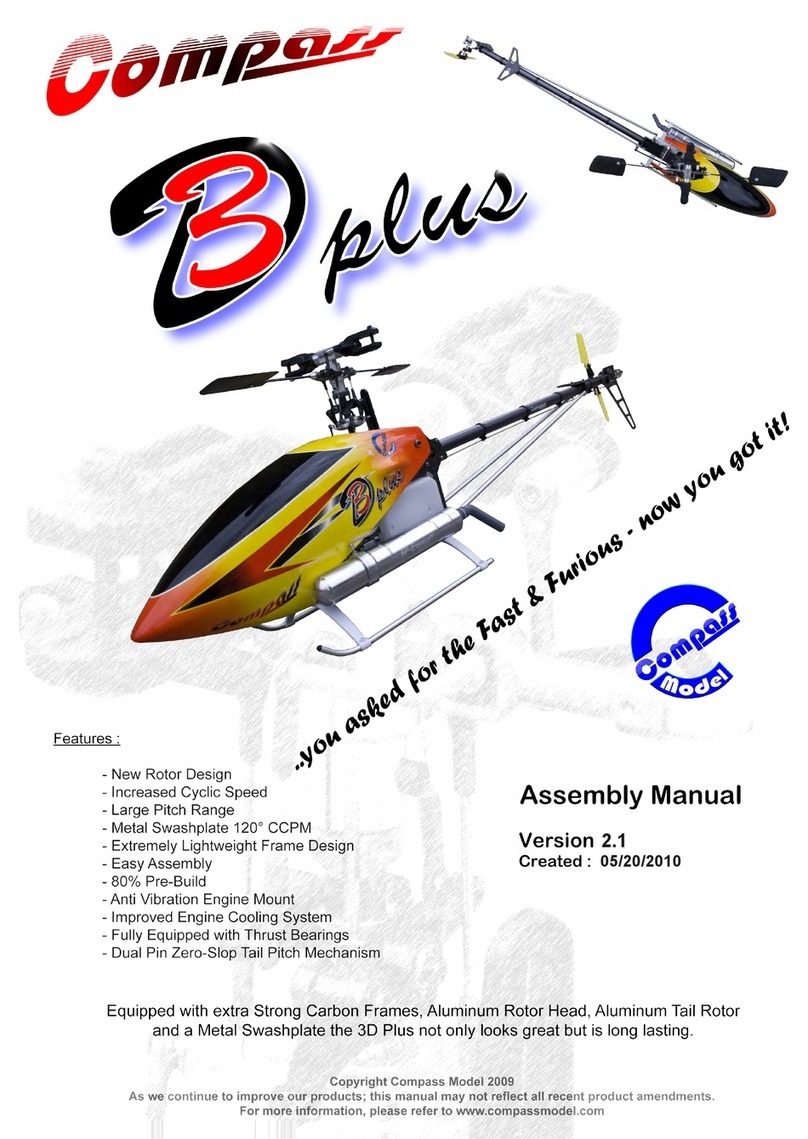

Thank you for choosing the Knight 3D and welcome to Compass Model. The Knight 3D has been carefully designed to offer

out standing flight performance and includes many innovative features along with proven components to provide you with a

model which is accurate, durable and agile. The 3D was developed with input from leading pilots to meet the requirements of

the most demanding aerobatic flight styles, both now and in the future. The control system incorporates a closed loop push-

pull system for all swash plate linkages and optimum ccpm geometry to ensure unrivalled control accuracy and rapid head

response. Similarly, the frame lay out has been designed to create an extraordinarily rigid platform which is both durable and

further improves control accuracy. This compact layout features light weight, raised centre of gravity and unique engine

isolation mounting.

Please read the complete manual before assembly, which has been designed to enable you to get the best from your model -

please take careful note of all precautions and assembly tips. Please also keep the manual as a reference for part numbers and

reassembly following maintenance.

. .

, .,,.

,,.. ,,.

.

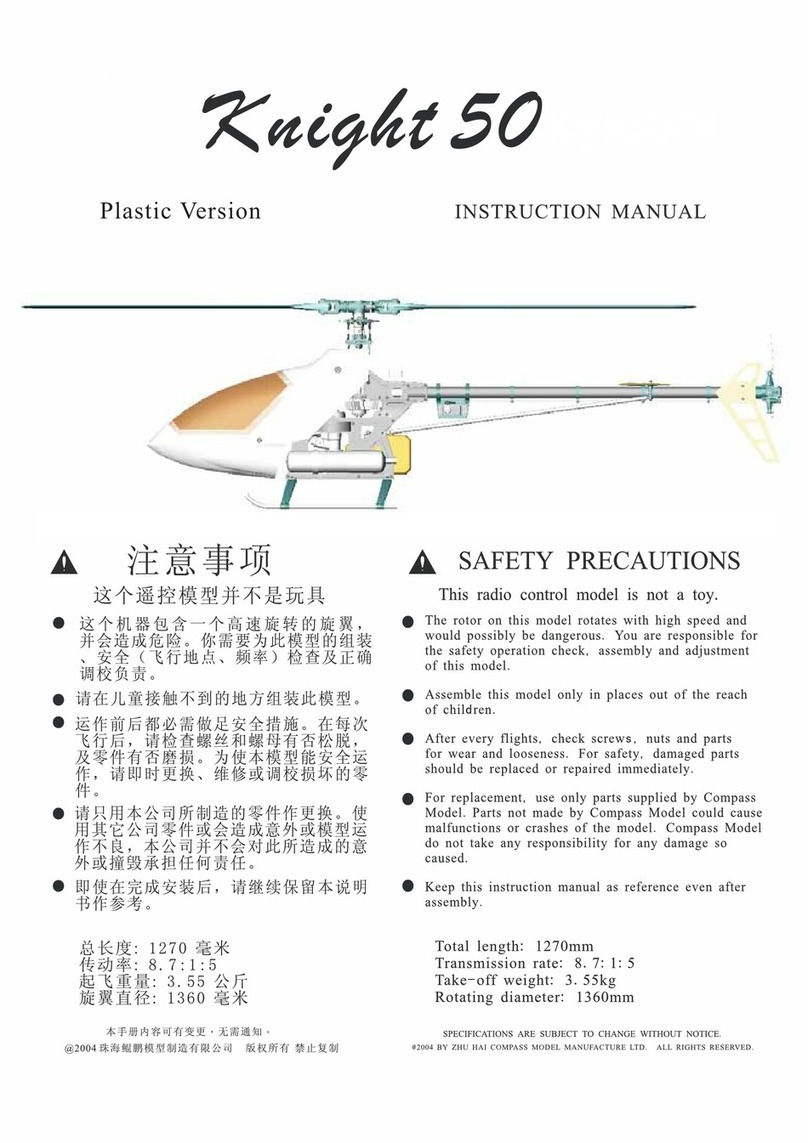

KNIGHT 3D

KNIGHT3D 3D CCPM

Introduction

Mishandling due to failure to follow these instructions may result in damage personal injury or danger,.

,,.

Blue Thread lock should be applied.

The Meaning of Symbols

Warning

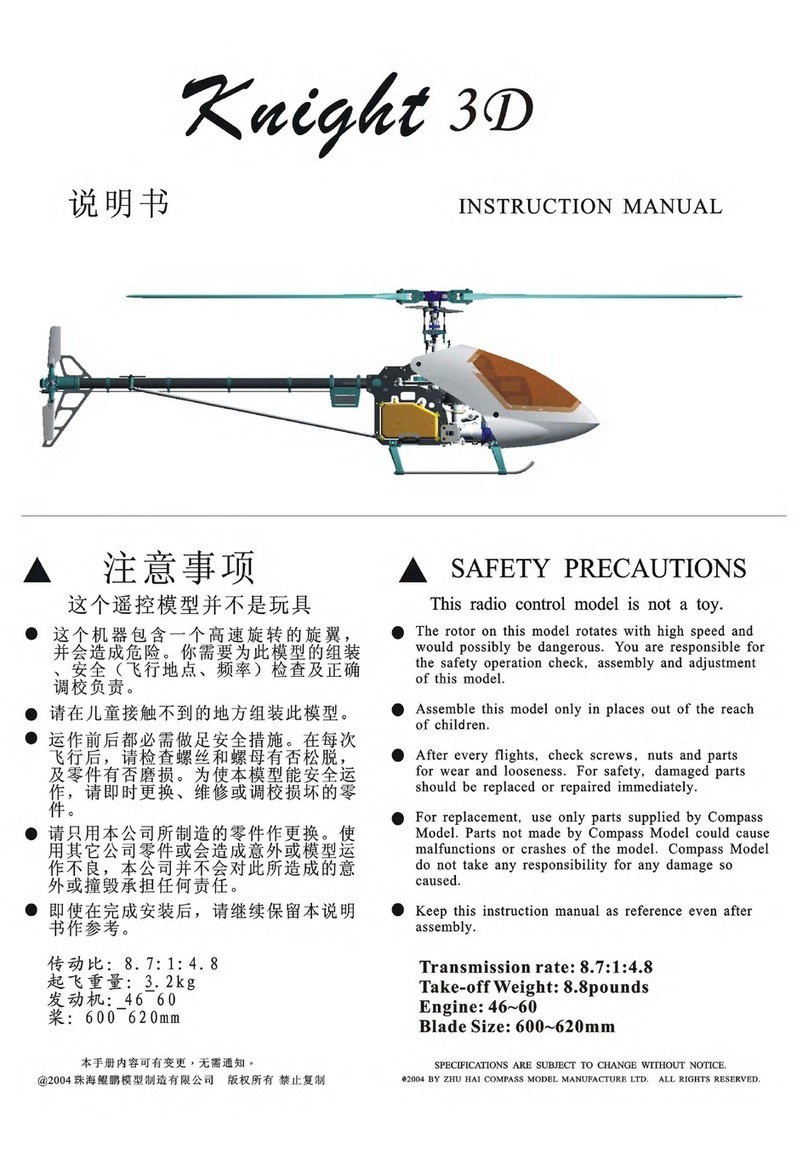

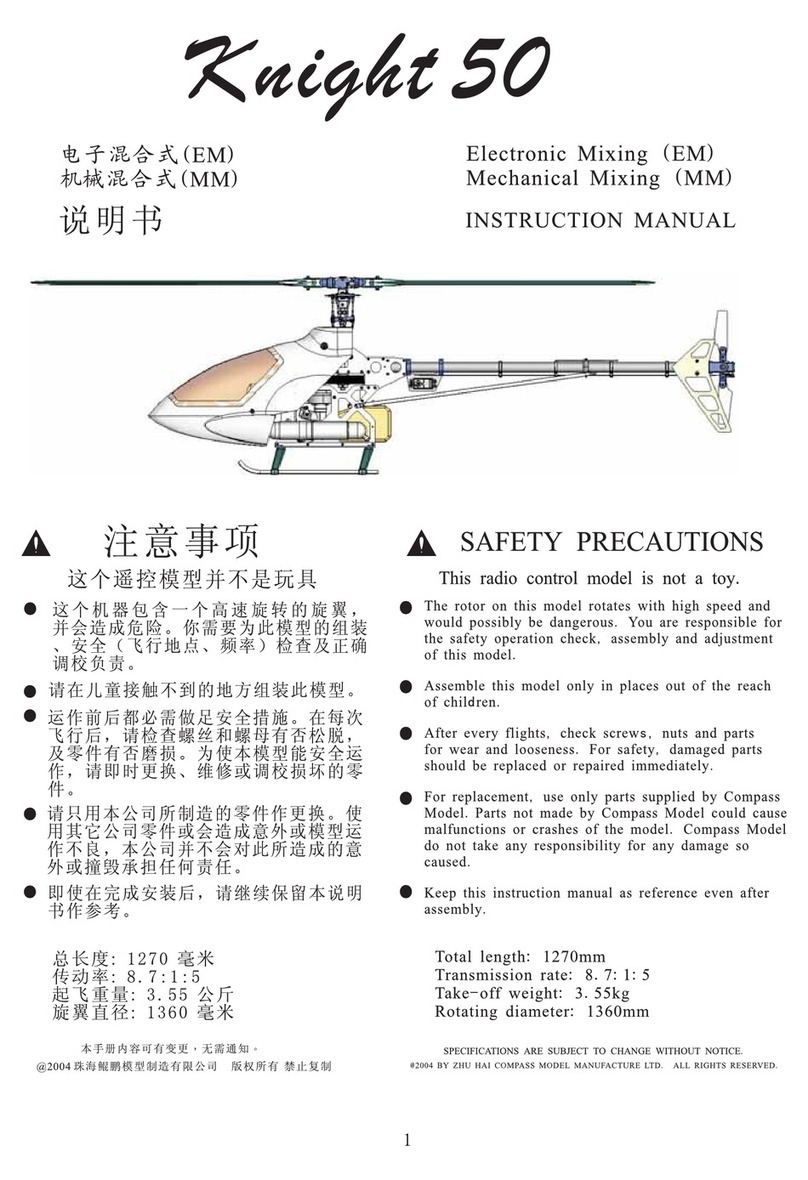

This radio controlled helicopter model is not a toy.

Manufacturer and Sellers assume no responsibility for using and operating this product.

.

,., ,

,.,.

,,, . ,

.

( ).

。 ,。

:

It is a sophisticated piece of equipment for hobby use only.

Improper operation or assembly of this product can cause serious injury or death for both operator and spectators.

The customer must

take full responsibility for the safe operation of this product

AMA INFORMATION

Academy of Model Aeronautics

Academy of Model Aeronautics

We strongly encourage all prospective and current R/C aircraft pilots to join the Academy of Model Aeronautics. The AMA

is a non-profit organization that provides services to model aircraft pilots. As an AMA member, you will receive a monthly

magazine entitled , as well as a liability insurance plan to cover against possible accident or injury. All

AMA charter aircraft clubs require individuals to hold a current AMA sporting license prior to operation of their models.

For further information, you can contact the AMA at:

5151 East Memorial Drive

Muncie, IN 47302

Academy of Model Aeronautics AMA AMA

AMA

AMA AMA

5151 East Memorial Drive

Muncie, IN 47302

Model Aviation

Model Aviation

This

product is not recommended for use by children.

Safety Notes

Operate in safe areas.

Do not fly r c helicopter model near buildings high voltage cables trees or other obstacles Do not fly r c

helicopters in poor weather such as rain snow or fog Do not fly r c helicopters over crowds of people cars or

other property Flying field should be a smooth clear and flat field

/,,./

,./ ,

.,.

,,.,,.,

.,,.