Installation

INSTALLATION

GENERAL INSTRUCTIONS

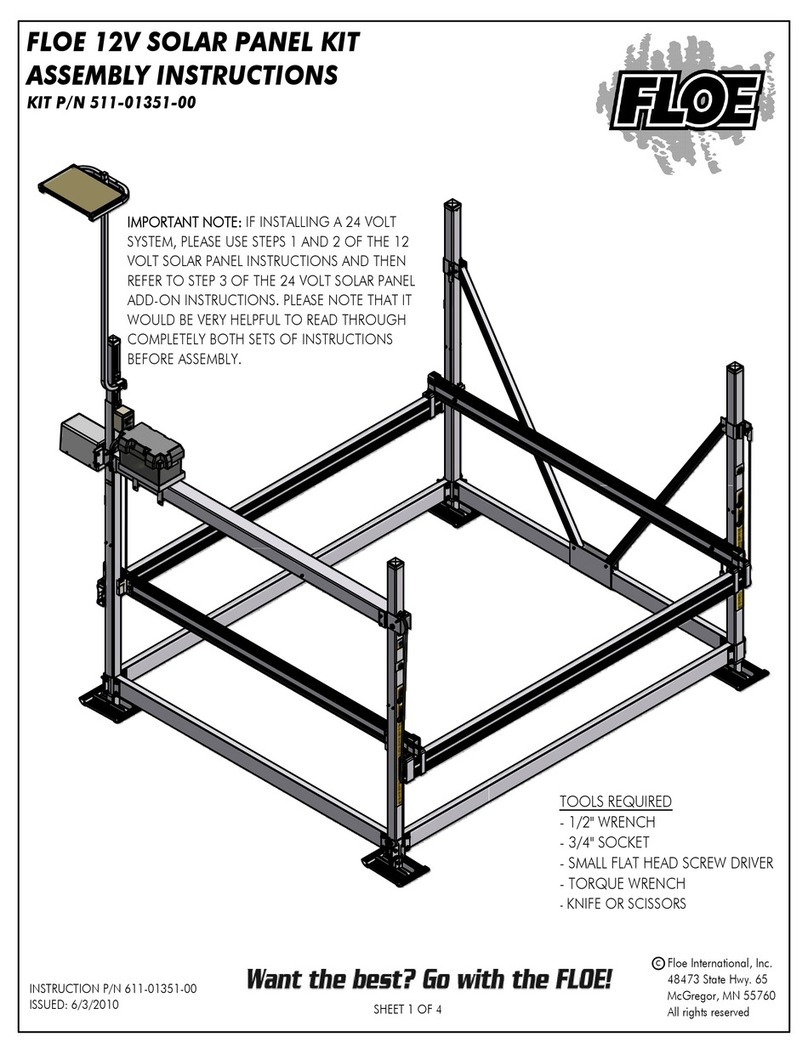

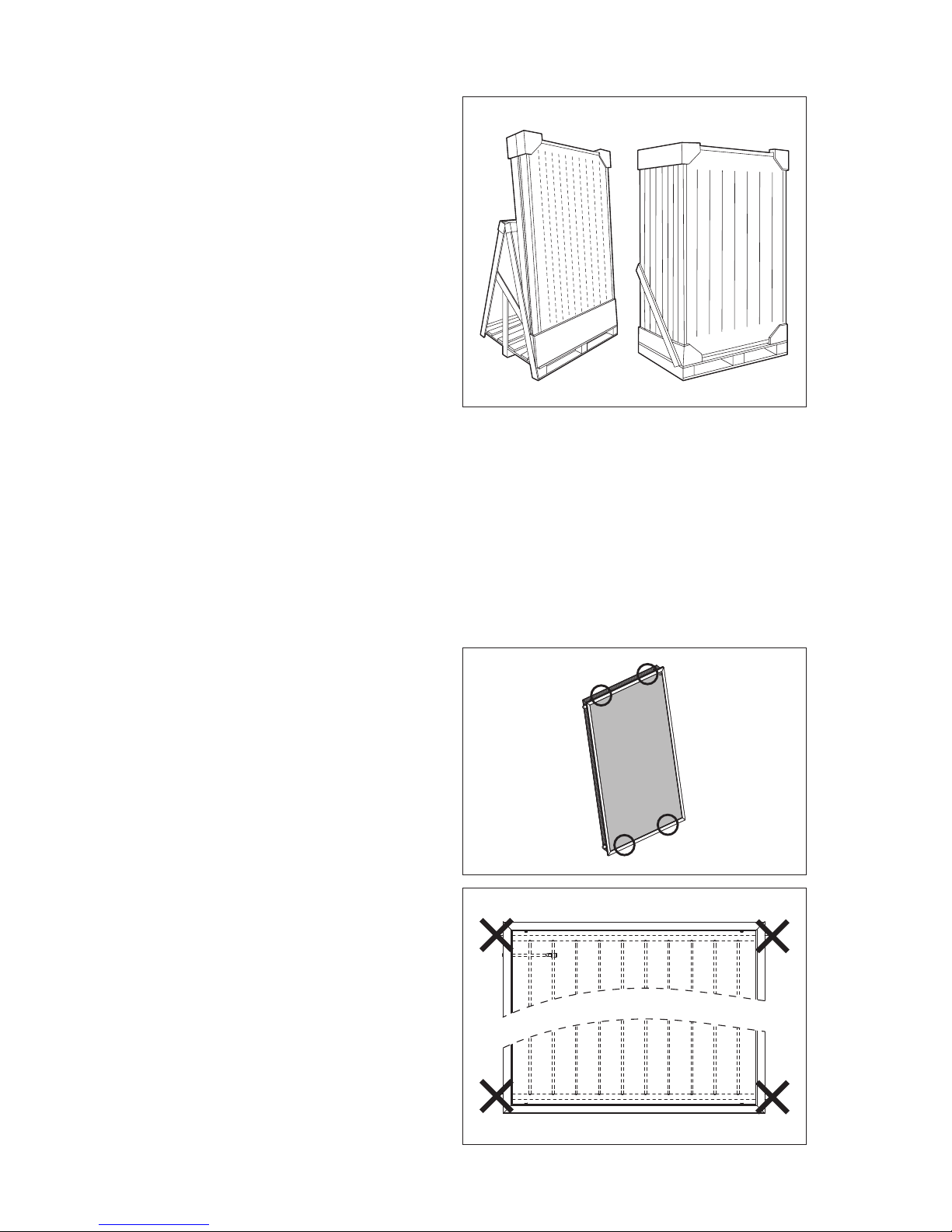

Assembly

The system must be installed by specialist personnel. Use

only the assembly material supplied with the solar collec-

tor. The supporting framework and all masonry or brick-

work fixing points must be checked by a person expert in

static loading, and must be suitable for the nature of the

installation site.

Static load

The solar collector must only be installed on roofs or frames

that are strong enough to support its weight. The strength

of the roof or frame must be verified on site by a person ex-

pert in static loading before the solar collector is installed.

During this process, it is important to verify the suitability

of the supporting frame to hold the screw fasteners that fix

the solar collector in place. An expert in static loading must

verify that the entire frame complies with relevant stand-

ards, especially in areas liable to snow and areas exposed

to high winds. Conditions (gusts of wind, formation of wind

vortices, etc.) at the point where the solar collector is to

be installed must be carefully considered since these can

increase the loads on the supporting structure.

Lightning protection

The metal piping of the solar heating circuit must be con-

nected to the main potential compensation bar by a (yel-

low-green) copper wire (H07 V-U or R) of at least 16 mm2. If

a lightning conductor system is already installed, the solar

collectors may be connected to the existing system. Alter-

natively, the solar collector piping may be connected to

ground via a ground wire sunk into the earth. Ground wires

must be sunk outside the house. The ground wire must be

connected to the potential compensation bar through a

wire of the same diameter.

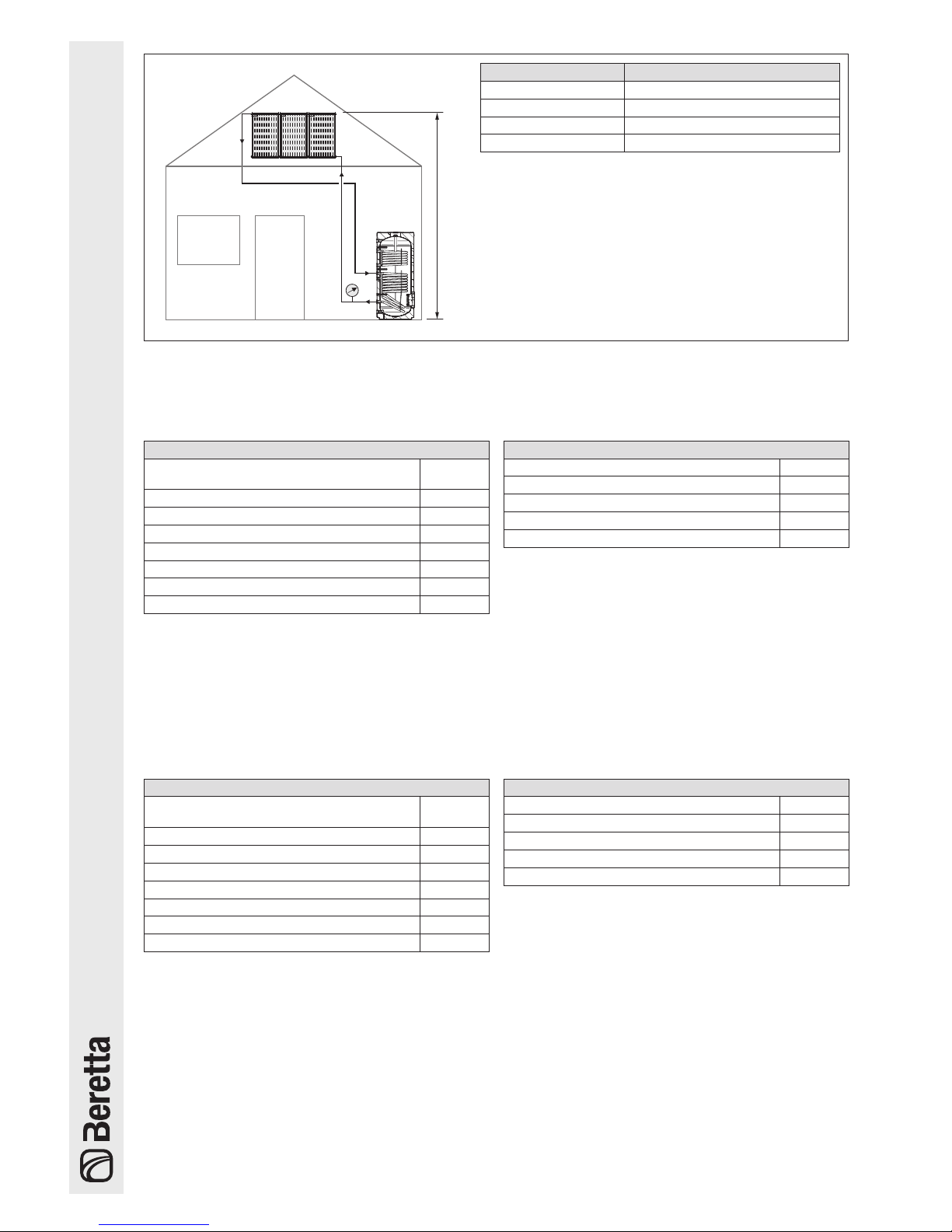

Water connections

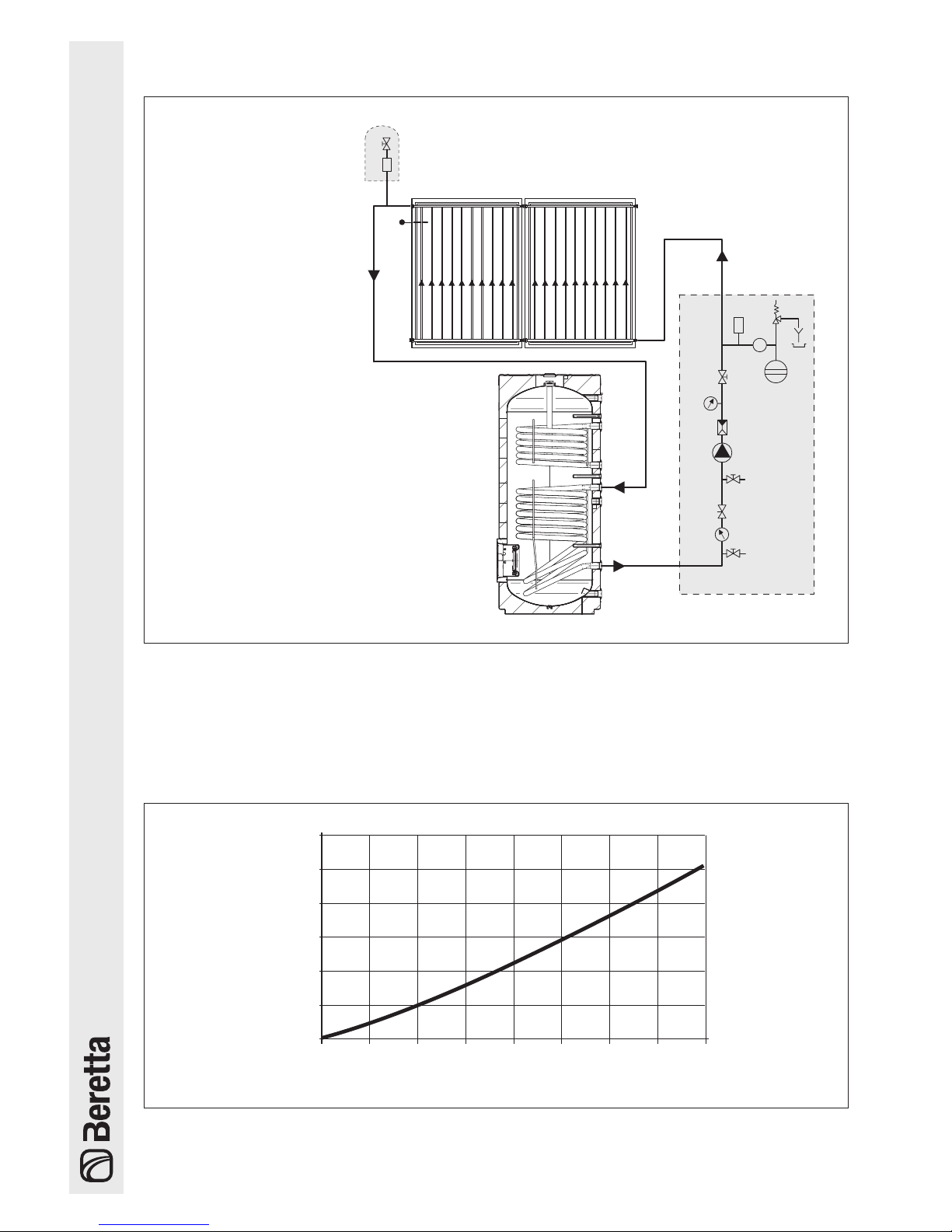

The solar collectors must be connected in series using the

fittings and seal rings provided. If flexible hoses are not

used to connect up the ends of solar collector lines, we

recommend that you fit devices in the connecting pipes

to permit thermal expansion (U-type expansion joints, sec-

tions of flexible hose or dedicated expansion joints). Pro-

vided adequate expansion joints are used, up to 6 solar

collectors may be connected in series. Make sure that the

seal rings are correctly positioned in their seats. When

tightening a fitting with a pipe wrench or spanner, always

hold the opposite fitting steady with a second tool to avoid

damaging the absorber.

b All pipes in the water circuit must be insulated in con-

formity to relevant standards. Lagging and insulation

must be protected against damage by the weather

and birds and animals.

Angle of collectors / General

Solar collectors are designed to be installed at angles of

between 15° (minimum) and 75° (maximum). Make sure

that the bleed and vent valves of the collectors remain

open while the collectors are being installed. Take care

to protect all fittings, connections, bleed and vent valves

against dirt and dust etc. In installations which serve pri-

marily to produce domestic hot water in the summer, install

the collectors facing from east to west at an angle of be-

tween 20 and 60°. The ideal orientation is southwards, at

an angle equal to the latitude of the location minus 10°. If

the system sustains the greatest thermal load in the winter

(as in systems that combine domestic hot water production

with central heating), install the collectors facing south (or

south-east or south-west) at an angle greater than 35°. The

ideal orientation is southwards, at an angle equal to the

latitude of the location plus 10°.

b Work near uncovered and live electrical wires, with

which it is possible to come into contact, is only per-

mitted under the following conditions: wires must be

free from voltage for the entire duration of the work;

parts remaining live must be covered or accidental

contact prevented; the following minimum safety dis-

tances must be respected: 1m (for voltages of up

to 1000 Volts), 3m (for voltages from 1000 to 11000

Volts), 4m (for voltages from 11000 to 22000 Volts),

5m (for voltages from 22000 to 38000 Volts), >5m

(if the voltage is not known). Contact with open, live

electrical wires may lead to electrocution and may

even be fatal.

b Always wear safety goggles when drilling. Always

wear safety shoes, cut-proof protective gloves and a

safety helmet when performing installation work.

b Before beginning installation work on roofs, install the

necessary fall prevention and fall arrest devices and

ensure that all applicable safety standards are ap-

plied. Use only tools and materials that conform to

the safety standards that are applicable in the place

of work.

b Only wear overalls that have a safety harness (with a

suitable safety or fall-arrest belt, ropes or slings, fall

dampers or dissipaters). In the absence of adequate

fall prevention and security devices, failure to use a

proper safety harness may lead to falls from great

heights with serious or even fatal consequences.

b The use of ladders leaned against walls can lead to

serious falls if the ladder slips, slides of falls. When

using ladders, always ensure that they are stable,

and that suitable ladder stops are present. If possible

secure the ladder with hooks. Make sure that there

are no live electrical wires near the ladder.