4

Audio inputs (ohmically isolated)

Operation & Maintenance Manual

Page 1 of 4

Tel: 01732 223900 – www.contacta.co.uk

Operation & Maintenance Manual

Product Name

OEM Integrated Induction Loop Driver

Issue

Product Code

IL-A42

2.0

Project Number

PN0666

28/01/15

1. Introduction

The IL-A42 OEM induction loop module is part of Contacta’s induction loop system range. It has been designed to

be incorporated into third party manufacturers’ equipment. It allows an easy integral solution to machines and

equipment requiring an induction loop. The unit is low profile, discreet and can be fitted in small confined spaces.

There is no setup required. The unit is “plug and play”. It is supplied as a bare board but a suitable housing is

available separately.

2. Safety Precautions

Installation by a qualified engineer is strongly recommended

Ensure that you use a Contacta PS-55-00 power supply or a suitable power supply with a rating of 12-

14volts 2 amps peak. Do not attempt to plug it in to any other device otherwise damage may occur.

Do not attempt to dismantle or modify any parts of the unit. No user serviceable fuses or parts are included.

Warranty may be void if you do so. For repair, consult a Contacta engineer

3. Components

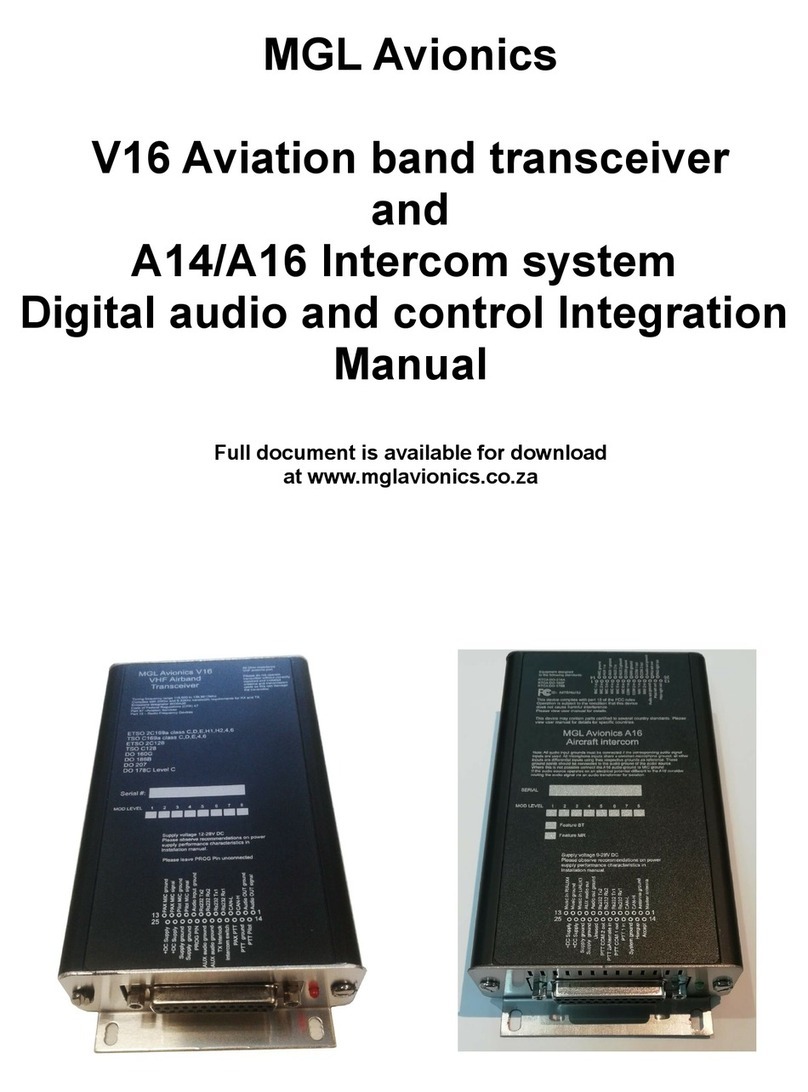

IL-A42 OEM Integrated Induction Loop Driver

4. Installation Instructions

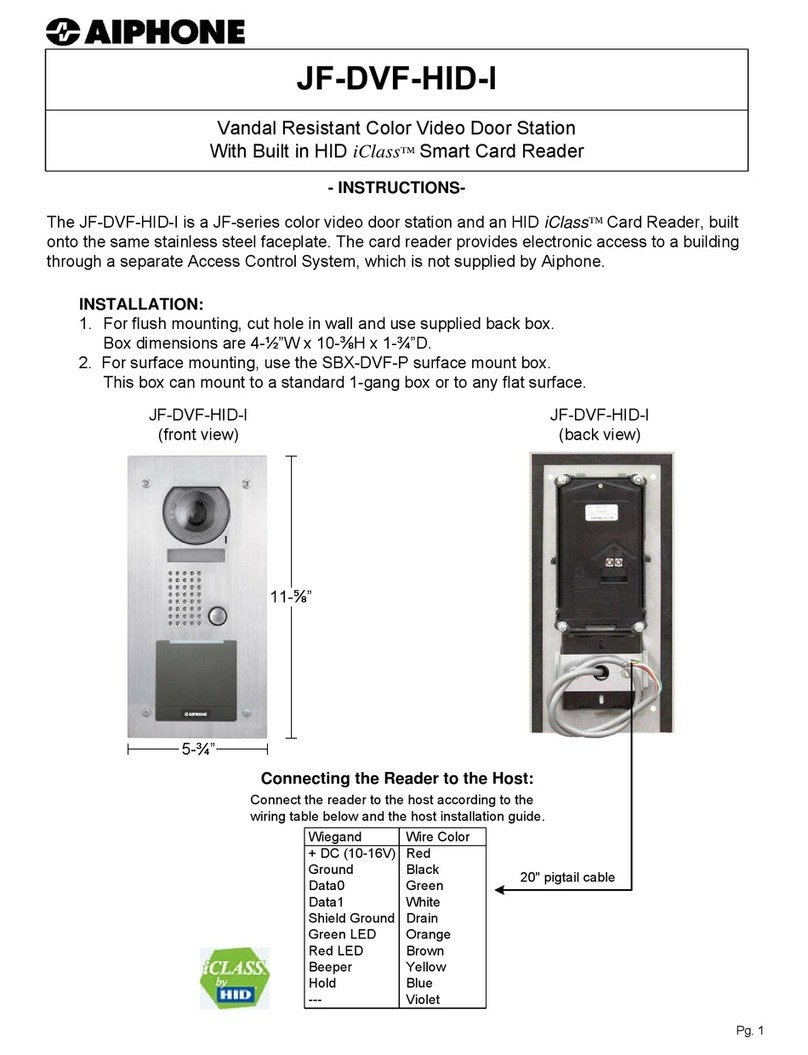

J3

J1

J2

POWER

IN/OUT

HDR1

ACTIVEOVERDRV

DCIN

LOOP

OUT/IN

IL-A42 OEM Integrated Driver

Figure 1

Audio In or out

Audio out or in

Output to

Induction Loop

Aerial

DC in 12-14v Input

(Designed for Contacta’s

PS-55-00 Power Supply)

For 3way version see figure 3 below

Connections

Operation & Maintenance Manual

Page 1 of 4

Tel: 01732 223900 – www.contacta.co.uk

Operation & Maintenance Manual

Product Name

OEM Integrated Induction Loop Driver

Issue

Product Code

IL-A42

2.0

Project Number

PN0666

28/01/15

1. Introduction

The IL-A42 OEM induction loop module is part of Contacta’s induction loop system range. It has been designed to

be incorporated into third party manufacturers’ equipment. It allows an easy integral solution to machines and

equipment requiring an induction loop. The unit is low profile, discreet and can be fitted in small confined spaces.

There is no setup required. The unit is “plug and play”. It is supplied as a bare board but a suitable housing is

available separately.

2. Safety Precautions

Installation by a qualified engineer is strongly recommended

Ensure that you use a Contacta PS-55-00 power supply or a suitable power supply with a rating of 12-

14volts 2 amps peak. Do not attempt to plug it in to any other device otherwise damage may occur.

Do not attempt to dismantle or modify any parts of the unit. No user serviceable fuses or parts are included.

Warranty may be void if you do so. For repair, consult a Contacta engineer

3. Components

IL-A42 OEM Integrated Induction Loop Driver

4. Installation Instructions

J3

J1

TB1J2

POWER

IN/OUT

HDR1

ACTIVEOVERDRV

DCIN

LOOP

OUT/IN

IL-A42 OEM Integrated Driver

Figure 1

Audio In or out

Audio out or in

Output to

Induction Loop

Aerial

DC in 12-14v Input

(Designed for Contacta’s

PS-55-00 Power Supply)

For 3way version see figure 3 below

Audio in or out

Audio out or in

Output to

hearing loop

14V DC 2.14A via 2.1mm

(from CA-10-02 or host

system)

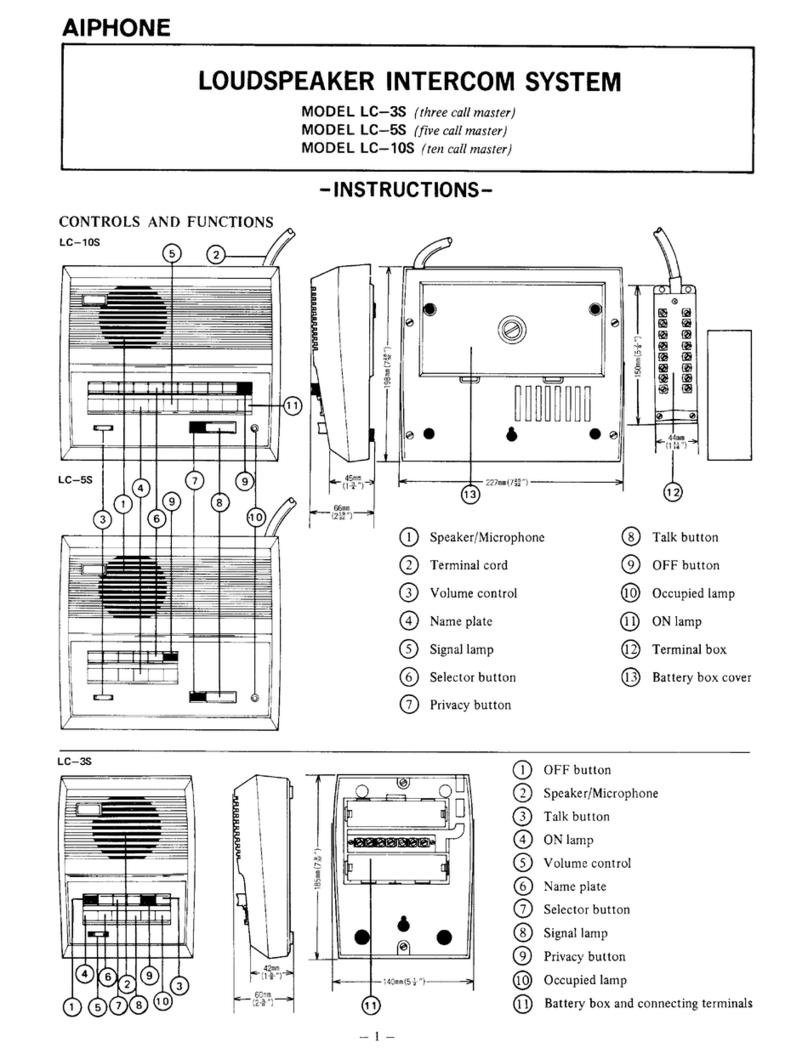

1 2 3

RIGHTLEFT

Power Supply

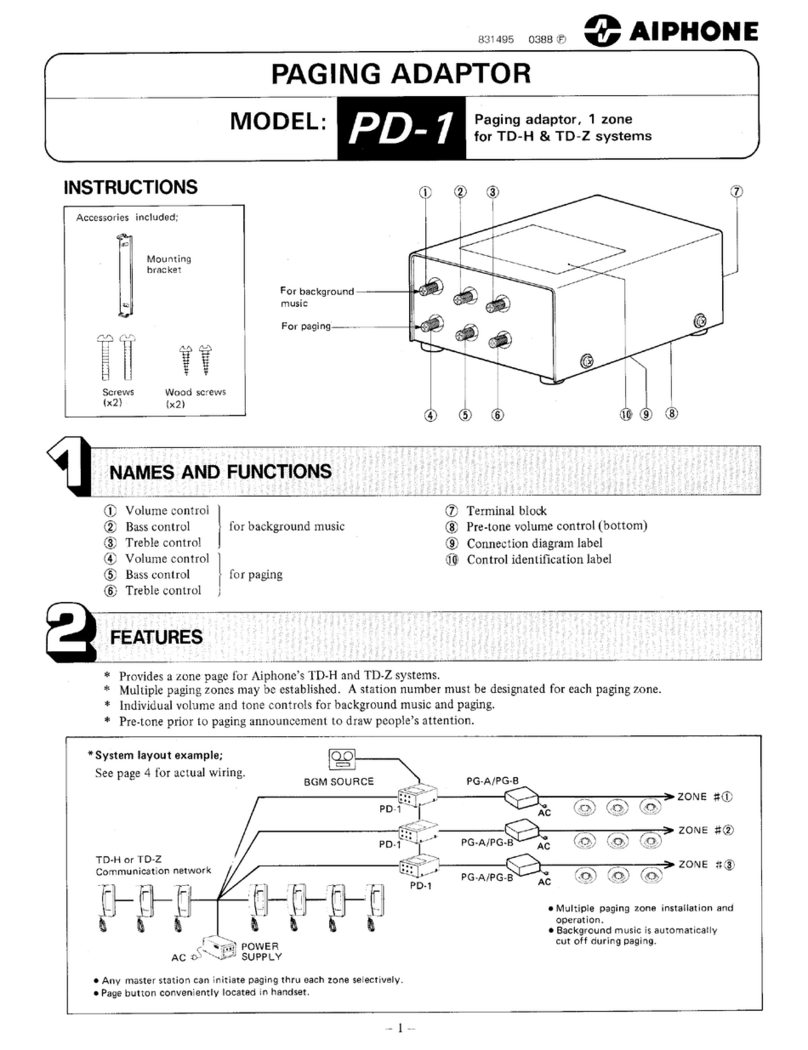

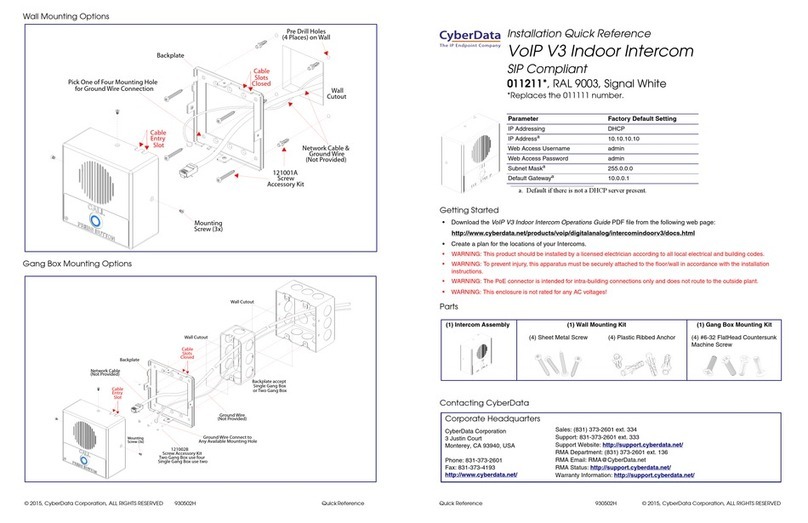

• We recommend the unit is powered using a CA-10-02 Power

Supply through port J1. If using a host system, ensure it meets the

following specications:

• Supply voltage: 14V DC

• Current output: 2A minumum

• 2.1mm power connector jack

• J1 is a 2.1mm DC jack with centre pin positive.

Audio Input Connection

• J2 is an audio input connection [100V line].

• J2 and J3 are connected in parallel and are therefore

interchangeable. They are ohmically ground isolated and have

series resistance to prevent interaction due to the paralleling of

stereo channels within the system.

Right (+) Ground (-)Left (+)

GND RIGHTLEFT