CGR/IO12/MID 2

I. INTENDED USE AND CONDITIONS OF USE

Intended use

Rotary gas meters CGR-01 are electromechanical pressure devices designed to measure the

volume of gas flowing through a system. In standard embodiment, the gas meters may be

used at sites with probable occurrence of explosive atmospheres formed as mixtures of gases

classified as explosion groups IIA and IIB (and group IIC for the special purpose

embodiment) with air. Table 1 lists the physical properties of the most common gases and gas

mixtures that may be measured with CGR-01 gas meters.

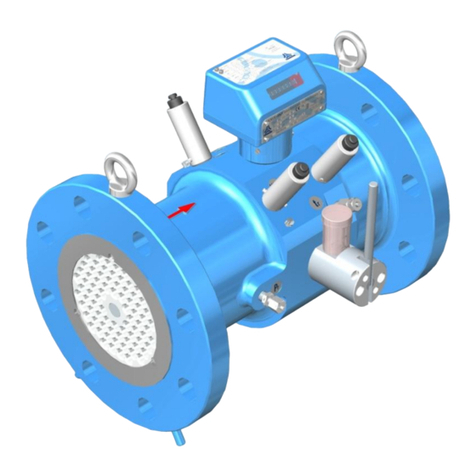

The rotary gas meters can be used both indoors in stabilized temperature conditions and

outdoors (open location); however, in the latter case, it is recommended that the gas meter is

shielded from direct exposure to atmospheric factors (metal containers, casings, roofs, shields

etc.) Ambient temperature range from –25°C to +70°C. System gas temperature range from

—20°C to +60°C. Storage temperature range from –30°C to +70°C. Maximum working

pressure pmax = 1.6 MPa.

Conditions for use

1. Compliance with Directive 2004/22/WE (MID) :

-certificate PL –MI 002 –1450CL0002

-CE marking 1450, Oil and Gas Institute

-ambient temperature range –25° C Ta + 70° C

-gas temperature range from –20° C to + 60° C

-storage temperature range from -30o C to + 70o C

-maximum working pressure pmax = 1.6 MPa

-mechanical environment class M2

-electromagnetic environment class E2

--metrological parameters Table 2.

-metrological accuracy class 1.0

-operational position HV,

- harmonized standards: PN-EN 12480:2005 (EN 12480:2002),

PN-EN 12480:2005/A1:2008 (EN 12480:2002/A1:2006),

2. Compliance with Directive 94/9/WE (ATEX) :

-certificate KDB 04ATEX034,

-CE marking 1453, Central Mining Institute, Experimental Mine

”Barbara”.

-operation conditions standard embodiment II 2G Ex ia IIB T5 Gb

special-purpose embodiment II 2G Ex ia IIC T5 Gb

- meter case index of protection IP66/IP67,

- harmonized standards: PN-EN 13463-1:2010 (EN 13463-1:2009),

PN-EN 60079-0:2009 (EN 60079-0:2009),

PN-EN 60079-11:2010 (EN 60079-11:2007).

3. Compliance with Directive 97/23/WE (PED) :

-certificate 37286/JN/001/04,

-CE marking 1433, Office of Technical Inspection

-compliance with technical specification WUDT/UC/2003.