10

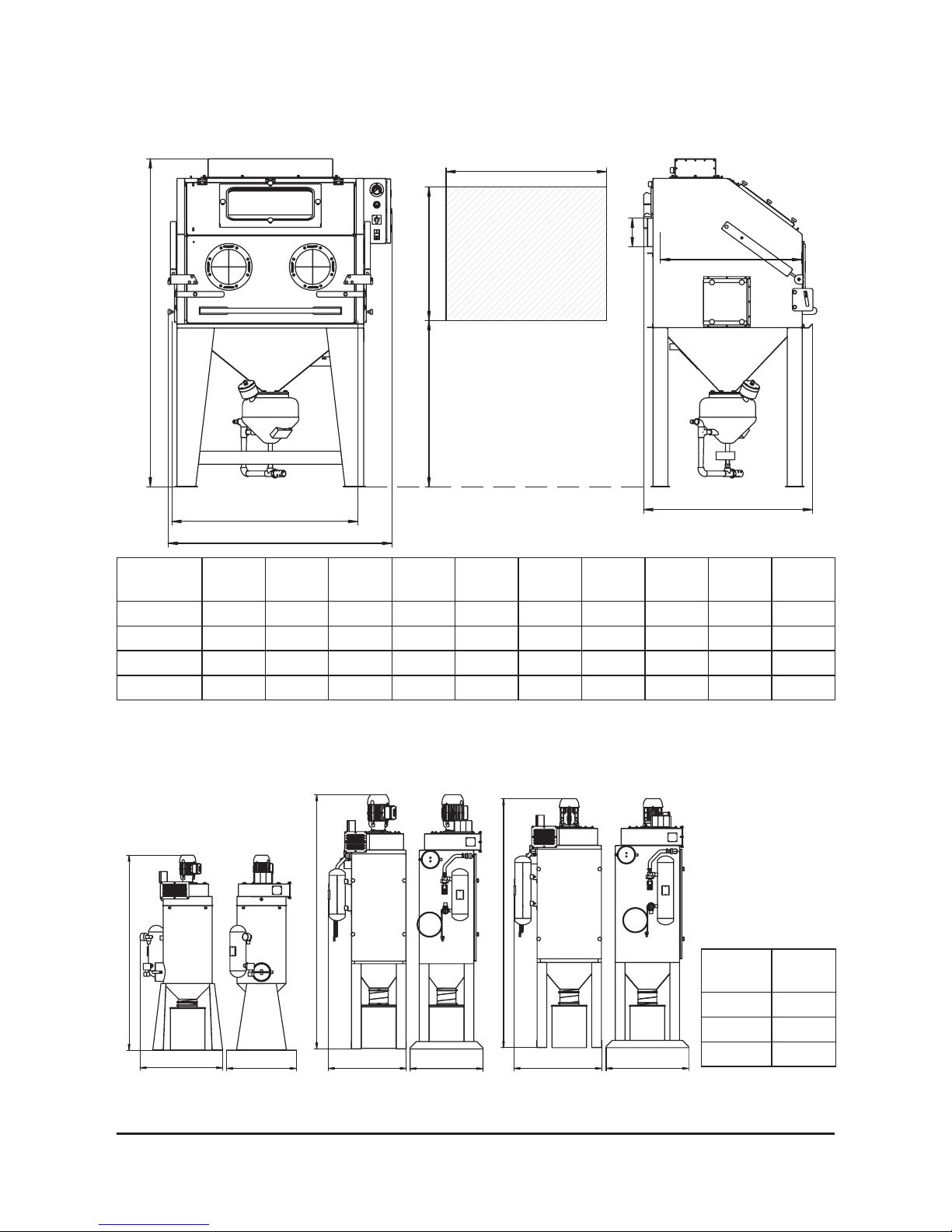

Order code Model Description, package

10217201 ECO-80P Blast cabinet, complete system, containing:

- Cabinet enclosure

- 13 liter blast machine

- Cartridge dust collector DC-370 (see. Table 2.2.)

Standard delivery:

- Quality 600 mm blast gloves with inner fabric lining

- 13x27 mm blast hose with coupling/nozzle holder

- Tungsten carbide venturi nozzle NTC-5.0

- FSV-0 metering valve

- Main airline ler with 5μ ltration grade

- Pilot regulated blast pressure

- Door safety interlocks

- Manual cleaned cartridge lter

- Electrical connection 0,50 kW, 380V, 3 phase, 50Hz

Working chamber size (W x D x H), mm 750 x 520 x 660

Weight, 139 kg

Noise level, 80 .. 120 dB (2000/14EC)

Standard load capacity, 350 kg

10217202 ECO-100P Blast cabinet, complete system, containing:

- Cabinet enclosure

- 13 liter blast machine

- Cartridge dust collector DC-370 (see. Table 2.2.)

Standard delivery:

- Quality 600 mm blast gloves with inner fabric lining

- 13x27 mm blast hose with coupling/nozzle holder

- Tungsten carbide venturi nozzle NTC-5.0

- FSV-0 metering valve

- Main airline ler with 5μ ltration grade

- Pilot regulated blast pressure

- Door safety interlocks

- Manual cleaned cartridge lter

- Electrical connection 0,50 kW, 380V, 3 phase, 50Hz

Working chamber size (W x D x H), mm 950 x 720 x 760

Weight, 246 kg

Noise level, 80 .. 120 dB (2000/14EC)

Standard load capacity, 350 kg

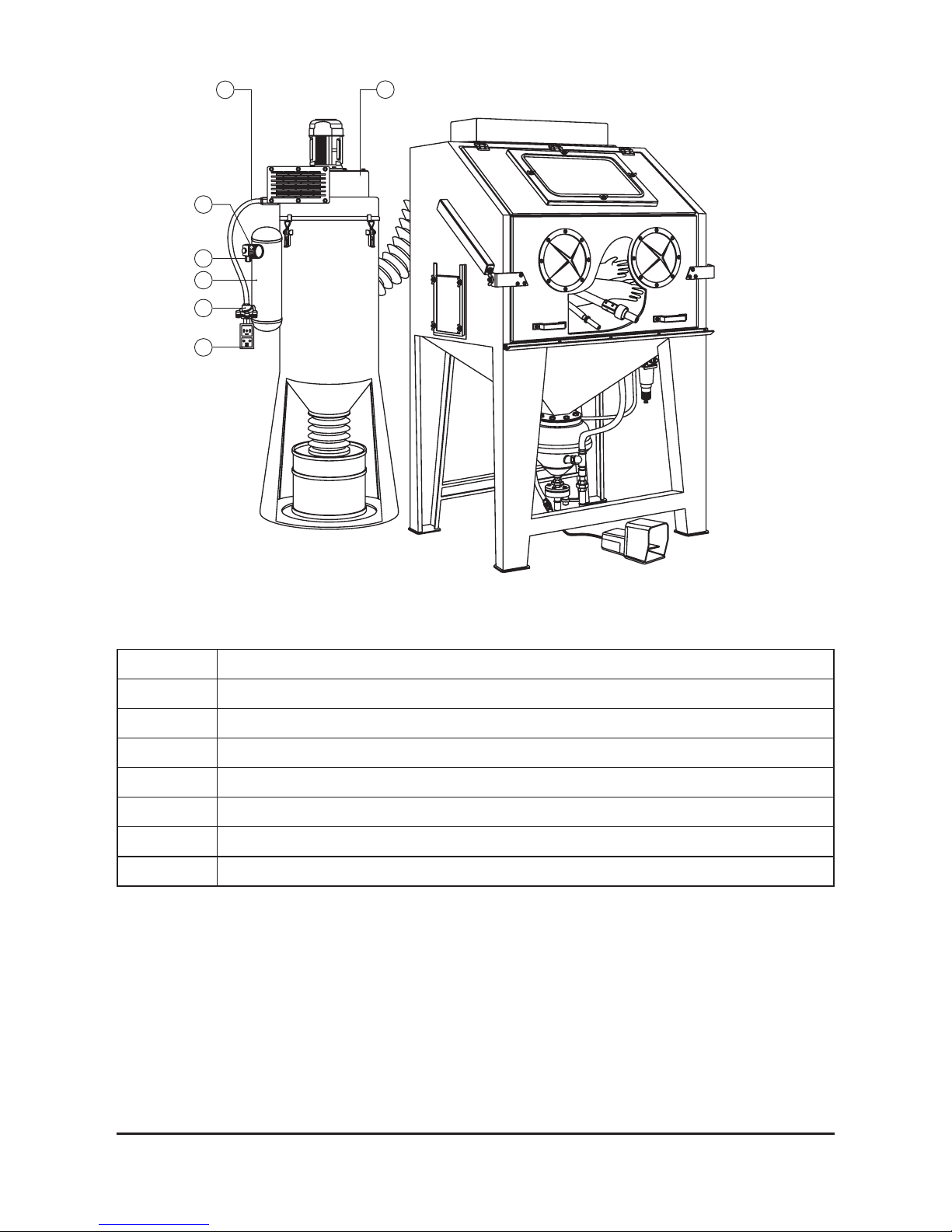

2.1. Package

Table 2.1