TB2

8

A0884-5.0 en/deHBM

2 Application

The transducer can measure static and dynamic torques in non‐rotating op

eration. The nominal (rated) torques lie between 100 N⋅m and 10 kN⋅m.

Transfer torque transducer

The main applications are the transfer of torque, e.g. when calibrating refer

ence transducers in test and calibration equipment, and the comparison of ref

erence standards in different calibration laboratories.

A high degree of comparability is important in transfer transducers. Compara

bility is, with regards to transfer of torque, a parameter for different observers,

test conditions, laboratories, installation and time situations. The same instal

lation conditions must be reproduced as in the calibration with reference stan

dard or calibrated with appropriate adapters when transfered.

Reference torque transducer

Reference torque transducers are installed in a calibration device and subse

quently the entire calibration unit is qualified or certified, for instance with a

transfer torque transducer. The exact sensitivity of the transducer is therefore

of secondary importance.

General torque measurements in non‐rotating operation

Due to the high mechanical loading capacity, the permissible oscillation width

of 200 % (160 % at 3 to 10 kN⋅m) of the nominal (rated) torque and the com

pact design, this transducer is also high suitable for applications in test ma

chines for component tests (rotation reversal cycling). A design with degree of

protection IP67 per EN 60529 is optionally available.

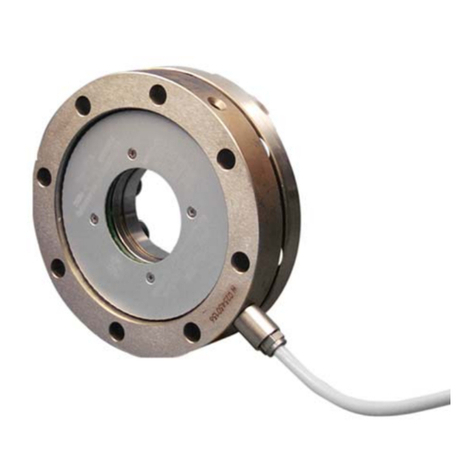

3 Structure and mode of operation

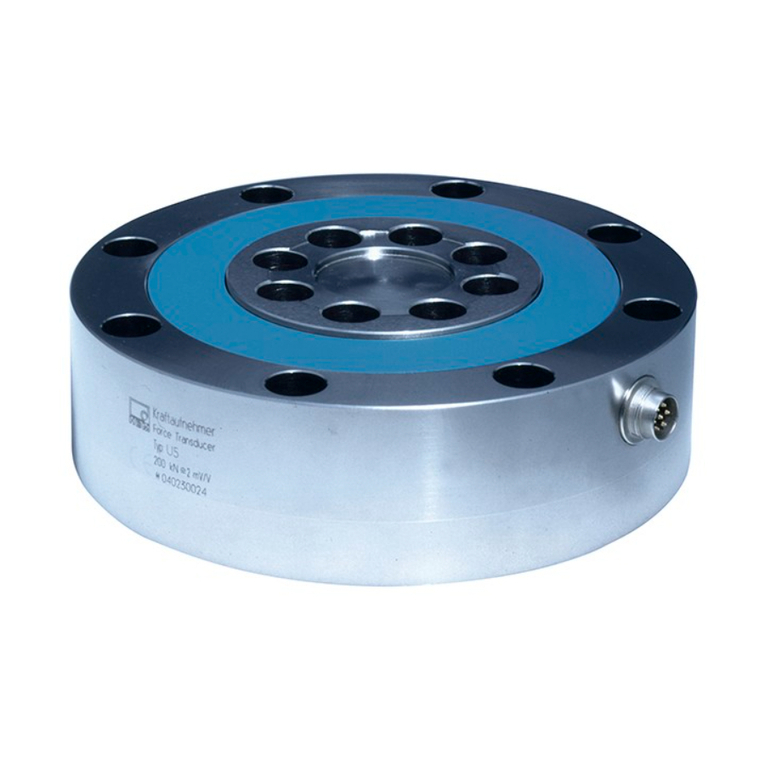

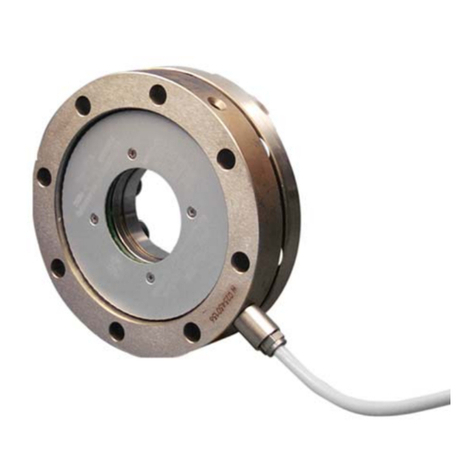

The torque reference transducer consists of a measuring body, installed with

strain gages, with a flange‐type torque application. The SG are arranged so

that an optimal torque flow is ensured between the flange and the SG installa

tion point.