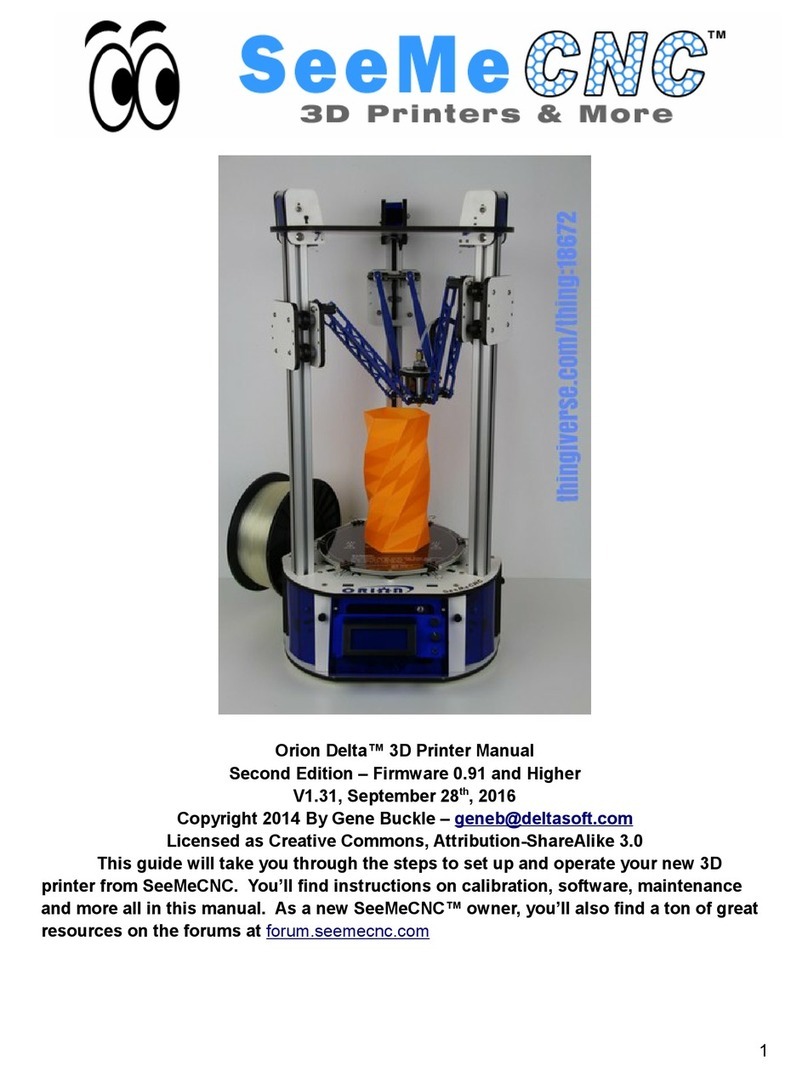

SeeMeCNC ERIS DELTA User manual

Eris® Delta 3D Printer Manual

First Edition

v1.10 – January 27th, 2017

MatterControl v1.

Copyright 2016 By Gene Buckle – [email protected]

Licensed as Creative Commons, Attribution-ShareAlike 3.0

Disclaimer text provided by LulzBot.

Official support is available through support@seemecnc.com

As a new SeeMeCNC printer owner, you’ll also find a ton of great resources on

the forums at forum . seemecnc . com

1

READ ME FIRST!

READ THIS MANUAL COMPLETELY BEFORE UNPACKING AND POWERING UP YOUR

PRINTER!

Hazards and Warnings

The SeeMeCNC Eris® Delta 3D rinter has motorized and heated arts. When the rinter is in

o eration always be aware of ossible hazards.

Electric Shock Hazard

Never o en the electronics bay of the rinter while the rinter is owered on. Before removing

the access door, always ower down the rinter and un lug the AC line cord.

Burn Hazard

Never touch the extruder nozzle or heater block without first turning off the hot end and allowing

it to com letely cool down. The hot end can take u to twenty minutes to com letely cool.

Also, never touch recently extruded lastic. The lastic can stick to your skin and cause burns.

Also before of the heated bed which can reach high tem eratures ca able of causing burns.

Fire Hazard

Never lace flammable materials or liquids on or near the rinter when owered on or in

o eration. Liquid acetone and va ors are extremely flammable.

Pinch Hazard

When the rinter is in o eration, take care to never ut your fingers in the moving arts,

including the belts, ulleys or gears. Also, tie back long hair or clothing that can get caught in

the moving arts of the rinter.

Static Charge

Make sure to ground yourself before touching the rinter, es ecially the electronics.

Electrostatic charges can damage electronic com onents. To ground yourself, touch a

grounded source.

Age Warning

For users under the age of 18, adult su ervision is recommended. Beware of choking hazards

around small children.

2

Table of Contents

1 – Unboxing your new Eris® Delta 3D Printer............................................................................4

2 – Installing MatterControl..........................................................................................................5

3 – Calibrating the Eris®............................................................................................................10

4 – Loading and Unloading Filament..........................................................................................12

5 – First Print!............................................................................................................................ 14

6 – MatterControl Basics: Slicing...............................................................................................15

7 – MatterControl Basics: Loading & Printing an Object.............................................................29

8 – Advanced MatterControl: O tions........................................................................................33

9 – Advanced MatterControl: Settings – Print............................................................................37

10 – Advanced MatterControl: Settings – Filament....................................................................47

11 – Advanced MatterControl: Settings – Printer.......................................................................50

12 – Using the 3D View and Layer View....................................................................................54

13 – A Strategy for Successful (and Great!) Prints.....................................................................62

3

1 – Unboxing your new Eris® Delta 3D Printer

If you're one of the rare eo le that downloaded the manual BEFORE o ening your new

Eris®, SeeMeCNC has a treat for you!

We've roduced a short little video that shows how to un ack your new Eris® as well as

how to load filament for the firs time!

Eris® Unboxing and Setu Video

4

2 – Installing MatterControl

MatterControl is the control rogram that you'll be using with your new Eris® rinter.

MatterControl is known as a combination host and “slicer”. It's “host” feature allow you to

control the Eris® directly – moving the axes, heating the hot end, etc. The “slicer” feature is

what converts a 3D model into a form suitable for rinting. We'll cover that shortly.

You can download MatterControl by going to the SeeMeCNC website –

htt ://seemecnc.com/ ages/downloads. Scroll down to the “Software” heading and you'll see

the links for MatterControl. Download the version for your latform and install it.

Note that the MacOS version is functionally identical to the Windows version, so I'll only

be showing exam les from Windows – the same rocedures should a ly to both versions.

You'll also want to download the Eris® Default Files from the Eris® age on the

SeeMeCNC website: htt s://www.seemecnc.com/collections/3d- rinters/ roducts/eris-deskto -

3d- rinter. Look for the link marked “DOWNLOAD ERIS SETTINGS HERE”. Un ack the files

so they're ready to use when you need them.

Start MatterControl. Below you'll see what the basic MatterControl interface looks like.

5

Your first ste will be to configure MatterControl to use the Eris®. Sim ly click the “Add

Printer” button that's located at the to of the left MatterControl ane.

When you click on the Add Printer button,

you'll be resented with the dialog you see to the

right. Click in the Printer Name field and enter the

name of your new rinter. Next, click the Select

Model button and ick “Eris”.

Click the Save & Continue button to

move on to the next ste .

Next, you'll be resented with the o tion to install

the communication driver that MatterControl needs to talk

to the Eris®. If you've used a RAMBo or Mini-RAMBo

based 3D rinter on your com uter before, you can ski

this ste . Otherwise, click the Install Driver button to

have MatterControl install the driver for you.

MatterControl will run a driver installer that will

likely ask you for ermission to continue. Please grant it

and a dialog similar to the one below will a ear. Click

on the Install button to allow the driver to install.

6

Once the installer finishes, MatterControl will

attem t to automatically configure the connection.

Please disconnect the Eris® and click the Continue

button.

Once you click on Connect, the following

dialog should a ear:

Congrats! You're all done. Click on the

Done button to continue.

7

The configuration rocess automatically loads a test object that you can rint. Let's take

a few minutes to go over the various features of the MatterControl interface.

The MatterControl interface

is s lit into two halves. The left

half is where you can load objects

or G-code to rint, start rints, and

manually control the rinter.

1. This is the rint queue dis lay.

If nothing is queued u , you'll see

the message, “No items in the rint

queue”. To add an item, click the

“Add” button (#13). We'll cover

this in detail later. Note that you

can only select STL or GCODE

files.

2. This is the tem erature dis lay.

The figure dis layed shows the

current nozzle tem erature. If you

ever install a heated bed on your

Eris®, a second box will a ear

that will show the bed

tem erature. Both values are

shown in degrees Celsius.

3. Queue Count. This shows the

number of objects currently in the

rint queue.

4. Library – This is a list of items that you've stored in your object “library”. We'll cover this one

in detail later.

5. Print History. This will show you what you've rinted in the ast along with statistics about

each rint.

6. Settings & Controls – this is where you can edit your slicer & rinter settings as well as

manually control your Eris®

7. The Edit button will allow you to choose which items in the rint queue will be available for

rinting.

8. The Export button will allow you to ex ort the currently select item as an STL, AMF, or

GCODE file. You can use this to save GCODE if you want to share your sliced object with

another Eris® user.

9. The Copy button will make co ies of the currently selected item in the rint queue.

10. The Remove button will remove the currently selected item in the rint queue.

8

11. The More dro -down will allow you to send the currently selected item to another device, or

to the rint Library.

12. Items currently in your Queue.

13. The Add button will allow you to add objects or G-code files to the rint queue.

14. The Create button dis lays a list of available lug-ins that are used to create rintable

objects right inside of MatterControl.

15. The Buy Materials button will o en your web browser and oint it to the SeeMeCNC store.

16. The Queue button o ens a menu list that will allow you to ex ort the current file and erform

other o erations on the rint queue.

The right half of the MatterControl interface is taken u by a 3D view of your build

latform and what objects are currently loaded and ready to rint.

1. The 3D and Layer view controls allow you to switch between the 3D view (shown) and the

Layer view. The layer view shows

you the ath the rint head will

take as your art is rinted. The

layer view won't dis lay anything

until the art you want to rint has

been “sliced”.

2. View mani ulation controls –

Rotate, Pan, and Zoom. By

default, the 3D view will show a

rotating dis lay of the art. You

can sto the rotation by clicking

anywhere in the 3D view window.

3. The object currently ready to

rint.

4. This is a re resentation of the

rint bed on your Eris®. As long

as your object fits within the

circle, you can rint it!

5 & 6 The Insert and Edit buttons allow you to add and mani ulate multi le objects to the

current rint job. We'll cover this in de th later as well.

7. The Export button allows you to save the current state of the build late in a few different file

formats.

9

3 – Calibrating the Eris®

Before you can start using your new Eris®, we'll need to calibrate it first. This is really

easy to do!

Click on the Settings & Controls button and then click on the Options button.

Once you're on the Options age, click on the Show Terminal button to o en u

the serial console.

Before you roceed to the next ste , make sure that the nozzle on the hot end is free

from any filament or other debris. A clean nozzle will ensure a clean “hit” as the calibration

routine robes the bed surface. You also want to make sure that you've got the hot end cold –

the calibration rocess will not work reliably if the hot end heater is active.

Click in the in ut field

as shown and enter G29

and ress the enter key.

This will run the calibration

rocess on your Eris®!

This robing rocess

works out a few basic

arameters about your

Eris® and is considered a

“basic” calibration.

10

In order to obtain the best calibration ossible for your Eris®, you should also use the

online calibration wizard that SeeMeCNC has created. This tool is very easy to use and

includes very detailed instructions on how to use it!

The calibration wizard can be found here:

htt s://www.seemecnc.com/ ages/delta-calibration-wizard

11

4 – Loading and Unloading Filament

Loading new filament into your Eris® is a very straightforward task. First, you'll need to

feed new filament into the filament guide tube on the Eris® as shown below:

O en the filament tensioner by

com ressing it between your thumb and

forefinger, then feed the filament into the

EZStruder.

Feed only enough filament to exit about 1”

ast the PTC fitting on the outfeed side of the

EZStruder as shown below.

12

Into the guide tube...

...to the EZStruder...

Compressing the filament tensioner.

1" feed through.

In MatterControl, click the LOAD FILAMENT item in the queue to make it the active job

and click Print.

The Eris® will begin to heat

the hot end u to o erating

tem erature and it will then finish

feeding filament in and rime the hot

end.

You can tell the Eris® hot end is active by looking for the red LED on the effector PCB as

shown below.

Unloading filament is just as easy – go to the queue and choose the Unload Filament

item and hit Print! The Eris® will bring the hot end u to o erating tem erature and then ra idly

back the filament out of the system.

13

– First Print!

Since MatterHackers was kind enough to su ly us with a small calibration cube, let's

make that the first rint!

Before your first rint, make sure that the build surface is clean and free from finger

rints. The oils in your fingers can cause rints to not stick sometimes. The easiest way to

clean the Eris® build surface is with either soa & water (rinse well!) or with a small alcohol wi e

– these are erfect for getting finger marks cleaned off!

Because we've already loaded the Eris® defaults, all you'll need to do is click on the

object (Calibration – Box) and then click Print to being the rint job.

With the rint job started, you'll notice that the hot end tem erature is increasing and

there's a tiny u -arrow indicating that the hot end is active and is heating. When the set

tem erature is reached, the little arrow will go away.

The dis lay will also give you an estimate of the time it will take for the rint to finish.

Sometimes the estimate is a ball ark, sometimes it's a national ark.

Congratulations on the first rint from your new Eris®!

14

6 – MatterControl Basics: Slicing

MatterControl is a very com lete 3D rinting ackage and it's got a LOT of o tions.

Some eo le can find this intimidating, but I assure you – there's nothing to be worried about!

MatterControl is an integrated host a lication. This means that it rovides everything

needed to control the Eris® and to re are models for rinting. The task of re aring a model

for rinting is called “slicing”. It's a very descri tive term for what is actually ha ening. In order

to rint a 3D model, it needs to be converted from a solid object into a series of very thin layers

that are in turn converted into G-code (s ecial instructions that tell the rinter how to move). For

exam le, if your rint layer height is 0.2mm, the slicing tool is going to “slice” your model into a

number of layers – basically the model height divided by 0.2mm. For a tall art, this can mean a

LOT of layers!

MatterControl rovides three slicers for your use. MatterSlice, CuraEngine, and Slic3r.

This guide will only cover the s ecifics of MatterSlice, but don't let that sto you from

ex erimenting with and using the other slicers! I'll show you how to change the slicing engine

later on in this guide.

The final task of the slicer is to translate the sliced layers of model into something called

G-code. G-code is a sim le control language that's used to osition the rint head and tell the

extruder how much lastic to deliver and at what rate. Going into the details of G-code is

beyond the sco e of this guide, but if you'd like to learn more you can check out the following

resources: htt ://en.wiki idia.org/wiki/G-code and htt ://re ra .org/wiki/G-code.

For the most art, you'll never directly interact with G-code, but it's nice to know what's

going on behind the curtain!

15

I want you to click on the Settings & Controls button to bring u the Settings,

Controls, and Options ane.

Click on the SETTINGS link to make sure your dis lay follows (by and large) what you

see below.

The first thing I want you to do is click on the Show Help check box that's highlighted by

the arrow in the image above. This will turn on verbose descri tions of each one of the

arameters available in the Settings age.

I'm going to only cover the “Sim le” configuration settings for right now. There's a LOT

that goes on to configuring your slicer and the Sim le configuration setting allows many of those

to be hidden until you're more comfortable with how your rinter works.

Layer Height – This arameter tells the slicing engine how thin to make the layers when

it slices u the model as I described earlier. A good default layer height is 0.2 or 0.25mm. The

lowest ractical layer height with a 0.5mm nozzle is 0.1mm. You can go lower than that, but it

requires a smaller nozzle diameter. You can also got a lot thicker, but that requires a larger

nozzle. If you change the Quality from Standard to Coarse or Fine, you'll notice how the layer

height changes.

16

Here's what the Coarse, Standard, and Fine layer heights look like when rinting the

little test cube.

Starting from left to right, the layer heights are 0.1mm, 0.2mm and 0.3mm. You'll notice

that the to layer on the 0.1mm rint is kind of ratty and torn u . This is because the number of

to layers is set to 3. This is erfectly ok with thicker layer heights, but it should have been set

to at least 5 for the 0.1mm layer height that the Fine setting uses. You'll learn how to tweak that

in a little bit.

You can see how the smoothness of the sides decrease as the layer thickness

increases. If you want to rint something really quick, you could go u to a 0.35mm layer

height. I wouldn't recommend anything over 0.40mm if you're using a 0.5mm nozzle however.

Fill Density – This arameter controls how solid your rinted art is. The number is a

ercentage, from 0 (totally hollow) to 1 (totally solid). The default fill density (also known as

“infill”) is 0.2 or 20%. The image below shows what that looks like inside our little test cube.

You can tweak the infill to get a more

robust or a lighter art. For most rints, 20% is a

good infill value.

The Fill Density o tion also allows you to

choose one of three reset values. Light sets

the infill to 10%, Standard to 30%, and Heavy to

90%.

Later on I'll show you how to change to a

different infill attern. The one shown on the

right is the Triangle attern.

17

Support Material – Su ort material is used when the art you're rinting has free-

standing features (like the chin on a bust) or another feature that requires it to be hysically

su orted during the rinting rocess. When you check the Support Material box, the slicer

will automatically design su ort for the art that's currently (or will be) loaded.

Create Raft – A raft is essentially what it says, a “raft” of material that your art will rint

on to of. Rafts are most often used when rinting a art that is having bed adhesion roblems

due to its geometry. For exam le, if you're rinting a art that sits on small feet, a raft would

come in handy if the initial layers of the feet don't stick very well.

In the image below, you'll see an exam le of both su ort material and a raft.

I took the little test cube and through a little mani ulation, rinted it tilted at 30 degrees. I

took this o ortunity to also demonstrate what a raft looks like. This one is exaggerated in its

size, but gives a great exam le of what a ty ical raft will look like.

18

The image to the right should give you a

retty good idea of what the art looks like from the

side. You can easily see the su ort material as

well as the layer lines that will be at a 30 degree

angle when the little cube is laid flat.

Su ort material is generated in such a way

that there is just enough of it there to handle the

actual rint layer that it will be su orting. In my

exam le, the su ort material has a 2.5mm

s acing between the walls of su ort material and

it uses an infill angle of 45 degrees.

The rinted art will usually se arate from the su ort material fairly easily – however,

some material will be left behind if you're using a raft. Cleaning u the left over su ort material

is a sim le and straightforward task.

19

Here's what you end u with after removing the su ort material from your art. As you

can see, there's still a little clean u to to be done to the rinted cube (on the left). A quick hit

with some 220 grit sand a er will knock the rough edges of the su ort material down.

That's retty much all there is to the Simple settings level. Next, let's dig into the

Standard setting!

20

Table of contents

Other SeeMeCNC 3D Printer manuals

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC DropLit User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC Delta User manual

SeeMeCNC

SeeMeCNC Rostock Max v3 User manual

SeeMeCNC

SeeMeCNC Rostock Max User manual

SeeMeCNC

SeeMeCNC rostock max v2.0 User manual

SeeMeCNC

SeeMeCNC Rostock MAX v2 User manual

SeeMeCNC

SeeMeCNC orion delta User manual

SeeMeCNC

SeeMeCNC Artemis User manual