Page 6

Speed range - Optical mode - 3 - 99,999 rpm (or equivalent in rps)

Contact mode - Max. 50,000 rpm for 10 sec (or equivalent in rps)

Linear speeds - maximum - 0.30 - 1500.0 Metres or Yds/min. (4,500 ft/min) or equilavent in sec-

onds

Resolution range features - Fully Autoranging up to 0.001digit or +/- 1 digit fixed, User selectable

Accuracy speed modes only - 0.02% +/- 1 digit

Count mode resolution - +/- 0.1 Metres (or equilavent in all ranges)

Time interval mode - 0 - 99999 seconds Autoranging only (max 0.01 resolution)

Timebase standard - 0.8 seconds or time between pulses,whichever is longest

Timebase, Fast modes - 0.1 seconds auto-selection in Maximum or Minimum capture mode

Memory features - Last reading held for 1 minute, Auto Switch Off

- Program settings retained in memory after power down off

Contact adaptor - Included complete with rpm cone & metric wheel assembly (remova

ble)

Ex works setting - rpm mode, non autoranging

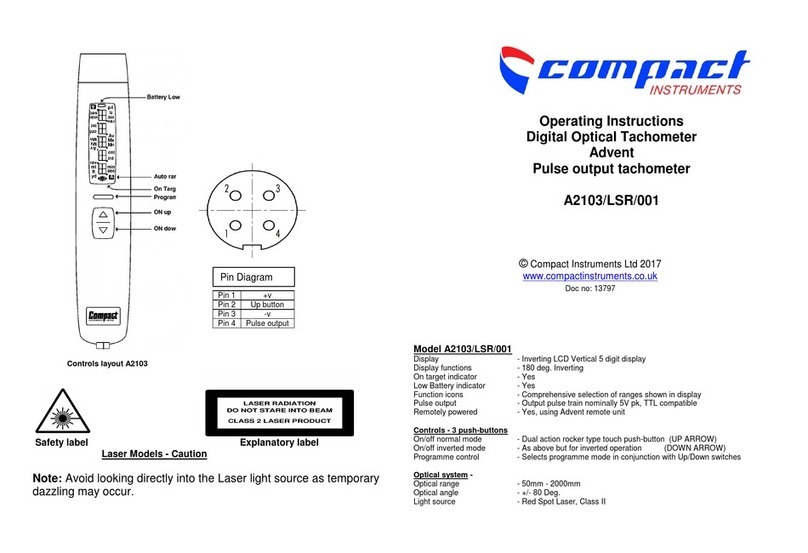

1. Programming - measurement mode selection

All measurement modes are chosen by this method and once confirmed, selected mode remains in

permanent memory until re-programmed by the user.

1.1. To change mode hold programme button on and press up measure button and then release

both buttons, the display will now illuminate all icons, and the current range will flash.

1.2. To select new measurement mode press either up or down button to scan through the

modes, when the required mode icons flash release measure button & press programme

button once to confirm settings.

for non-speed modes the unit is now programmed and read for use.

1.3. To select mx, mn, av. modes continue to scan through each one, if the mode is not re-

quired, stop scan when all three icons illuminate continuously, then press programme button

once.

The instrument is now ready to use. Set parameters will be retained until reprogrammed.

2. Optical revolutions speed measurement - rpm or rps.

2.1. Ensure batteries are correctly fitted.

2.2. Attach small reflective target to machine shaft (typically 6mm x 25mm, less for laser version)

2.3. Start machine and point the tachometer towards the target.

2.4. Press and hold either of the on/off buttons to suit application and hold continuously.

2.5. Aim light beam onto target, ensure “on-target” sign is glowing or flashing steadily

2.6. Read off rpm, releasing button will hold last reading.

2.7. Last rpm reading will be held in display for 1 minute.

2.8. Press the On button to zero reading or take another measurement.

3. Contact revolution speed measurement - rpm or rps.

3.1. Fit contact adaptor into the tachometer and ensure a good click fit connection.

3.2. Start machine and make clean contact with the recess in shaft end (wheel can be removed).

3.3. Contact the shaft end via the rubber cone, ensure a steady firm pressure is applied and that

the instrument is in line accurately with the machine shaft.

3.4. Press and hold either up or down measure button as required & read speed

3.5. Releasing the On switch will hold the reading automatically for 1 minute, automatic switch

off.