6X-1109E 5

Pressurized camera

This environmentally sealed camera housing is pressurized with dry nitrogen to prevent moisture from af-

fecting the optics or electronics. The nominal internal pressure is 3.5 psi (24.1 kPa).

• Installation must be done by qualied installers, and conform to all local codes.

• It is the user’s responsibility to ensure that the mounting methods are safe and adequate for the

location.

• Use only stainless steel hardware to fasten the mount to an outdoor surface.

• To prevent damage from water leakage when installing a mount outdoors, apply sealant around the

bolt holes between the mount and mounting surface.

• All servicing must be performed by qualied service personnel. The unit contains sensitive

devices that can be damaged by static discharge. To reduce the risk of damage to the unit by static

discharge do not perform any servicing other than described in these instructions. If the unit is

defective, please contact the Customer Service Department for technical assistance.

• It is the sole responsibility of the installer to provide proper installation in compliance with all local

codes and regulations.

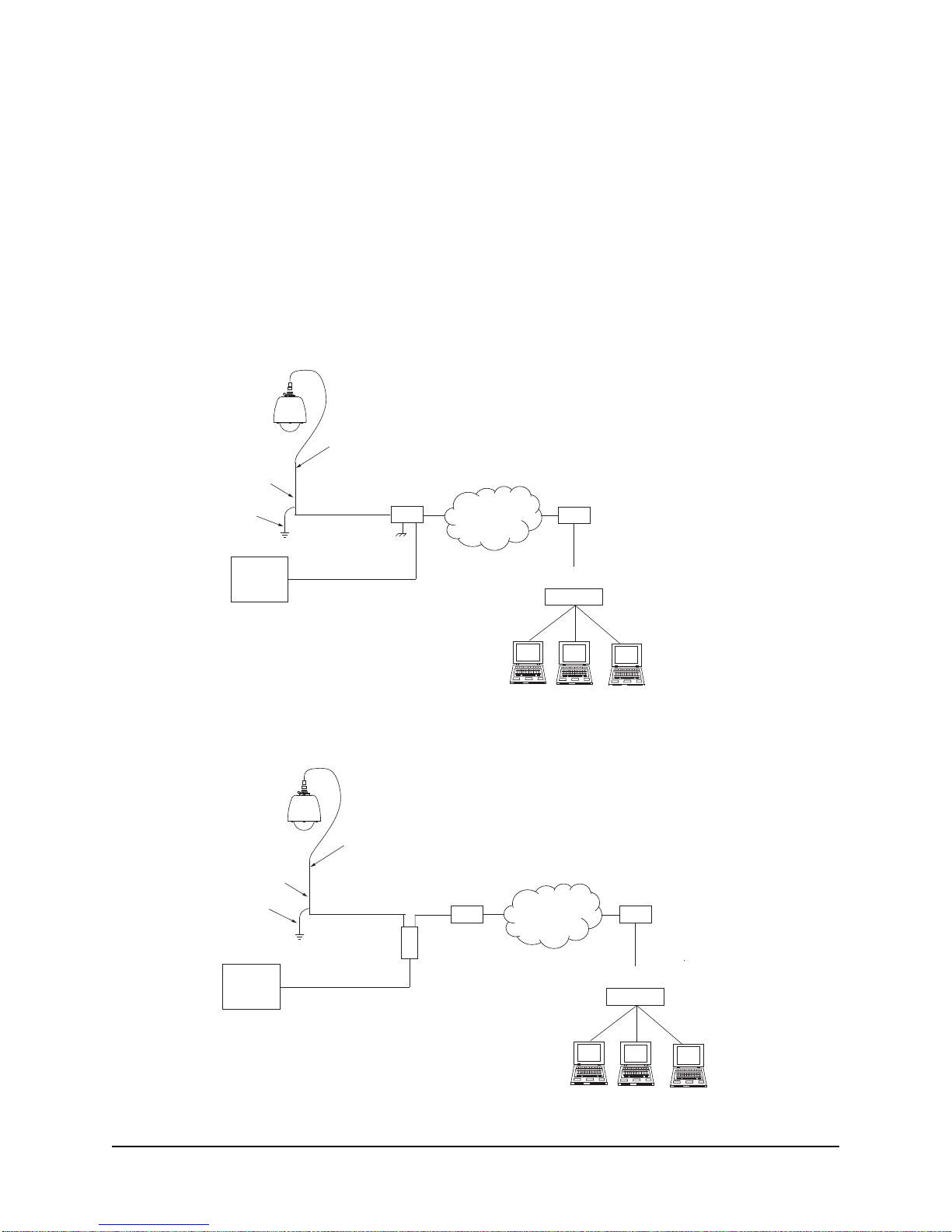

• To provide protection against electrical surges induced by lightning, static charges, or any other

cause, the camera and cabling system must be properly grounded to earth. For installation on

a building, the camera must be bonded (that is, provided with a low impedance connection) to the

building’s structural earth ground system. For installation on a metal pole with a proper ground

system at the base, the camera must be bonded to the pole. For installation on a non-grounded or

insulated support, the camera must be grounded with an adequate ground strap or wire between

the camera and a nearby ground system, or to a ground system installed at the base of the support.

Failure to adequately ground the camera may lead to failure of the camera. This applies to low

voltage (i.e. PoE cameras) as well as to 115 Vac cameras. Failures due to surges are not

covered by the warranty, as they are not due to defects in material or workmanship, and it is

the installer’s responsibility to meet these grounding requirements.

IMPORTANT

Do not remove the clear plastic tube that protects the pressure relief valve poppet, or the pressuriza-

tion could be lost. The pressure relief valve is designed to open when the internal pressure exceeds

5 psi (34.5 kPa). Environmental factors such as high temperature or high altitude (including during air

transport) can cause the relief valve to open and bleed off excess pressure, resulting in lower pressure

at normal environmental conditions. See Section 5.1 of this manual for more information on maintaining

the camera housing pressurization.

IMPORTANT

the packing foam material is selected to provide appropriate shock absorption in shipment,

and that the same material must be used if the camera needs to be shipped (whether on RMA

back to us, or to anywhere else for deployment).

CAUTION

Prolonged exposure to temperatures below -25°C (-13°F) without power applied to the camera is to be

avoided. It will affect operation of the lens and/or motion functions, and can result in damage.

A warm-up time of 90 minutes is required before full operation can be commenced. A reset of the cam-

era module is required after the warm-up period and prior to operating the camera.