Parameter Programming 5

Some parameters

are accessible only

when the respective

functionality is installed.

(see 'Specifications').

- Changing

Point Position value

reflects on the real value

of all parameters

with ISU!

E.g.: changing

Point Position value

from (0) to (0.0)

would change

a Set-point value

of 100 to 10.0!!!

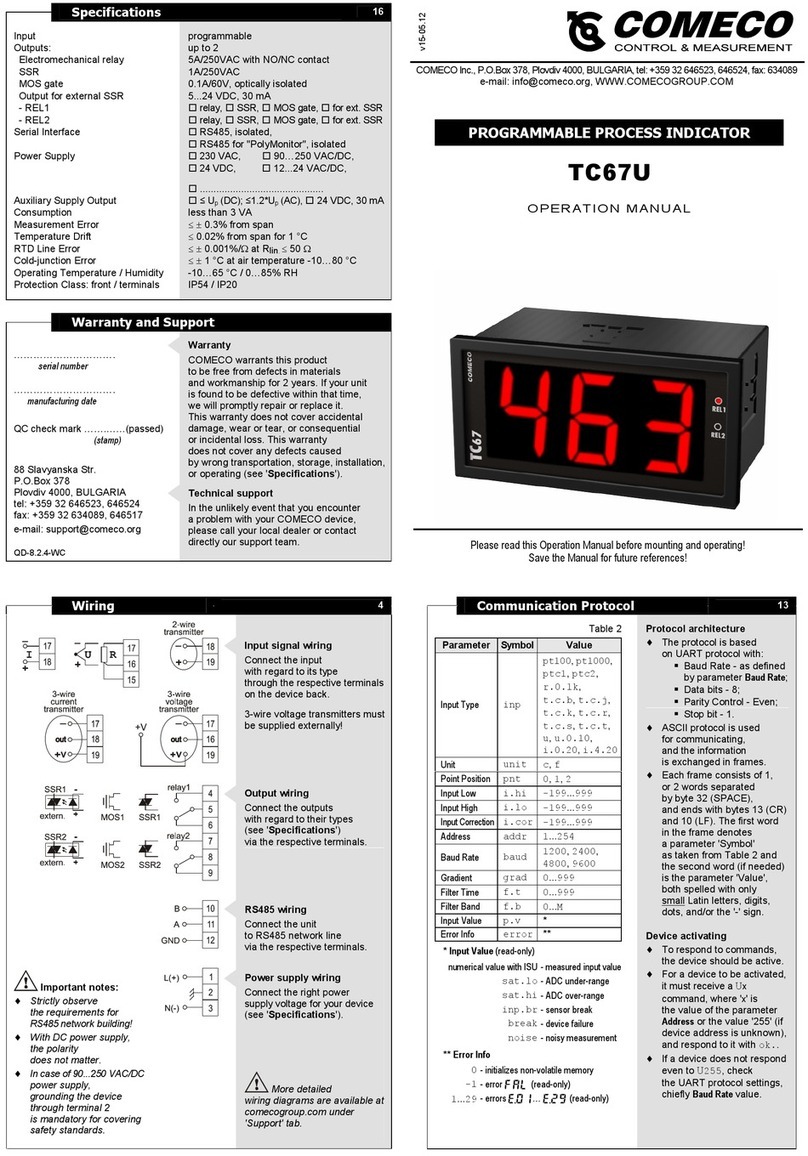

Device parameters

TC67U is a programmable device whose

service behavior is determined by a set

of parameters. All the parameters, along

with their names, symbols, and value ranges,

are given in Table 1.

Setting numerical parameter value

♦Enter parameter value adjustment mode

(see 'Program Levels').

♦The whole part of the value together with

the left zeroes appears on the display,

and the rightmost digit blinks.

♦To select another digit, press .

♦The 3 rightmost digits can accept values

from 0to 9, and the leftmost digit

can also accept the values -and `.

♦To increase or decrease the blinking digit

value, use respectively or

.

♦Confirm the adjusted value by pressing

simultaneously + or + .

♦If the new value has not been confirmed

and no key has been pressed for a certain

period of time, value adjustment

automatically ceases, and the parameter

retains its initial value.

Setting symbolic parameter value

♦Enter parameter value adjustment mode

(see 'Program Levels').

♦Read the blinking parameter value.

♦To change the value, use or ,

and to confirm, press +

or + .

♦If the new value has not been confirmed

and no key has been pressed for a certain

period of time, value adjustment

automatically ceases, and the parameter

retains its initial value.