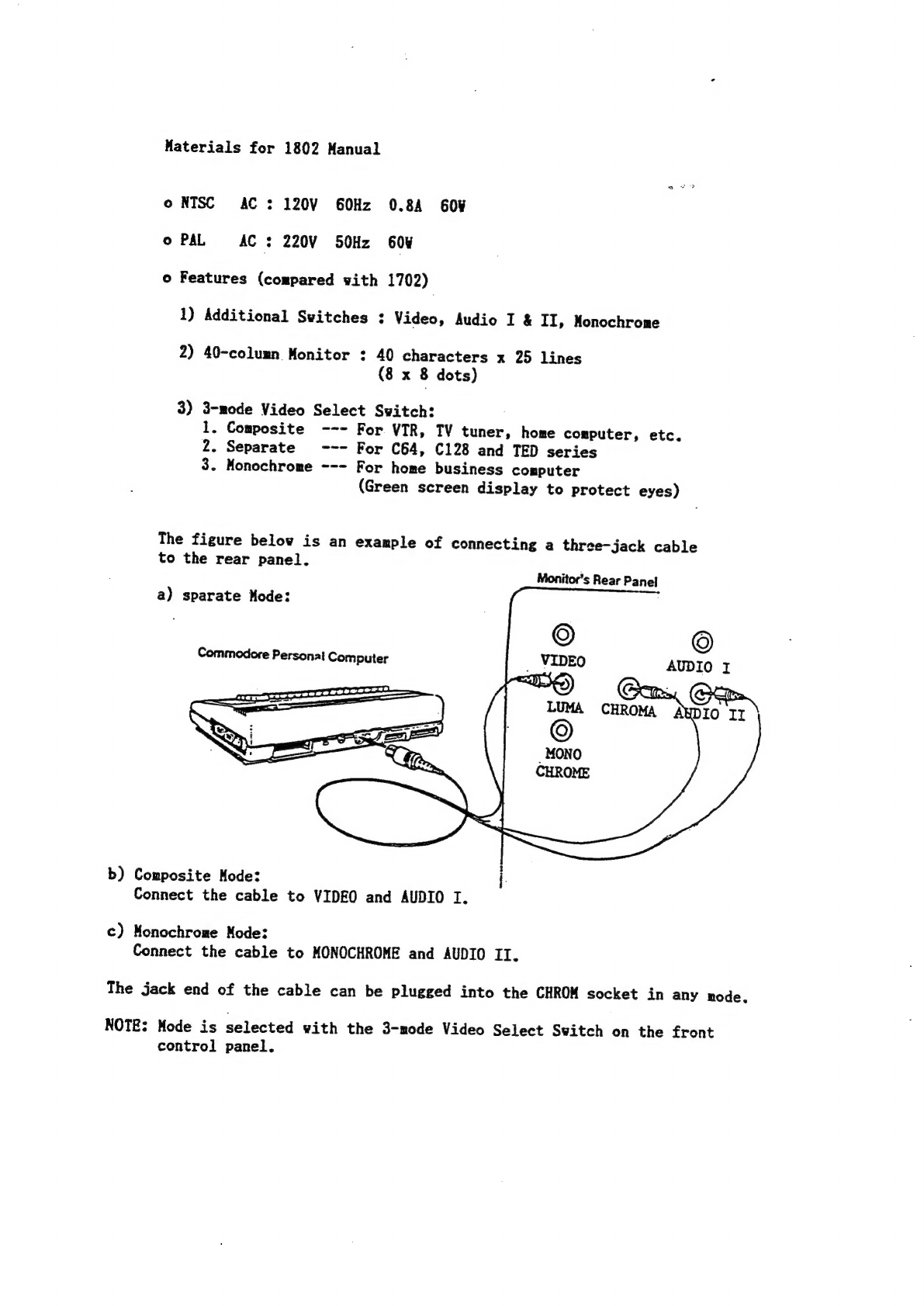

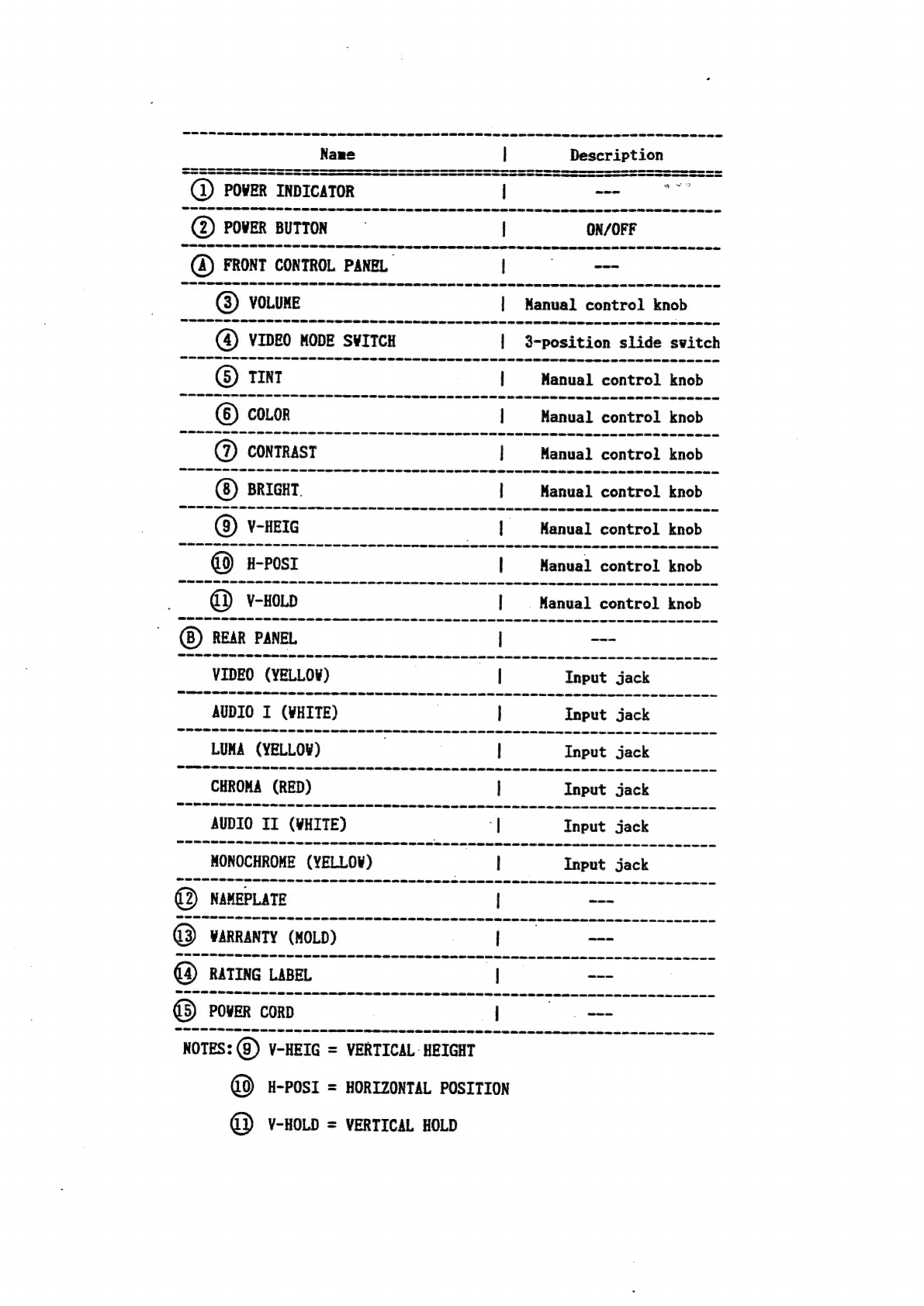

Commodore 1802 User manual

Other Commodore Monitor manuals

Commodore

Commodore 1084S User manual

Commodore

Commodore 1960 User manual

Commodore

Commodore 1084S User manual

Commodore

Commodore 1702 User manual

Commodore

Commodore 1902A User manual

Commodore

Commodore 1084S User manual

Commodore

Commodore 1902A User manual

Commodore

Commodore 1084S-P1 User manual

Commodore

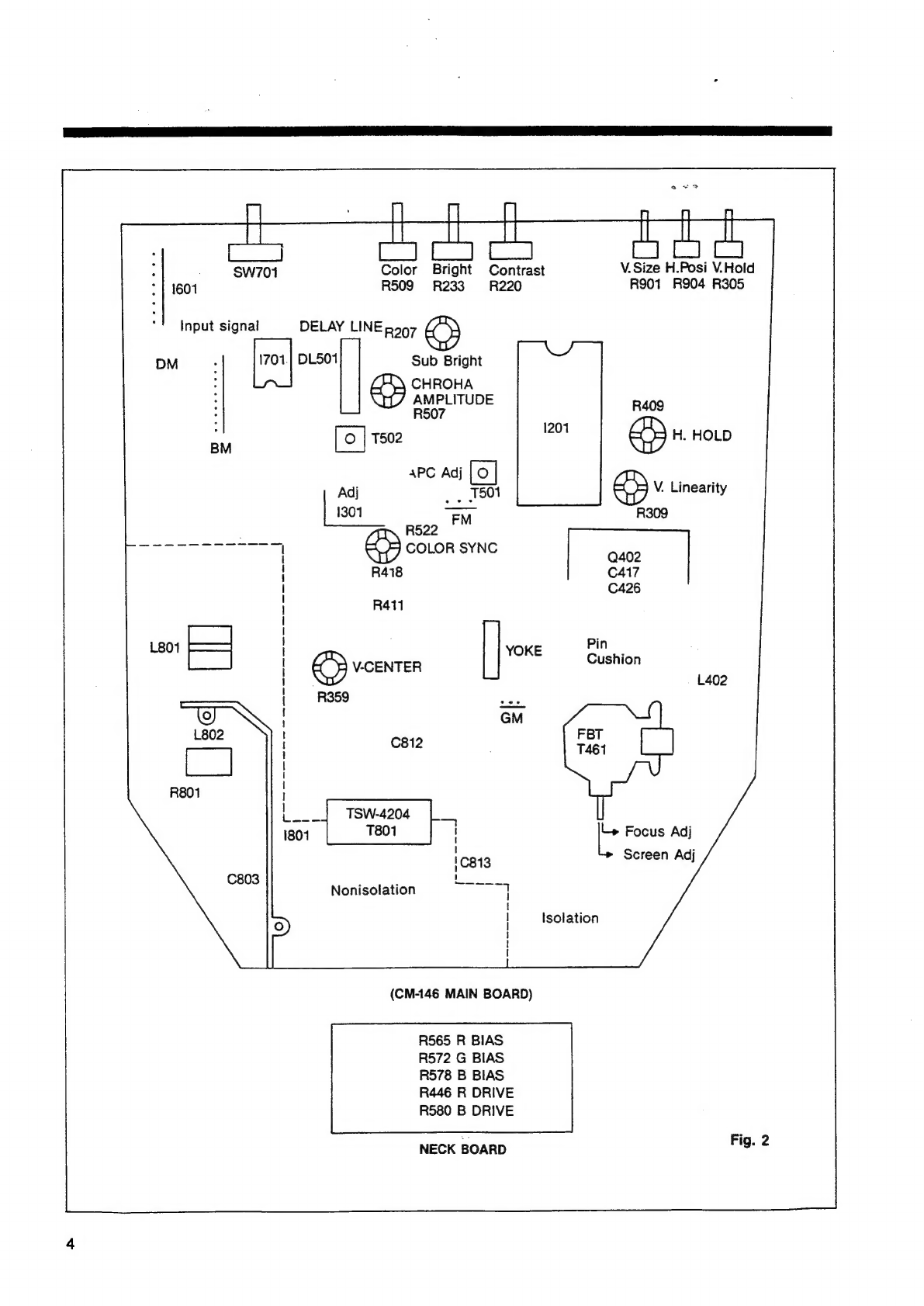

Commodore CM-141 User manual

Commodore

Commodore 1702 User manual

Commodore

Commodore AMIGA 1085S User manual

Commodore

Commodore AMIGA 1081 User manual

Commodore

Commodore 1083S Amiga User manual

Commodore

Commodore 1084S User manual

Commodore

Commodore 1084 User manual

Commodore

Commodore 1084 S-D1 User manual

Commodore

Commodore 1084S User manual

Commodore

Commodore 1402 User manual

Commodore

Commodore 1701 User manual

Commodore

Commodore AMIGA 10855 User manual