INTRODUCTION

GUIDE TO THIS MANUAL

This manual contains all the necessary

information necessary to safely operate the

Conestoga Models CM-25 & CM-50 Ground-drive

Spreaders. Should any questions arise, please

contact Conestoga Mfg. or your Dealer before

starting this equipment.

..

Regarding the information presented in this

manual: All safety, operating and service

information reflect current production units at the

time this manual was published.

References made to Left. Right, Front or Rear are

directions given when you are facing the unit from

the rear.

Please read this entire manual carefully before

operating this unit: doing so will insure your safety

and prolong the high performance of the

equipment.

FOR YOUR SAFETY

This manual contains the following Safety

Statements, listed separately here to impress

upon you their importance:

!NOTE: A clarification of information previously

stated or additional pertinent information.

!ATTENTION: A safety statement indicating that

potential damage to the equipment may occur if

instructions are not followed.

CAUTION: A Safety Statement which

reminds you of a good safety practice and/or

directs your attention to an unsafe practice which

could result in Personal Injury.

WARNING: A Strong Safety Statement;

indicating that a Hazard exists which may result in

Injury or Death if proper procedures are not

followed.

DANGER: The utmost level of safety must be

observed; an extreme hazard exists which

will result in the high probability of death or

irreparable serious personal injury if proper

precautions are not taken.

The best equipment operator is a careful

operator. By using common sense. observing the

safety rules and adhering to the precautions

specific to this spreader, you the operator can

expect this unit to provide many hours of carefree

service.

In addition to observing the specific precautions

listed throughout this manual, the following

general precautions apply and must be adhered

to in order to ensure safe and proper operation

of this equipment.

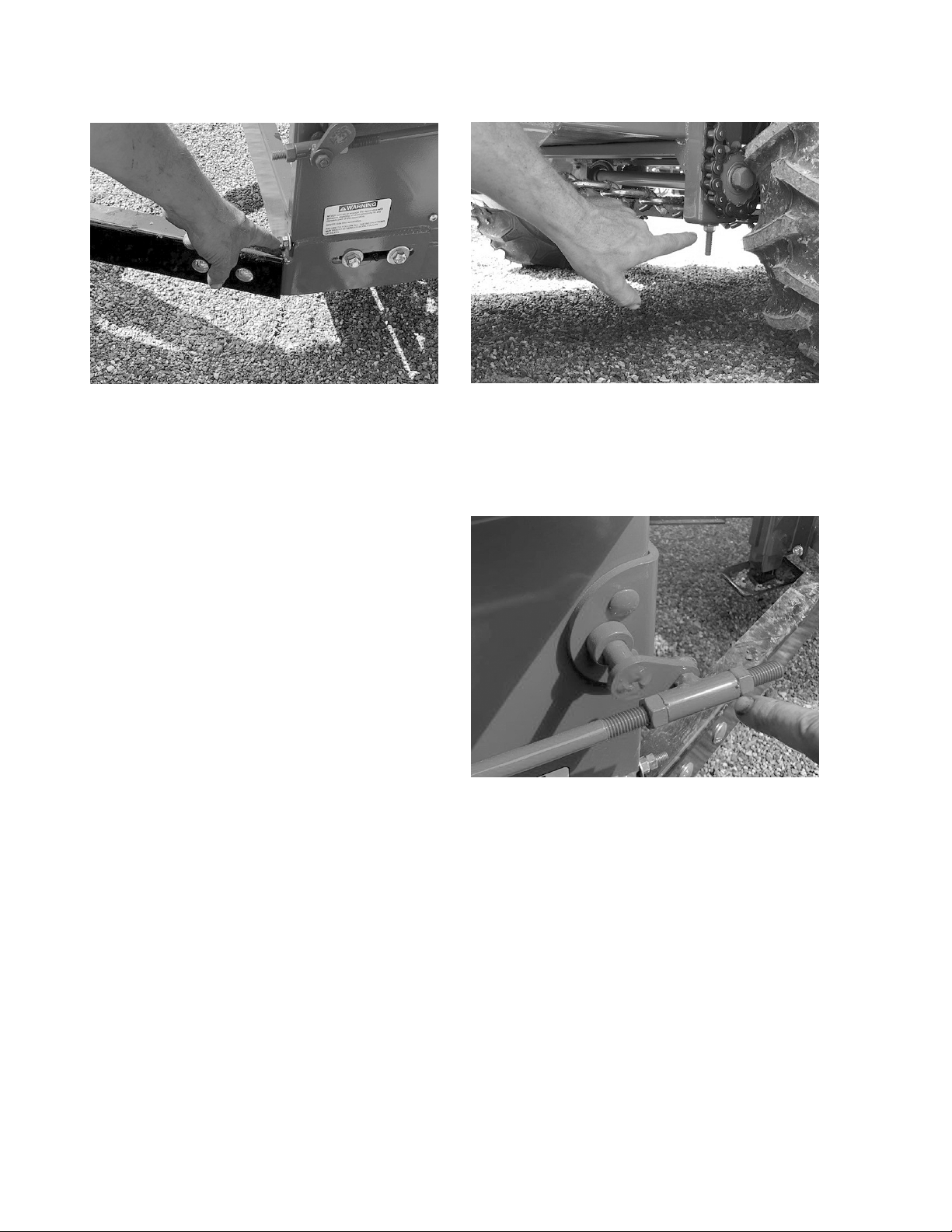

WARNING: Keep bands and feet from under

the spreader at all times. Be sure other persons

are at a safe distance from the equipment before

operating the unit.

WARNING: DO NOT attempt to operate the

spreader in areas with steep inclines. ditches.

large rocks. stumps or holes which may

endanger the operator by upsetting the tractor or

causing damage to the spreader.

CAUTION: To prevent injury and promote

safe spreader operation. keep all shields in place

during operation. Ensure that all mounting

hardware is properly tightened.

WARNING: Never clean, adjust or repair the

spreader while the tractor is running.

WARNING: Never get off the tractor while it

is in motion and/or the spreader is in operation.

WARNING: Never wear loose clothing when

operating the spreader as it may become caught

in the moving parts of the machine.

WARNING: Never allow children or anyone

else to ride on the spreader.

ATTENTION: To ensure proper and safe

operation of the spreader, periodically inspect all

parts for excessive wear. Replace worn

components with factory authorized parts.

ATTENTION: DO NOT back up when the

spreader is in unloading mode; doing so can

cause the beater drive chain to jump off its

sprocket.

The following Safety Decals have been placed

on your spreader to remind you of the critical

safety precautions which must be heeded to

ensure the personal safety to you the operator,

and any persons in the vicinity of the equipment

while it is in operation. Be sure to keep the

Safety Decals clean and readable. If the decals

ever become damaged or illegible. contact your

Conestoga dealer for replacements.

3