2

Installation

6

© Moffat Ltd, August 2012

Revision 3

Moffat Cobra Series CS9 - Gas Salamander

Gas Connection

NOTE: ALL GAS FITTING MUST ONLY BE CARRIED OUT BY A QUALIFIED SERVICE PERSON.

1. Cobra Salamanders do not require an electrical connection, as they function totally on the gas supply

only.

2. It is essential that the gas supply is correct for the Salamander to be installed and that adequate

supply pressure and volume are available. The following checks should be made before installation:-

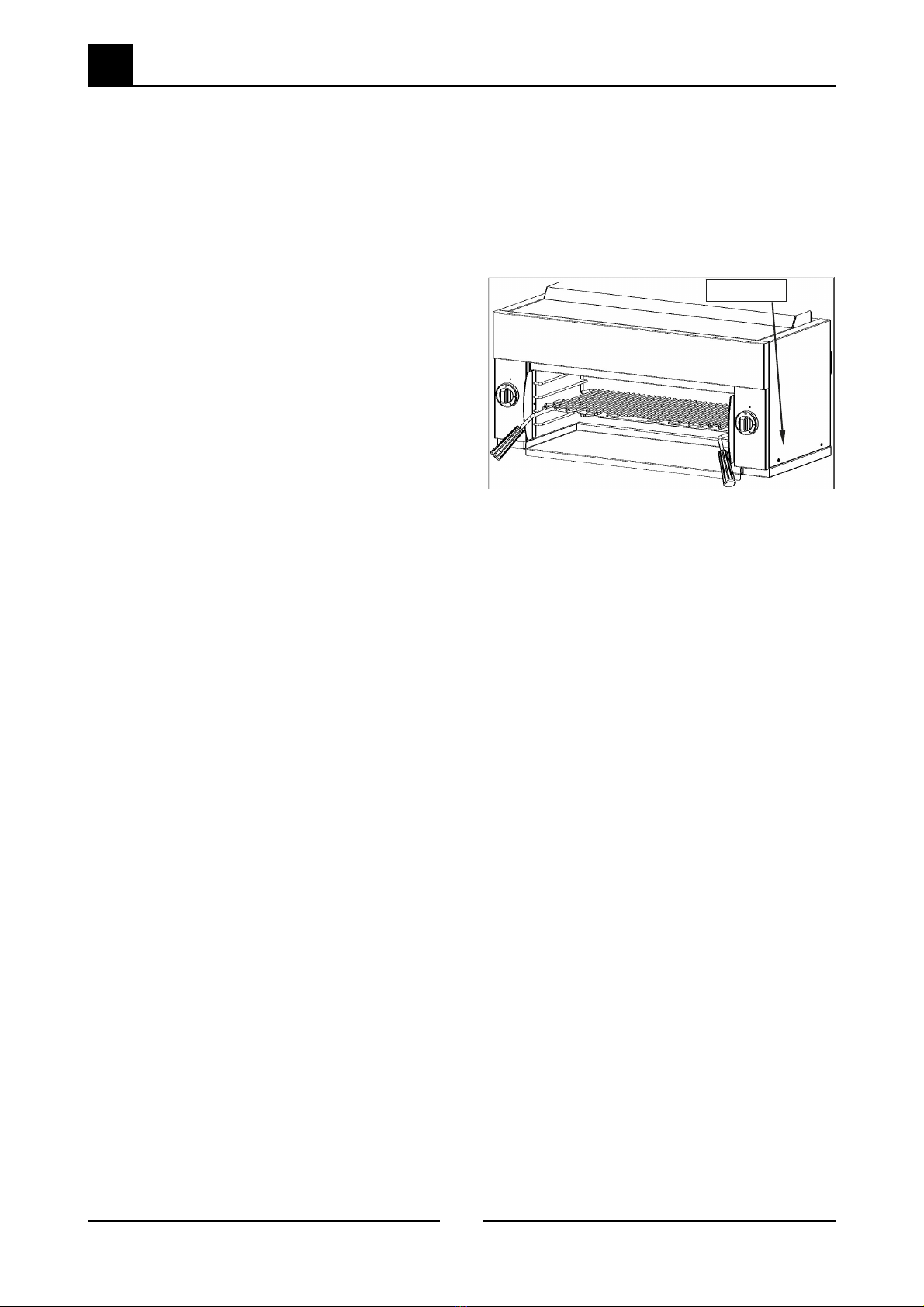

a. Gas Type the appliance has been supplied

for, is shown on a coloured stickers located

above the gas connection and next to the

rating plate. Check that this is correct for

the gas supply the appliance is being

installed for. The gas conversion procedure

is detailed in this manual.

b. Supply Pressure required for this

appliance is shown in the 'Specifications'

section of this manual. Check the gas

supply to ensure adequate supply pressure

exists.

c. Input Rate of this appliance is stated on the Rating Plate and in the 'Specifications' section of

this manual. The input rate should be checked against the available supply line capacity.

Particular note should be taken if the salamander is being added to an existing

installation.

NOTE: It is important that adequately sized piping runs directly to the connection joint on the

appliance with as few tees and elbows as possible to give maximum supply volume.

3. Fit the gas regulator supplied, into the gas supply line as close to the appliance as possible.

NOTE:

The burner operating pressure is to be measured at the manifold test point with both

burners operating at the 'High Flame' setting.

NAT, LPG & Butane Only - The operating pressure is ex-factory set and is not to be

adjusted, apart from when converting between gasses, if required.

TOWN GAS Only - The burner operating pressure is to be adjusted using the adjustable gas

regulator supplied.

Refer to the ‘Gas Conversion and Specifications' section of this manual for further details.

The regulator connections are 1/2" BSP female.

The connection to the appliance is 1/2" BSP male.

NOTE: A Manual Isolation Valve must be fitted to the individual appliance supply line.

4. Ensure the regulator has the correct colour spring fitted for the gas type, as detailed in the

'Specifications' table. Opposite gas type replacement spring is part of the gas conversion kit

supplied.

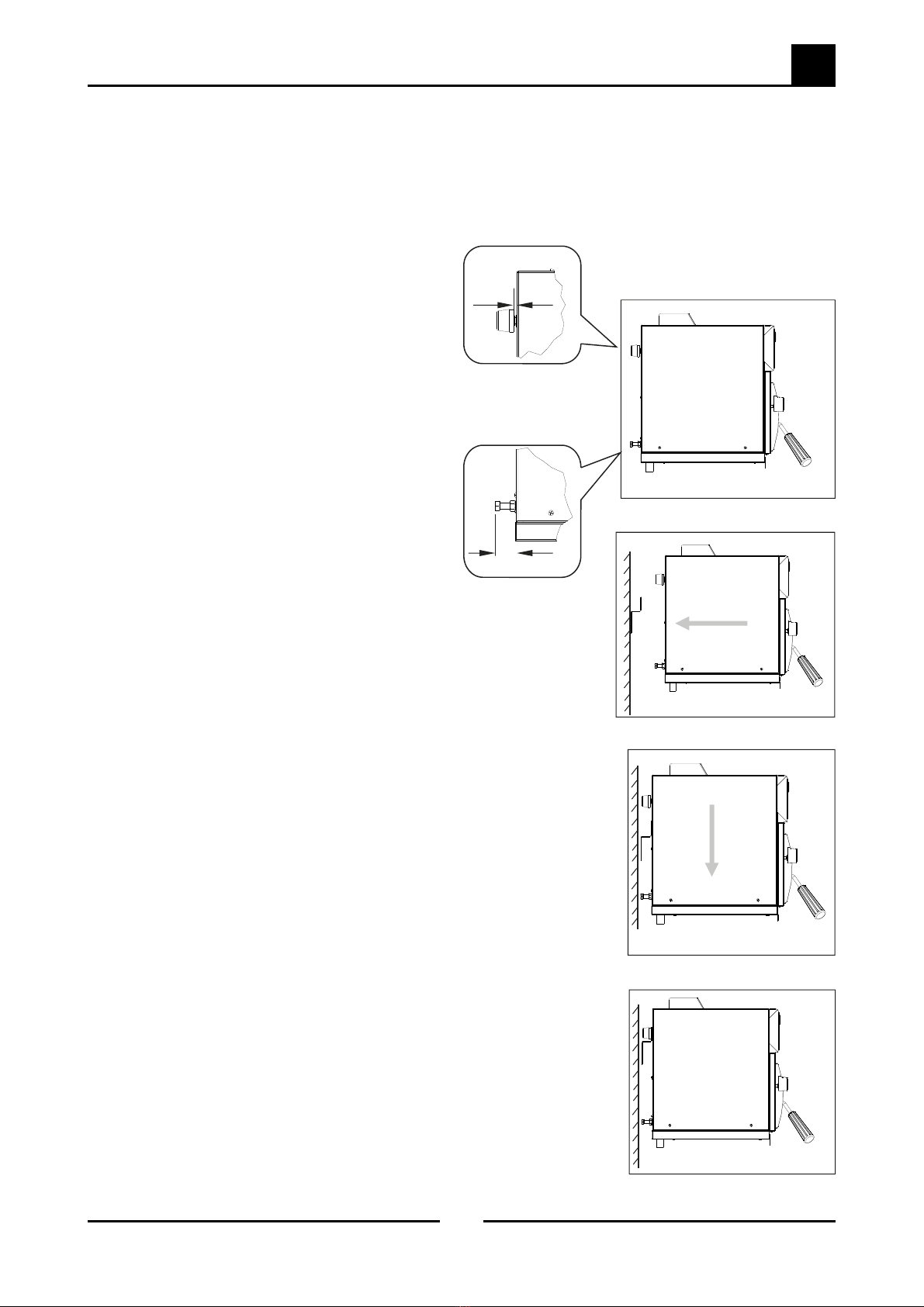

5. Correctly locate the appliance into its final operating position and using a spirit level, adjust the legs

so that the unit is level and at the correct height.

6. Connect gas supply to the appliance. A suitable jointing compound which resists the breakdown

action of LPG must be used on every gas line connection, unless compression fittings are used.

Rating Plate

Figure 2e