9

HS150 / HS300 / HS500 BLADE AWARENESS

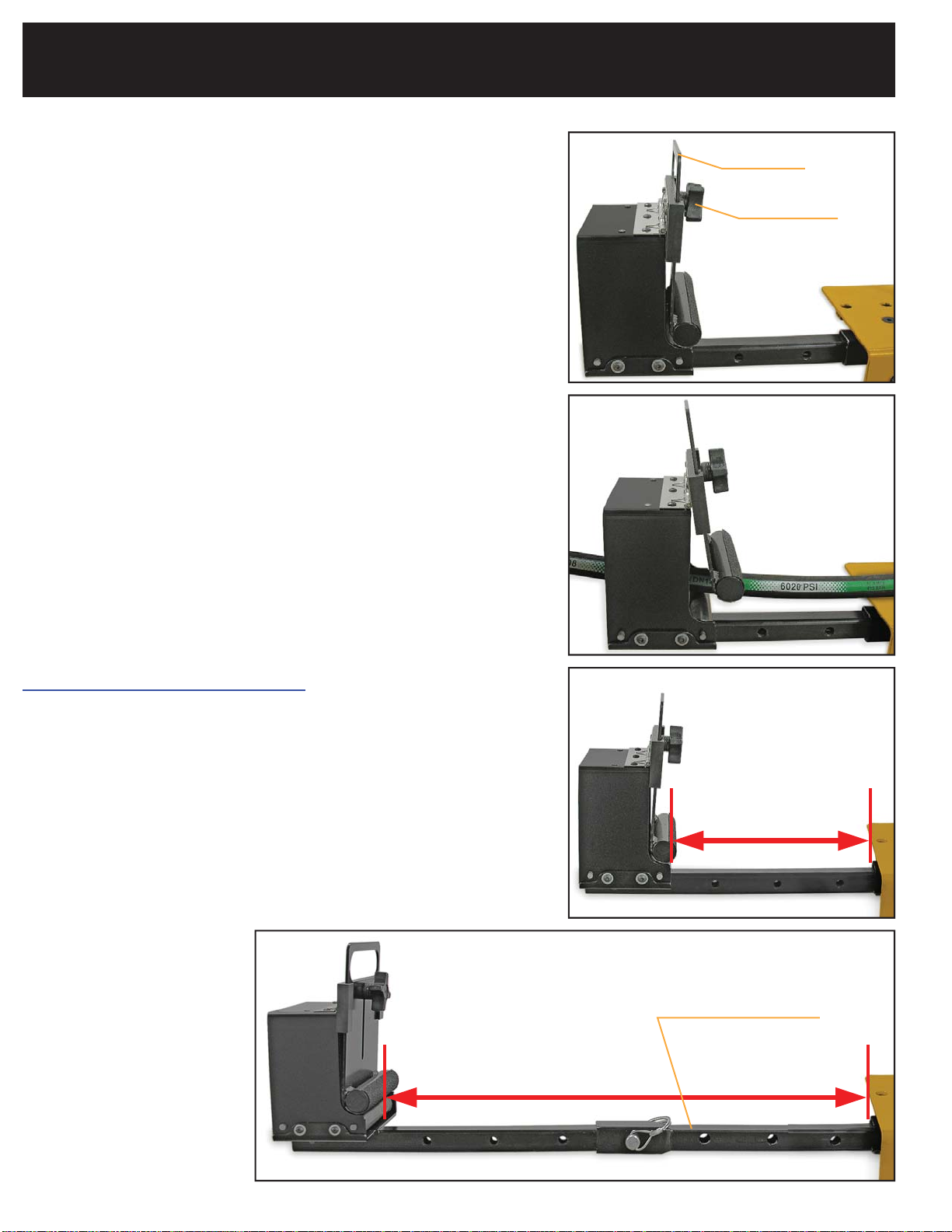

Note: New blades must be properly conditioned to

assure long life and clean cuts. For the first ten cuts,

feed the blade slowly through a medium size hose.

this will properly break in and condition the blade for

long life.

Note: The hose should begin to bend before contacting

the blade. This will increase blade life and keep the

hose from tearing and deforming.

Note: Once the blade and motor reach full RPM apply

steady downward pressure on the handle in order to force

the hose into the blade. Do not apply enough force to stall

the blade, and ease up on the pressure before the blade

completes the cut. This will keep from separating the wires

as the blade exits the hose.

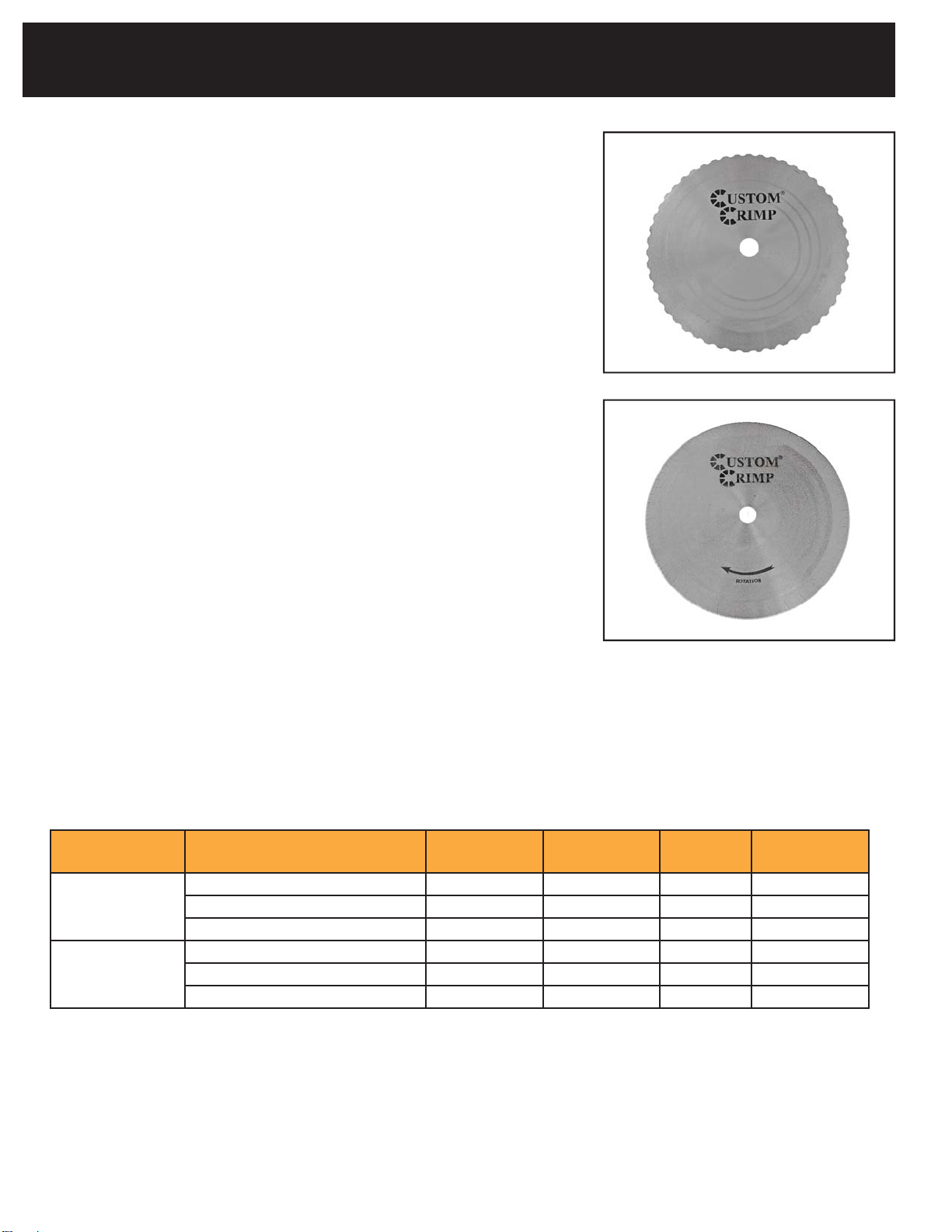

Note: The edges of the blade may appear to be dull.

This does not mean that the blade is not effective.

As long as the blade is still giving clean cuts, do not

replace the blade.

NOTE: PAY CLOSE ATTENTION TO THE DIRECTION OF

ROTATION MARKED ON THE SERRATED BLADE.

IT IS THE OPPOSITE OF MOST BLADES OF THIS TYPE.

CAUTION: Cracks can cause extremely damage to the

blade, periodically examine the blade for cracks and / or

broken teeth.

Serrated Blade

Scalloped Blade

Double Bevel w/SS Slots Blade

Damaged Blade