HR300 SERIES DEHYDRATOR USER MANUAL

Page 2of 12

Contents

Section 1 General Information.............................................................................................................................................................3

1.1 Introduction..............................................................................................................................................................................3

Section 2 Safety Information ...............................................................................................................................................................3

Section 3 Equipment............................................................................................................................................................................4

3.1 Supplied Equipment .................................................................................................................................................................5

Section 4 Description...........................................................................................................................................................................6

Section5 Installation ...........................................................................................................................................................................6

5.1 Unpacking.................................................................................................................................................................................6

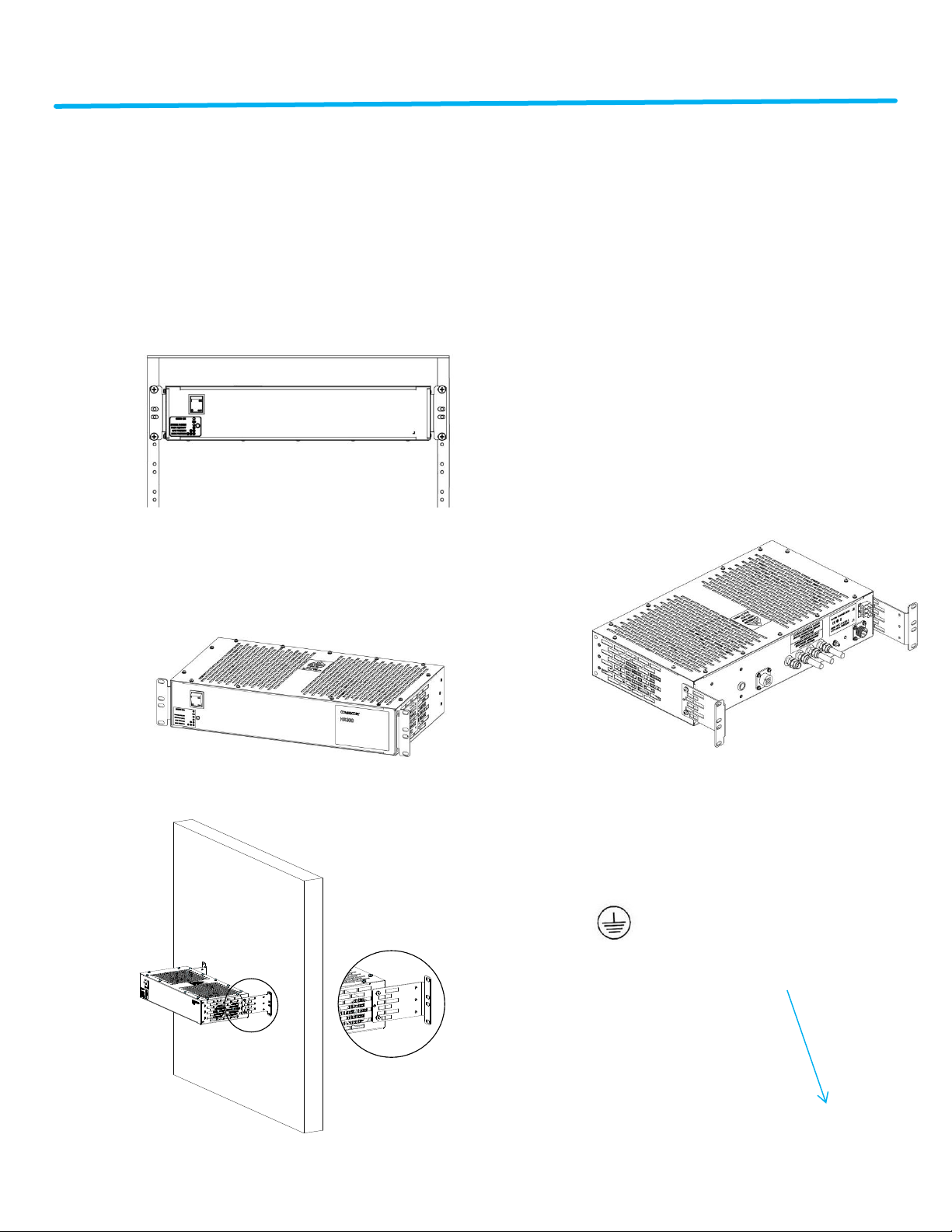

5.2 Mounting..................................................................................................................................................................................7

5.2.1 19” Rack Mounting...................................................................................................................................................................7

5.2.2 Wall Mounting..........................................................................................................................................................................7

5.3 Electrical Connections ..............................................................................................................................................................7

5.3.1 Power Connections...................................................................................................................................................................8

5.3.2 Power Connections...................................................................................................................................................................8

5.4 Pneumatic Connections............................................................................................................................................................8

5.4 Operation .................................................................................................................................................................................8

5.6 Alarms.......................................................................................................................................................................................9

Section 6 Corrective Maintenance and Spare Parts ............................................................................................................................9

Section 7 Outline................................................................................................................................................................................10

Section 8 Customer Service ...............................................................................................................................................................10

8.0Introduction............................................................................................................................................................................10

8.1 In Case of Trouble...................................................................................................................................................................11

8.2 Initial Steps by CommScope ...................................................................................................................................................11

8.3 Repair Center Process ............................................................................................................................................................11