Overview

2

TC67U is a lo -cost multifunctional

programmable process indicator.

Its universal input accepts the most

common RTDs, thermocouples,

and linear signals. The device can be

equipped ith up to 2 alarm outputs,

hich can control various actuators

using ON/OFF control algorithm,

and the optional RS485 interface

enables net orking.

The TC67U indicator allo s

adjusting of the built-in digital filters

and the programmable output delay,

resulting in increased operation reliability

in case of industrial interferences.

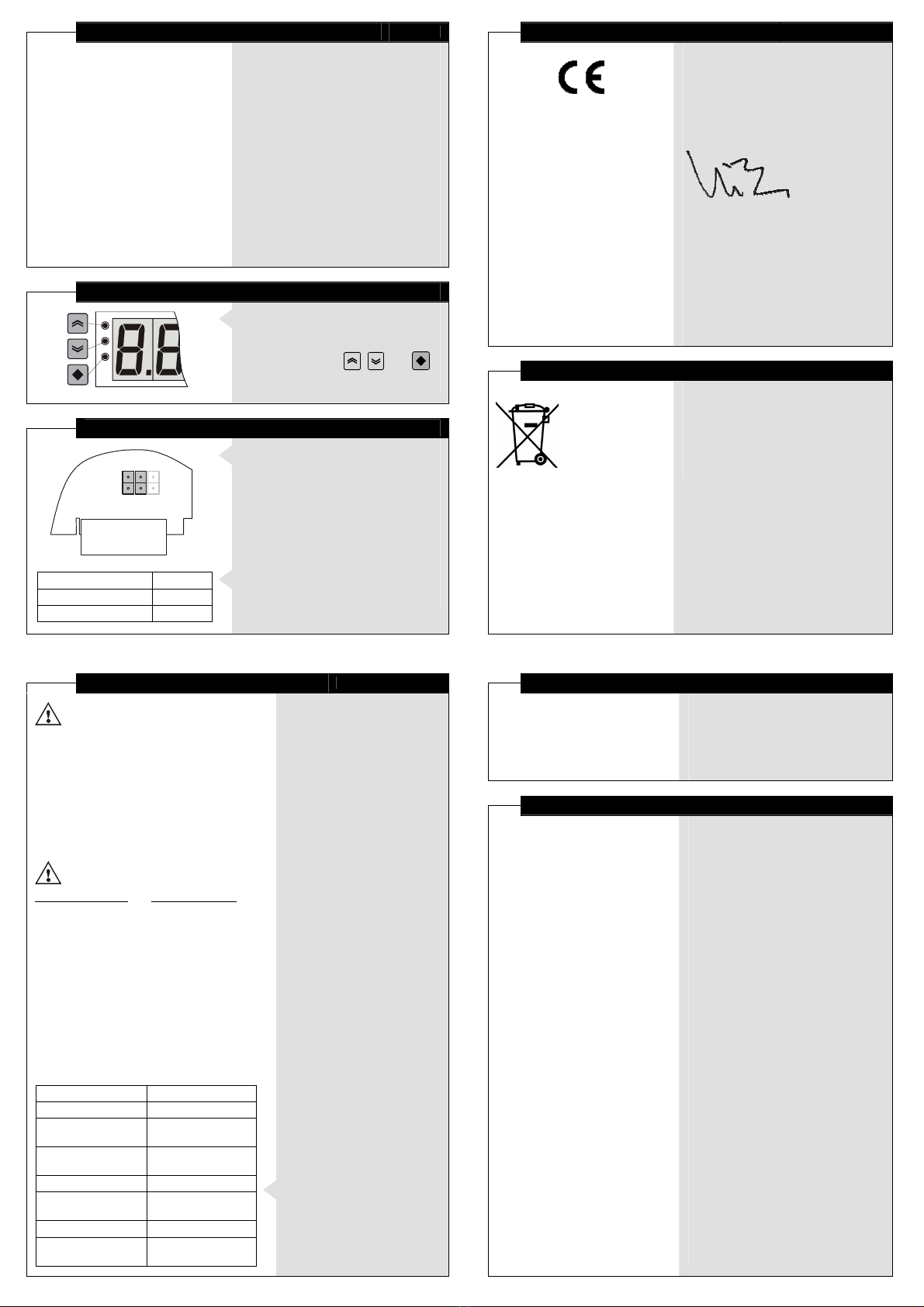

Controls

♦

Remove the front frame and panel

to reach the 3 hidden keys

next to the display.

♦

The key symbols , , and

are used further in this manual.

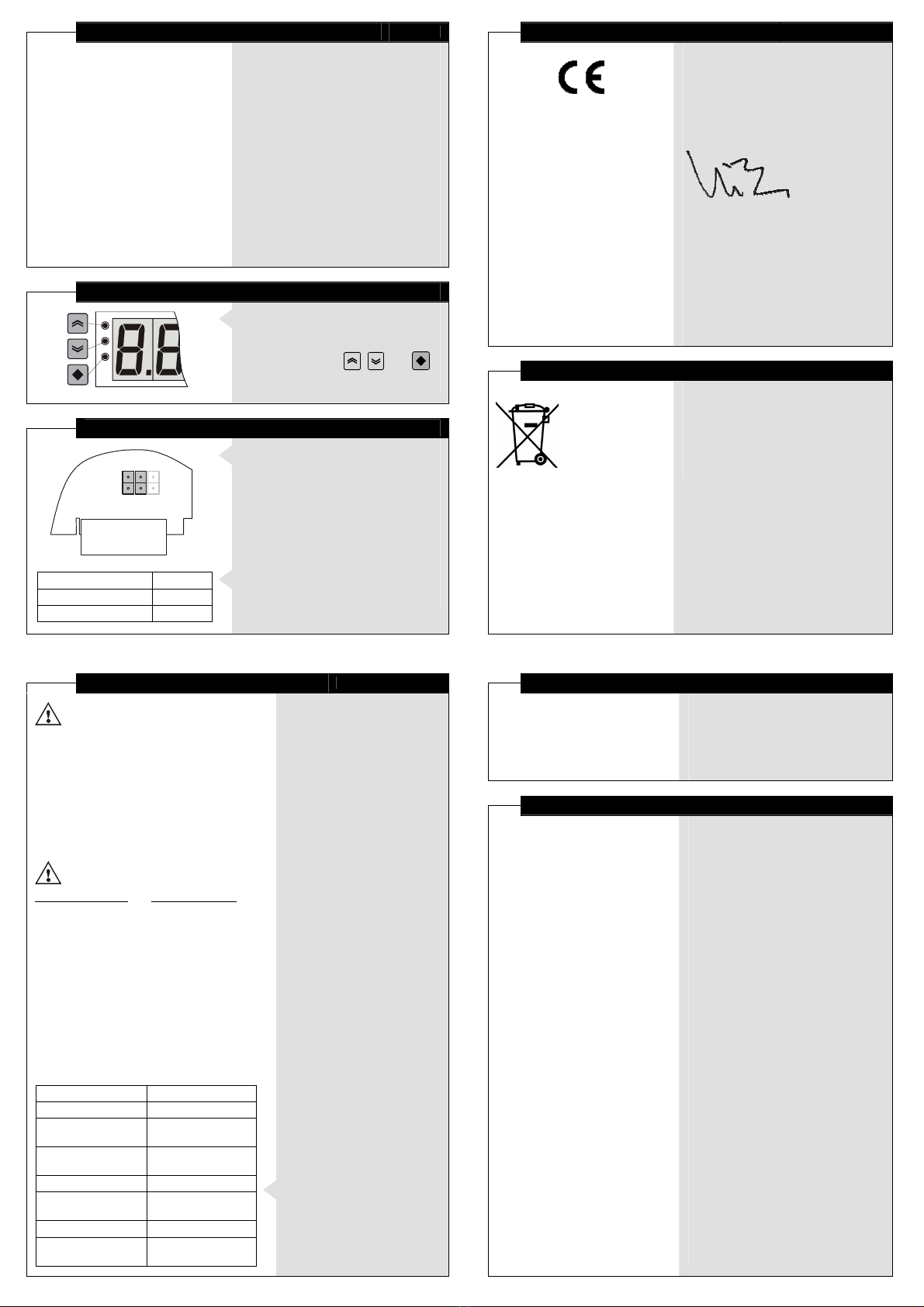

Input Setting

J1 J2

Input type short out

0...10 V J2

all the rest J1

♦

Open the case to reach

the configuration jumpers J1 and J2,

located on the main board.

♦

To set the desired input type,

short out the respective

configuration jumper.

Declaration of Conformity

15

The undersigned hereby declares,

on behalf of COMECO Inc.,

that this device has been manufactured

in compliance ith standards

EN 61000 and EN 61010,

and meets the requirements

of Directives 73/23/EEC and 89/336/EEC.

Vladimir Sakaliyski

CEO

COMECO Inc.

Waste Disposal

Do not dispose of

electronic devices

together with

household waste

material!

If disposed of ithin European Union,

this product should be treated

and recycled in accordance ith the la s

of your jurisdiction implementing

the WEEE Directive 2002/96

on the Waste Electrical and Electronic

Equipment.

Communication Protocol

14

Notes:

♦

TC67U adds 3 spaces

in the beginning of the response.

♦

TC67U returns decimal point

even when the value is integer.

♦

#13 (CR) is byte 0x0D;

#10 (LF) is byte 0x0A.

♦

The

U

255 command should be used

only in case just one slave is presented.

Protocol exa ples:

PC or other device: TC67U response:

activating device number 10

U10#13#10 ok.#13#10

reading filter time

f.t#13#10 f.t 0015.#13#10

riting filter time of 30

f.t 30#13#10 f.t 0030.#13#10

reading input value of 27.5

p.v#13#10 p.v 027.5#13#10

invalid command.

command not recognized

parity rror. parity error detected

not a numb r. attempt to write symbols

for numerical parameter

point rror. value resolution greater

than parameter’s one

out of rang . value out of range

unit is busy. writing is allowed only

to device at Basic level

r ad only. parameter is read-only

can't sav . problem with writing

in non-volatile memory

♦

The device remains active

until it receives another

U

х

command, but ith different

device address, a FAL

error, or ith reset.

♦

Any Baud Rate value change

through the communication

interface also deactivates

the device.

Reading fro a device

♦

If the frame consists of only

one ord, it is recognized

as a command for reading.

♦

The device responds to it by

returning the same ord and

its value, according to Table 2.

Writing in a device

♦

If the frame consists of

t o ords, it is recognized

as a command for riting.

♦

With riting, transferred

are the same t o ords

that ould have been

received at the respective

command for reading

from the device.

♦

After successful riting,

the device responds ith

the respective command

for reading, except for

the baud command.

Other device responses

♦

When Error Info value is -1,

the device substitutes any

command for rror reading.

♦

TC67U responses in case

of incorrect protocol use

are given on the left.

Reset

To reset the device,

send command r s t.

Mounting

3

♦

Place TC67U into a 136x66 mm

panel cut-out.

♦

Tighten it into place using

the enclosed mounting brackets.

Electro-Magnetic Interference (EMI) Issues

♦

All signal ires must be shielded.

They must not be packaged together

ith po er cables!

♦

Never lay the signal ires close

to inductive or capacitive noise

sources, such as relays, contactors,

motors, etc.!

♦

All shields have to be grounded ONLY

at one end, as closer as possible

to the indicator terminals!

♦

Avoid sharing supply lines

ith po erful consumers,

especially ith inductive loads,

s itched on and off.

♦

To stop un elcome interference

signals entering through the po er

supply lines, use shielded 1:1

isolation transformer!

♦

Shunt all s itched (not only those

s itched by the indicator) inductive

consumers ith special suppression

net orks: RC group and varistor -

for AC loads, or diode - for DC loads.

♦

If the indicator operates in a very

po erful EMI area, it has to be

mounted inside a grounded metal

shielding box!

♦

To protect the interface from electro-

magnetic disturbances, follo

the RS485 standard guidelines.