Tinkerine Studio DittoPro-R Parts list manual

Setup & Operations Manual

Version 1.0

Welcome

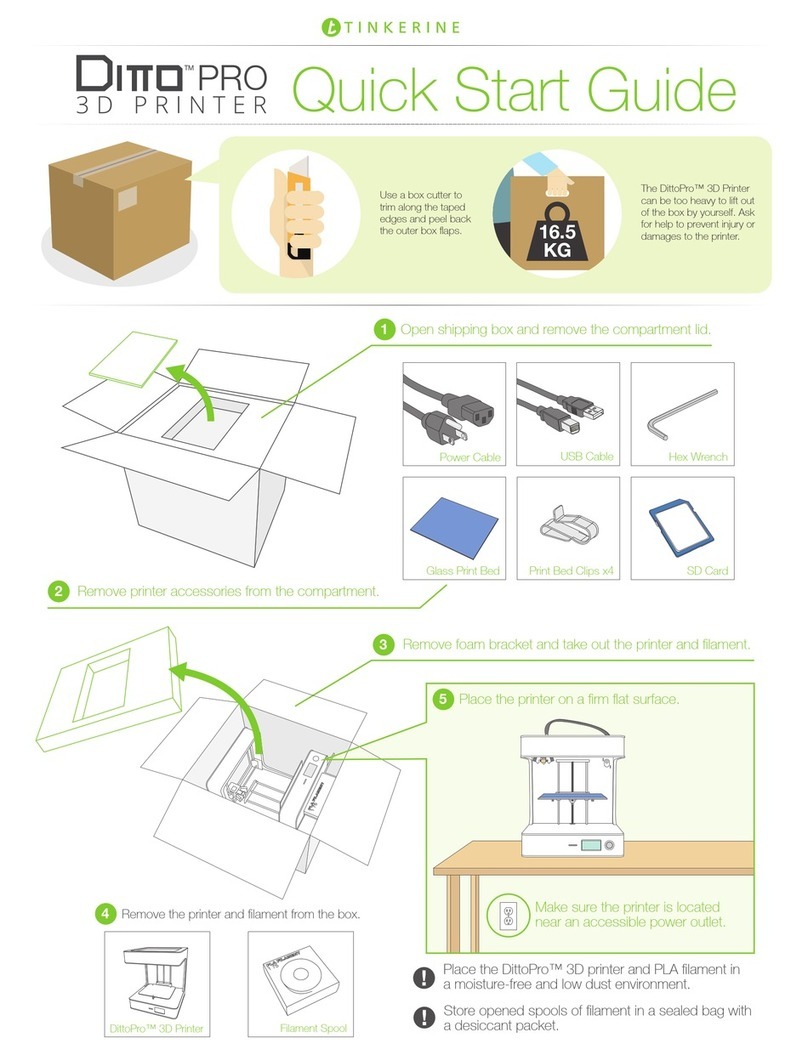

Congratulations on receiving your DittoPro-R 3D Printer! This guide is designed to walk you through the unboxing

and setup process so you can start printing your 3D creations.

Got space? Save the

shipping box and

foam brackets for

printer storage and

shipping.

The DittoPro-R 3D Printer

can be too heavy to lift out

of the box by yourself. Ask

for help to prevent injury or

damage to the printer.

16

KG

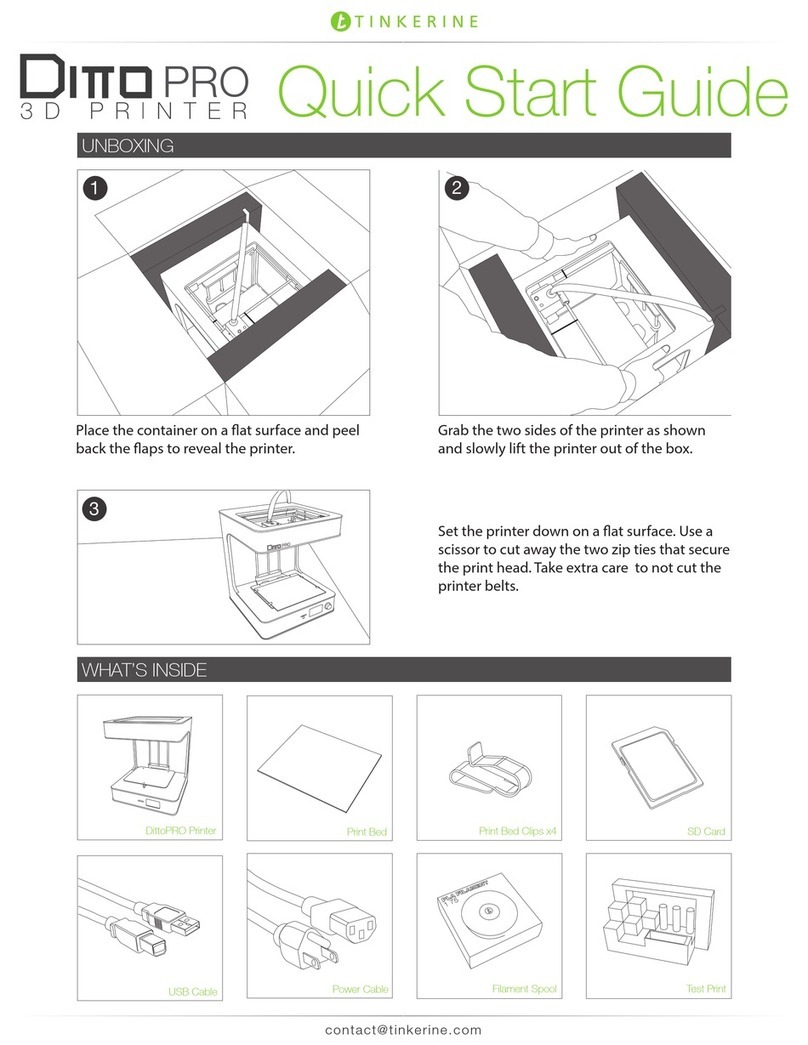

Unboxing 1

Step 1

Removing the Accessory Box

The accessory box is slotted into the top foam compartment

of the printer’s packaging. Remove the accessory box and

check to see that you have all of the following accessories.

Product Warranty Registration

Visit the online printer registration page

and follow the instructions to activate

your product warranty.

Locating the Product Serial Number

You can find your product serial number

located on the bottom panel in the back

of the printer. Your printer’s serial number

is required for warranty registration.

warranty-registration.tinkerine.com

Glass Print Surface

USB Cable

Power Cable USB Flash Drive

Unboxing

Hex Wrench Inspection Certificate Test Print

REV#

2

3

Airflow

Allow passive airflow around the DittoPro-R 3D Printer.

Avoid obstructing the cooling fan intake located at the

bottom of the DittoPro-R 3D Printer.

Stability

Place the DittoPro-R 3D Printer on a flat and firm surface.

Excessive vibrations or shaking will affect print quality.

High Temperature

The printer’s nozzle can reach upwards of 200°C during

operation. Children and pets should be kept clear of

moving parts during the printing process.

Power

Ensure the printer is placed near an accessible power

outlet. Avoid plugging the printer into an overloaded

power bar as electrical shorts may cause the printer to

reboot during printing.

Unboxing

For long term storage, cover your printer to prevent

dust from accumulating on motion components.

Step 2

Removing the Shipping Bracket and Filament

Remove the top foam shipping bracket and take out the 3D

printing filament located at the side of the box. Remove the

DittoPro-R 3D Printer and place it upright on a firm flat surface.

Unboxing

Step 4

Turning on the Printer

Insert the female end of the power cord into the socket located on the back panel of the printer and the male end into the power socket. Turn on

the printer by flipping the power switch to the On position ( I ).

Store the removed clips and reuse when transporting the printer for shipping.

2x

Top View

Step 3

Removing the Gantry Clips

Located near the top of the DittoPro-R 3D Printer are two plastic gantry clips that prevent the extruder from moving freely during shipping. You

can remove the two gantry clips securing the extruder by pushing down the tabs on each end of the clips.

4

Loading the Filament

Step 5

Loading the Filament

Remove the spool of filament from the packaging and place it on the spool holder. Take the end of the filament from the spool and insert it into

the guide tube. Make sure the filament spool spins clockwise as the filament feeds into the guide tube.

Have a frim grip on the loose end of the filament when installing or

removing the spool from the printer. Letting go of the loose end before it is

secured may cause it to coil back and become tangled. These tangles are not

easily spotted, and may cause problems during printing.

For long term storage, retract and remove the filament from the printer. PLA

filament can become brittle over time as it is exposed to UV and moisture.

Store opened spools of filament inside the original packaging or in a sealed

bag with a desiccant packet.

The use of third-party filament voids the warranty on your DittoPro-R 3D Printer.

Spool Holder

Guide Tube

Removing

When removing filament, thread the loose end

through the storage holes on the spool.

Loading

When installing filament, thread the loose end through

the filament guide tube.

5

Loading the Filament

Step 6

Loading the Filament (Cont.)

Thread the filament through the guide tube (1). Push the tensioner button (2) down to make it easier to thread the filament through the drive

gear and into the hotend (3). Once the filament is inserted all the way down into the hotend, insert the guide tube into the top of the extruder

cap.

6

1

2

3

Trim off the tip of the filament with a pair of scissors if you are having trouble feeding the filament into the hotend.

Installing the Glass Print Surface

Step 7

Installing the Glass Print Surface

Slide the glass print surface onto the bed with the blue painter’s tape side facing upward. The taped surface will act as an adhesion material for

the PLA plastic. At an angle, slide the glass print surface into the two rear corners of the bed. While gently pushing it against the rear corners,

clip the print surface into the two front corners as illustrated below.

7

Replace any worn or damaged blue painter’s tape as needed to ensure that your prints stick properly during the printing process.

When replacing worn print surface tape, avoid overlapping strips of tape. The overlaps create an uneven print surface, which can

result in poor print adhesion.

1 1

2

First Time Setup

Step 8

First Time Setup

Upon powering up your DittoPro-R for the first time, you’ll be prompted to perform a one-time setup for your printer. The setup process will

guide you through the steps of naming your printer and connecting it to a wireless network.

Touch the on-screen button to proceed or select Skip

the setup to perform the setup at a later time.

Use the on-screen keyboard to type and assign a

identification name for your printer. Press OK to

proceed.

8

To transfer files for wireless printing, you’ll need to

connect the printer to a wireless network. Select the

network you wish to connect to and enter the password

on the following screen. Press Skip to setup wireless

connection at a later time.

Setup complete! Click OK to process to the Home

screen.

Print Surface Levelling

Step 9

Print Surface Levelling

You’ll need to perform a print surface calibration for your printer to ensure the print surface is perfectly levelled in relation to the print nozzle.

Doing so allows the molten plastic to evenly adhere onto the print surface during printing. It is recommended that you perform the calibration

process every time the printer has been transported to a new location.

9

Press Start to initiate the the print surface levelling

wizard.

From the Home Menu, select Surface Levelling to

access the calibration wizard.

Once pre-heating is complete, follow the

on-screen instructions to level the print surface.

Once the calibration is complete, press Back to Home

to return to the Home Menu or Start a Print to select a

file for printing.

Tall Vase

Starting a Print

Step 10

Starting a Print

Follw the instructions below to begin your 3D print! Before you proceed, make sure you’ve installed the filament and performed the print surface

calibration.

10

Select a file to print from the list. Use the Copy button

(1) to copy the file from the USB drive into the printer’s

on-board storage.

Select Print from the Home Menu to access the

printing menu. From here, you can select a file stored

on the printer or on a connected USB drive.

Once you have selected a file, the estimated print time

and filament usage will be displayed. Press the >button

(2) to see more detailed file information. Press Start

Print to start the print.

On the secondary file information page, detailed export

settings (resolution, infill, wall, support) are displayed.

The settings are for reference purposes and can not be

modified directly from the printer.

1

2

11

Print Adhesion

Important!

Ensuring Proper Print Adhesion

Whenever you begin a print, always check that the first layer of the print is properly stuck onto the blue painter’s tape. A properly levelled print

surface should have the extruded filament a bit squished. While the printer is printing the skirt (outer perimeter), observe the deposited filament

and make micro-adjustments with the thumbscrew if necessary.

Signs of nozzle too close to print surface:

(A) Inconsistent width along extrusion.

(B) Portion of the layer appear thin or

non-existent.

(C) Squshed filament causes areas to

overfill.

Signs of nozzle levelled to print surface:

(A) Consistent width along extrusion.

(B) Thickness appears consistent across

entire layer.

(C) Infill is even and joins up neatly with

the perimeter.

Signs of nozzle too far to print surface:

(A) Filament appear stringy and doesn’t

adhere to print surface.

(B) Infill doesn’t meet up with perimeter.

(C) Infill line doesn’t stick to other infill

lines.

TOO CLOSE TOO FARLEVELLED

Not sure if the bed calibration was done correctly?

Watch our online bed-leveling tutorial video by

scanning in the QR code on your phone or visiting

this link: https://youtu.be/GpMtpL-FfDM

12

Final Step

Print Removal

When your print is completed, it’s time to remove it from the print surface. While smaller prints can sometimes be easily removed by hand, we

recommend you to use a Print Removal Knife for removing prints.

After your print has completed, remove the glass print surface from

the printer and place down on a flat surface.

Using the Print Removal Knife, slowly wedge the knife between the

print and taped surface and lift upward. Repeat the process around

the print until you can easily pop the print off the print surface.

Print Removal

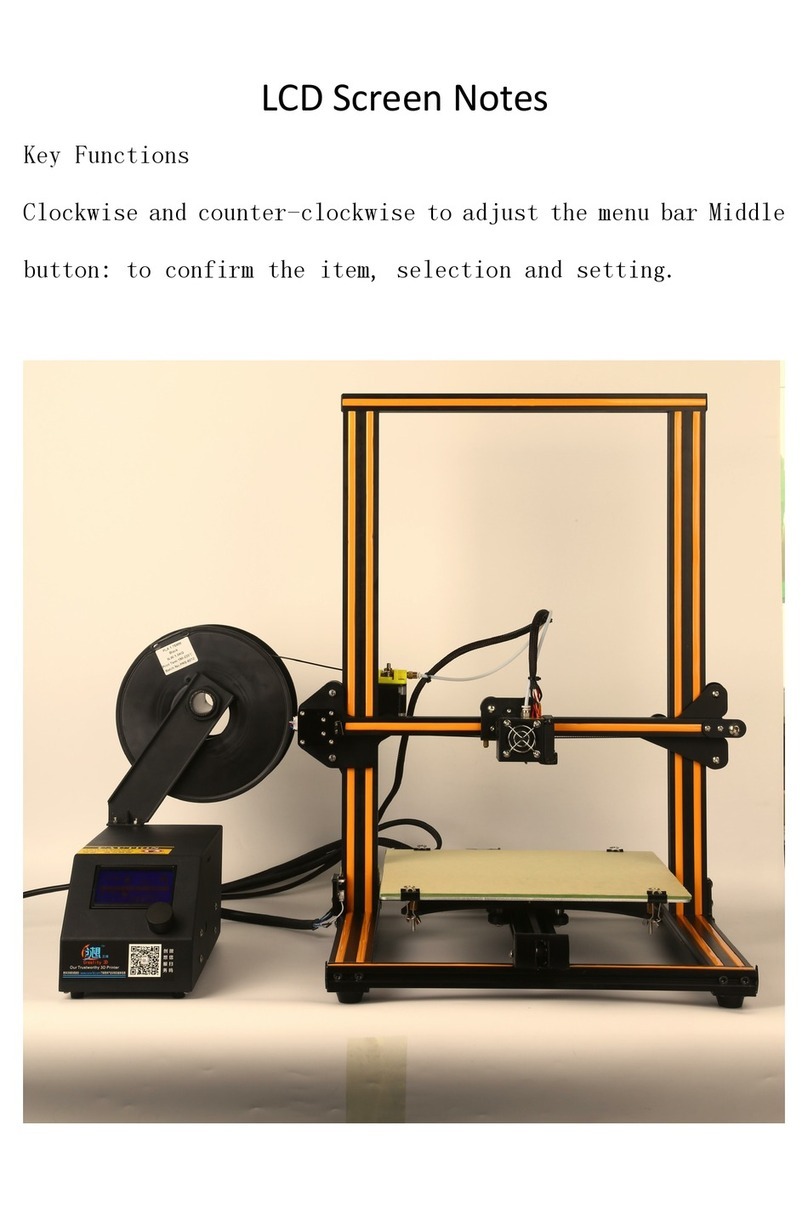

LCD Menu Settings

Additional LCD Menu Settings

Home Menu

Print - Select a file for printing.

Filament - Load/remove filament wizard.

Surface Levelling - Print surface calibration wizard.

Settings - Settings menu.

Filament Menu

Accessed from the Home Menu, the Load/Remove Filament wizards will

guide users with loading and unloading filament from the printer.

Load Filament - Assists the users with loading the filament into the printer.

Remove Filament - Assists the users in removing the filament from the

printer.

13

LCD Menu Settings

Additional LCD Menu Settings

Print Status Menu

Default screen shown when printing is in progress.

1. File Name

2. Estimated remaining print time shown in (Hours : Minutes)

3. Print progress (0-100%)

4. Elapsed print time shown in (Hours : Minutes)

5. Show Print control menu

6. Hide Print control menu

Print Control Menu

Control menu shown when printing is in progress.

Pause/Resume - Pause or resume the current print.

Change Filament - Change the filament mid-print.

Stop - Cancel the current print.

Completion Control Menu

Control menu shown when printing is complete.

Print Again - Print the same file again.

Print Other - Select a new file for printing.

Back to Home - Return to the Home Menu.

14

2

1

3 4

5

6

LCD Menu Settings

Additional LCD Menu Settings

Settings

The Settings menu contains different printer functions.

Printer Name - Set or rename printer’s identification name.

Network - Wireless connection setup.

Storage - View and manage on-board storage space.

Sleep - Change printer sleep timer.

About Printer - Printer information and statistics.

Firmware - Print firmware information and update.

Debug - Debug menu for printer testing and service.

Contact - Tinkerine Tech Support contact information.

15

Printer Specifications

Printer Specifications

PHYSICALS

Dimensions 37 x 49 x 43.6 cm (14.6 x 15.4 x 17.2 in)

Weight 10 kg (22 lb)

PRINTING

Build Volume 21.5 x 16 x 22 cm (8.4 x 6.3 x 8.7 in)

Filament Ø 1.75mm

Layer Resolution 50-300 microns (0.05-0.3 mm)

Material PLA Filament

Nozzle Ø 0.35mm

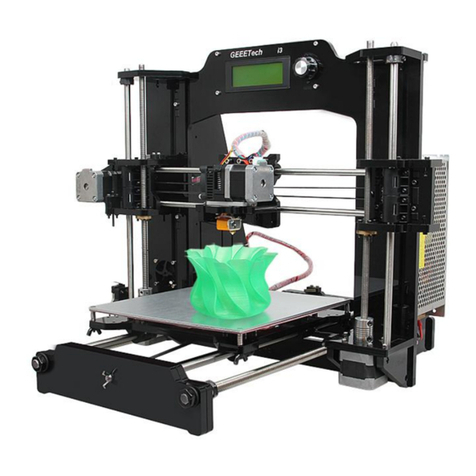

Technology Fused Filament Fabrication (FFF)

SOFTWARE

File Type STL, OBJ

OS Compatibility Windows, Mac

Software Tinkerine Suite

MECHANICAL

Body Aluminum Composite

Print Surface Glass (Adhesive material required)

Linear Motion Linear bearings, bronze bushings

Motor 1.8° step angle, 1/16 micro-stepping

ELECTRICAL

Connectivity USB, Wifi

Consumption ~7W (sleep), ~17W (idle), ~72W (operational)

Electronics RAMPS 1.4, AT mega 2560, A4988 stepper driver,

DRV8825 stepper driver, BCM2837 micro-processor

Power Input AC 110-220V, 50-60 Hz

Power Output DC 12V, 15A

CERTIFICATION

cULus Passed

16

Notes 17

Email:

Phone:

1-604-288-8778 (Vancouver, BC)

1-844-846-5377 (International)

Questions?

18

Table of contents

Other Tinkerine Studio 3D Printer manuals

Tinkerine Studio

Tinkerine Studio Ditto Pro Parts list manual

Tinkerine Studio

Tinkerine Studio LITTO User manual

Tinkerine Studio

Tinkerine Studio Ditto Pro User manual

Tinkerine Studio

Tinkerine Studio Ditto User manual

Tinkerine Studio

Tinkerine Studio Ditto Pro User manual

Tinkerine Studio

Tinkerine Studio Ditto Pro User manual

Tinkerine Studio

Tinkerine Studio Ditto Pro User manual