7Implementation

1. Open the air-guiding doors,andplacethemascloseto

theedgesoftheworkingareaaspossible.(Figure 1)

• Thedoorsareunlockedandlockedbylooseningand

tighteningtheknurled-headscrews.

2. Removetheprotectivecapfromtheexhaustairoutlet,if

thereisone.

3. Connect the device to the power gridUseasocketthatis

earthedand,ifpossible,equippedwitharesidualcurrent

device.

• First,thedevicecalibratesthefiltermeasurement

system,andthenitswitchestostandbymode.

• Inthecalibrationmode,bothindicatorlightsflash

greeninturns.

• Inthestandbymode,bothindicatorlightsareflashing

atthesametimeandindicatingthesaturationrateof

thefilters.Seesection8.6.

4. Connect the handheld concrete mixer to the socket of

the device.

• Nomorethan3,000Wmaybeconnectedtothe

sockets.

• Donotconnectextensioncordstothesocketsof

thedevice.Onlyelectricalequipmentusedatthe

workstationmaybeconnectedtothesocketsofthe

device.

5. Start the device.See section 8.2.

• Whenthemachineisrunning,theindicatorlightsare

constantlyonandindicatethesaturationrateofthe

filters.(Figures 2 and 3)

• Ifthedeviceshutsdownandtheindicatorlightsstart

flashingredatthesametime,checkthattheair-guid-

ingdoorsandexhaustairoutletareopenandthatthe

filtersareinplace.Presstheoperatingbuttonagain.

Protectthefloorsurfacebeneaththedevicewith,e.g.,corru-

gatedcardboard,plastichoneycombboard,orplywoodboard,

ifnecessary.

8Use

8.1 Operation at the workstation

Carryoutallthemixing-relatedworkphasesinfrontofthe

device,betweentheair-guidingdoors,andasclosetothesuc-

tioninletaspossible.Alwaysmakesurethatthedeviceisrun-

ningbeforestartingtoworkattheworkstation.

Pleasenotethatdustisproducedwheneverabagofdrymatter

isbeinghandled.Thelargestamountofdustisproducedwhen

thebagis opened,closed,or emptiedand whendrymatter is

mixed.

8.2 Use of the air-guiding doors

Thepurposeoftheair-guidingdoorsistorestrictthesourceof

dusttoassmallanareaaspossible,sothatthedustcanbeef-

fectivelydirectedtothefilters.Dustsuctionisthemosteec-

tivewhentheair-guidingdoorshavebeenplacedclosetothe

rimsofthemixingcontainer.

Theair-guidingdoorsalsofunctionasasplashguard,sothatthe

splatter flying o from the handheld concrete mixer does not

entertheworkingenvironmentandlandonthecompletedsur-

faces.

8.3 Startup and shutdown

Thedeviceisonlyequippedwithoneoperatingbuttonthatis

usedforcontrollingthedevice.

• Oneshort pushstartsthedevicefor5minutes,afterwhich

4 Consair CAMU D2

itswitchestostandbymode.

• Onelong push(5seconds)startsthedevice,anditre-

mainsinoperationuntilitisswitchedobypressingthe

operatingbutton.

Whenthedeviceisrunningandthesuctionison,theindicator

lightsandtheworklightareon.Whenthedeviceisinthestand-

bymode,theindicatorlightsflashsimultaneouslyandthework

lightiso.

8.4 Work light

The device is equipped with an eective 10W LED work light

that is always on when the device is running and the suction

ison.Direct thelighttothemixingcontainer.Thelightmakes

workingattheworkstationfasterandeasier,anditalsomakes

theproduceddustvisible.

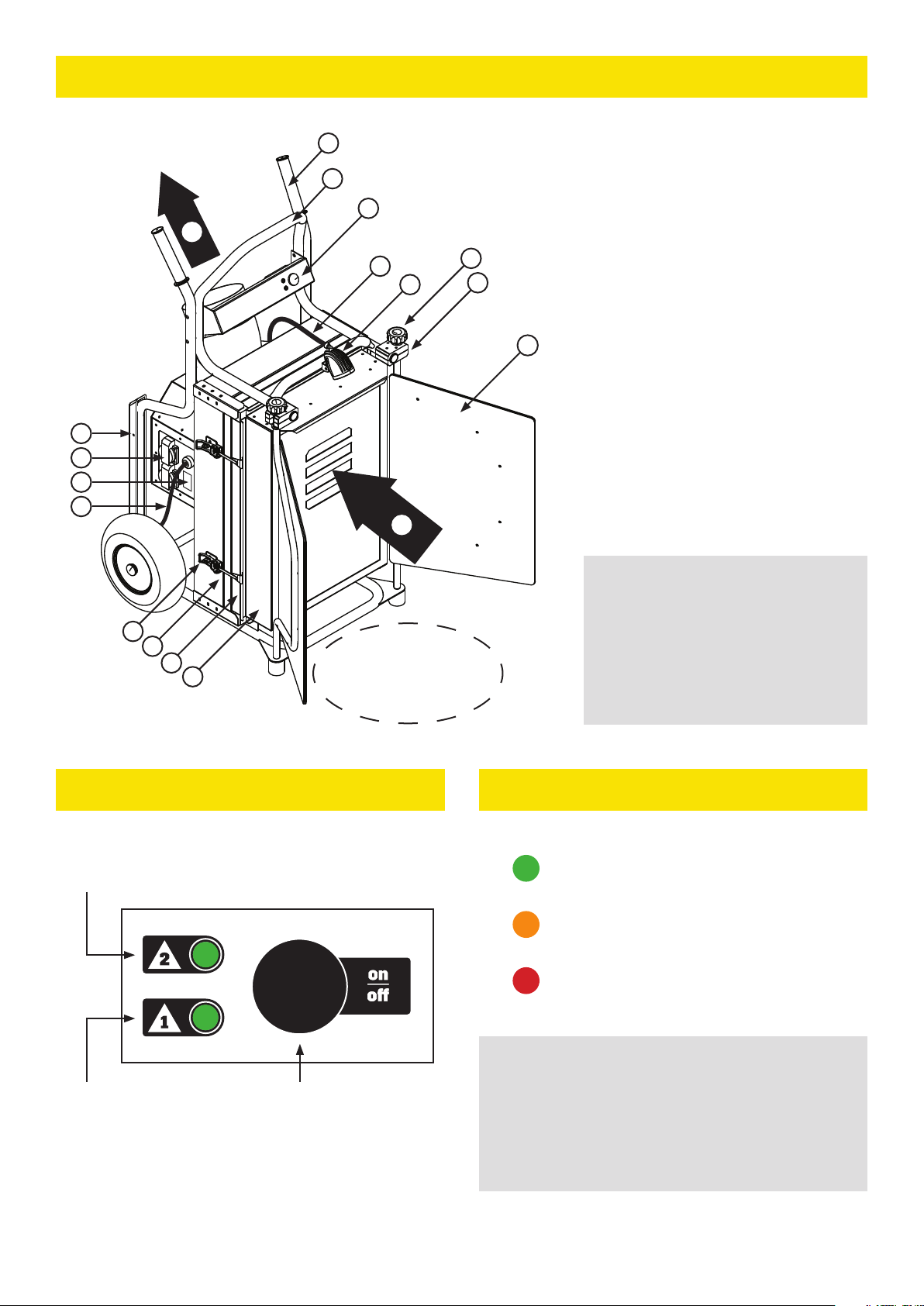

8.5 Indication of the need for a filter replacement with

an indicator light (Figures 2 and 3)

Thecontrolpanelofthedeviceisequippedwithtwoindicators

thatindicatewiththeaidofcolouredlightshowsaturatedthe

filters are.The upper light (2) indicates the saturation level of

themainfilterandthelowerlight(1)indicatesthesaturationlev-

elofthepre-filter.

• Whenthegreenindicatorlightison,thefilterisingood

condition.

• Theorangeindicatorlightindicatesanimpendingfilter

change.Whentheorangelightison,thesaturationlevelof

thefilterhasexceeded70%.

• Whentheredindicatorlightison,thefilterisfull.Thede-

vicecannolongermaintainasucientlyhighairflowrate

andthedevice’sabilitytoabsorbdustreduces.

8.6 Indication of fault modes with an indicator light

Thedeviceindicatesfaultmodeswithtwoflashingredindicator

lights.

Ifbothredindicatorlightsareflashingatthesametime,thede-

vicehasdetectedthemodethatpreventsitsuse.

• Checkthattheair-guidingdoorsareopen,theexhaustair

outletisopen,thefiltersareinplace,andthelatchesof

thefilterenclosuresareclosed.

• Thedeviceswitchestoamodethatpreventsitsuseevery

timethelatchesofthefilterenclosuresareopenedand

thefiltersareremovedfromthedevice.Themodethat

preventstheuseofthedevicestopstherotationofthefan

andthusensuressafefilterreplacement.

• Alsocheckthatthemeasurementtubecomingfromthe

intermediatefilterenclosureframeisintactandinits

place.

• Whenyouhaveinspectedthemachine,presstheoperat-

ingbuttonagain.Thedevicecalibratesthefiltermeasure-

mentsystemandswitchestostandbymodeifeverything

isinorder.

Ifbothindicatorlightsareflashingredinturns,thereisafaultin

thedevicethatneedstoberepaired.

• Contactthemanufacturer,retailer,orthecompanythat

leasedthedevice.

8.7 Exhaust air outlet

Thedeviceisequippedwitharound160-mmexhaustairoutlet.

Ifanexhaustpipeisconnectedtotheexhaustairoutlet,itmust

benotedthatthegreaterbackpressureconsequentlydirected

atthefanunitreducestheservicelifeofthefilters.Forthisrea-

son,itisnotadvisabletoconnectanover1-metrelongexhaust

pipetothedevice.Onlyusehardpipewithasmoothsurface.

Iftheexhaustairoutletofthedeviceisconnectedsothatitis

directedoutwardsfromthebuilding,itmustalsobenotedthat

duetofluctuationsintemperatureandairhumidity,condensa-

tion,whichreduces theservicelife ofthe filters,mayoccurin

thefilters.