CONSORT SOLAR CO., LTD.

ETERNAL SUN VALUE CREATOR

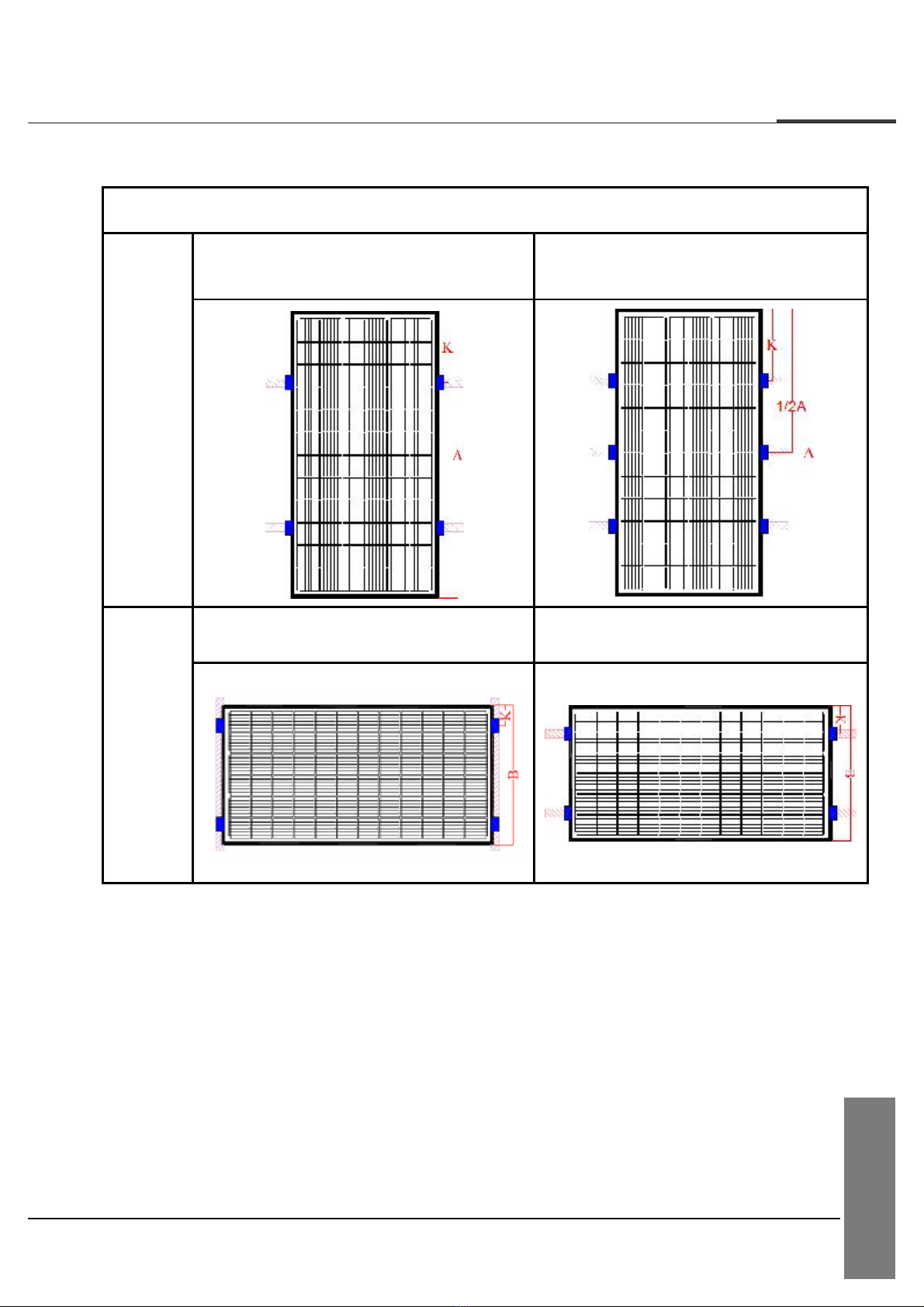

Installation requirements

Ensure the module installation method and support system sufficiently robust, so that

the Modules can undertake the preset loading conditions, the support installer or

supplier shall provide necessary guarantee and other related certifications. The

installation support system shall pass the inspection and test by the third-party test

institution with the static mechanic analysis capability, and use the local national or

international standards, such as DIN1055 or equivalent.

The support structure shall be made of the durable, corrosion resistant and ultraviolet

resistant materials.

The module shall be firmly mounted on the support.

Choose proper installation height of the photovoltaic support system, and ensure the

lowest part of the module is high enough, to avoid being shaded by plant or being

damaged by the flying sand. Or being covered by snow for a long time in winter.

When the module is installed on the roof or the building, it is necessary to ensure that

the roof structure is fixed firmly and will not be damaged by heavy wind or heavy

snow, and the back of the module shall be well-ventilated to facilitate the cooling of

the module (the minimum gap between the module and installation surface is 10cm).

Considering the influence of linear thermal expansion of the module frame, the

minimum distance between two Modules should not be less than 10mm.

Ensure that the module backside will not contact the support or architectural structure

even if there is the module surface is under the external pressure.

It is required to observe the instruction guide and safety rules attached on the support.

It is not allowed to drill the hole in the glass surface or frame of the module.

otherwise ,the guarantee will be invalidated

When to install the Modules on the roof, it is necessary to guarantee the roof

structure is suitable for the module installation. And the installed modules should not

be beyond the roof zone. Additionally, the roof area where it is penetrated by module

installation shall be properly sealed to prevent the roof from water leakage.

When the module is installed on the supporting column, it is necessary to ensure the

supporting column and module installation structure is capable of withstanding the

expected local wind.