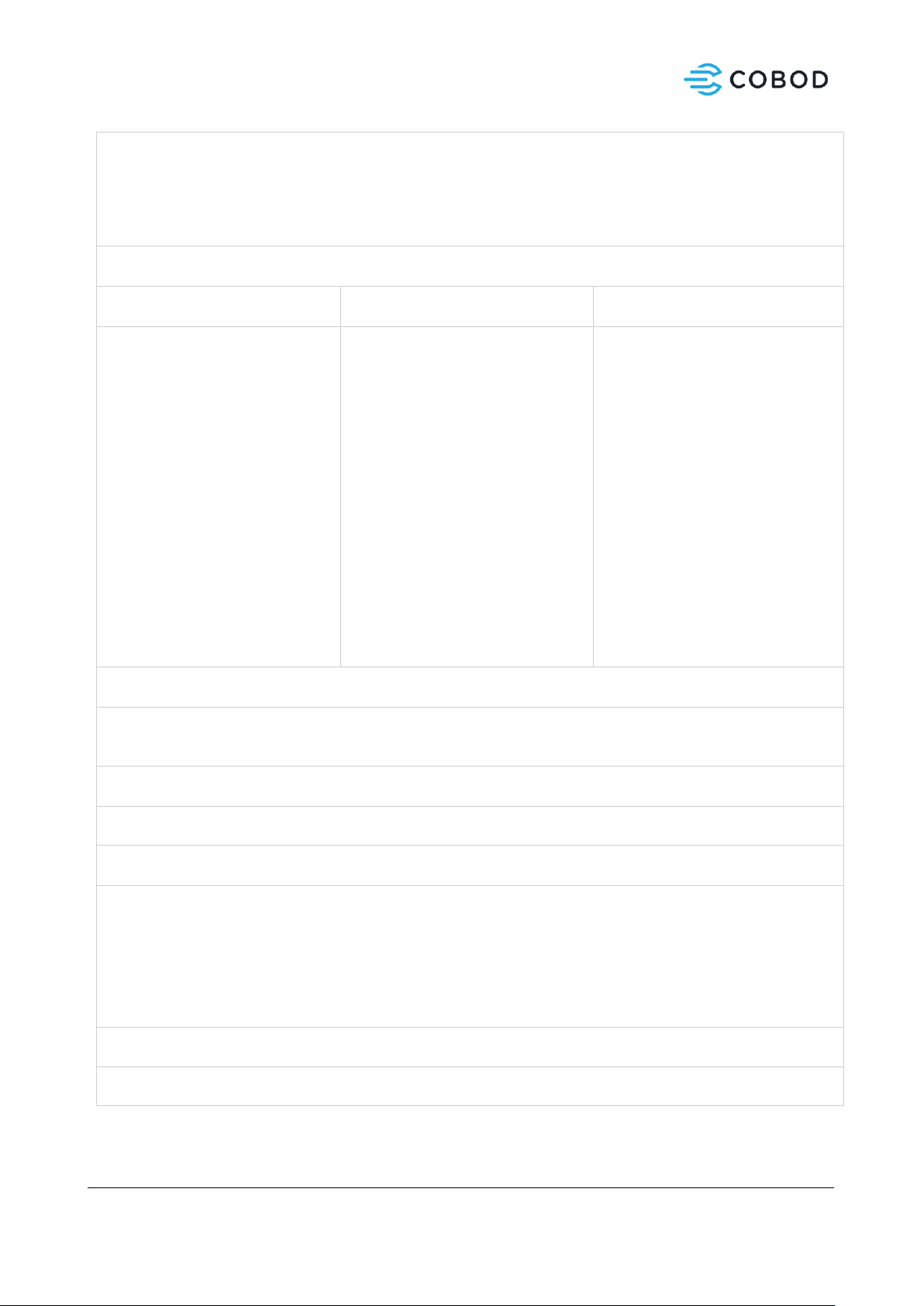

Components included in the safety function.

Input part

Logical part

Output part

Encoder.

If the speed limit of 250mm/sec is

exceeded by the X-axis or the print

head, the machinery is stopped.

The encoders are located at/on the

drive for the X-axis and on the drive

for the Print head.

Safety controller.

Intelligent controller monitoring the

safety function.

The service life of the safety

controller is 20 years.

The safety function i.e. the machine

must not be used beyond 20 years.

The use beyond 20 years is

conditional to the fact that the

relevant components are replaced by

new components of identical or

improved properties than the

original ones.

The safety controllers are located in

the control cabinets.

Servo drives.

Disconnects the power supply to the

moving parts.

-Y-axis (Up-, Down wards);

-X-axis (For-, Back- wards);

-Print head (Sidewards);

-Mixer in the print head.

-Rotation of the print head.

The service life of the servo drives is

20 years.

The servo drives are located in the

control cabinet.

Displays and alarms

When the door is open, the status will appear on the operator monitor:

”Door open, running with reduced speed”

Operating conditions

Works:

-only together with perimeter guarding and interlocked door;

-in automatic and manual mode when interlocked door is open.

Maintenance and test

The encoders must be tested before commissioning, after each installation or reinstallation of the machine.

Test by opening the door, speed must be reduced to 250 mm/sec. When door is closed, speed is increased.

As a minimum, the encoders function must be visually checked and activated at least every 6 months.

Also see section 7 of this instruction manual.

The safety function complies with EN ISO 13849-1:2015.

The speed monitoring function is constructed as a Category 3, PL d.

Interlocked door, perimeter guarding (optional, speed > 250mm/sec.)

This safety function is to protect the operator against the hazardous fast moving parts (Speed > 250mm/sec), the

X-axis and the movement of the print head.

The perimeter guarding is optional and comes together with the speed monitoring, which also is optional.

Instruction Manual - Original Version

Page 17 of 50

If the application requires a speed higher than 250 mm/sec. for the X-axis and print head, the perimeter guarding

together with an interlocked door must be installed. When entering the guarded zone, opening the interlocked

door, the speed of the X-axis and the Print head is automatically reduced to 250mm/sec and is then monitored by

the speed monitoring as long as the door to the guarded zone is open. As soon as the door is closed the speed is

automatically increased.

Components included in the safety function

Input part

Logical part

Output part

Interlock.

The Interlock is an electrical safety

device.

The safety device may be coded to

prevent bypassing.

The safety device is installed on the

doors to the guarded zone:

Safety controller.

Intelligent controller monitoring the

safety function.

The service life of the safety

controller is 20 years.

The safety function i.e. the machine

must not be used beyond 20 years.

The use beyond 20 years is

conditional to the fact that the

relevant components are replaced by

new components of identical or

improved properties than the

original ones.

The safety controllers are located in

the control cabinets.

Servo drives.

Reduces the speed on the following

moving parts.

-X-axis (For-, Backwards);

-Print head (Sidewards);

The service life of the servo drives is

20 years.

The servo drives are located in the

control cabinet.

Displays and alarms

When the door is open, the status will appear on the operator monitor:

”Door open, running with reduced speed”

Operating conditions

The safety function operates unchanged in any operating conditions of the machine.

Maintenance and test

The safety function must be activated and tested before commissioning after each installation or reinstallation of

the machine.

Test by opening the door, speed must be reduced to 250 mm/sec. When door is closed, speed is increased again.

As a minimum, the safety function must be visually checked and activated at least once a day.

Also see section 7 of this instruction manual.

The safety function complies with EN ISO 13849-1:2015.

The speed monitoring function is constructed as a Category 3, PL d.

Instruction Manual - Original Version

Page 18 of 50

4Definitions

4.1 Technical terms and abbreviations

In the following, the technical terms and abbreviations used in this instruction manual are described.

Terms

Explanation

Instructed person

A person having received the necessary training to carry out a task in a safe and

responsible way

3DCP

3D Concrete Printing

Print head

The device that attached on the carriage, handles extrusion and depositioning of

material

Nozzle

The small piece that sits on the end of the print head, that shapes the final form of

the extruded material. Can be 3D printed or machined.

Origo

The starting position of the printer, defined as [X,Y,Z,E,U] = [0,0,0,0,0]

4.2 References

1. Mixing/pumping equipment M-tec duo mixer. https://m-tec.com

2. Hilti HIT-Z anchors

https://www.hilti.dk/medias/sys_master/documents/h1c/h4b/9330166333470/Instruction-for-

use-HIT-RE-500-V3-Instruction-for-use-PUB-5307431-000.pdf

3. G-code documentation https://duet3d.dozuki.com/Wiki/G-code

4. Duet3D documentation, firmware updates, maintenance, etc. - https://duet3d.dozuki.com/

Instruction Manual - Original Version

Page 19 of 50

5Handling

This section describes how the machine is to be operated in various situations. Where specific personal

qualifications are required, this will be described.

Installation and dismounting of the machine must be carried out by qualified and trained personnel. To

prevent accidents, all safety instructions must be observed.

5.1 Transport and storage

The machine is built of components from various suppliers. Some of these parts are of a size, shape and

weight that require special handling. Follow the instruction manual from the manufacturer or supplier on

how to apply lifting equipment and the appropriate lifting points.

Only instructed and certified personnel have the permission to move machine parts using a

fork lift truck or crane.

Only appropriate and certified equipment must be used for the lifting of machine parts.

5.2 Unpacking

When unpacking the machine, it is to be controlled if damage to the machine has occurred during

transport. Damage affecting the functionality or safety of the machine must be repaired before the

machine is put into operation.

5.3 Safe disposal of packing material

Packing material consists of:

-120x120x1500mm wooden joists

-EU Pallets (120x80 cm)

Both are reusable items and should not be disposed of, unless damaged. If damaged or unusable, dispose

as wooden waste according to local law.

5.4 Installation and assembly of the machine

5.4.1 Mechanical assembly

Instruction Manual - Original Version

Page 20 of 50

To ensure the safe intended use of the printer, it needs to be installed and assembled according to the

following instructions.

Steps for installation:

1. Mapping and Anchoring

4. Mounting X-Axis

2. Mounting Z-Axes

5. Connecting cables

3. Mounting Y-Axes

5.4.1.1 Mapping and Anchoring

This section covers installation of Anchors, serving as a base for securing Z axes to the ground plane. The

procedure involves precisely mapping and marking where the anchors will be placed, drilling holes and

securing anchors with glue. Protective gear (gloves/mask/safety glasses) is required for drilling and while

handling Hilti glue.

Tools needed

•16 x Hilti HIT-Z anchors

M16x240

•1 x Laser measuring

device

•1 x Angular laser

•1 x Marker Pen

•1 x Hammer Drill

•1 x M8 Concrete drill bit

•1 x M18 Concrete drill bit

•1 x 3D printed drill guide

Table of contents