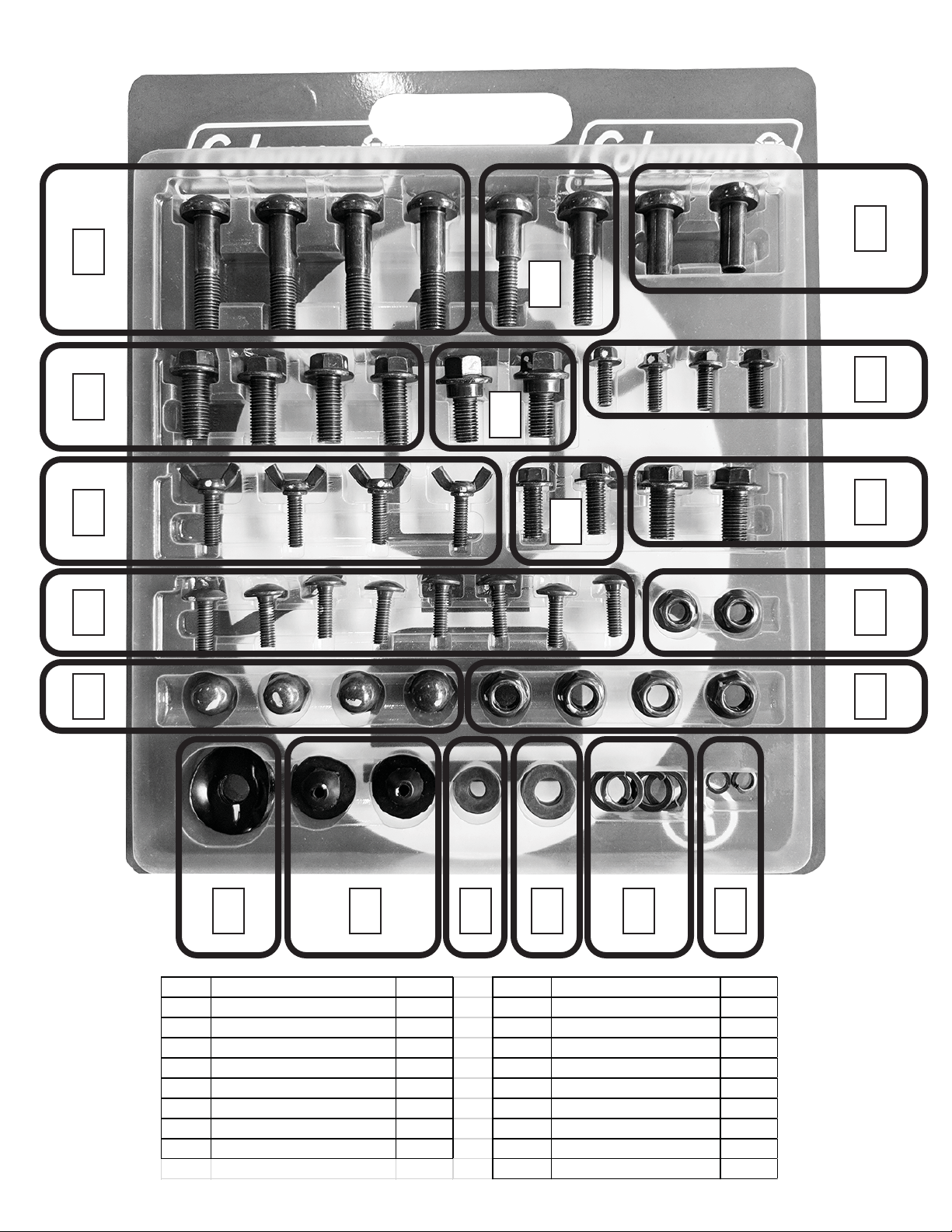

2 - M6X20

Seat back screws

(outer)

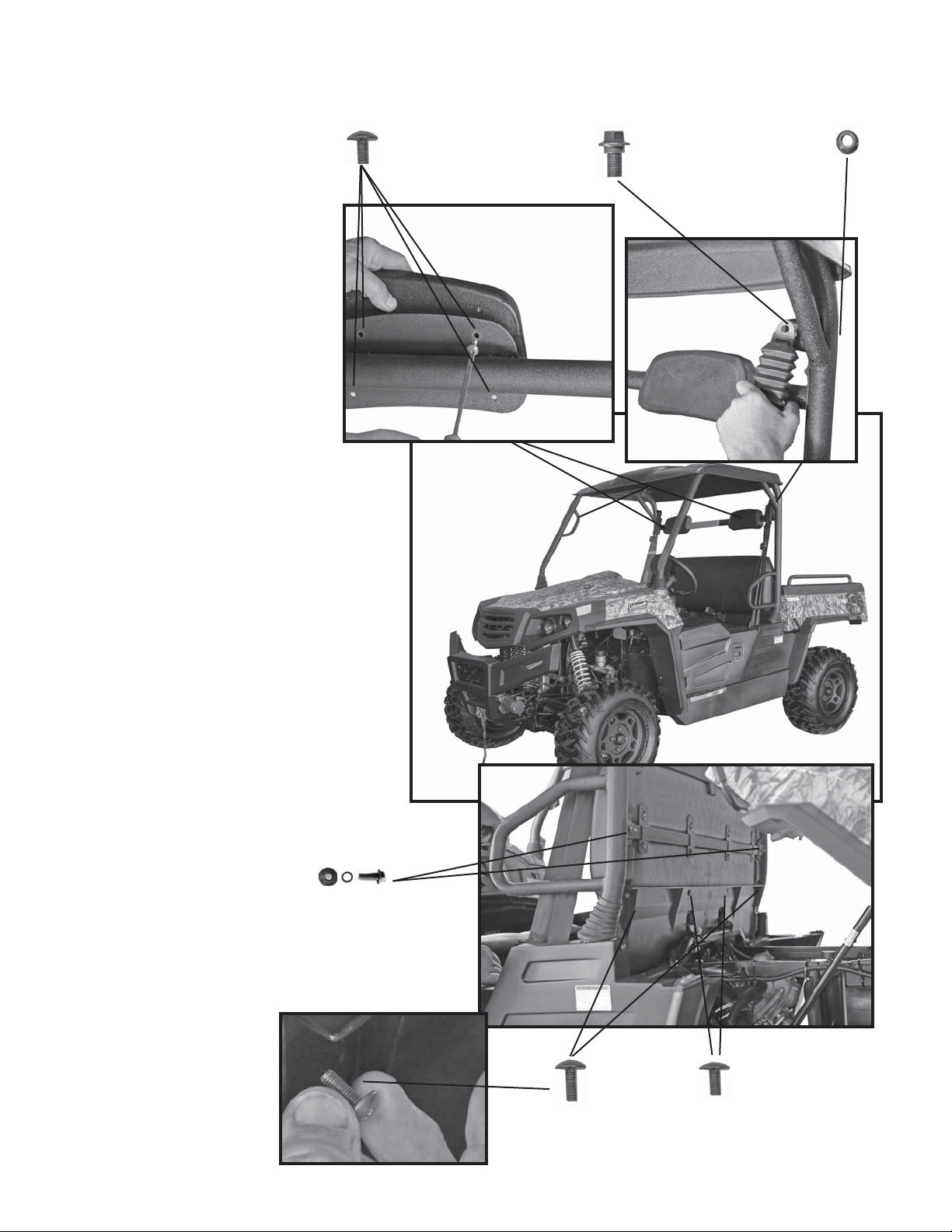

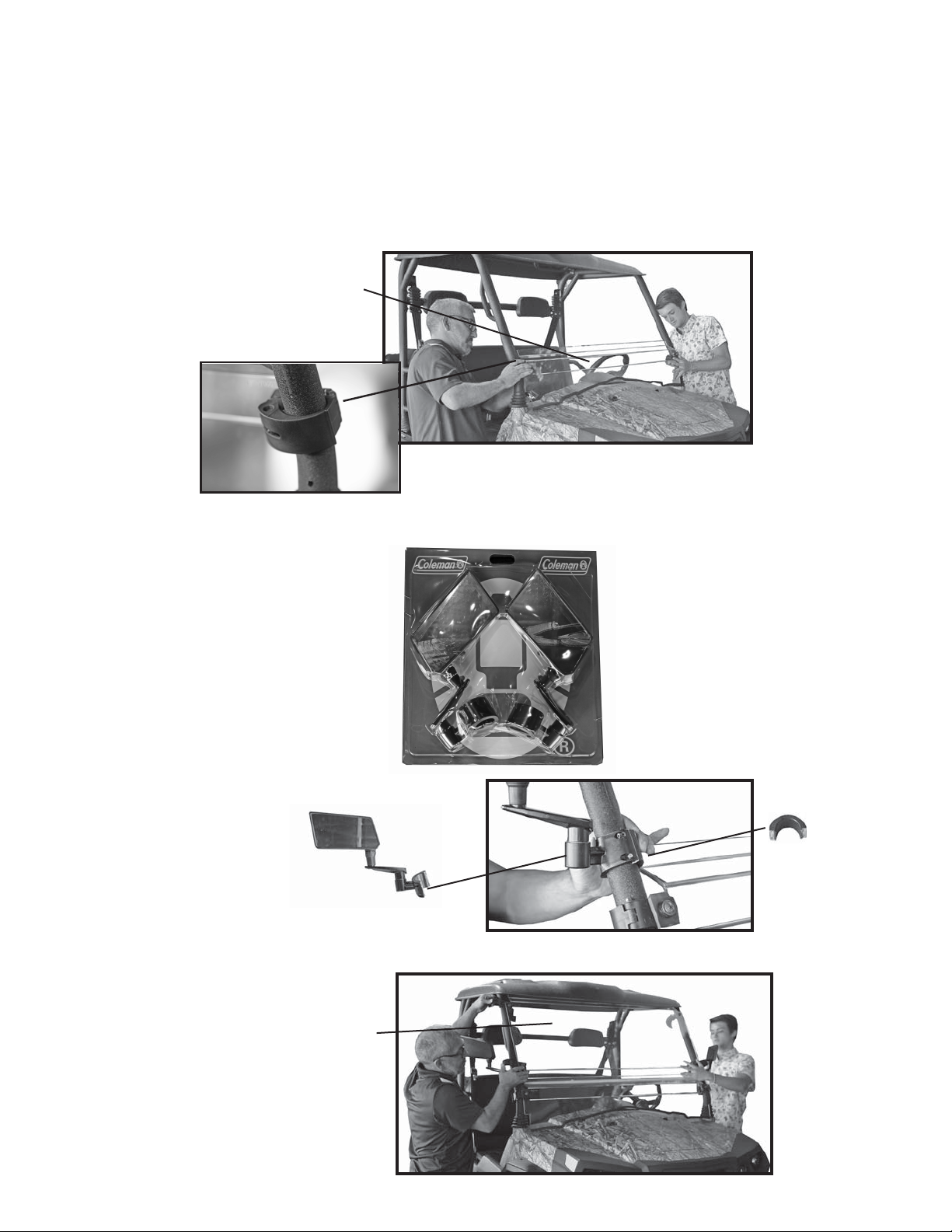

1. Attach head rests to roll cage

assembly using M6X15 screws.

2. Attach back rest to roll cage

using M6X16 bolts, M8 spring

washers and M8 flat washers.

3. Attach rear plastic backing to

rear of seat back using 2 - M6X20

Screws (outer) and 2 - M6X12

Screws (inner.)

Note: M6X20 and M6X12 Screws

are already installed on seat back.

They must be removed and

reinstalled during this process.

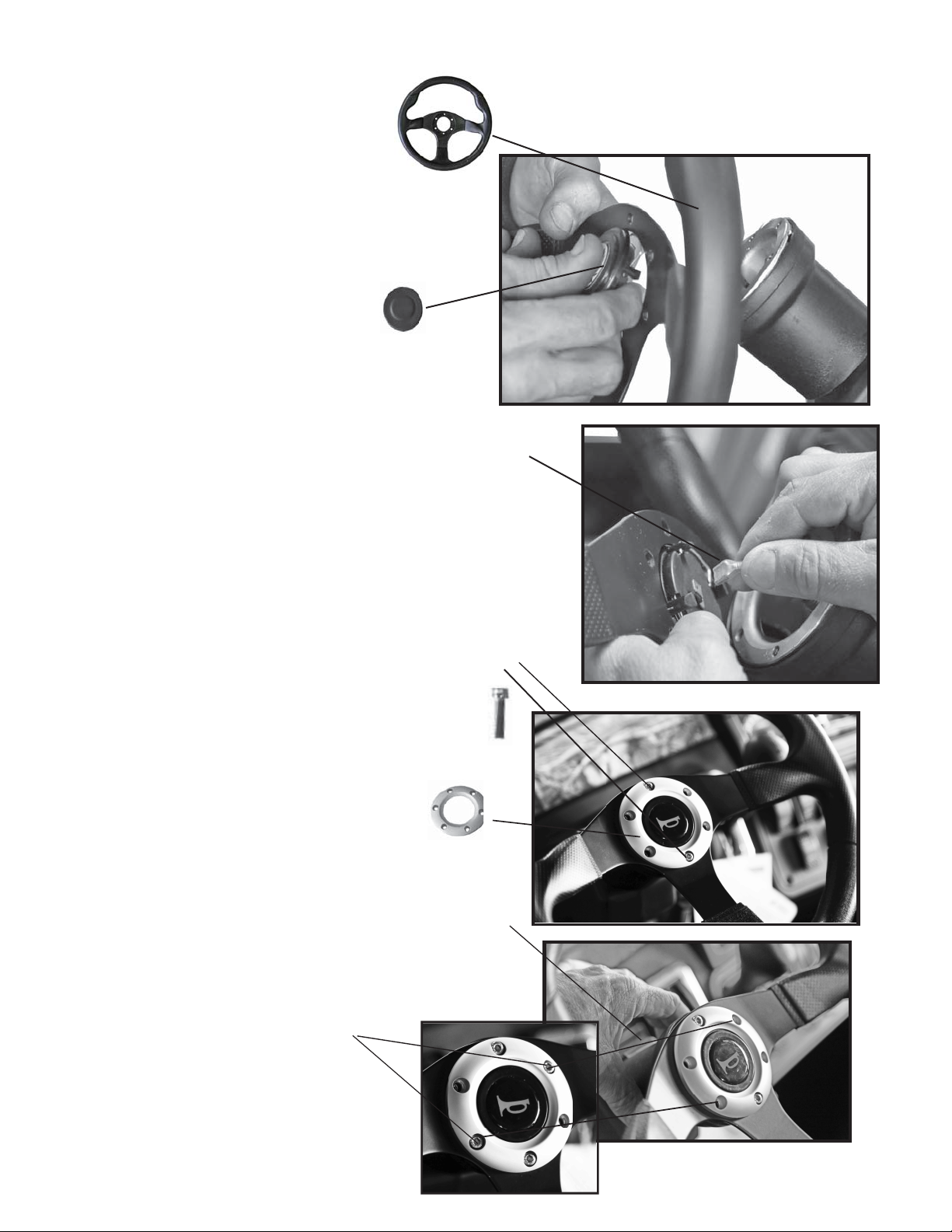

4. Attach seat belt assembly to roll

cage using M10 shoulder bolt and

M10 lock nut.

Note: Take care in alignment of the

seat belt. Make sure it isn’t twisted

prior to install. The top curved

mount should be curving toward

the front of the UTV after install.

2 - M6X16 Bolts (Hardware Fig. #6)

2 - M6 Lock Washers (Hardware Fig. #19)

2 - M6 Flat Washers (Hardware Fig. #16)

4 - M6X15 Screws (per side)

(Hardware Fig. #10)

HEADRESTS, SEAT BELTS AND SEAT BACK ATTACHMENT

Tools needed:

10mm Socket/Wrench

12mm Socket/ Wrench

14mm Socket/Wrench

Phillips screw driver

M10 Shoulder Bolt (per side)

(Hardware Fig. #5)

M10 Lock Nut (per side)

(Hardware Fig. #13)

2 - M6X12

Seat back screws

(inner)

5