Ender 3 Neo User manual

V1.0

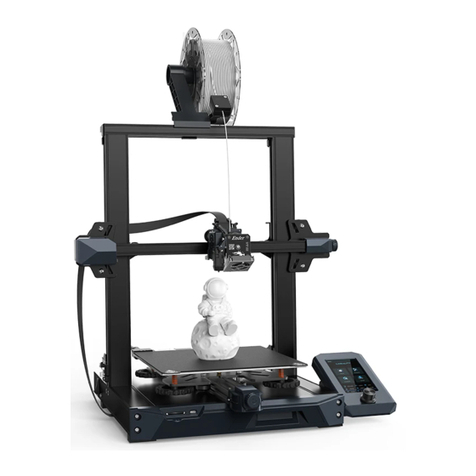

Ender-3 Neo

3D Printer User Manual

CREATE REALITY,ACHIEVE DREAMS

To Our Dear Users

Thank you for choosing Creality. To make using our products easier, please read this User Manual before you start andfollow the instructions provided carefully.

Creality is always ready to provide you with high-quality services. If you encounter any issues or have any questions whenusing our products, please use the

contact information at the end of this manual to contact us.

To further improve your user experience, you can find more about our devices via the following methods:

User manual: You can find instructions and videos in the TF card provided with the printer.

You can also visit our official website (https://www.creality.com) to find information regarding software, hardware,contact information, device instructions, device

warranty information, and more.

Firmware Upgrade

Please visit our official website https://www.creality.com/download, switch to your language, then select your printerand model. Download the required firmware

and install it to use it with your printer.

NOTES

1

3

5

6

7

8

9

10

12

11

Do not use the printer any way other than described here in order to avoid personal injury or property damage.

Do not expose the printer to violent vibration or any unstable environment, as this may cause poor print quality.

Do not place the printer near any heat source or flammable or explosive objects. We suggest placing it in a well-ventilated, low-dust environment.

Do not use any other power cable except the one supplied. Always use a grounded three-prong power outlet.

Do not wear gloves or loose clothing when operating the printer. Such cloths may become tangled in the printers moving parts leading to burns, possible bodily injury, or printer damage.

When cleaning debris from the printer hotend, always use the provided tools. Do not touch the nozzle directly when heated. This can cause personal injury.

Clean the printer frequently. Always turn the power off when cleaning, and wipe with a dry cloth to remove dust, adhered printing plastics or any other material off the frame,

guide rails, or wheels. Use glass cleaner or isopropyl alcohol to clean the print surface.

Children under 10 years old should not use the printer without supervision.

This machine is equipped with a security protection mechanism. Do not manually move the nozzle or printing platform mechanism manually while booting

up, otherwise the device will automatically power off for safety.

Users should comply with the laws and regulations of the corresponding countries and regions where the equipment is located (used), abide by professional ethics, pay attention to

safety obligations, and strictly prohibit the use of our products or equipment for any illegal purposes. Creality will not be responsible for any violators' legal liability under any circustance.

Before using experimental or exotic filaments, we suggest using standard filaments such as ABS or PLA to calibrate and test the machine.

Do not touch the nozzle, hotbed or motor while the printer is in operation, otherwise you may get burned.

2

4

About the Printer 01-01

Device Specifications 02-02

List of Parts 03-04

05-12

Installing the 3D Printer

13-13

On-screen information

17-18

Filament infill

19-20

Start Printing

14-14

Auxiliary leveling

Table of Contents

21-21

Circuit Wiring

15-16

Auto Leveling

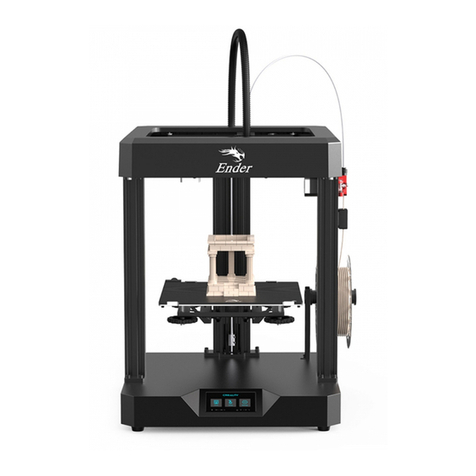

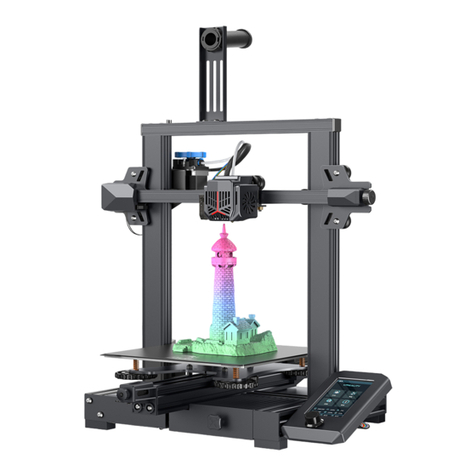

1. About the Printer

01

1

2

3

4

5

6

7

9

8

1X-axis limit switch

2CR-Touch

3Printing platform

4Storage card slot

5Y-axis tensioner

6Material rack and

material barrel

7Extrusion kit

8Nozzle kit

9X-axis tensione

10 Power switch and

socket

11 Screen

12 E-axis motor

10

11

13 X-axis motor

14 Z-axis motor

15 Y-axis motor

16 Power supply module

15

12

13

14

16

2. Equipment Parameters

02

Model

Modeling Dimensions

Modeling Technology

Number of Nozzles

Slice Thickness

Nozzle Diameter

Precision

Printing Material

Supported File Format

Printing Method

Supported Slicing Software

Rated Voltage

Rated Power

Nozzle Temperature

Power Loss Recovery

Auto Leveling

Language

PC Operating Systems

Printing Speed

Ender-3 Neo

TF card/USB on-line printing

FDM

1

220*220*250mm

0.1mm-0.4mm

≤120mm/s

STL/OBJ/AMF

PLA/ABS/PETG

≤100°C

≤260°C

Yes

100-120V~ 200-240V~ 50/60Hz

WIN/MAC/Linux

350W

General Specifications

±0.1mm

Creality Slicer/Cura/Repetier-Host/Simplify3D

Yes

中文/ English

0.4mm (standard)

Heated Bed Temperature

3. Parts List

03

Parts List

Screen

41

Nozzle kit

45

Material barrel

49

Z-axis profile (Left)

413

Z-axis passive

block

34

Z-axis motor

component

38

Z-axis profile

(Right)

312

T-type screw

rod

3

16

Power supply module

23

X-axis passive

block

27

2020 profile cover

2

11

X-axis profile

2

15

Base component

12

Extrusion kit

16

Material rack

110

114 Top gantry profile

Note: The components above are for reference only. The actual product shall prevail.

3Nozzle Cleaner

20

Nozzle

24

Filament

3

28

M5×45Hexagon Socket

Head Cap Screws

(with spring washers) ×4

3

32

TF Card and

Card Reader

17

power cable

4

21

Quick release claw

1

25

M5×8 Hexagon Socket

Button Head Screw×4

1

29

M5 T nuts×2

1

33

Wrench and

screwdrive

1

18

Blade

1

22

Cable tie

4

26

4

30 M4×20Hexagon Socket

Head Cap Screw×2

M4×18Flat Head Socket

Cap Screw×2

3

34

3. Parts List

Tool list

Cutting plier

2

19

Blue clip×2

2

23

X-axis timing belt

2

27

M4×16Hexagon Socket

Button Head Screw

(with spring washers)×4

2

31

M5×25Hexagon Socket

Head Cap Screws

(with spring washers)×4

2

35

04

Note: The components above are for reference only. The actual product shall prevail.

4. Install the Printer

4.1 Assemble Z-axis profiles

Make sure that the Z-axis profile is perpendicular to the profile of machine base and

flush with both left and right sides of the base profile, and tighten the four M5 x 45

screws from the bottom upwards.

4.2 Install screen and power supply components

1

29

4

30

Front

41

23

Fix the power supply behind the right profile of the Z-axis, pre-lock it first with two

M4 x 20 screws aligned with the holes and then tighten to secure it.

Secure the display fixing plate to the base assembly using two M5 x 8 screws.

A.

B.

05

413 312

3

32 3

32

12

4.Install the Printer

4.3 Install Z-axis motor component and T-type screw rod

4.4 Install the extrusion kit

Fix the extrusion kit to the left end of the X-axis profile

using two M4 x 16 screws.

2

15

2

31

16

06

Insert the T-rod onto the Z-axis motor assembly and tighten to secure.

Lock the Z-axis motor assembly to the profile using two M4 × 18 screws.

A.

B.

Back

3

16

3

34

4. Install the Printer

07

4.6 Install the nozzle kit

Slide the nozzle kit into the X-axis profile.

45

4.5 Install the X-axis timing belt

Thread the X-axis timing belt through the XE-axis assembly. (As shown in the diagram below)

*Snap the V-wheels into the

V-slot of the X-axis profile

2

27

4.7 Install Z-axis passive block

Fix the Z-axis passive block to the right end of the X-axis

profile using two M4 x 16 screws.

34

2

31

* just pre-tight the screws

4. Install the Printer

08

4.8 Install X-axis passive block

A. Snap the brass sleeve on the left side of the X-axis timing belt into the extruder back support plate.

B. Fix the X-axis passive block to the X-axis profile. (Be careful not to screw it down and make sure the X-axis passive block can slide along the X-axis profile.)

C. After winding the X-axis timing belt around the X-axis passive block, snap the brass sleeve at its right end into the extruder back support plate.

D. Push the X-axis passive block to the right to tension the X-axis timing belt to the same state as the Y-axis timing belt, then tighten the set screw on the

X-axis passive block.

StepA StepB

StepC StepD

Push to the right and

tighten the retaining

screws

27

27

4.Install the Printer

4.9 Install the X-axis kit and adjust tightness

Fit the X-axis kit into the Z-axis profile, with the V-wheels on the left and right sides aligned with the slot in the profile and the T-rod nut aligned with the

T-rod. (Note: The eccentric spacers on the left and right need to be adjusted if the left and right passive blocks cannot get in.)

4.10 Install the top gantry profile and profile cover

A. Secure the top gantry profile to the top end of the gantry with four M5 x 25

B.Attach the profile covers to the ends of the top gantry profile.

4.11 Install the material rack and barrel

09

*Do not tighten the screws

Left

A.Assemble the material rack and barrel.

B.Thread the two M5 x 8 screws through the material rack and then screw

on the M5 T-nuts. (Note that there is no need to screw it down)

C.Finally, fix those components to the top gantry profile.

Hexagonal eccentric

isolation column

C.

Tighten the two retaining screws on the Z axis passive block.

49

110

Back

1

33

1

29

35

211 11

35

35

211 11

35

1

14

*Tighten the two retaining screws

4.Install the Printer

4.12 Equipment Wiring

X,E,Z-axis motor port X-axis limit

switch

6pin (4 wires) 3pin (2 wires)

A1.Follow the yellow label on the 6pin (4 wires) port to connect the X-axis stepper motor;

A2.Follow the yellow label on the 6pin (4 wires) port to connect the E-axis stepper motor;

A3.Follow the yellow label on the 6pin (4 wires) port to connect the Z-axis stepper motor;

B. Follow the yellow label on the 3pin (2 wires) port to connect the X axis limit switch;

C. Connect the mainboard power cable;

D. Connect the display cable.

Caution

●

Please ensure the correct position for the power

supply switch and mains before supply connection

, in order to avoid damage to the device.

●

If the mains between 200V and 240V, please select

the 230V for the power supply switch(default is

230V).

●

If the mains between 100V and 120V, please select

the 115V for the power supply switch.

10

Mainboard

power cable Display cable

E-axis

Z-axis

X-axis

X-axis

A2

A1

A3

B

C

D

4.Install the Printer

4.13 Install the Teflon Tube

11

Quick release

claw Wire clip (blue)

X/Y/Z axis pulley adjustment: Gently turn the pulley to check whether it is idling or jammed. If this phenomenon occurs, use an open-end wrench to adjust the

tightness of the hexagonal eccentric isolation column to make it rotate smoothly.

4.Install the Printer

4.14 Adjusting pulley tightness

Check the pulley looseness before switching on the machine.

X axis

Z axis

Y axis

12

5. On-screen information

Displayed information

1

2

3

4

5

6

7

8

9

10

11

12

1Set nozzle

temperature

2Model 3Current nozzle

temperature

4Printing Speed 5Prompt 6Set heated bed

temperature

7Current heated

bed temperature

8Fan speed 9Current nozzle position

10 Printing time 11 Printing Progress

12 Press: Select OK

Rotation: Toggle option/Change value

Motion

Info screen

Move Axis Moving X/Y/Z/Extruder

Auto Home/Level Bed

Probe Z Offset/

Disable Steppers

Temperature Nozzle/ Bed/ Fan Speed/

Preheat PLA/ Preheat ABS

Advanced Settings

Set Home Offsets / Velocity /

Acceleration / Jerk /Probe Offsets /

Steps (mm) / Temperature /

Fillament / Initialize EEPROM

Probe Z offset

CR Touch Reset / Self-Test / Deploy/

Stow / SW-Mode

Preheat PLA Conf /

Preheat ABS Conf /

Configuration

Change Filament Preheat PLA/ Preheat

ABS/Preheat Custom

Change Media

Print from Media

Languages

About Printer

13

Power Outage

Store Settings /

Load Settings /

Restore Defaults

Fan Speed / Nozzle / Bed/

Store Settings

rabbit.gcode

6. Auxiliary leveling

6.1 Info screen → Motion → Auto Home. (Waiting for the end of the CR-Touch detection platform)

6.2 Info screen → Motion → Move Axis → Move Z. (Adjust the value to 0)

6.3 Info screen → Motion→ Probe Z offset. (Observe the clearance between the nozzle and the platform and adjust the Z Offset to allow a distance of

approximately 0.2mm between the nozzle and the platform.)

14

6.4 Info screen → Motion → Disable Steppers. (Move manually the nozzle to the top of the platform adjusting knob and adjust the four knobs in

turn to make the distance between the nozzle and the platform about 0.2mm. Repeat the adjustment 1 to 2 times if necessary. )

7.Auto Leveling

7.1 Info screen → Motion→ Level Bed → Return to info screen.

7.2 Info screen → Configuration → Store Settings. (Save Z-axis compensation data)

7.3 Info screen → Print from Media → Select print file → Print.

15

Probing point 3/16

Media

English

boat.gcode

rabbit.gcode

CR Touch

Table of contents

Other Ender 3D Printer manuals

Ender

Ender Ender-3 Max Neo User manual

Ender

Ender Ender-3 Assembly instructions

Ender

Ender 3 Series User manual

Ender

Ender 3 V2 Neo User manual

Ender

Ender 3 Series Assembly instructions

Ender

Ender Ender-3 Assembly instructions

Ender

Ender 3 S1 User manual

Ender

Ender 3 S1 User manual

Ender

Ender 3 S1 Plus User manual

Ender

Ender Ender-3 Pro User manual