GT-3600 G+

2-1

Chapter II Controls and Gauges

Content of Chapter

This chapter describes engine, hydraulic, and electrical

controls. It also gives the basic operating procedures

for the GT-3600. Read this chapter thoroughly to

identify the controls and operations. Pay particular

attention to all safety statements.

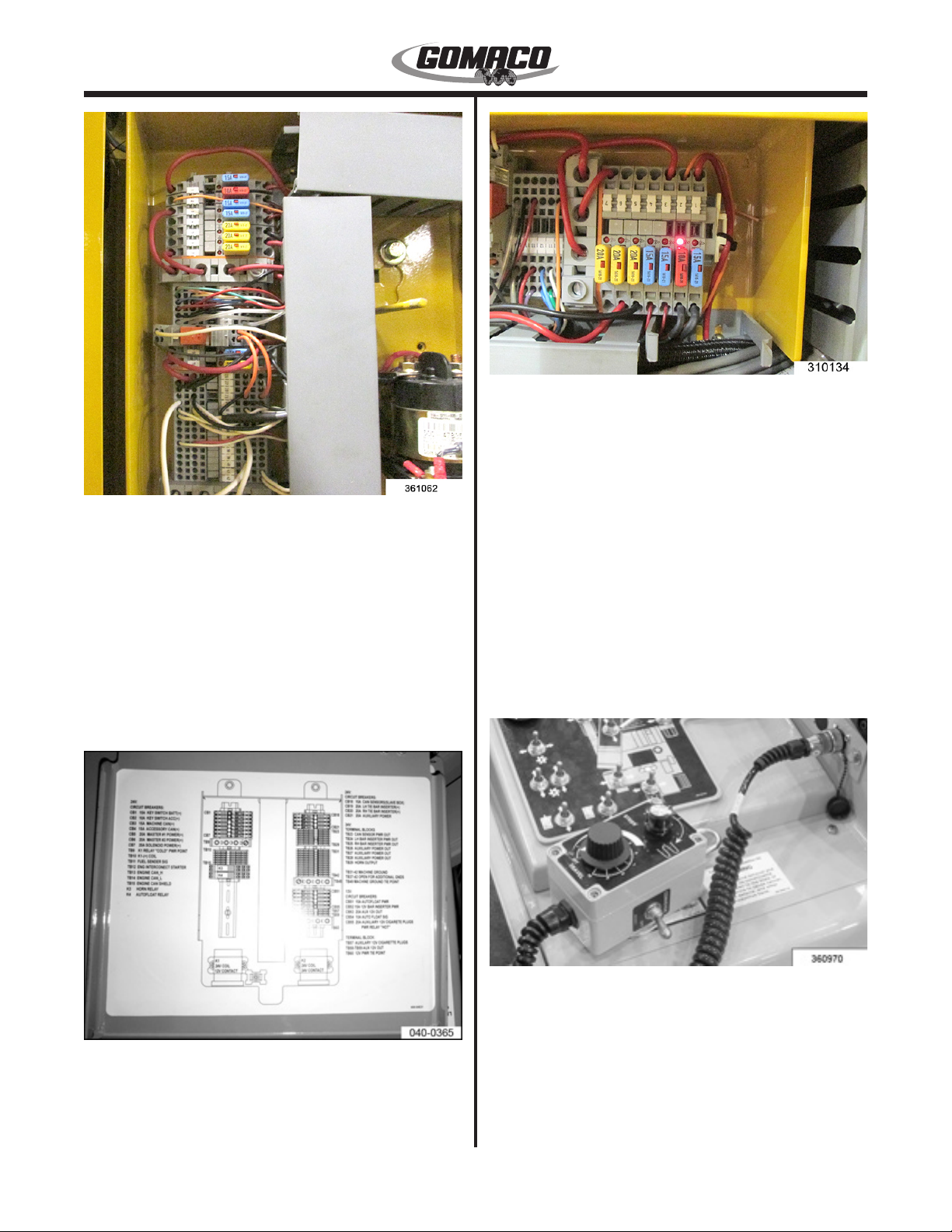

Control Console Cover

361064

The electrical control has a locking, sliding cover to

protect the switches and displays. To open, use the

key to turn the lock. Move the left handle toward the

key lock to unpin. Slide the panel upward. To close,

slide the cover all the way down. Move the left handle

away from the key lock to pin. Secure with the key

lock.

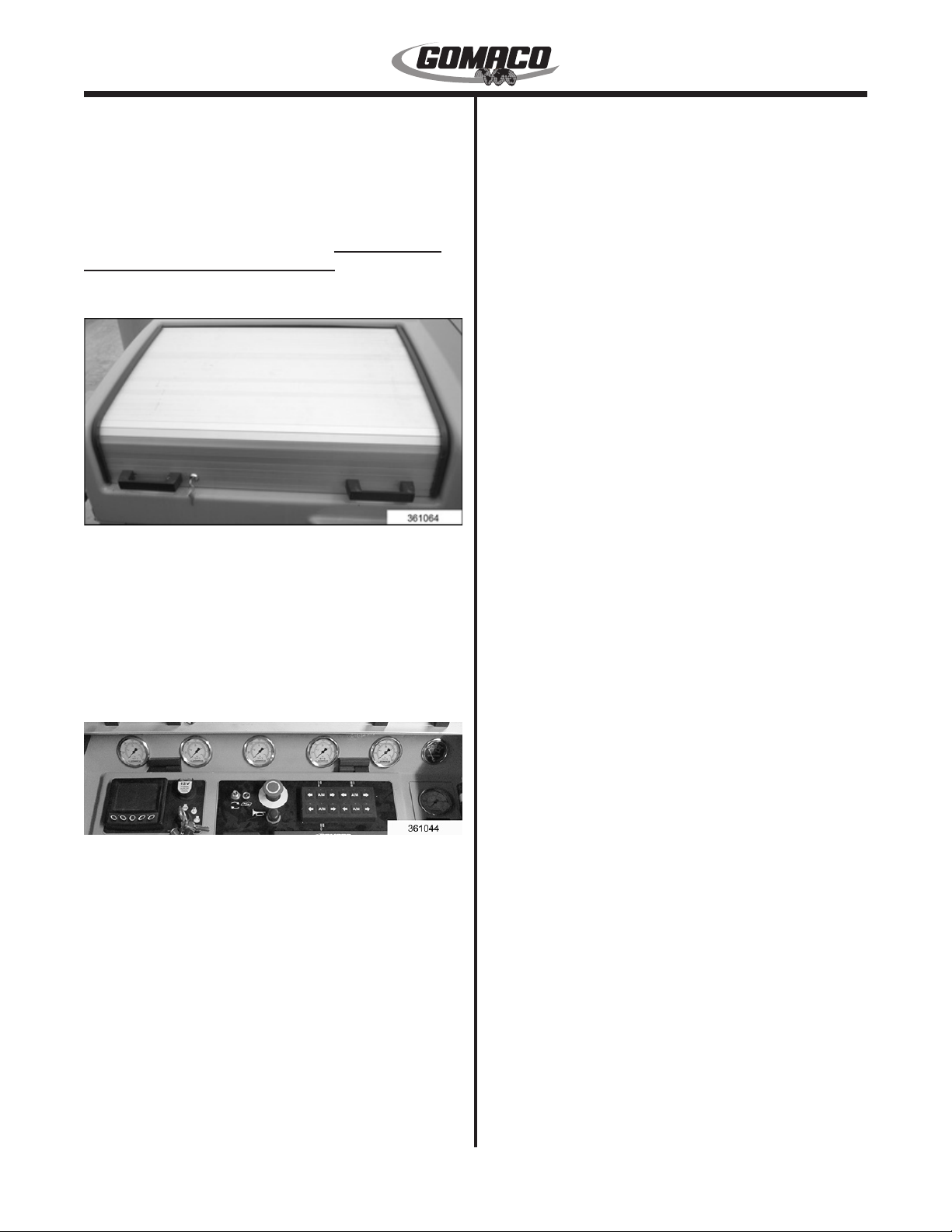

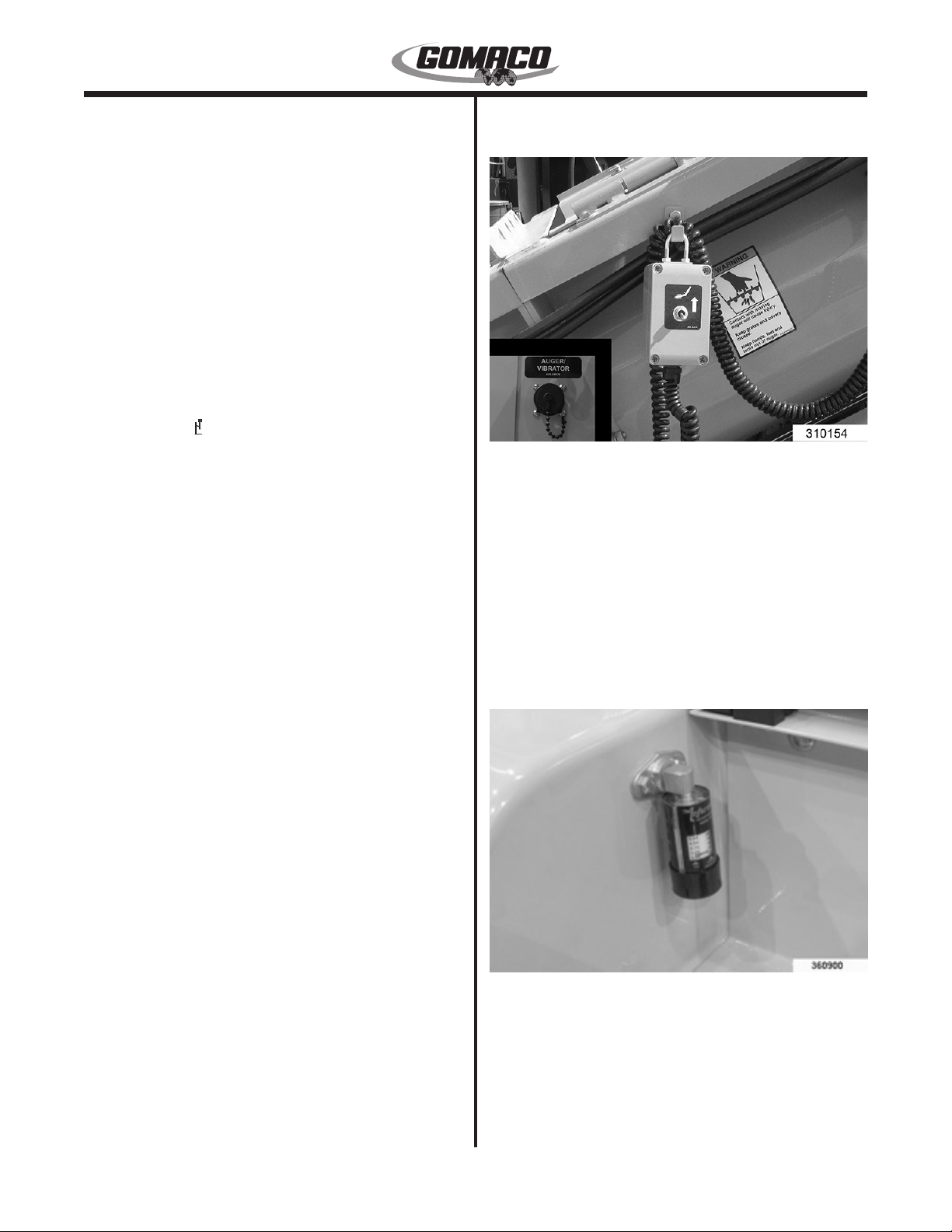

Hydraulic Controls and Gauges

361044

Vibrator Pressure Gauge: Monitors the amount

of pressure required to operate the vibrator circuit.

Amount of pressure required will depend on the

number of vibrators being operated and their speed.

Normal operating pressure range is 500 to 1500 psi

(34 to 103.4 bar). Stall pressure for the vibrator system

is 2000 psi (138 bar). One pump supplies oil to the

conveyor, vibrator and lift hydraulic systems.

Track Pressure Gauge: Monitors the amount of

pressure required to operate the track drive system in

forward or reverse. Normal operating pressure range

is 500 to 1800 psi (48 to 124 bar). Relief pressure

setting for the tractive system is 2500 psi (172 bar).

Conveyor Pressure Gauge: Monitors the amount of

pressure required to operate the charging conveyor.

Amount of pressure required will depend on the

amount of concrete on the conveyor. Normal operating

pressure range is 500 to 1800 psi (34 to 124 bar).

Relief pressure setting for the conveyor system is

2000 psi (138 bar). One pump supplies oil to the

conveyor, vibrator and lift hydraulic systems.

Note: If the machine is equipped with an auger

conveyor, the relief pressure setting on the pump

is increased to 2200 psi (151 bar).

Trimmerhead Pressure Gauge: Monitors pressure

required to drive the trimmer wheel. Normal operating

pressure range is 500 to 2500 psi (34 to 172 bar).

Pressure will vary depending on depth of cut, width

of cut, grade density and forward travel speed. Relief

pressure setting for the trimmer system is 3600 psi

(248 bar).

Lift Pressure Gauge: Monitors the amount of

hydraulic pressure available for machine elevation and

steering control. Normal lift pressure is 2000 psi (138

bar). One pump supplies oil to the conveyor, vibrator

and lift hydraulic systems.

Note: If the lift pressure drops below 1500 PSI

(103 bar), the machine control may become slow.

Hydraulic Oil Temperature Gauge: Monitors

the hydraulic oil temperature. Normal operating

temperature is 140° to 180° F (60° to 82° C)

depending on the ambient temperature. If the hydraulic

oil temperature rises above 195° F (90.5° C), locate

the cause of the overheating. Overheating can be

caused by excessive load on all systems on a warm

day, air ow through the oil cooler(s) restricted and/

or by a system that is constantly exceeding relief

pressure. The overheating can be corrected by

reducing the load on all systems on a warm day,

cleaning the oil cooler ns, and/or by reducing the load

on the various systems to maintain pressure below

relief setting.

Note: Excessive oil temperature may cause

serious damage to components.

Draw Bar Pressure Gauge: Monitors the amount of

pressure applied to the hydraulic cylinder holding the

front of the slipform mold down in contact with the

concrete. The regulated pressure range is 0 to 800 psi

(0 to 55 bar).

Drawbar Hold Down Pressure Control Valve: Used

to adjust the amount of pressure holding the front of

the slipform mold down on the concrete. Pressure