6

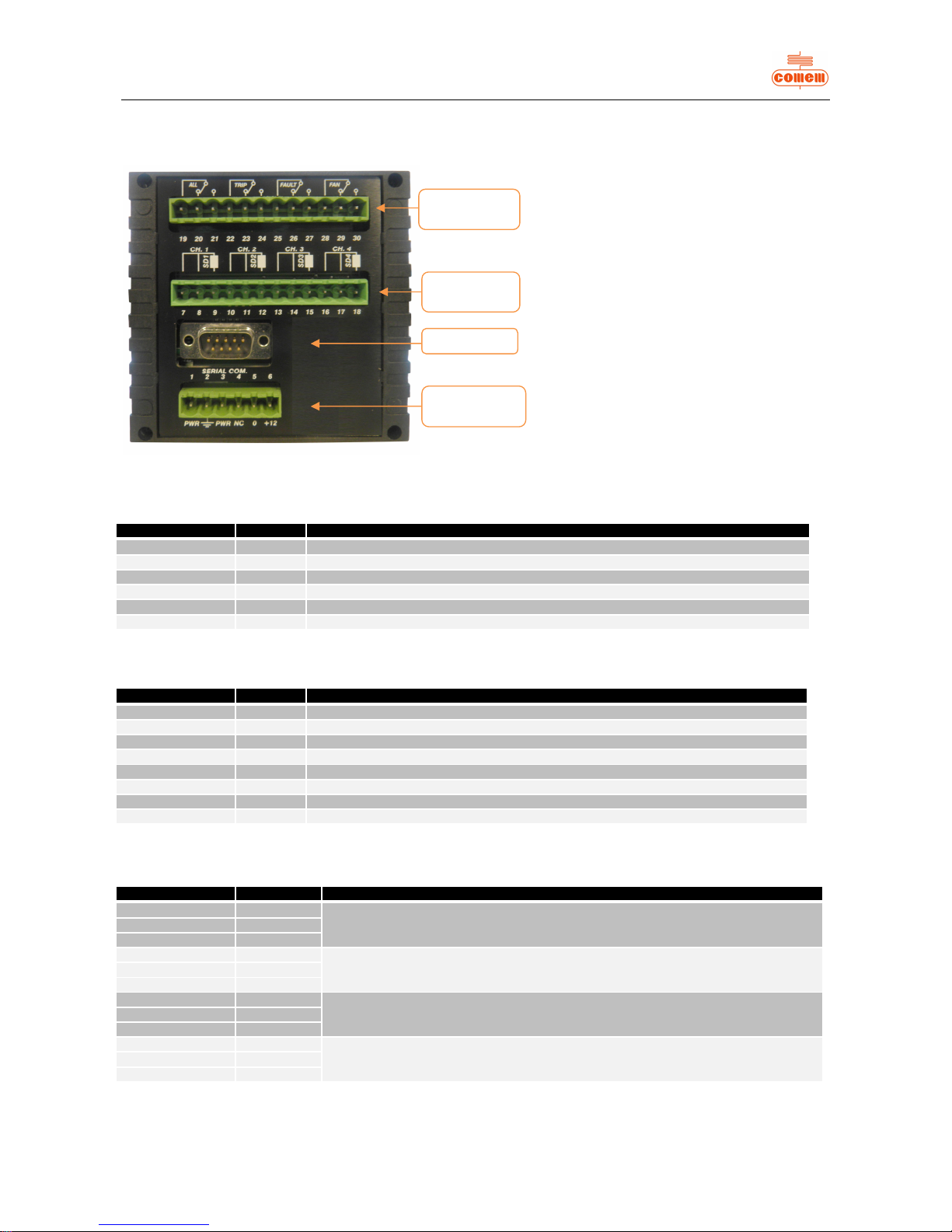

2.3 Main characteristics

System programmed directly from the front panel.

Each channel can be selected independently.

Automatic display of max. temperature and relative channels.

Software configuration for controlling inputs and outputs.

Maximum temperature memorized for each channel.

Relay test command.

Programmable ventilation settings.

Up to four channels during activation.

Two thresholds: one alarm threshold and one release threshold with change-over contacts.

Automatic probe fault indicator with change-over contact.

2.4 Operation

The software immediately detects, saves and signals any temperature irregularities in the automatic mode.

The entire programming procedure controls both the requests and data entered in the smart mode.

The Temperature Control Unit settings are standard factory values that can be modified as required. The alarm threshold is 140°C with

release at 160°C and ventilation excluded.

The 19 LEDs on the display allow the MB 103 unit to clearly signal and handle information concerning the temperature situation.

2.5 Temperature display

The Temperature Control Unit always switches on in the automatic mode.

To change the display, press

: when the key is pressed, the operating mode of the instrument changes in sequence:

“AUTO”, “MAN” and “MAX”

AUTO: Automatic operation

Both the maximum temperature and the channel this measurement comes from are

displayed in the automatic operation mode.

MAN: Manual operation

The temperature of each sensor is displayed in real time in the manual operation mode. The arrow keys are used to

scroll the active channels.

MAX: Maximum operation

The maximum temperature reached by each probe is displayed in the maximum operation mode. The arrow keys are used to

scroll the active channels.

2.6 Programming

Press the key for 3 seconds to program.

The “PROG” LED will light up on the instrument panel and the letter “S” followed by a number will appear on the display.

Use the arrow keys to re-program the operating mode of the unit as shown in the table below.

The table contains four pre-defined profiles for programming the active channels and a fifth profile.