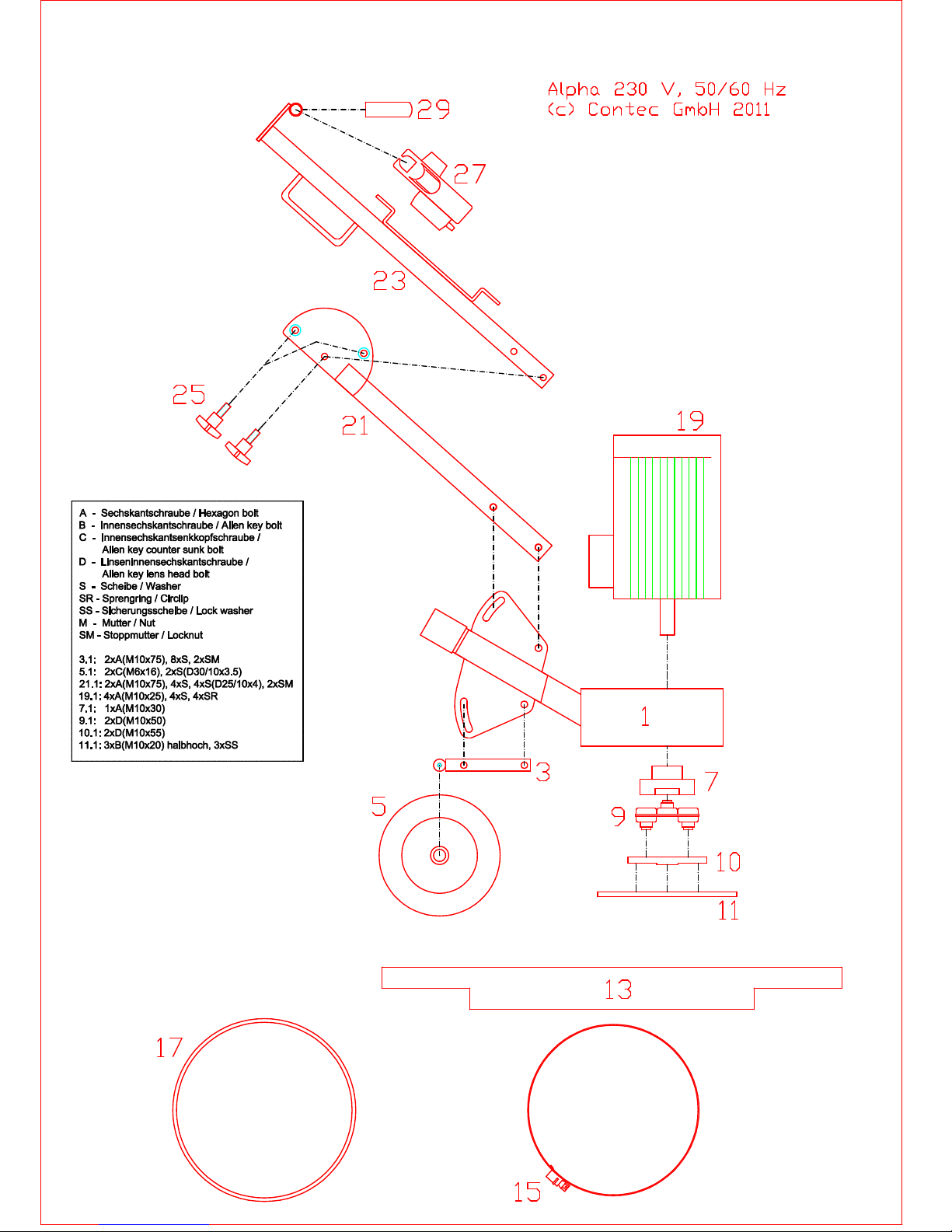

04-10-01-00 Grinding Head FrameAlpha 1 6,10

04-10-04-01 RearSwing ArmAlpha 3 1,00

80-20-52-22 RearWheelAlpha 5 1,45

18-17-06-01 Bracket forCoupling Alpha 7 1,12

90-25-10-01 RubberCoupling ForDriveAlpha 9 0,50

04-10-05-01 Bracket forPlatesAlpha 11 2,40

70-23-76-70 RubberSealing Alpha 13 0,35

90-27-03-01 ClampAlpha 15 0,21

70-23-81-50 Dustring Alpha 17 0,20

55-03-02-18 Motor1,8KVA, 230 Volt, 50 HZ, Omega 19 23,80

55-03-11-15 Motor1,5KVA, 110 Volt, 50 HZ Omega 19 15,00

04-10-02-01 BottomHandleAlpha 21 0,75

04-10-03-00 Top HandleAlpha 23 2,10

04-10-03-00-US Top HandleAlpha GBand USVersion 23 2,10

60-30-10-30 HandlescrewM10-25 Alpha 25 0,05

50-20-203-742 SwitchforAlpha 27 0,85

70-21-120-90 RubberGripAlpha 29 0,03

18-21-C1 Diamond PlateC1 Yellow 51 0,26

18-21-C2 Diamond PlateC2 Aubergine 51 0,26

18-21-CA1 Diamond PlateCA1Brown 51 0,26

18-21-CA2 Diamond PlateCA2Green 51 0,26

18-21-CS06 Diamond PlateCS06 Red 51 0,26

18-21-CS16 Diamond PlateCS16 Silver 51 0,26

18-21-CS40 Diamond PlateCS40 Blue 51 0,26

18-21-CS6/16 Diamond PlateCS6/16 Gold 51 0,26

18-21-MBC0 Diamond PlateMBC0 Brownround 51 0,26

18-21-MBC0+ Diamond PlateMBC0+Silverround 51 0,26

18-21-MBC1 Diamond PlateMBC1 Black round 51 0,26

18-21-MBC2 Diamond PlateMBC2 Green round 51 0,26

18-21-MBC3 Diamond PlateMBC3 Blue round 51 0,26

18-21-MBC4 Diamond PlateMBC4 Yellowround 51 0,26

18-21-PKD-S Diamond PlatePCD inSegment 51 0,26

18-10-29-11 Plateforpolishing Dotts 55 0,20

18-21-120-N Resignbond Wet Grid120 Black 57 0,09

Seite1von 2