Comfort Flex

Rev: February 5th 2016

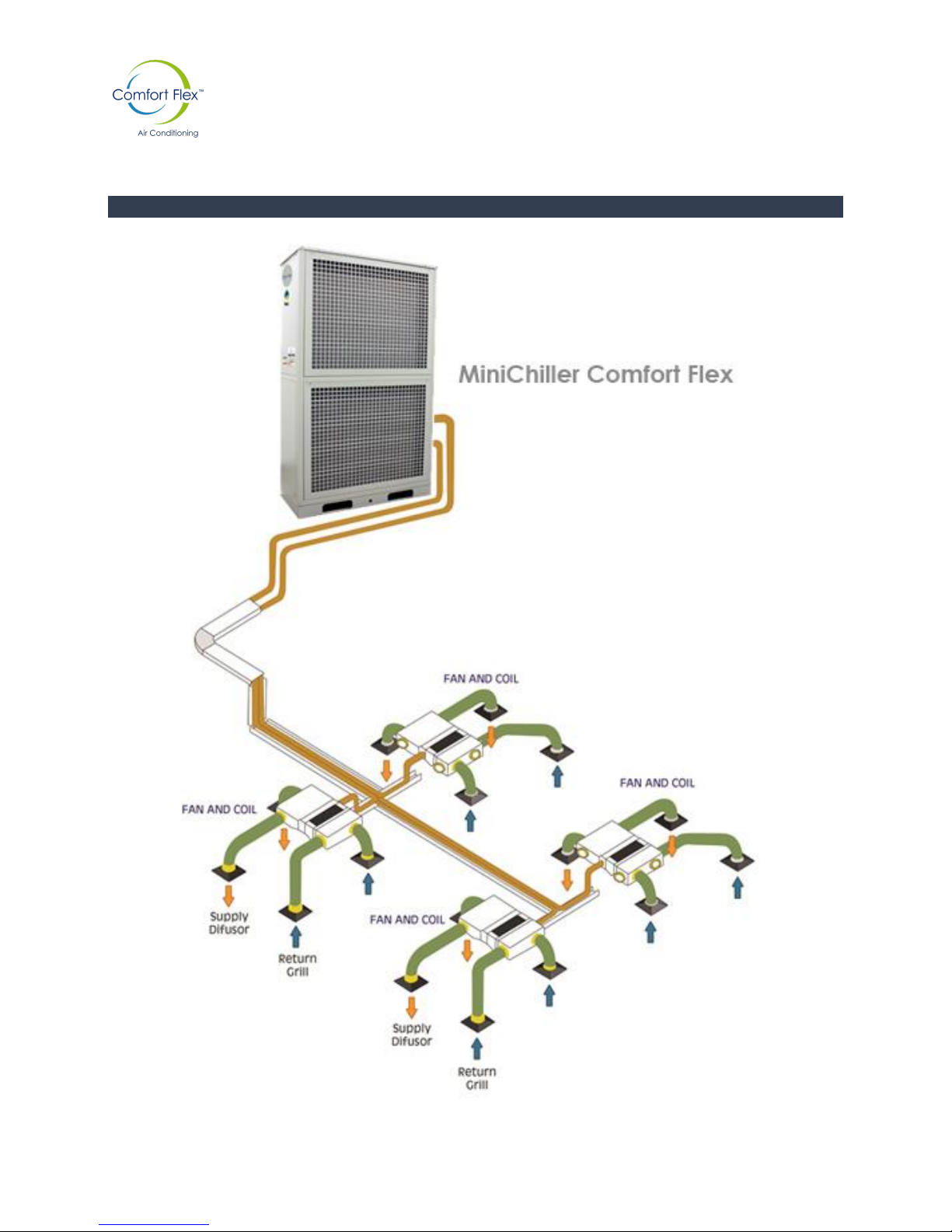

GENERAL DESCRIPTION

Comfort Flex chiller units are built with control and design in

mind, assembled with technically specialized control

software. Some of our features are in house production of all

piping and wiring, scroll type compressors, new generation

evaporators, air cooled condensers, optional hydraulic

components, and several safety and security protections.

Our units are ecofriendly and operate with R-410A

refrigerant.

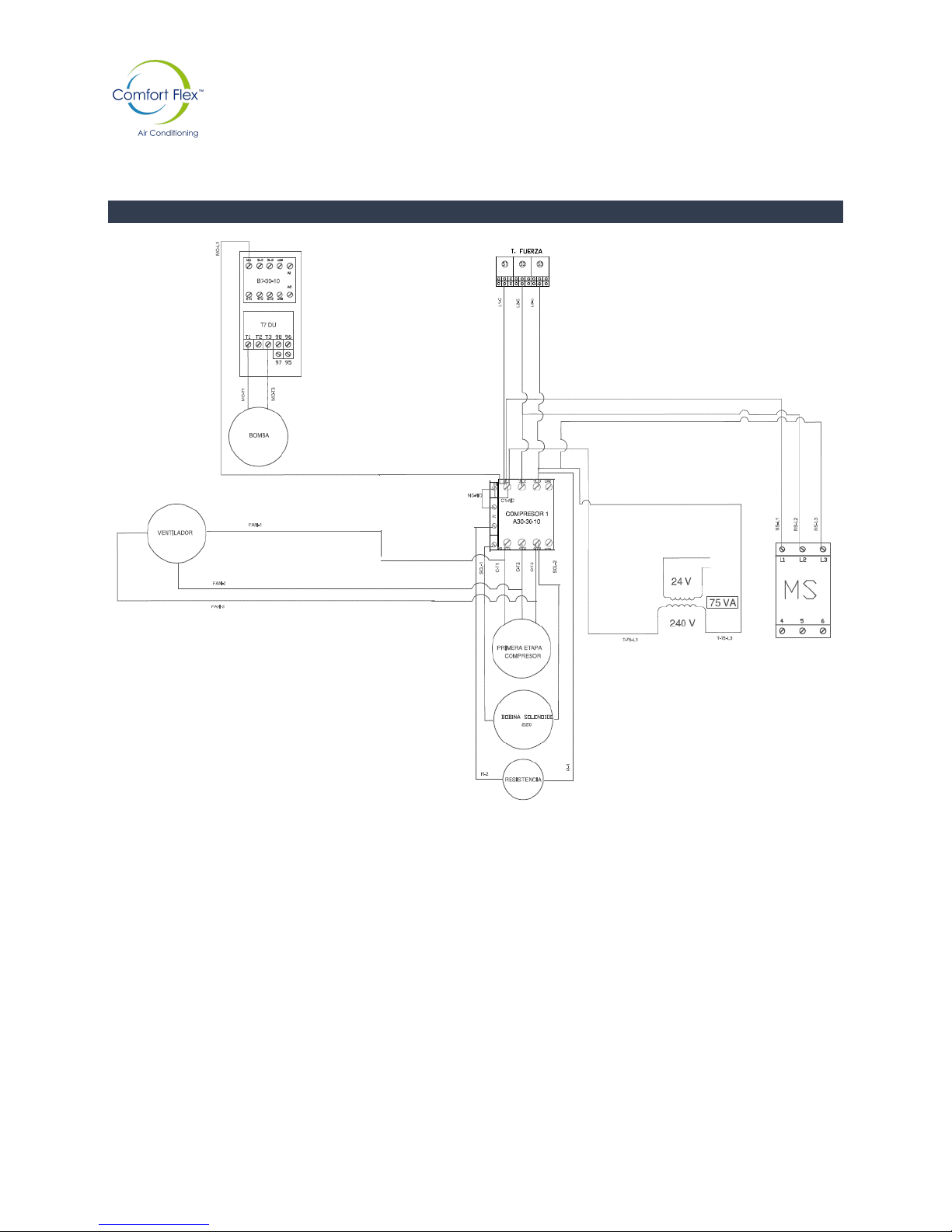

ELECTRICAL COMPONENTS

All units are equipped with a control panel, security anti-

theft devices, internal and external overheating protection,

compressor drive protection, flow protection, freezing

protection and electrical failure protection. The control

panel has LED operation indicating lights.

EQUIPMENT

Fully Factory assembled, and individually run tested with all

required piping, wiring, and controls for operation.

HYDRAULIC COMPONENTS (OPTIONAL)

WATER PUMP

The drive in the water pump is TEFC (Totally Enclosed

Fan Cooled) and has anti-corrosive coating on the

housing.

MODULE

Steel base, anti-corrosive painted steel panels. Easy Access

for maintenance without compromising the unit´s stability.

The control unit allows the connection of the unit to the

INTERNET, and allows the user to visualize all the unit’s

operating information, such as variable graphics, tendencies

cycle time, diagnosis of components, alarms, etc. Access to

this information renders a more efficient operation and

system control.

COMPRESSORS

Two stage Scroll type hermetic compressors.

CONDENSERS

High efficiency microchannel with optional anti-corrosive

coating.

EVAPORATORS

Compact Plate Heat exchangers with thermally isolated

hydraulic refrigerant pipes and connections.

FANS

Low vibration and noise Axial Fans.

REFRIGERATION CONTROLS

The units are equipped with solenoid valves, expansion

valves, dehydrator, and service valves.