Coda SC2-F User manual

Coda Audio CiRAY Rigging Maintenance 1

Coda Audio Rigging System’s Maintenance

The following general maintenance procedures apply to Coda Audio CiRAY and

SC2-F/ SCV-F, rigging parts and accessories.

As there are some differences to certification and other local regulation requirements from

one territory to another. The following maintenance procedures are supplied as a guide to

general good maintenance of your rigging system. This guide should be studied in

conjunction with any local rules and regulations for your territory. This guide does not

replace any local rules and regulations and should not be taken as an overriding guide to

any local rules and regulations that you may need to adhere to in your own territory.

General

All rigging parts, including cabinet fixtures and fitting, fly-bars, extension bars, shackles and

dollies should be fully inspected every 12 months. The owner of the equipment should set

up their own schedule for undertaking this work. It is recommended that the first general

inspection should be undertaken 12 months from date of first system use.

In addition to an annual inspection of all parts; Coda Audio recommends that a general

visual inspection of all parts should take place before each system is installed or used. A

further visual inspection should be undertaken at the end of each use. These inspections

should be performed by a suitably experienced and qualified system technician, and a log

should be kept of all inspections completed.

It is important to remember that the cabinet fixtures and fastenings form an integral part of

the overall suspension (flying) system. Therefore, great care must be taken when using,

transporting or storing your cabinets and accessories so as to avoid any physical damage,

either via hard contact with floors, walls or other equipment coming into contact with your

speaker cabinets and their accessories. Coda Audio provides a variation of transport dollies,

flight cases and soft covers to help protect your system, and these should be used at all

times. Coda Audio does not accept any liability or responsibilities for damage, how so ever

caused, to your systems or accessories at any time. Coda Audio recommends the use of the

accessories made available, at all times without exception. It is the responsibility of the

equipment “owner” to keep all equipment in good working order and for it to be used only

as intended, within its listed specification area of use. Should you have any questions

relating to the correct usage of the equipment, please contact your Coda Audio

representative or Coda Audio direct for further assistance and support. Contact information

is listed at the back of this document.

This document will only discuss and cover Coda Audio supplied products and accessories.

This document does not take into account any equipment which is used in conjunction with

Coda Audio products and accessories, such as chain motors, electric hoists, steel wire,

shackles or other rigging equipment.

Coda Audio CiRAY Rigging Maintenance 2

Overview

The correct usage of your Coda Audio system must be adhered to at all times. If you are

unsure of any point, it is always best to ask before you start using the system; this will not

only assist in a better understanding of your equipment, but also further your general

knowledge of Coda Audio systems.

This document is not a training manual. For any and all training related information, you

must contact your local Coda Audio supplier or Coda Audio Hannover Germany for further

information.

It is Coda Audio’s requirement that all systems will only be used by suitably experienced and

qualified individuals. This includes both the use of the system and its general maintenance.

Any and all test certificates that may be required for your territory must be obtained in

accordance with local rules and regulations; this is the responsibility of the equipment

owner, not Coda Audio or its local sales representatives.

Cabinets

All Coda Audio line array cabinets are designed to be used in both ground stack and

suspended formats (using the appropriate accessories designed for these functions).

Your Coda Audio speaker cabinet (where applicable) has integrated steel flying hardware

which has been designed and fitted to the cabinet by Coda Audio during the manufacturing

process. All such flying hardware has been designed to perform its function in line with the

overall system design and specifications for use.

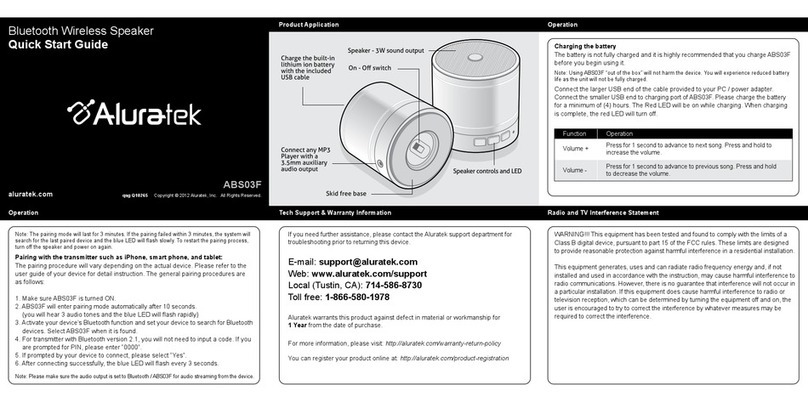

Example of integrated flying hardware:

Image 1: CiRAY 3D view

Coda Audio CiRAY Rigging Maintenance 3

Image 2: CiRAY Rear view

Images 3: SC2-F and SCV-F

The pictures above show examples of the integrated flyware on cabinets designed to be

suspended either from a supporting Fly-Bar, Fly-Frame or from one another below the Fly-

Frame. The external and internal flyware parts have been designed from high grade steel,

which has been anti-rust coated and then painted with multiple coats of paint to its finished

level.

Normal wear and tear on all parts which form part of the connection process will result in

some paint being scratched and in time even worn off. This is normal and to be expected. It

will not affect the function of the parts or their construction.

Coda Audio CiRAY Rigging Maintenance 4

Image 4: Example picture of CiRAY (used) inter-cabinet connection arm

This picture shows an example of an CiRAY inter-cabinet connection arm after multiple

usage; slight surface to surface rubbing takes place as the arm is positioned into its “female”

corresponding position. Where the two surfaces meet, paint may be rubbed off. This is

normal. There is no need to repaint this urgently – this can remain as it is or be re-painted at

an annual inspection and service time.

Checks should be made to all metal to metal connecting surfaces, to ensure that no actual

hard scoring of the metal has taken place. Hard scoring only takes place when two metal

surfaces are rubbed together with excessive pressure on one or both surfaces. If evidence of

this is found on any two-mating metal surfaces a full test and inspection is recommended.

Checks should be made to all metal work for any damage that may arise from cabinets or

other equipment bumping or banging into one another during transport, usage or storage.

Checks should be made for any larger signs of damage, such as may be caused by long

periods of transport where cabinets are not flight cased or dollied, or where other

equipment may come into contact with the cabinets. A simple visual check made by lightly

running your hand along the metal work, looking for scratches, pitting or other dents in the

metalwork will show up any problems easily.

Checks should also be made at the same time to all fixings and fastenings used to fix the

metal work to the cabinet.

Coda Audio CiRAY Rigging Maintenance 5

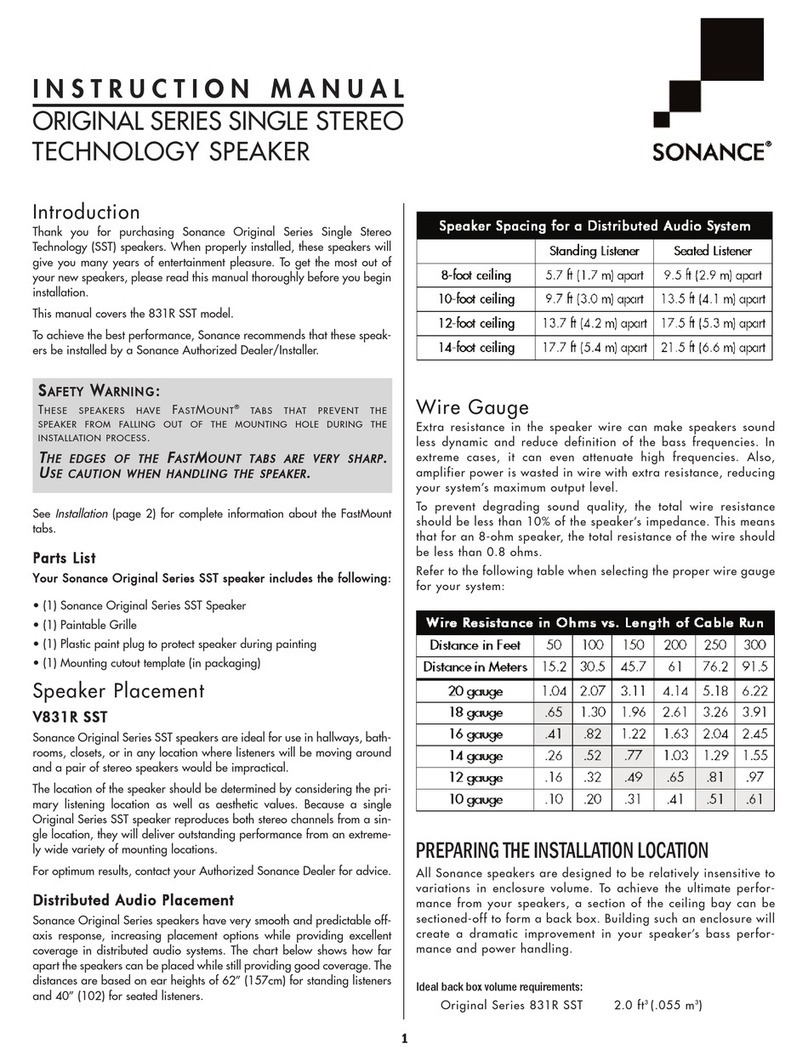

Fixings / fastenings

Images 5, 6 and 7: Typical examples of fixings / fastenings used on Coda Audio cabinet

These fixings and fastenings should show no signs of movement, or be loose in any way;

they should be flush fitting to the metalwork surface. These fixings and fastenings are

installed at the Coda Audio factory and under normal conditions will not move. However,

under some long-term transport conditions, particularly where roads are bad, long term

vibration might have an effect. Undertake a visual inspection at regular intervals. Once every

12 months undertake a full manual check, as follows;

Check each screw fixing in turn using the appropriate tools (Coda Audio use a variation of

fixings / fastenings; Torx head – Allen key type) make sure you use the correct tool format

and size. Simply insert the tool into the fixing head, and apply a little pressure in the

clockwise direction. Normally there will be no movement and this indicates that the fixing is

tight and all is OK.

Torx Allen

Image 8: Two types of fixing head used

Coda Audio CiRAY Rigging Maintenance 6

Do not apply greater pressure than 1 kg of test pressure. Do not attempt to force the fixing

in any way. Do not use air tools.

If any fixing or fastening is found to be loose, carefully tighten until the stop position is

found. Do not over tighten as this may lead to damage of the fixing threads.

If movement is found on any fixing, perform a full check to all metalwork and fixings on the

cabinet, as movement in one area normally indicates that the cabinet has been stressed in

some way and a full check is required. Perform a visual inspection first, followed by a fixings

inspection using the correct tool.

Flying Pins

A specially designed Coda Audio retaining pin is always attached to its metalwork on the

cabinet and operates on a “Spring & Ball” system that does not come away from the cabinet.

This design has achieved a near zero loss of pins since its introduction. The pin works simply

by depressing the plunger and moving the complete mechanism forwards to lock and

backwards to unlock. Like all Spring & Ball systems once the pin is in place and the plunger

released, the pin will be locked in place. To remove the pin, depress the plunger and pull the

complete mechanism backwards, fully.

Regular visual inspections of the pins should be undertaken. Once every 12 months a full

physical inspection should take place, at this time inspect the pin for alignment and any

operational defects that do not allow free movement and operation.

It is vital that all pins are correctly secured during operational use, transport and storage.

Pins left un-secured will become a hazard to staff, and may also be damaged which must be

avoided.

Image 9: CiRAY side view

Coda Audio CiRAY Rigging Maintenance 7

Image 10: SC2-F/ SCV-F side view

Part number: Coda-Pin F ViRAY

These pins form a vital part of the flying system and its safe operation; they should be

visually checked at regular intervals for any damage or poor functionality.

Check the pin plunger is depressing correctly – check that when depressed the two ball

locks at the end of the pin, move into the body of the pin, and back out again when the pin

plunger is released.

Check that without the pin plunger depressed, the two ball locks are fixed in the “out”

position and will not go back into the body of the pin

Every 12 months run a full check on all pins for correct operation.

Coda Audio CiRAY Rigging Maintenance 8

Image 11: CiRAY and SC2-F/ SCV-F pin in transport position

Always train staff to place the pins in this position when not in use, this will help protect the

pin from damage and will also keep the pin with the cabinet at all times. Pins which are not

in transport position may get knocked off or damaged in transit. This can cause delay at

setup time.

The pins supplied by Coda Audio are the correct specification for their designed usage, if

you lose a pin, please contact your Coda Audio representative for replacements; do not

replace with none Coda Audio parts.

Check regularly that the pins are in place, replace with original Coda Audio parts as required

The CiRAY system also uses a separate retaining pin for the rear part of the flying system.

Image 12: CiRAY Rear hardware pin

Part number: Coda-Pin-R ViRAY

Coda Audio CiRAY Rigging Maintenance 9

Image 13: Coda-Pin-R ViRAY in single cabinet transport position

This pin is housed and used in various parts of the flying system and is also retained to the

flying system by a steel retaining wire.

The pin has a location home point when not in use as shown in the image above.

Always make sure that all staff are trained to place these pins in the correct position when

not in use. The steel retaining wire is just to hold the pin in close proximity to its area of use.

Due to the nature of usage, it is possible for the steel retaining wire to become broken if

caught or snagged on something while the cabinet is being moved, the steel retaining wire

is made so that if it does become stuck or snagged in something it will break after a certain

amount of pressure, this is by design, as this retaining wire is only used for keeping the pin

with the cabinet. This retaining wire has no load bearing function; it must not be used for

any other purpose than retaining the pin to the cabinet.

Check regularly that the retaining wire and pin are in place, replace with original Coda

Audio parts only as required.

Never use damaged pins for operational use; this is unsafe and may lead to accident or

injury.

Coda Audio CiRAY Rigging Maintenance 10

Do’s & Don’ts

Do

Always run a visual inspection of the cabinet(s) before and after use.

Always run a full inspection of the cabinet(s) once every 12 months, check all rigging

metalwork and fixings for wear & tear, check for rust, check for alignment.

Always check that no metal parts have become damaged in any way, this includes

bends (alignment to another part), corrosion via rust or other type.

Check all “pins” are working and fully functioning regularly.

Check all product labels, indicators and data labels are in position and not damaged,

replace any which are worn or missing.

Do obtain spare parts only from your Coda Audio representative.

Do flight case any accessories in suitable designed flight cases.

Do use Coda Audio transport dollies / flight cases and soft covers.

Don’t

Don’t forget to visually inspect your system before use.

Don’t forget to visually inspect your system after use.

Don’t forget to check all pins are in place and functioning correctly.

Don’t use none Coda Audio replacement parts or accessories.

Don’t over tighten “fixings / fastenings” when checking.

Don’t allow lose items to be carried via any transport method, always pack correctly.

Don’t allow un-skilled operation of any part of the system.

Don’t over-load any part of the system.

Don’t forget- “Safety First” whenever using the system.

Annual Inspection

The annual inspection of your cabinet(s) should be formed of three parts

Visual inspection of metalwork and woodwork

Physical inspection of all metalwork and woodwork

Acoustical check of all components and electronics

We will only deal with points 1 & 2 in this document.

Point 1: run a visual inspection of all cabinets; clearly mark any cabinets that require

attention based on the visual inspection.

Point 2: run a physical inspection of all cabinets; this should include checking all metalwork,

fixings, fastenings and the cabinet woodwork.

Under normal conditions your cabinet(s) should require nothing more than a clean after all

testing has been completed.

This manual suits for next models

2

Other Coda Speakers manuals