Coffed BDH, ul. Ceramiczna 28, 64-920 Piła PL, tel 48 (67)214 2629, www.coffed.pl

78## #

77# #/.1 ##

This manual is an integral part of the equipment and it needs to be stored in the place

where the equipment is being used. The persons installing, providing maintenance, cleaning or

using the equipment should have constant access to the manual. The manual should be used by

qualified personnel only. The knowledge of and compliance with all safety and operating

instructions is essential for safe and proper operation of the equipment. In addition, when using

the equipment all the local regulations regarding health and safety precautions should be

observed.

7$- / 0#<#0

Personal injury or property damage liabilities and warranty claims are void if they occur as a result

of:

- misuse of the equipment

- wrong installation, commissioning, start-up, maintenance or handling of the equipment

- use of the equipment with damaged or faulty functioning of the protective and safety appliances

- not abiding to the precautions in the manual

- making unauthorized changes (including construction changes) in the equipment

- installing additional parts that have not been tested and authorized by Coffed

- making changes in the gas burner that modify the burner manufacturers - set creation of the

flame

- insufficient control of the elements, that can wear

- unprofessional repairs

- using the equipment despite being faulty

- using inappropriate fuel

- defects of the power cords that are not a part of the equipment

- using parts that are not original parts supplied by Coffed

701! #<. 1 #=.> 1#

The data referring to the safety of operation are in relation to European Union legislation

that was in effect at the date of the equipment’s production. If the equipment is used in industrial

conditions, the user is obliged to check the accordance of the recommended safety measures with

the current regulations and to comply to the newest rules.

If the equipment is used outside the European Union, the user should abide to the health

and safety regulations of the place where the equipment is installed. The specific environmental

guidelines also need to be respected.

4# #=?

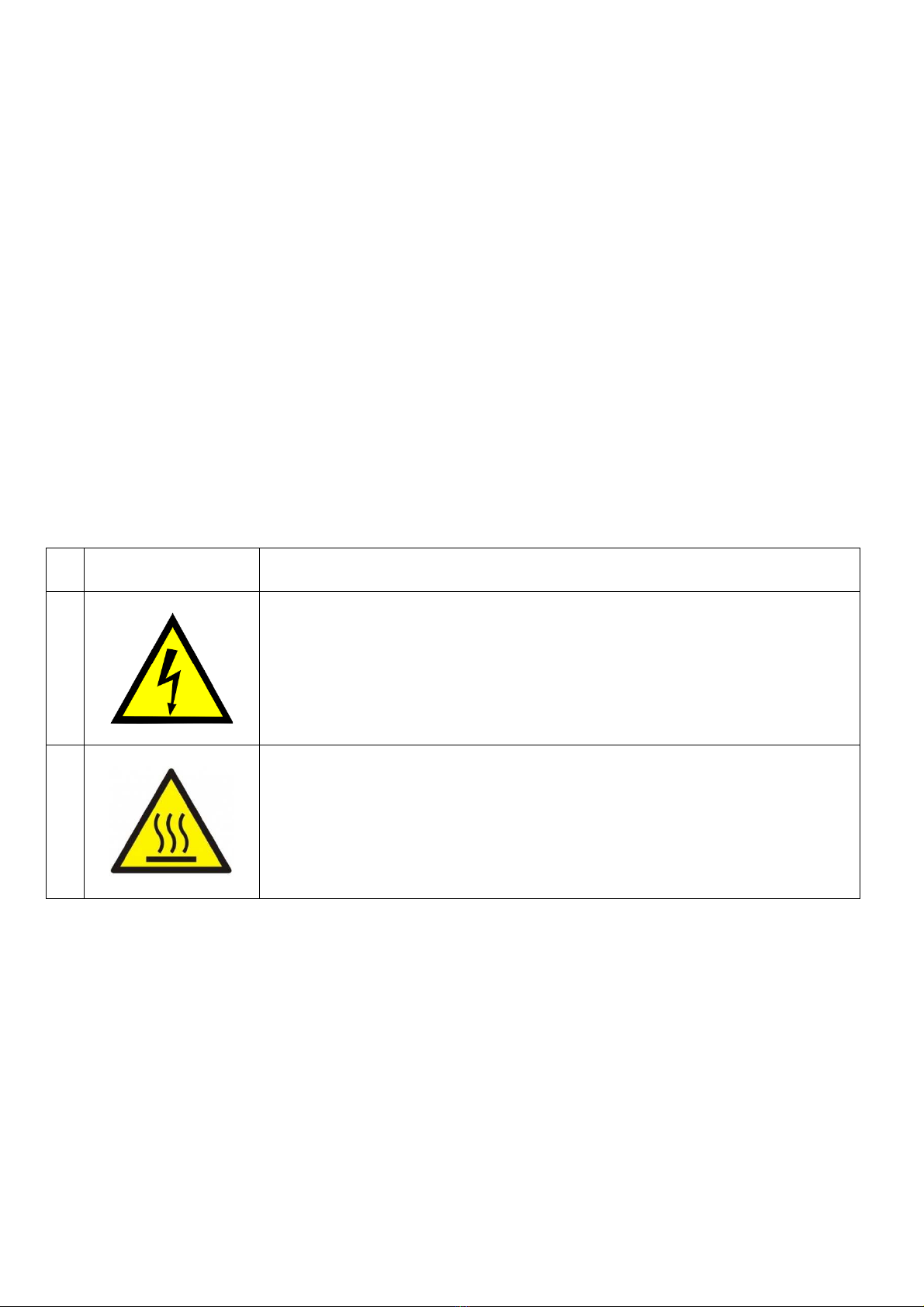

@.> 1# # =#//011A #! #=!. #B< .#

#0# ##/01#< ..#!0C1 #!#

D#<=

@.> 1#!#//0./E(# #1##0#1E #

> # #1#. 1# /. 0#.= E#..

#!0= #.<.> 1#

@. ##/# !1E ##..0#10 #=< ..

> 1#

@. ##/!0##E#. #=.!. #< ..

11.##/.