Instruction Sheet www.commscope.com

Page 2 of 21

How to Contact Us

•To find out more about CommScope® products, visit us on the web at http://www.commscope.com/

•For technical assistance:

-Within the United States, contact your local account representative or technical support at

1-800-344-0223. Outside the United States, contact your local account representative or

PartnerPRO™Network Partner.

-Within the United States, report any missing/damaged parts or any other issues to CommScope

Customer Claims at 1-866-539-2795 or email to claims@commscope.com. Outside the United

States, contact your local account representative or PartnerPRO Network Partner.

Tools Required

•Screw-starter

•Flat-blade screwdriver

•Isopropyl alcohol

•Lint-free wipes or tissues

Ordering Information

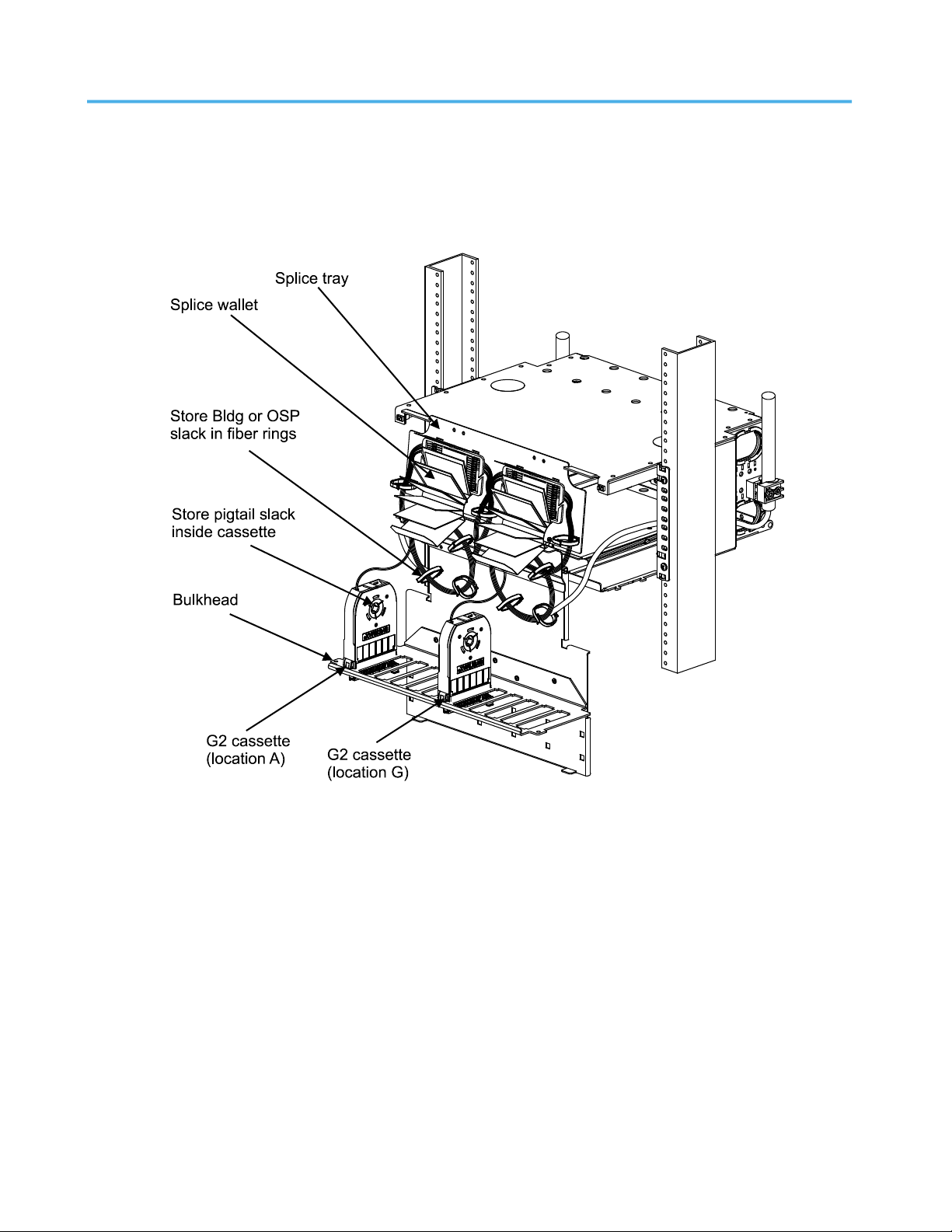

For most versions of this shelf, termination cartridges, bezels and panels, splice organizers and splice carriers

(example: Splice Wallet®, RoloSplice®) are optional and must be ordered separately. Build-out blocks,

couplers, splicing materials and equipment used with this shelf must always be ordered separately.

Separately orderable accessories are available for this shelf. Ordering information is listed below.

Material ID Product No. Description

760101410 360G2-4U-FLK 4U Flip label kit

760027516 RS-00 RoloSplice (unpopulated, splice trays available separately)

760031849 RS-4AM-12SF RoloSplice, 2U version, equipped w/ mechanical splice trays

760031856 RS-4AF-16SF RoloSplice, 2U version, equipped w/ fusion splice trays

760039859 RS-2AM-12SF RoloSplice, 1U version, equipped w/ mechanical splice trays

760039867 RS-2AF-16SF RoloSplice, 1U version, equipped w/ fusion splice trays

760148502 360-LP-STACK-SPT Stackable fusion splice tray kit

760032102 MODG2-BLANK G2 Modular blank panel bezel (package of 4)

760032110 MODG2-MGS G2 Modular MGS bezel (package of 4)

760039875 G2-SRF Liquid-tight cable fitting kit for small-diameter cables

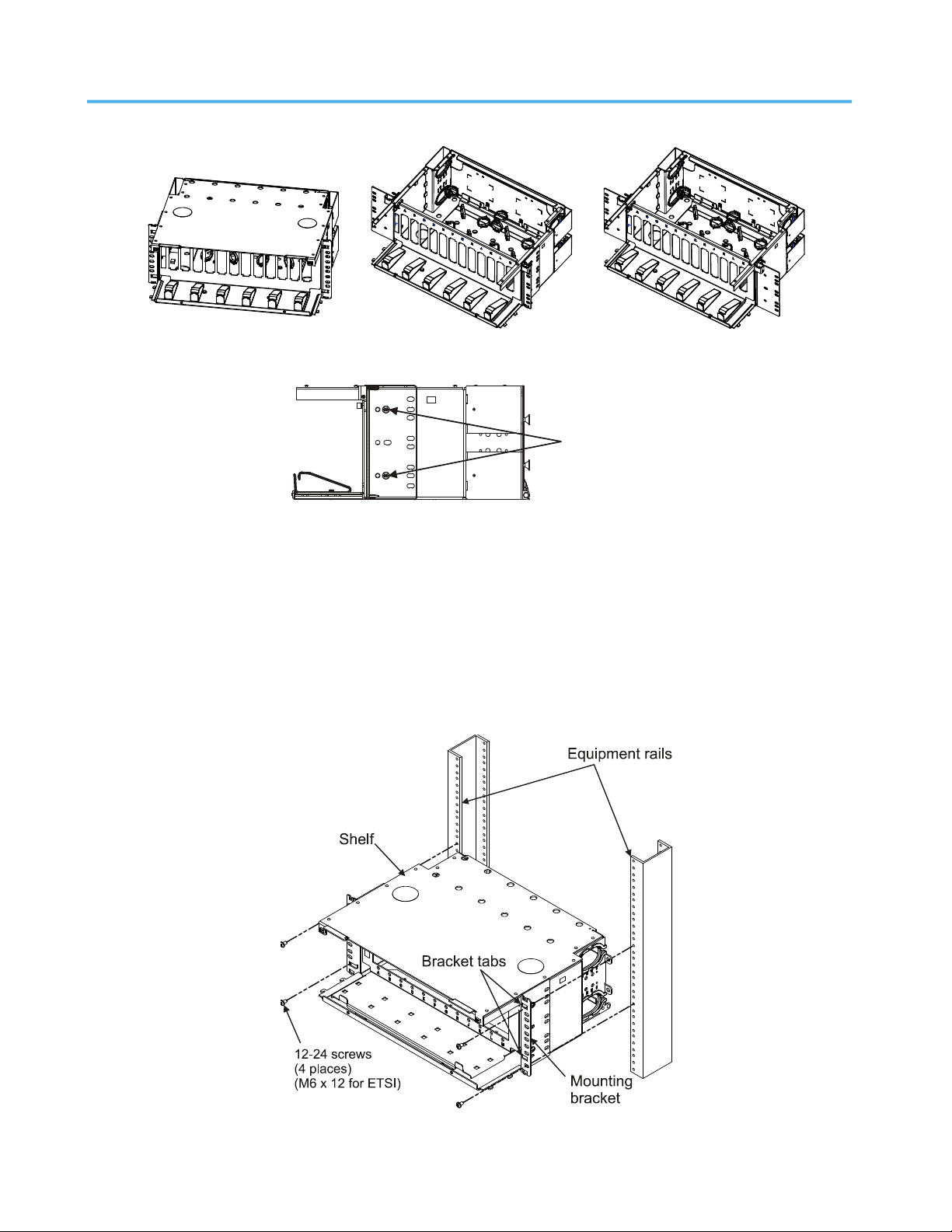

760039883 G2-23BRKT Frame mounting bracket kit for 23” frames and ETSI frames

760107482 DP360-BLANK 360 InstaPATCH

blank panel (pkg of 4)

760107490 DP360-2MPO 360 InstaPATCH 2MPO adapter panel (MOD shelves only)

760107508 DP360-4MPO 360 InstaPATCH 4MPO adapter panel (MOD shelves only)

760107516 DP360-6MPO 360 InstaPATCH 6MPO adapter panel (MOD shelves only)

760107524 DP360-8MPO 360 InstaPATCH 8MPO adapter panel (MOD shelves only)

760128942 SMB-KIT-8-1/2-360G2 360G2 Fitment - InstaPATCH attachment bracket (2), shelf mounted,

four 1/2 inch fittings per bracket and (2) expanded cable protector covers

760128959 SMB-KIT-4-3/4-360G2 360G2 Fitment - InstaPATCH attachment bracket (2), shelf mounted,

two 3/4 inch fittings per bracket and (2) expanded cable protector covers

continued on page 3