1 Introduction 4

1.1 To the very beginning 4

1.2 Notes on the technical documentation 4

2 For your safety 6

3 Product Overview 8

3.1 Models overview 8

3.2 Identification of the unit 9

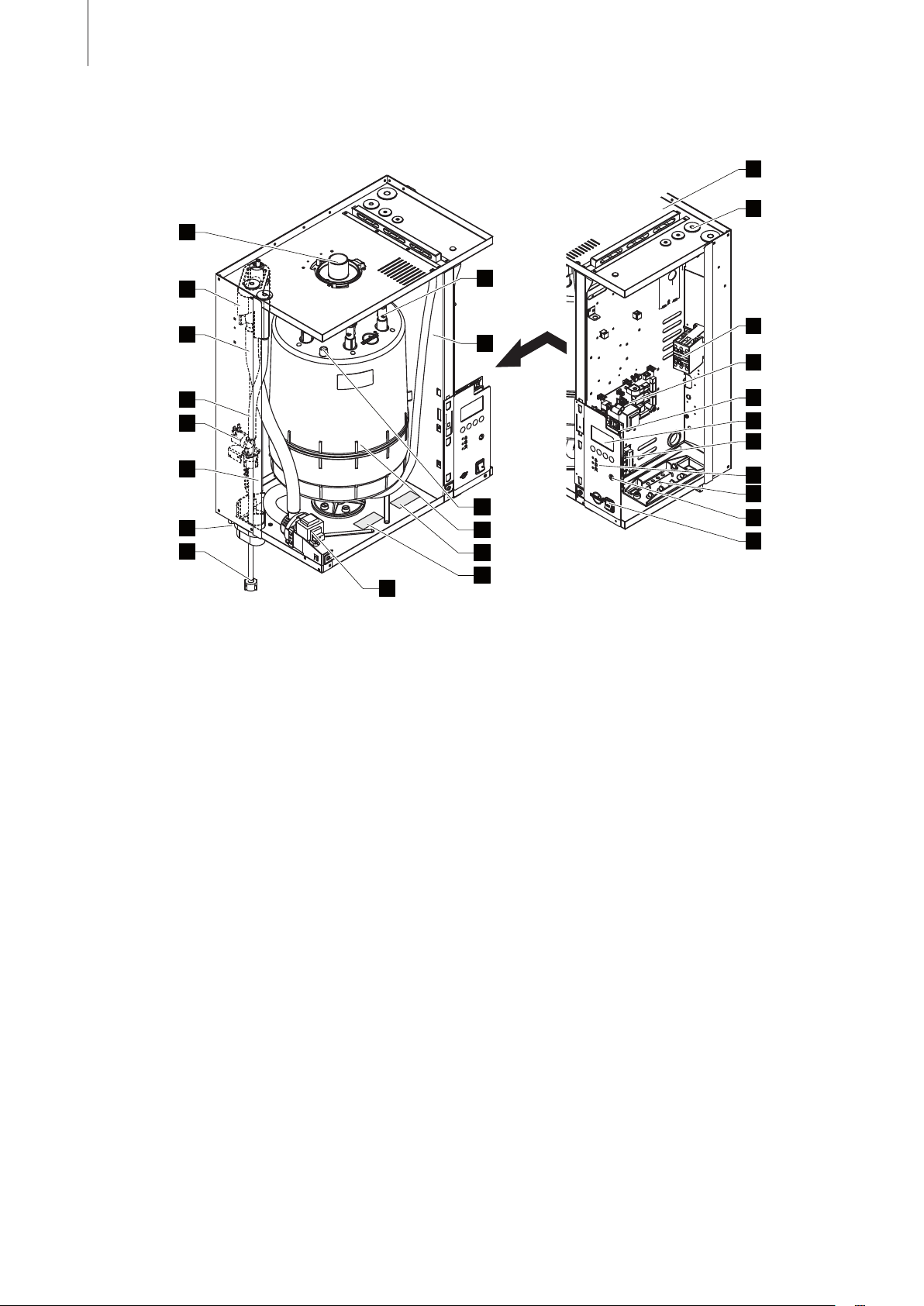

3.3 Steam generator construction 10

3.4 Functional description 11

3.5 System overview 12

3.6 Options 13

3.6.1 Options overview 13

3.6.2 Option details 14

3.7 Accessories 15

3.8 Standard delivery 16

3.9 Storing/Transportation/Packaging 16

4 Notes for the planning engineer 17

4.1 Selecting the unit version 17

4.1.1 Determination of the required steam capacity 17

4.1.2 Selecting the unit 18

4.2 Selecting the options an accessories 18

5 Mounting and installation work 19

5.1 Important notes for mounting and installation work 19

5.2 Installation overview 20

5.3 Mounting the unit 21

5.3.1 Notes on locating the unit 21

5.3.2 Mounting the unit 23

5.3.3 Inspecting the installed unit 24

5.4 Steam installation 25

5.4.1 Overview steam installation 25

5.4.2 Positioning/mounting the steam distributor 25

5.4.3 Installing the steam hose 26

5.4.4 Inspecting the steam installation 27

5.5 Water installation 28

5.5.1 Overview water installation 28

5.5.2 Notes on water installation 29

5.5.3 Inspecting the water installation 30

5.6 Electric installation 31

5.6.1 Wiring diagram Condair CP3 D 31

5.6.2 Notes on electric installation 32

5.6.3 Inserting the CP3 Card 34

5.6.4 Inspecting the electrical installation 34

6 Operation 35

6.1 Commissioning 35

6.2 Notes on operation 36

6.2.1 Function of the display and operating elements 36

6.2.2 Remote operating and fault indication 36

6.2.3 Inspections during operation 37

6.2.4 Carrying out manual draining 37

6.3 Taking the unit out of operation 37

6.4 Overview and operating of the menu 38

6.5 Interrogation functions 39

6.5.1 Information in the operating display 39

6.5.2 Interrogation of unit information 39

6.5.3 Interrogation of the malfunction list 40

6.6 Unit settings 40

6.6.1 Setting the setpoint temperature 40

6.6.2 Setting the control mode 40

6.6.3 Setting the fragrance pump settings 41

6.6.4 Unit settings in the settings menu 42

6.6.4.1 Launching the settings menu 42

6.6.4.2 Selecting the dialogue language 42

6.6.4.3 Steam bath control settings 42

6.6.4.4 Setting the date 45

6.6.4.5 Setting the time 45

6.6.4.6 Cylinder settings 45

6.6.4.7 Setting the capacity limitation 46

6.6.4.8 Activating/Deactivating fault current relay operation 46

6.6.4.9 Water management settings 46

6.6.4.10 Performing remote relay tests 47

6.6.4.11 Performing steam bath tests 48

6.6.4.12 Setting the display contrast 48

6.7 Modbus settings 48

7 Maintenance 49

7.1 Important notes on maintenance 49

7.2 Maintenance list 50

7.3 Removing and installing parts for maintenance 51

7.3.1 Removal and installation of the steam cylinder 51

7.3.2 Disassembly and assembly of

the cleanable steam cylinder type D... 53

7.3.3 Removal and installation of the water cup

and the water hoses 54

7.3.4 Removal and installation of the drain pump 55

7.3.5 Removal and installation of the inlet valve 55

7.4 Notes on cleaning the unit components 56

7.5 Notes on cleaning agents 57

7.6 Resetting the maintenance indication 58

8 Malfunctions 59

8.1 Malfunction list 59

8.1.1 System faults 59

8.1.2 Unit faults 60

8.2 Notes on fault elimination 62

8.3 Resetting the error indication (red LED lights) 62

9 Taking out of service/Disposal 63

9.1 Taking out of service 63

9.2 Disposal/Recycling 63

10 Product specifications 64

10.1 Technical data 64

10.2 Unit dimensions 65

Contents