3

I .Safety Requirement

WARNING: FAILURE TO READ AND FOLLOW THE SAFETY INSTRUCTIONS IN THIS

OWNER’S MANUAL BEFORE INSTALLING OR USING YOUR ATV/UTV WINCH COULD

RESULT IN DAMAGE TO YOUR WINCH AND SERIOUS OR FATAL INJURY!!

►General Rules

Check all safety and environmental conditions prior to and during use.

Before use, ensure that you are familiar with all winching performance and operation such as speed

& direction.

A wire/synthetic rope should be replaced if it shows signs of excessive wear, broken strands,

corrosion or any other defects.

The winches’ duty rating is S3 (intermittent – periodic

If the winch fails to pull a load under normal conditions, stop the operation within 30 seconds

otherwise motor damage may occur.

Ensure that the winch is connected to the correct voltage of 12vdc only.

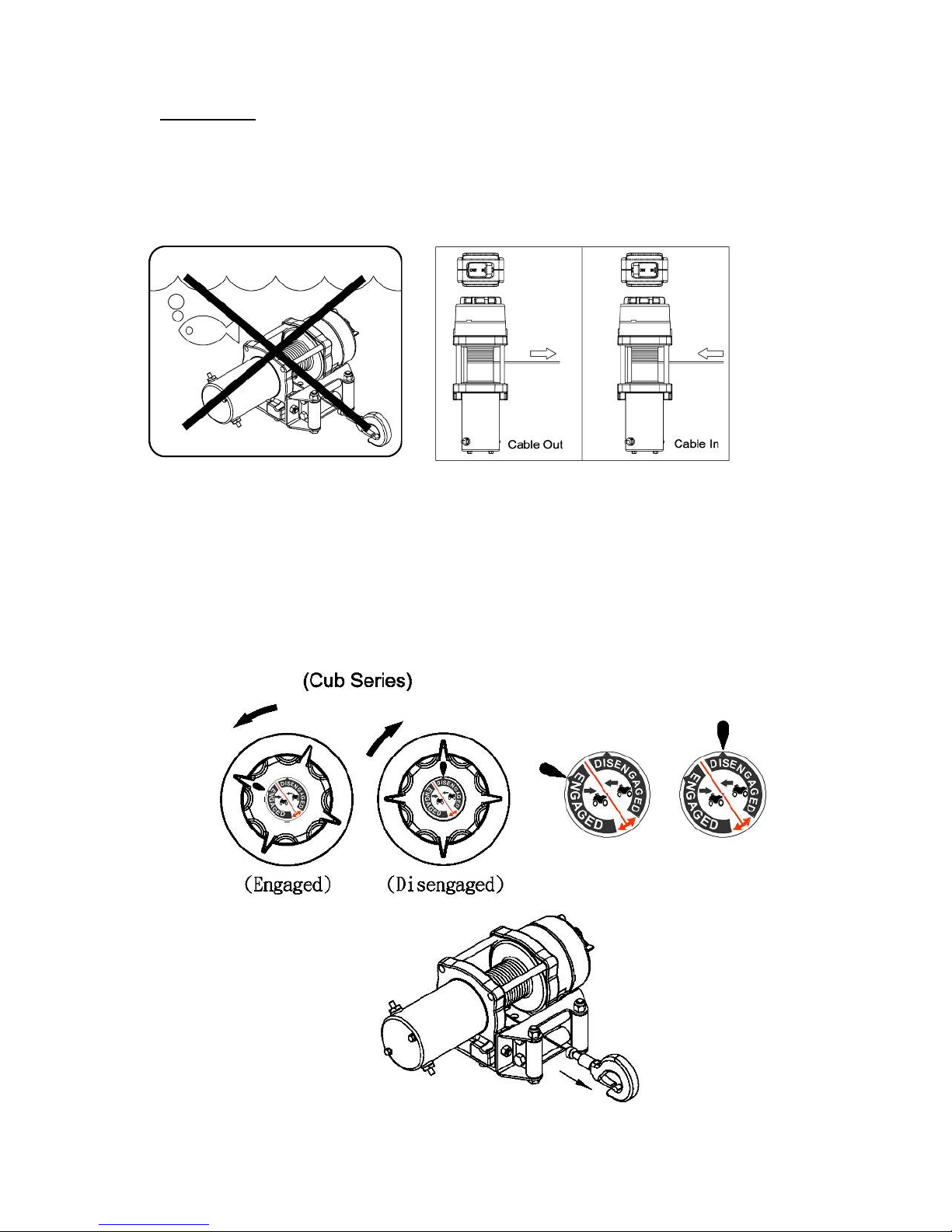

Check that the clutch shifter is in the “Engaged” position during and after use.

Remove the remote control from the winch when not in use.

Do not wrap the wire/synthetic rope around the load and back onto itself. Always use a strap to

ensure that the wire/synthetic rope does not fray or kink.

Keep hands and clothes away from the winch, wire/synthetic rope, and fairlead during operation.

Never unplug the remote control and battery leads when winching a load.

To avoid insufficient power when winching a load, the vehicle should be running and in neutral.

When winching a heavy load, lay a heavy blanket or jacket over the wire/synthetic rope near to the

hook end

If excessive noise or vibration occurs when running, stop the winch immediately and return it for

repair.

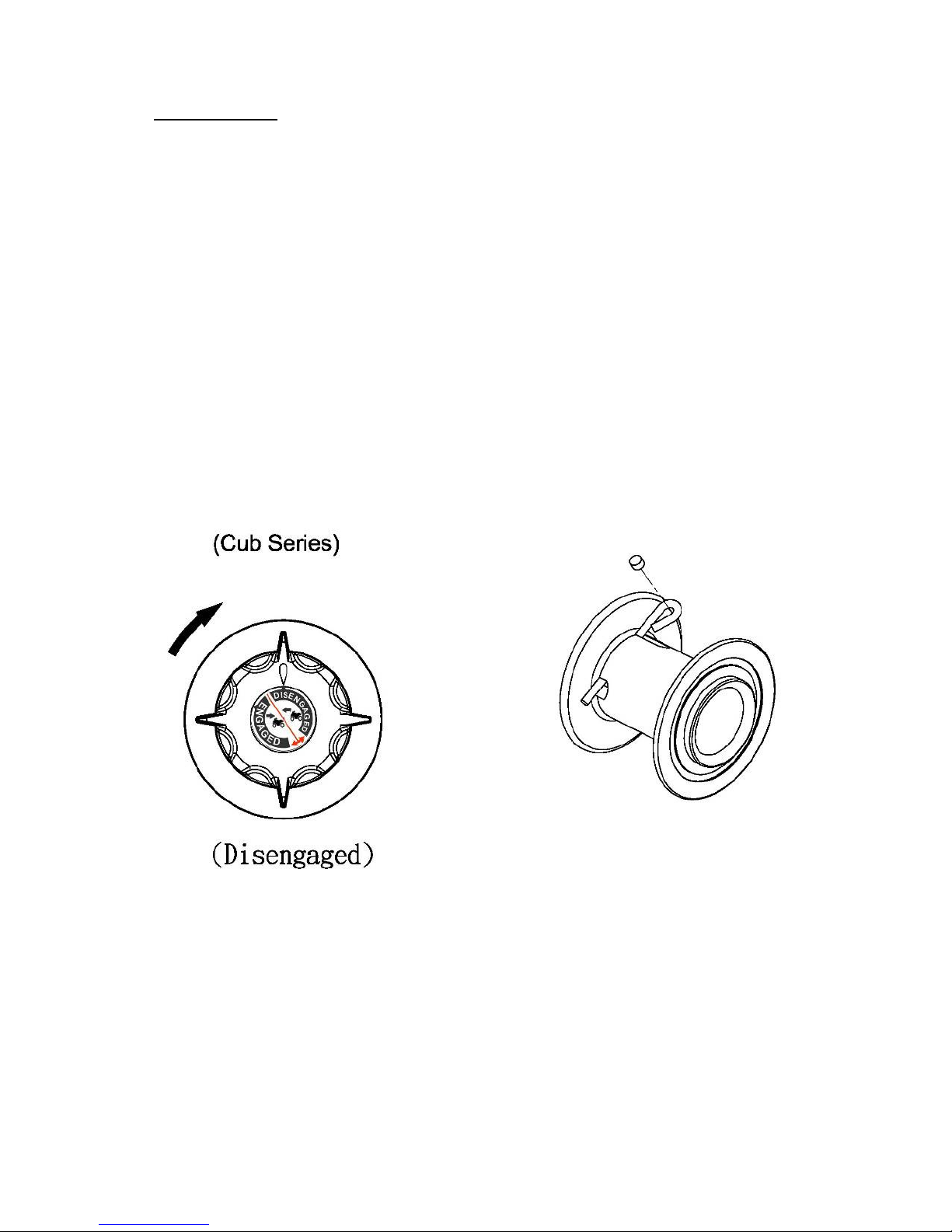

If a clutch can’t be properly locked in the “Engaged” position, rotate the drum to have the clutch

coupled to the gear train

. It is very important that the winch shall be mounted on a flat surface, with the wire/synthetic rope

feeding form the bottom of the drum.