Page 5Fiberlink® 5012 User’s Manual

Fiberlink® 5012

Technical Specications

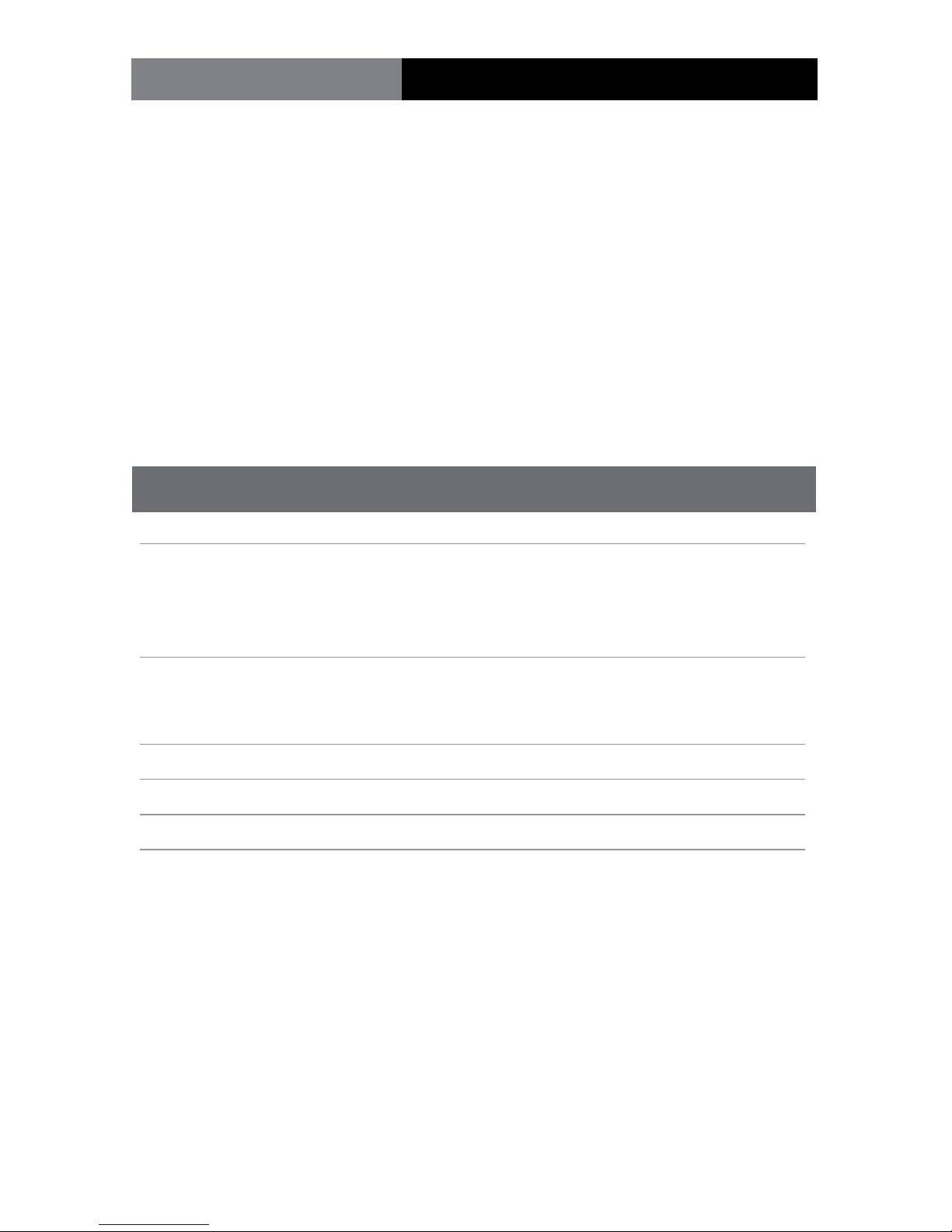

Technical Specications

Model Part Number Specication

System Protocols* EIA RS-232, RS-422, RS-485, 2-wire or 4-wire

System Data Rate* Low speed: RS-232, DC-200 kbps,

RS-422/485, DC to 2.1 mbps

High speed: RS-422/485, 10 kbps to 10 mbps

Modes of Operation* Simplex, duplex, drop-and-repeat,

Asynchronous, RTS or

Data Derived T/R control

Operating Wavelength 850 nm or 1310 nm

Optical Connectors ST (MM) or FCPC (SM)

Operating Temperature -35 to +75 degrees C

Wavelength Loss Budget (dB) Distance (km) Loss Budget (dB) Distance (km)

Low Speed Low Speed High Speed High Speed

850 MM 0-12 0-4 0-6 0-2

1310 MM 0-14 0-14 0-8 0-8

1310 SM 0-15 0-35 0-8 0-20

* Note that as provided from the factory, the universal data transceiver is set to the RS-232 point-to-point

(200 kbps) and low speed modes of operation. In the low speed mode the unit will operate with all duty

cycles including DC (logic 0 or logic 1 continuously). In the high speed mode of operation, the system will

operate properly with all duty cycles from 50-50% to 70-30%.

General Information

The Universal Data Transceiver is fully compatible with EIA standards for RS-232, RS-422 and

RS-485 at data rates from 0 (DC) to 2.1 mbps (200 kbps for RS-232) in the low speed mode

or from 10 kbps to 10 mbps in the high speed mode. It may be used for simplex or full

duplex asynchronous transmissions in both point-to-point systems and drop-and-repeat

data networks. It may also be used as a protocol converter. Although there are no operating

controls, the user must congure the unit for the protocol, speed and mode of operation

desired.

The universal data transceiver comes in two versions, the 5012 stand-alone model and the

5018A card-cage model. The two models are fully compatible with each other.