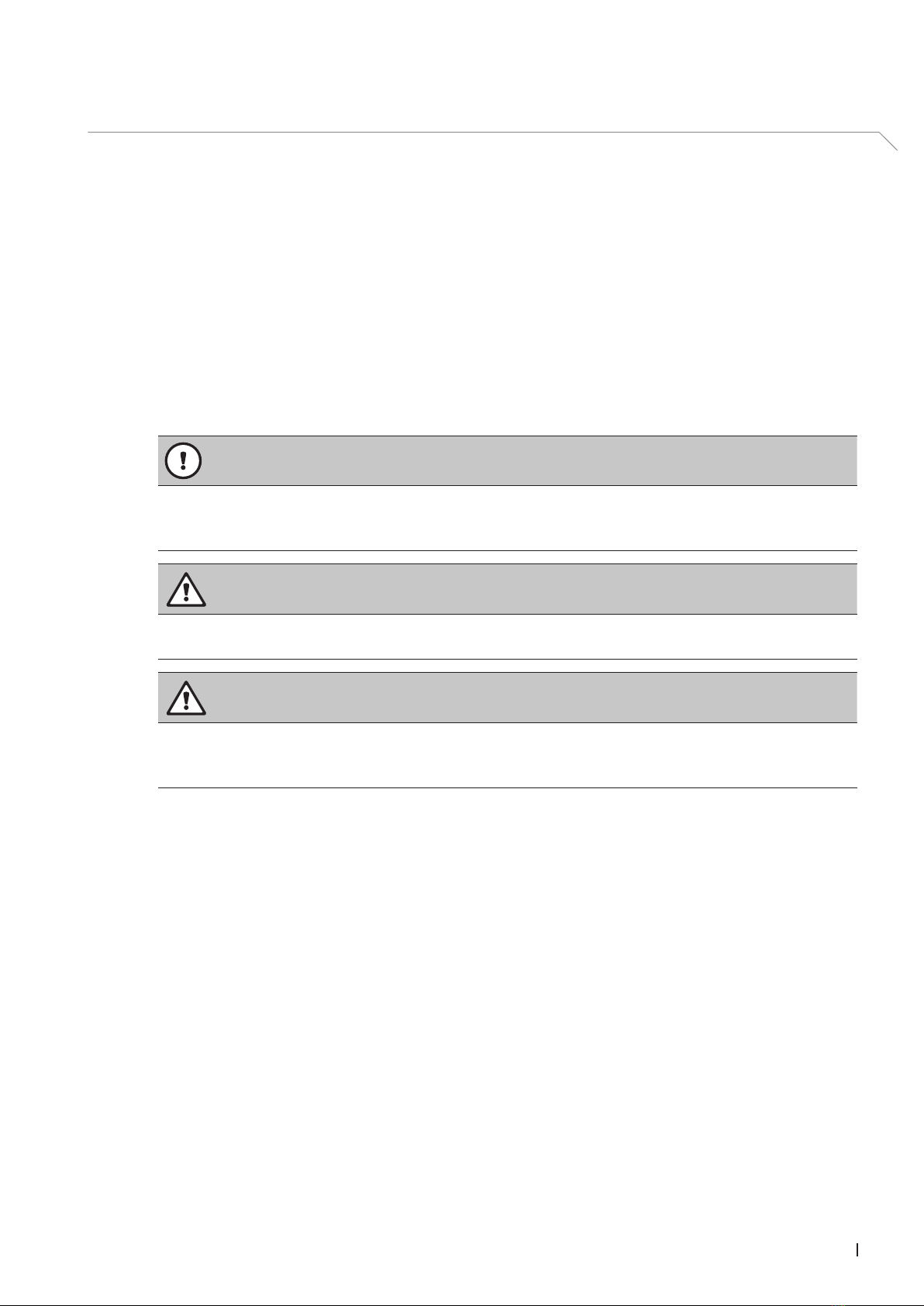

9Factory settings

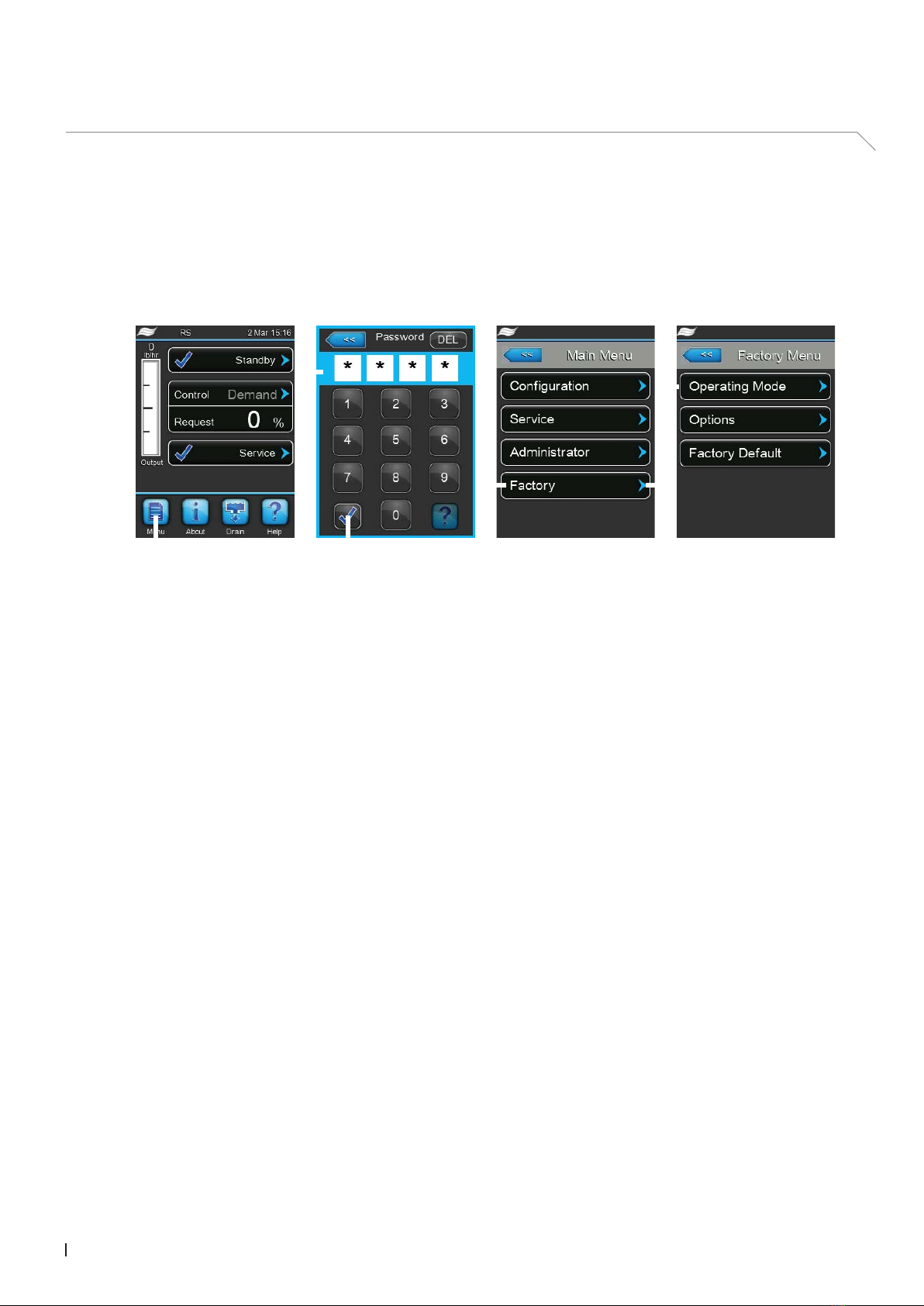

3.1.1 Determining unit settings

• In the "Factory" submenu press on the <Operating Mode> button. The unit settings parameter ap-

pear.

– Brand: With this setting you determine the brand name of the steam

generator.

Factory setting: Condair CE

Options: Condair CE (European version)

Condair UL (Amercian version)

Condair Spa (Spa version)

Attention: When you change the brand, the associated passwords

are also changed!

– Mode: With this setting you determine whether the controller is congured

to control the Condair Omega Pro only ("RS"), the Condair Omega Pro

with optional reverse osmosis system ("RS+RO") or the optional reverse

osmosis system only ("RO").

Factory setting: RS

Options: RS (congured to control the Condair Omega Pro

control only)

RS+RO (congured to control the Condair Omega

Pro control with optional reverse osmosis system)

RO (congured to control the optional reverse osmosis

system only)

– Nominal Voltage: With this setting you determine the heating voltage of

the of the steam generator.

Factory setting: 400V

Options: 200V, 208V, 230V, 240V, 380V, 400V, 415V,

440V, 460V, 480V, 500V, 550V, 600V

– Nominal Capacity: With this setting you determine the nominal steam

capacity of the steam generator.

Factory setting: 5kg/10lbs

Options: 5kg/10lbs, 8kg/15lbs, 10kg/20lbs, 16kg/30lbs,

20kg/45lbs, 24kg/53lbs, 30kg/65lbs, 40kg/90lbs,

50kg/110lbs, 60kg/130lbs, 70kg/550lbs,

80kg/180lbs

– Flicker Correction: With this setting you determine a icker Gradient to

adjust the factory set icker time.

Important: icker regulations are only complied if the "Consider icker

rule" function in the unit settings of the user level is set to "On" and the

icker Gradient is set ≥2.0.

Factory setting: 2.0

Setting range: 0.1 ... 4.0

– Evaporation correction: With this setting you determine a factor to mul-

tiply the minimal demand threshold of the evaporation monitoring. See

also fault description E121 in chapter 4.33.

Factory setting: 2.0

Setting range: 1.0 ... 5.0