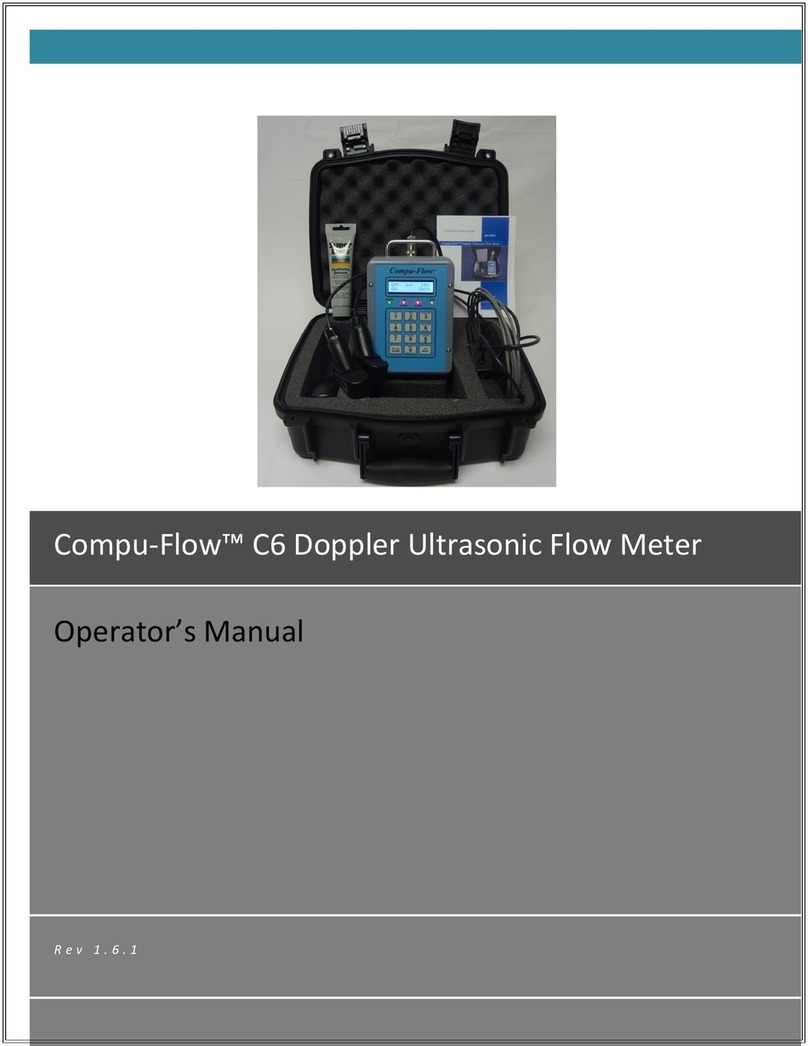

INTRODUCTION:

Compu-Flow™ Doppler

• In order to obtain accurate measurements adequate upstream and downstream

pipe runs are required. Recommended strai ht-run requirements from any

disturbance of flow are 10 diameters upstream and 20 diameters downstream.

Assessin Particles or Air Bubbles

The ultrasonic beam from the transducer is transmitted throu h the pipe wall into

the liquid. The particles, air bubbles suspended in the liquid, have to be lar e

enou h to act as reflectors to return the si nal back to the transducer so that a

measurement may be taken. It is important to understand that the ultrasonic beam

from the Doppler flow meter does not penetrate air very well. A few bubbles will

not affect flow meter performance, but too many bubbles may cause the meter to

malfunction.

The flow to be measured must always have a sufficient number of sonic reflectors

of ample size in order to provide reflection of the transmitted sound. If the

reflectors do not have sufficient density difference they will neither rise nor fall in

the solution but remain suspended. The specific ravity will also affect the ability of

a particle to reflect sound. A ood example of a reflector is a sand particle or an air

bubble. A poor example is al ae or onion skins.

5

sensed is 40 microns @ 35 parts per million (ppm) and at least 0.2% density

difference from the liquid.

Assessin Pipe Material and Condition

Doppler flow meter performance is best maximized by usin pipin that is sonically

conductive. The Doppler flow meter assumes that the path by which the ultrasonic

beam enters the pipe and returns to the transducer is ultrasonically homo enous,

which means that you must use your flow meter with pipes with non-porous

smooth pipe walls. Concrete-lined pipes, old or crystallized cast iron pipes, hand-

wrapped fiber lass pipe, and old pipin with air inclusions do not exhibit the

required homo eneity. Avoid usin the Doppler flow meter for flow measurement

on these pipes unless proper operation is proven by the manufacturer throu h

demonstration.

Contact “Compu-Flow Systems Support” for more information on an alternate

meter if your application is not suitable for the Doppler flow meter.