MAINTENANCE AND CAUTIONS

1. FOR SAFEST OPERATION KEEP DOLLY MAINTAINED AND WELL LUBRICATED:

A. CHECK AND PACK BEARINGS AS NEEDED, KEEPING MOISTURE OUT.

B. LUBRICATE SAFETY RATCHET SYSTEM AS NEEDED —ESPECIALLY IN INCLEMENT WEATHER.

C. GREASE ALL DOLLY FITTINGS REGULARLY—HUB FITTINGS WITH BEARING GREASE

D. KEEP LUG NUTS TIGHTENED TO 75-85 FT-LBS.

E. CHECK TIRE CONDITION AND AIR PRESSURE BEFORE EACH OPERATION.

2. BEFORE RAISING ANY VEHICLES, COMPLETE OPERATION OF DOLLY SHOULD BE PRACTICED EMPTY.

3. WEAR WORK GLOVES AND ALWAYS KEEP A FIRM GRIP WHEN HANDLING PRY BAR.

4. MAKE SURE SAFETY LOCKS ARE DISENGAGED BEFORE RAISING DOLLY.

5. MAKE SURE SAFETY LOCKS ARE ENGAGED AFTER RAISING DOLLY.

6. AREA SHOULD BE CLEAR OF OTHER PERSONNEL WHILE OPERATING DOLLY.

7. DO NOT TOW FASTER THAN 60 MPH ON SMOOTH ROADS; SLOWER ON ROUGH ROADS. RAIL ROAD

CROSSINGS AND POT HOLES SHOULD BE APROACHED AT A CRAWL. CHECK DOLLIES OFTEN IN TOW.

8. DO NOT EXCEED TIRE MANUFACTURER'S RECOMMENDED STATIC LOAD CAPACITIES:

4.80 x 8 static Load Range C = 760 lb. @ 90 psi per tire or 3,040 lb. per set of dollies w/ steel or aluminum axles.

(4.80 x 8 static Load Range C = 345 kg. @ 6.2 bar per tire or 1,379 kg. per set of dollies w/ steel or aluminum axles.)

5.70 x 8 static Load Range D = 1,070 lb. @ 100 psi per tire or 4,280 lb. per set of dollies w/ steel or aluminum axles.

(5.70 x 8 static Load Range D = 485 kg. @ 9.6 bar per tire or 1,941 kg. per set of dollies w/ steel or aluminum axles.)

C

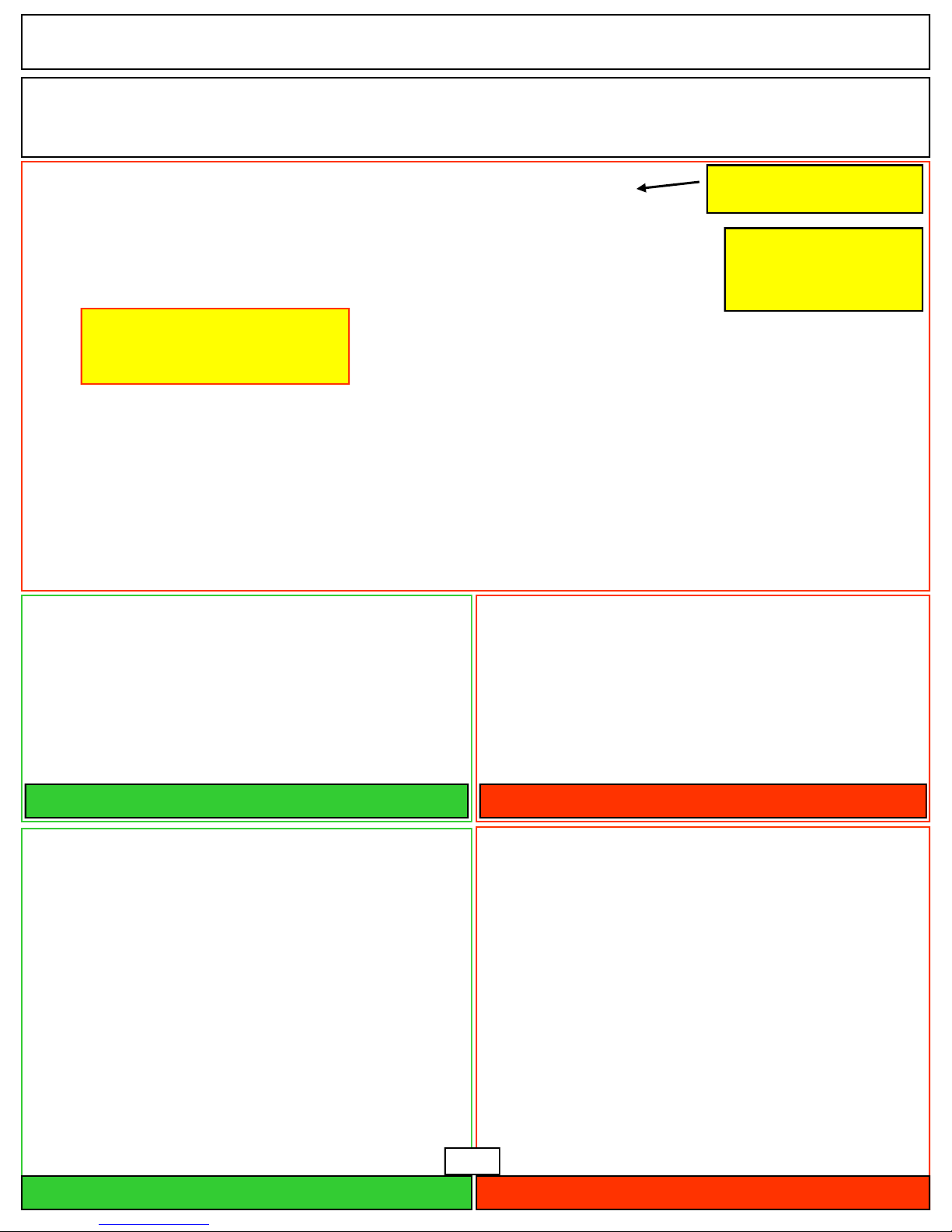

GENTLE LOWERING OF THE COLLINS HI-SPEED®DOLLY: 1975 - PRESENT

1. SKILL SET LEVEL: EXPERIENCED —PRACTICE EMPTY MULTIPLE TIMES BEFORE ACTUAL LOADING!

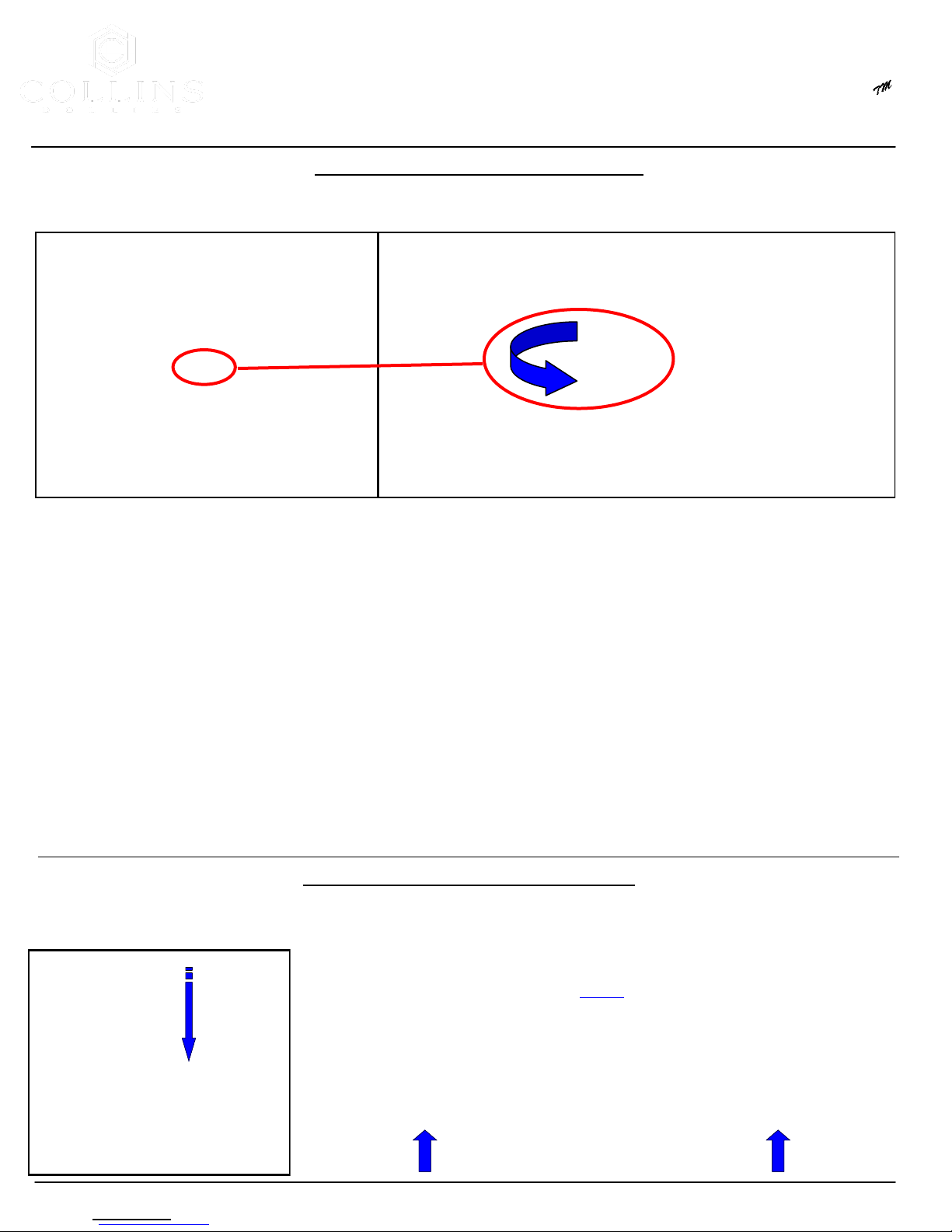

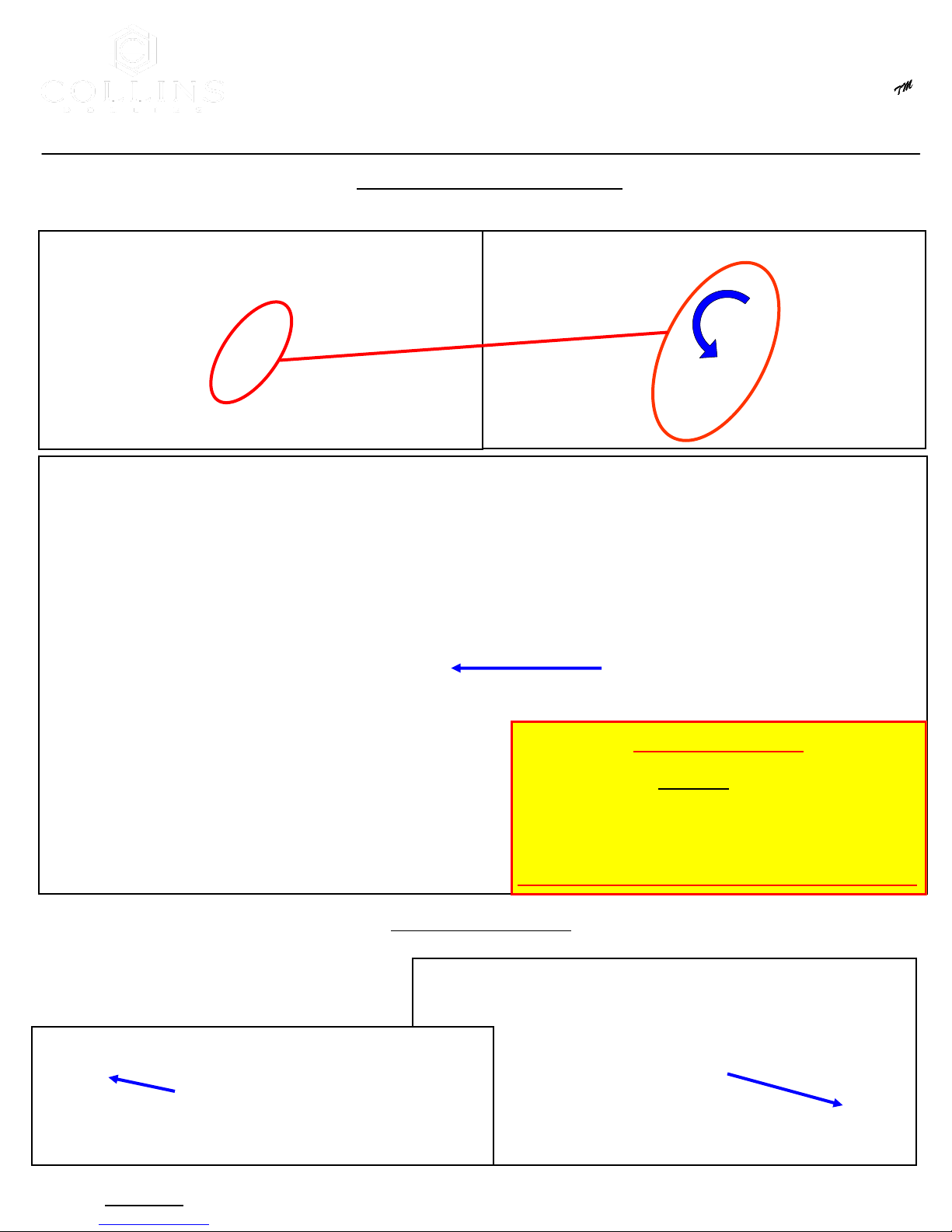

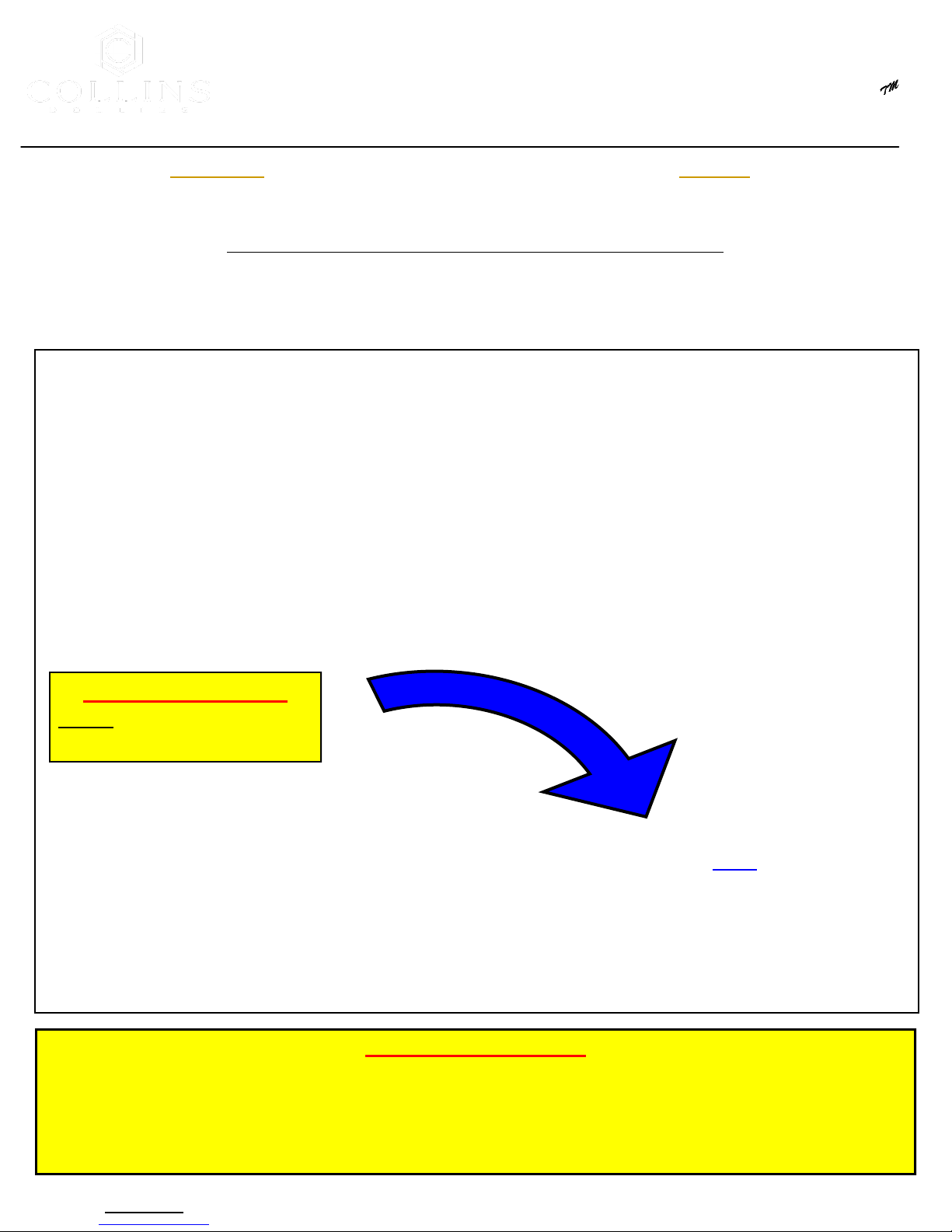

2. DISENGAGE RATCHETS (D) AND SAFETY LOCKS (C) BY TURNING LOCKS TOWARD END OF DOLLY BODY (J).

3. ROLL SPINDLE ASSEMBLY (H) TO OUTSIDE AND INSERT PRY BAR (E) INTO PRY POCKET (F).

4. GRIP PRY BAR (E) WHILE AT THE SAME TIME PLACING OTHER HAND ON TRIP HANDLE (G).

5. GENTLY LIFT TRIP HANDLE (G) WHILE SLOWLY ALLOWING SPINDLE ASSEMBLY (H) TO JUST CLEAR HEEL OF

TRIP BODY (L), A DISTANCE OF ABOUT ONE INCH.

6. WHEN SPINDLE ASSEMBLY (H) HAS JUST CLEARED TRIP ASSEMBLY (L),RELEASE TRIP HANDLE (G) AND

FIRMLY PLACE BOTH HANDS ON END OF PRY BAR (E). AT THIS POINT PRY BAR WEIGHT IS ONLY 5-10 LBS.

7. WITH A FIRM GRIP, SLOWLY LET WEIGHT SHIFT TOWARD OPERATOR AS PRY BAR IS BROUGHT AROUND AND

END OF DOLLY BODY (J) IS GENTLY LOWERED TO THE GROUND. REPEAT THIS FOR ALL FOUR ASSEMBLIES.

G

L

I

Page 8

G