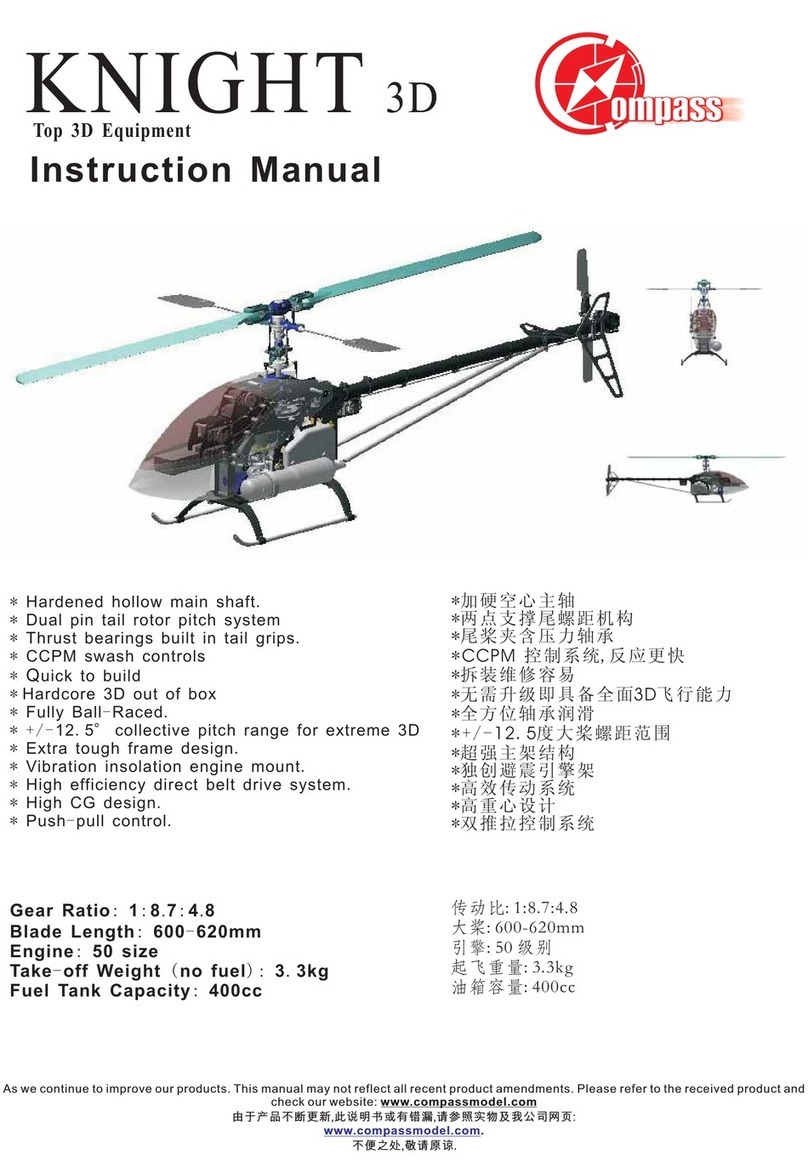

Compass Knight 3D User manual

Other Compass Toy manuals

Compass

Compass WARP 360 User manual

Compass

Compass 7hv User manual

Compass

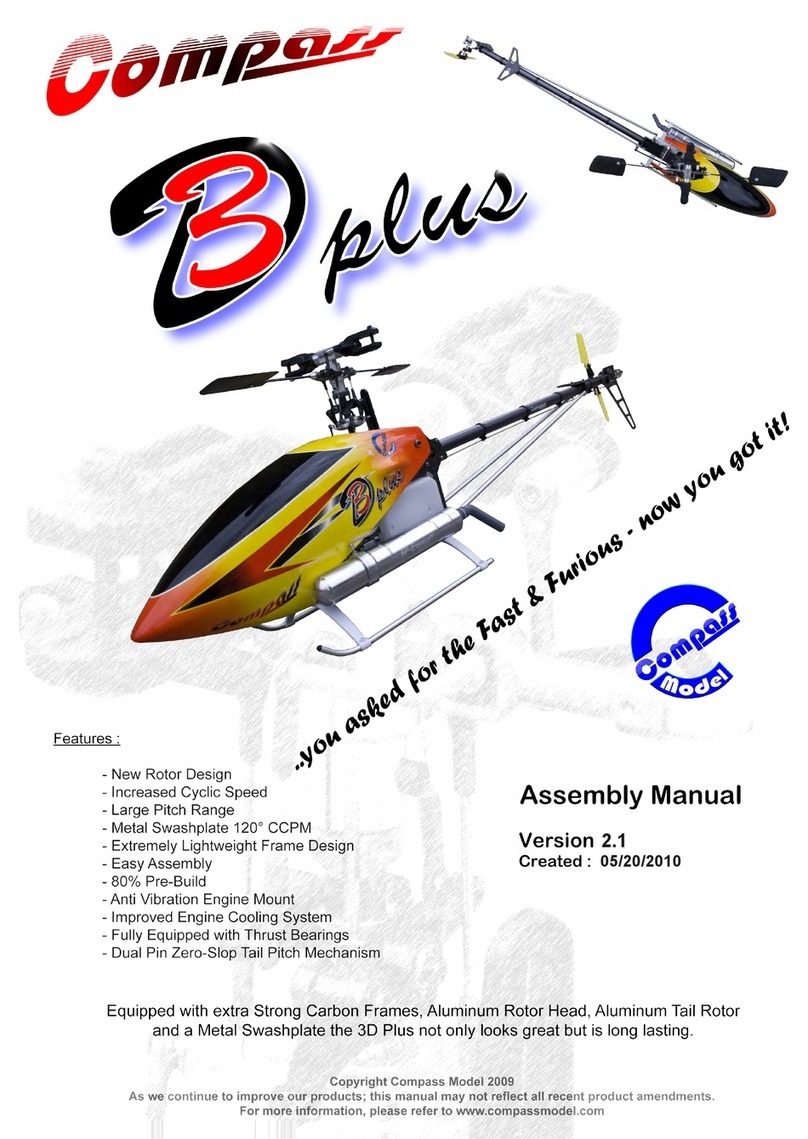

Compass 3D Plus Nitro Powered Helicopter User manual

Compass

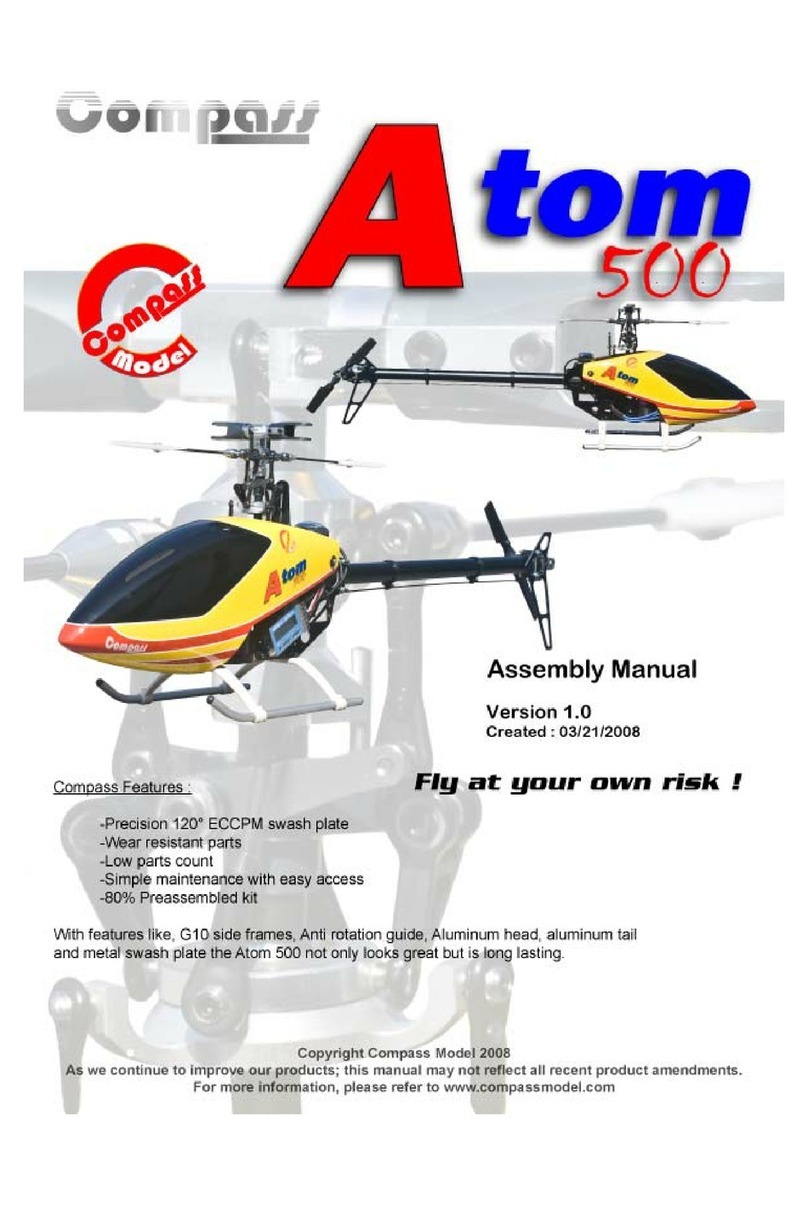

Compass Atom 500 User manual

Compass

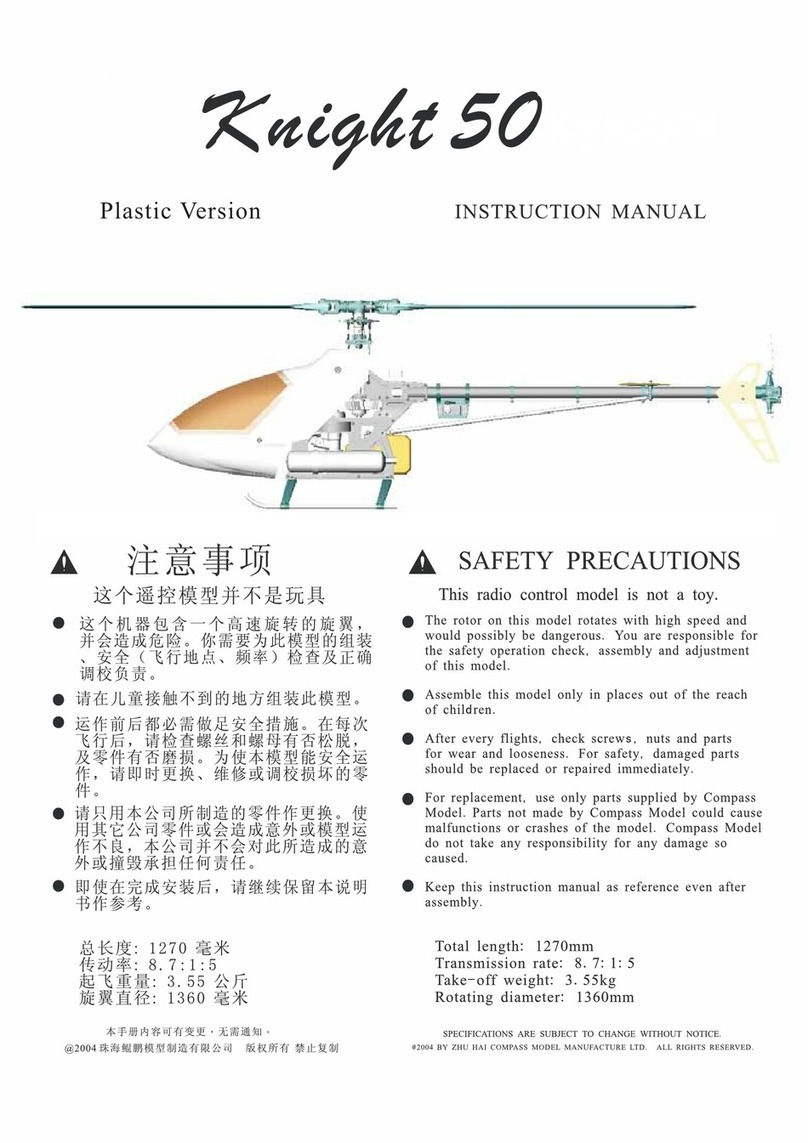

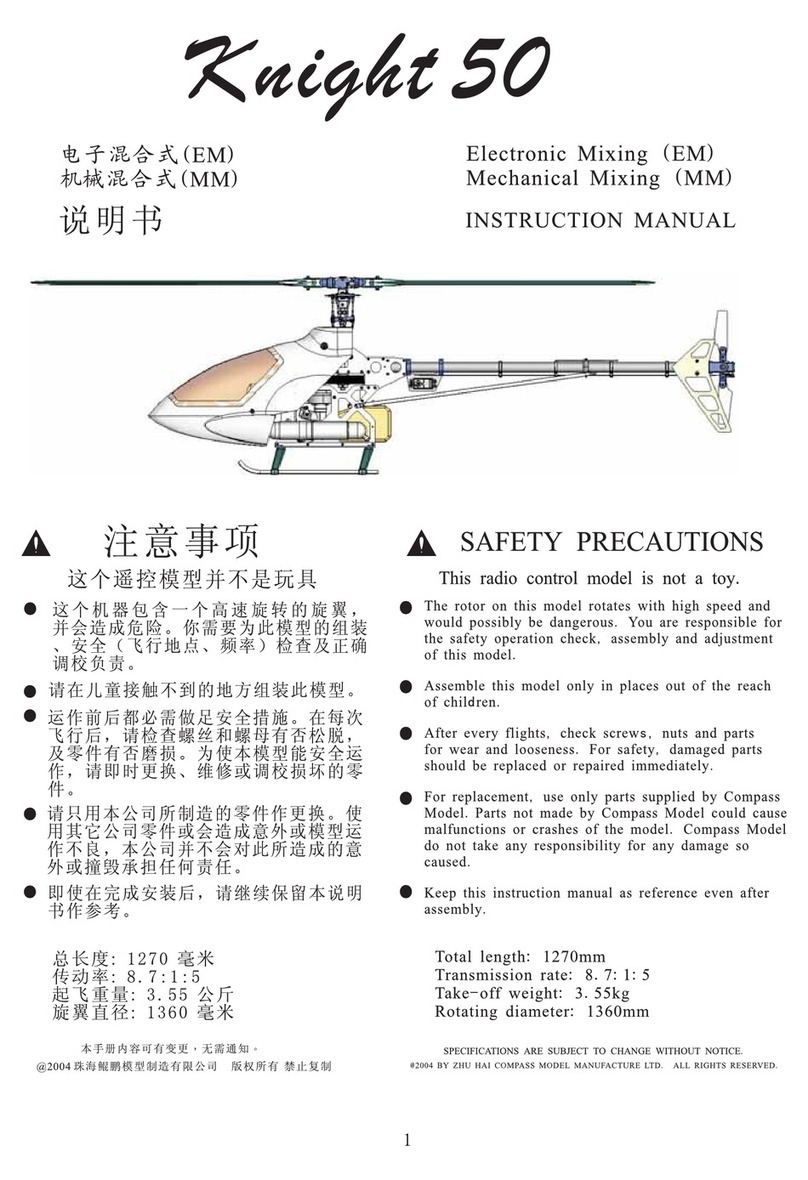

Compass Knight 50 User manual

Compass

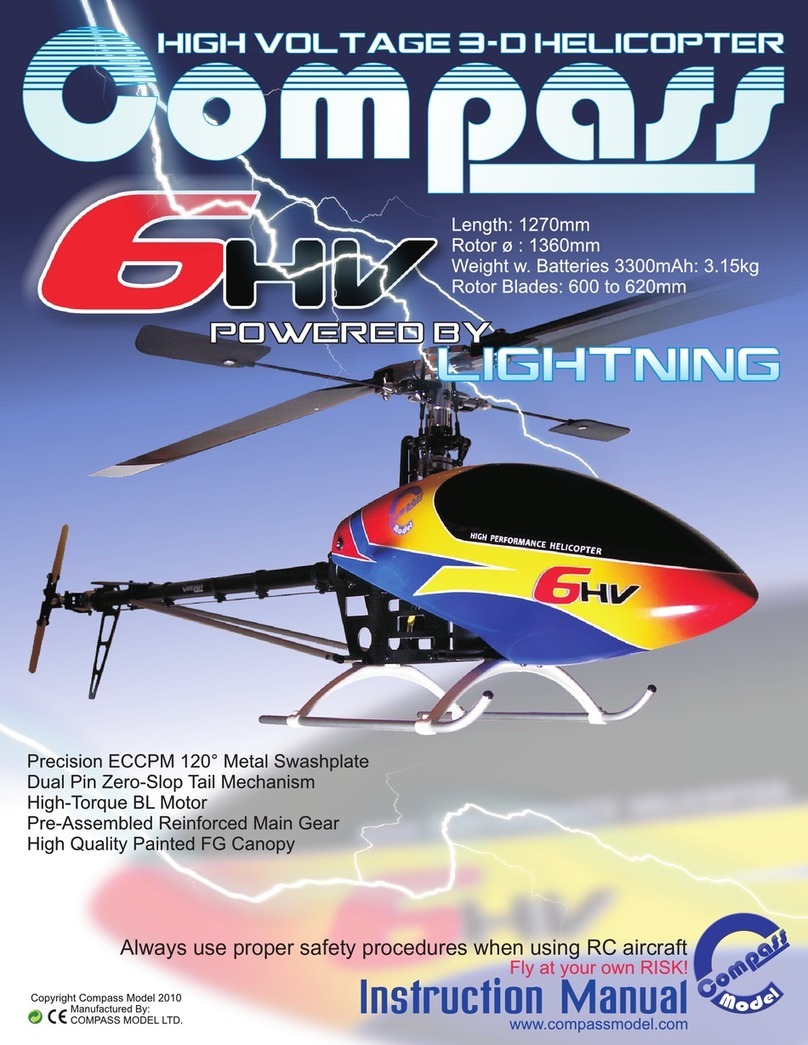

Compass Atom 6HV User manual

Compass

Compass Exo 500 User manual

Compass

Compass Atom 500 User manual

Compass

Compass Atom 6HV User manual

Compass

Compass Atom 6HV User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions