Section 1.....................................................................................................................................................1

An Introduction to leakage current testing with the LCB-1010-B ...............................................1

Safety Precautions........................................................................................................................1

Test Personnel..............................................................................................................................1

Testing Area.................................................................................................................................1

Section 2.....................................................................................................................................................2

LCB-1010-B Configuration .........................................................................................................2

Specifications...............................................................................................................................2

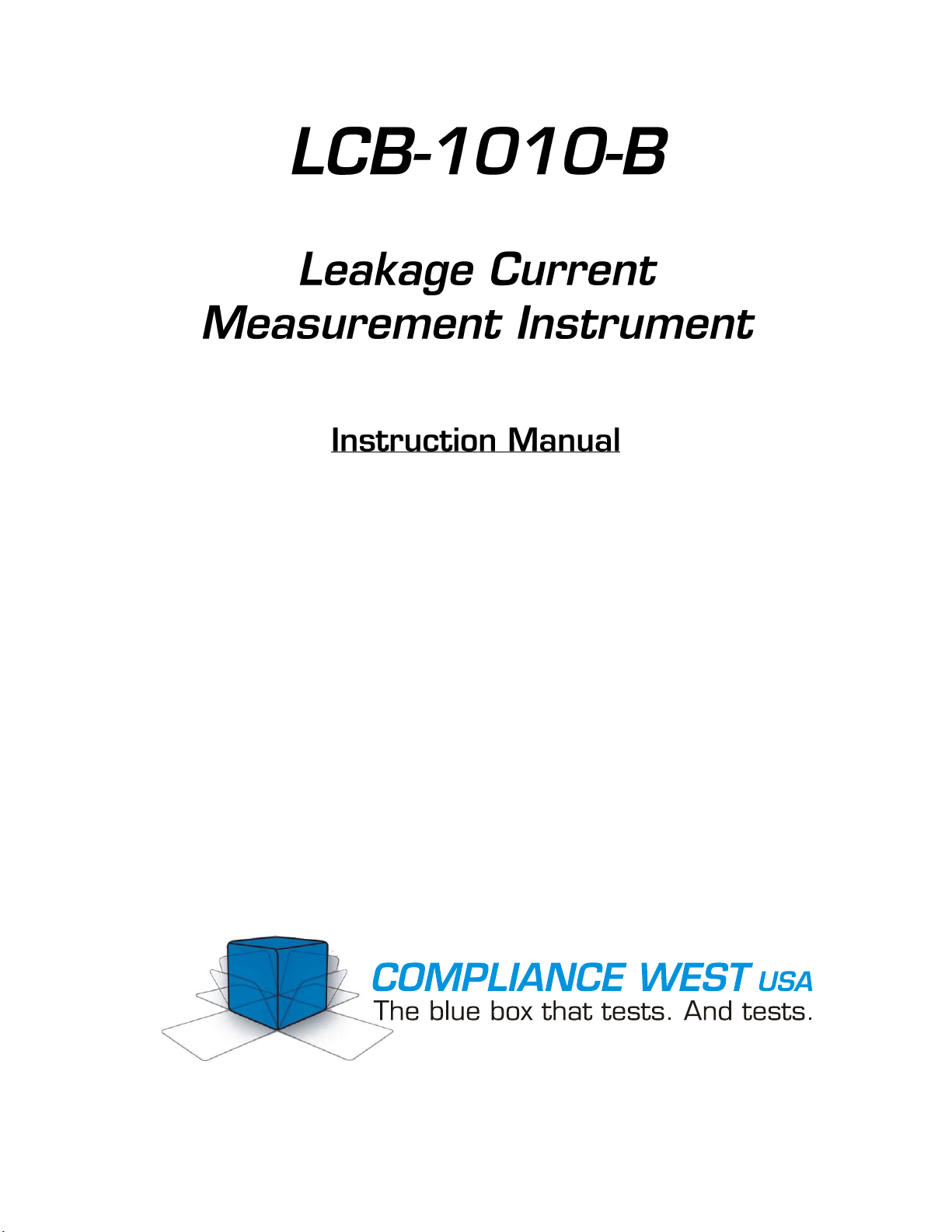

Configuration 1..............................................................................................................2

IEC 61010-1:2010 Fig. A.1 .............................................................................2

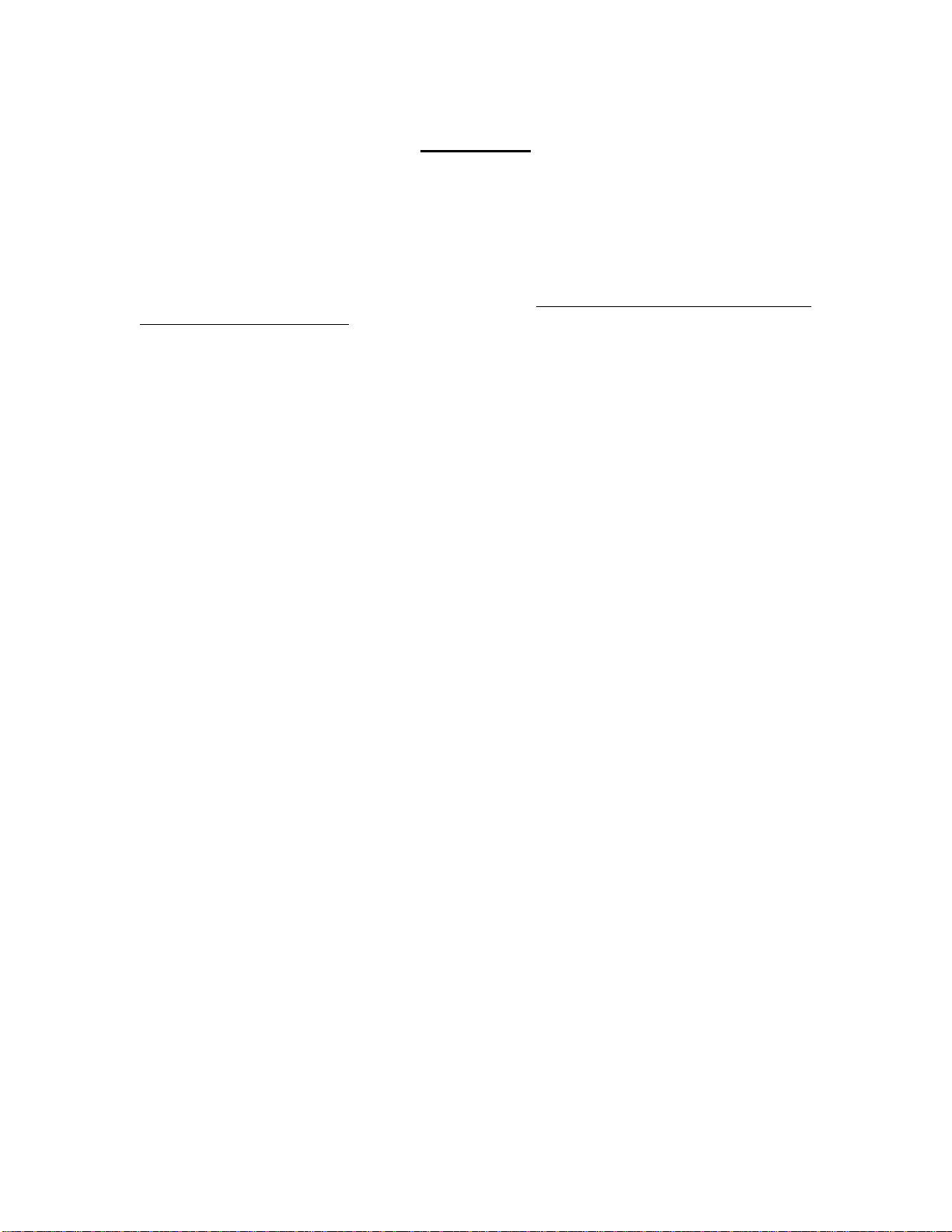

Configuration 2..............................................................................................................3

IEC 61010:2010 Fig. A.3 ................................................................................3

Configuration 3..............................................................................................................3

IEC 61010-1:2010 Fig A.4 ..............................................................................3

Section 3.....................................................................................................................................................4

Operating Instructions..................................................................................................................4

Setting up your Tester..................................................................................................................4

Fuse Verification Check...............................................................................................................5

Verification of Proper Operation..................................................................................................5

Section 4.....................................................................................................................................................6

Maintenance and Calibration .......................................................................................................6

Introduction..................................................................................................................................6

Service Information......................................................................................................................6

General Maintenance ...................................................................................................................6

Cleaning .......................................................................................................................................6

Calibration Information................................................................................................................6

Section 5.....................................................................................................................................................7

Technical Assistance....................................................................................................................7

Appendix A ................................................................................................................................................8

Tolerance comparison for LCB Configuration 1 (Fig.A.1)..........................................................8

Tolerance comparison for LCB Configuration 2 (Fig.A.3)..........................................................9

Tolerance comparison for LCB Configuration 3 (Fig.A.4)..........................................................10