2 IE-SNC-T4111-06

Instruction manual for use of T4111 transducer

Transducer is designed for temperature measurement at °C or °F by means of an external

temperature probe with Pt1000 sensor. Measured temperature is converted to linearized unified

signal 4-20 mA. Measured values are displayed on LCD display. It is possible to switch OFF

the LCD at all. Current loop has two-wire connection and requires power from evaluation device.

All transducer setting is performed by means of the PC connected via the optional SP003

communication cable (not included in delivery). Program Tsensor for transducer setting is available

to download free at www.cometsystem.com. Program enables to assign temperature measuring

range. It supports make the adjustment of the device too. This procedure is described at file

„Calibration manual.pdf“ which is installed commonly with the software.

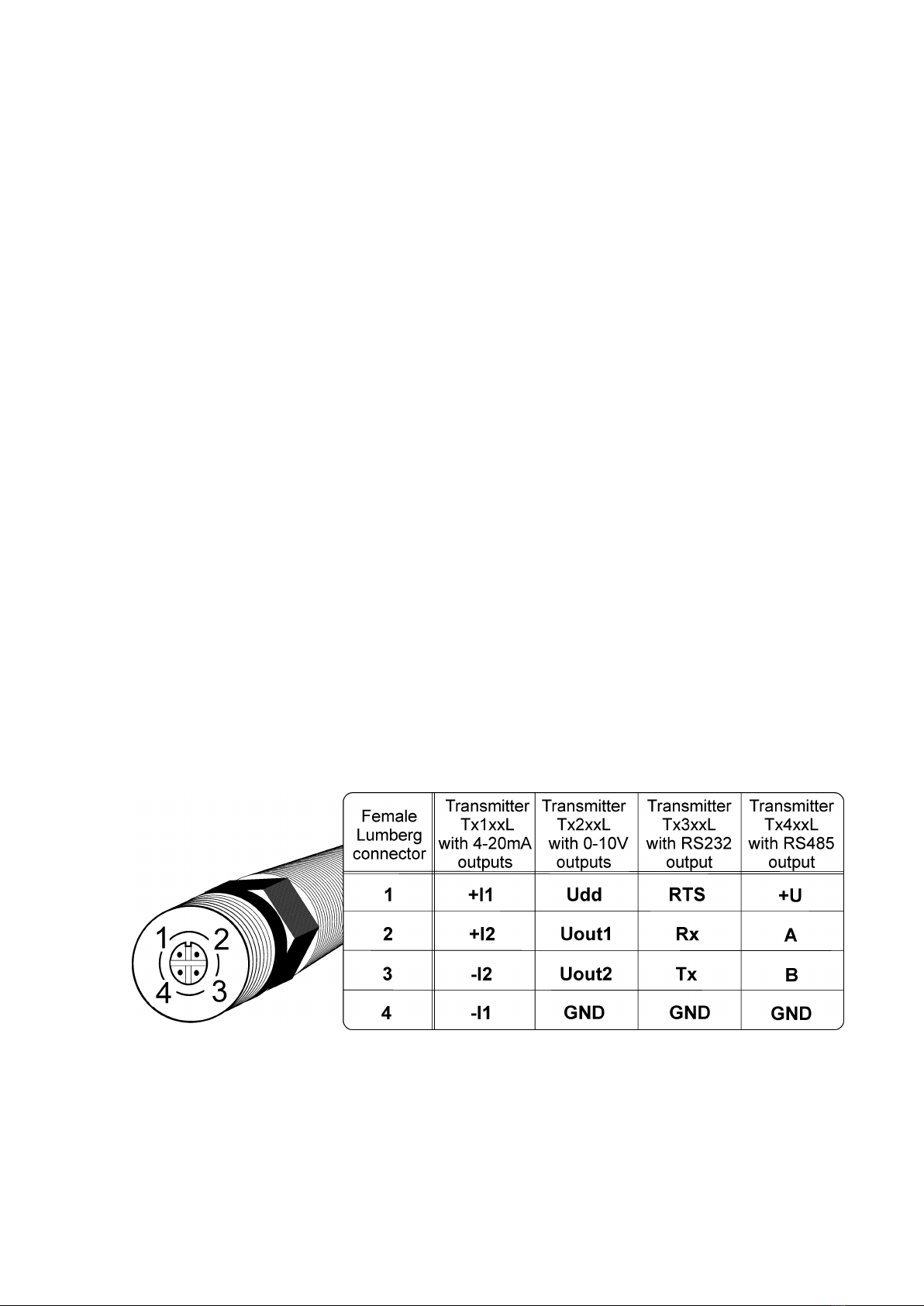

Transducer version TxxxxLwith watertight male connector instead of a cable gland is

designed for easy connection/disconnection of the output cable. The protection of male Lumberg

connector RSFM4 is IP67.

Models marked TxxxxZare non-standard versions of the transducers. Description is not

included in this manual.

Please read instruction manual before the first device connection.

Device setting from the manufacturer

Transducer is set from the manufacturer to the following parameters:

value at output I1: 4 –20 mA corresponds -200 to +600 °C

display: switched ON

Modification of the setting is possible to do by means of the PC using procedure described

at the end of this document.

Installation of the transducer

Transducer is designed for wall mounting. There are two mounting holes at the sides of

the case. Interconnection terminals of T4111 are accessible after unscrewing four screws

and removing the lid. Lace the cable through a gland at the case wall. Connect the cable to terminals

with respecting the signal polarity (see figure). Terminals are self-clamping and can be opened by

a suitable screwdriver. For the opening, insert the screwdriver to upper terminal hole and lever by

him. Do not remember to tighten glands and case lid with inserted packing after cables connecting.

It is necessary for warranting of protection IP65. Connect complementary female connector

for T4111L transmitter in accordance with the table in Appendix A of this manual.

It is recommended to use shielded twisted copper cable, maximal length 1200m. The cable

must be located at indoor rooms. The cable should not be led in parallel along power cabling. Safety

distance is up to 0.5 m, otherwise undesirable induction of interference signals can appear. Outside

diameter of the cable for T4111 device must be from 3,5 to 8 mm (e.g. SYKFY), for device T4111L

with respect to the female connector. Do NOT connect shielding at connector side.

External temperature probe should be of „shielded two-wire“type. For leading of the cable

same recommendations are valid as for current loop cable, i.e. cable should be located as far

as possible from potential interference sources. Maximum probe cable length is 10 m. Connect

probe cable shielding to proper terminal and do not connect it to any other circuitry and do not

ground it. If connected probe is equipped with metal stem, we recommend using probes with metal

stem not connected to cable shielding. Or else it is necessary to arrange metal stem is not connected

to any other circuitry.

Electrical system (wiring) may do only worker with required qualification by rules

in operation.