8

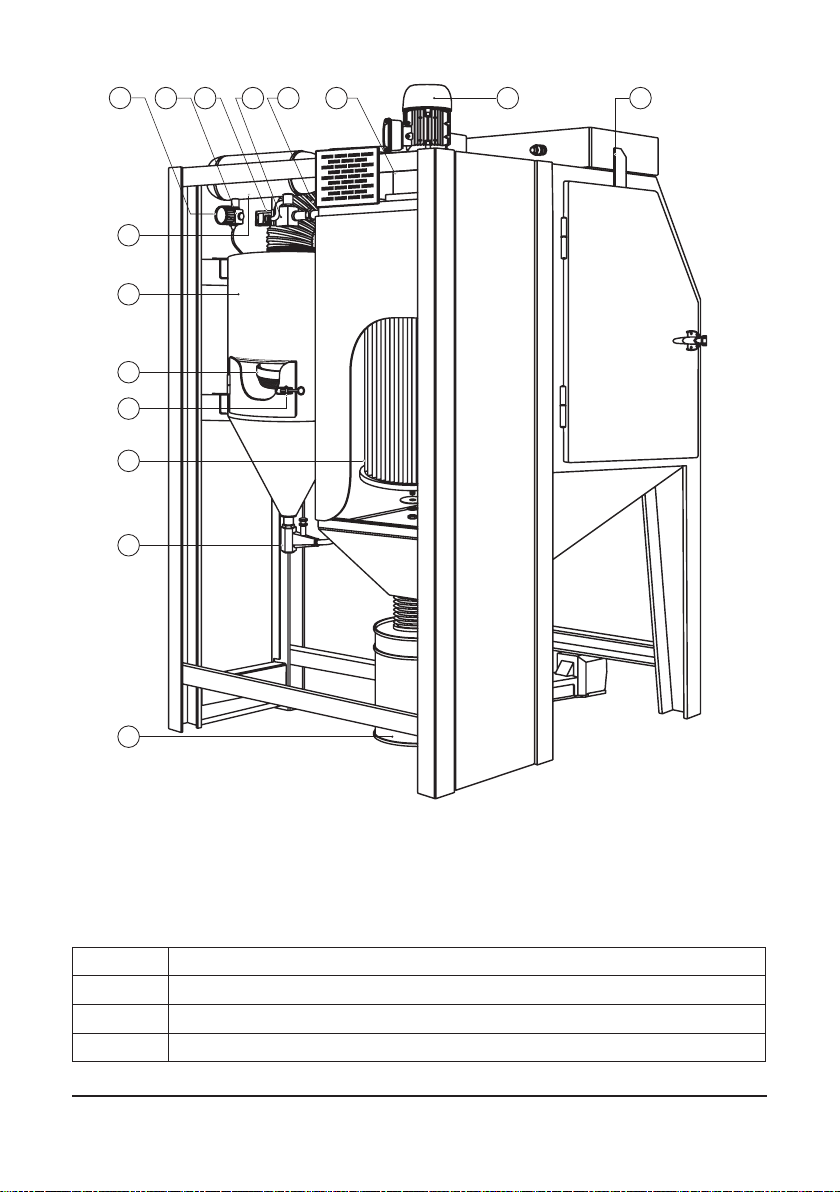

Order code Model Description, package

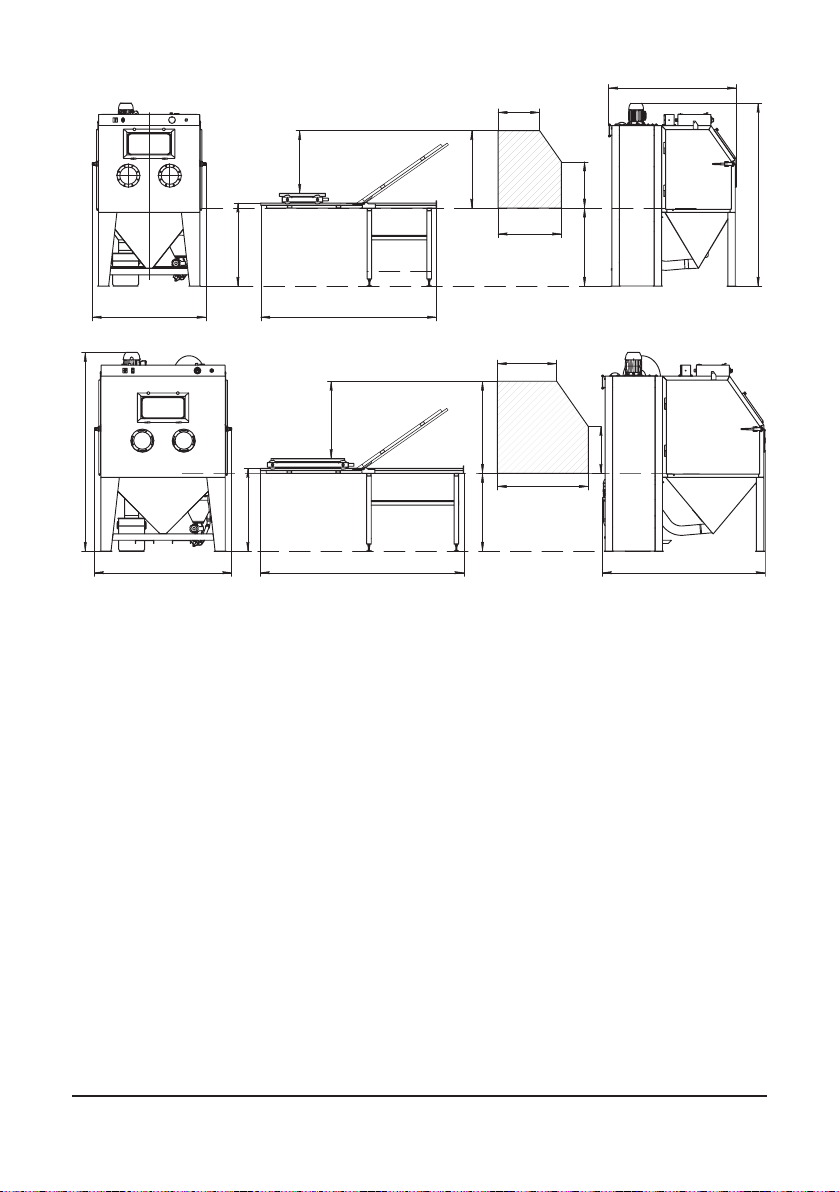

15105 CAB-110S BLAST CABINET, COMPLETE SYSTEM, CONSIST

- Cabinet Enclosure

- Cyclone reclaimer R-350

- Cartridge Dust Collector DC-1100 (see. Table 2.2.)

STANDARD DELIVERY:

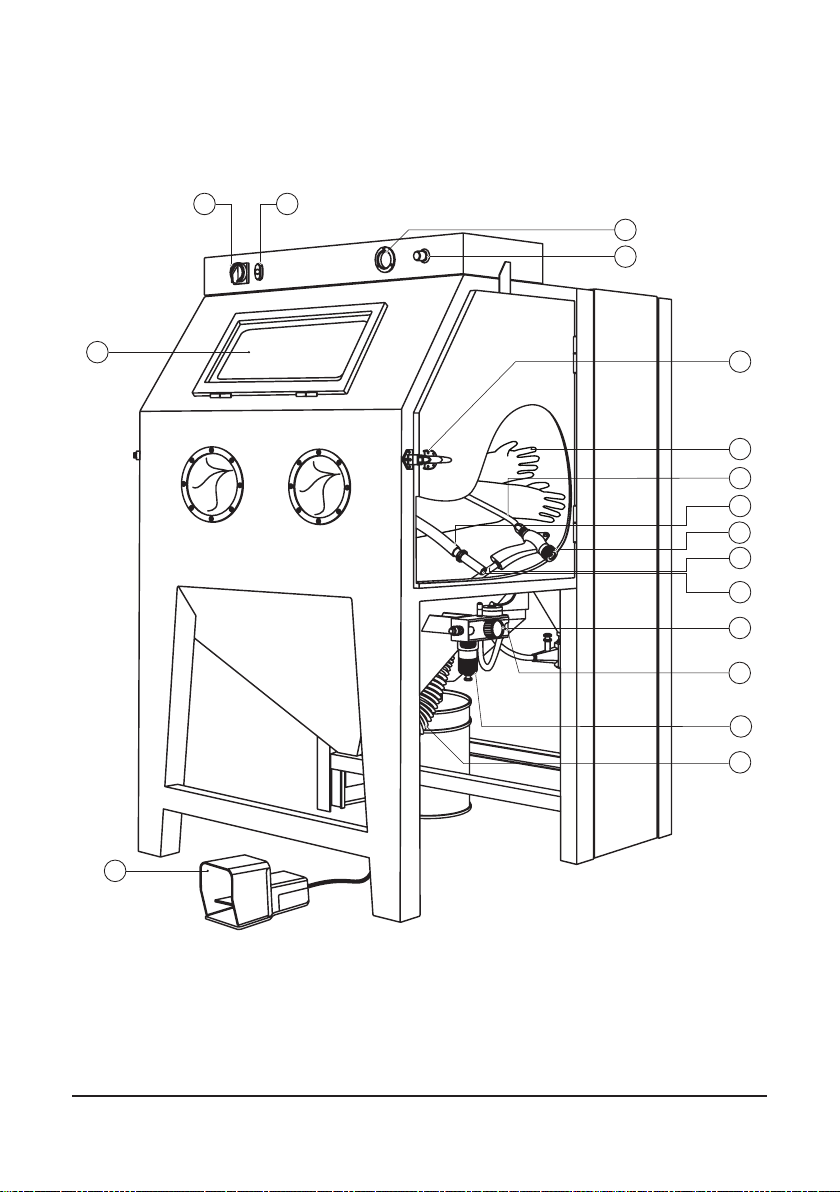

- Quality 800 mm blast gloves with inner fabric lining

- Manual suction blast gun GX

- GXT-8,0 tungsten carbide gun nozzle Ø 8mm

- Reclaimer metering valve

- Pilot regulated blast pressure

- Door safety interlocks

Electrical connection 1,10 kW, 380V, 3 phase, 50Hz

Working chamber size (W x D x H) 1100 x 800 x 840

Weight, 350 kg

Noise level, 80 .. 120 dB (2000/14EC)

Standard load capacity, 350 kg

15106 CAB-135S BLAST CABINET, COMPLETE SYSTEM, CONSIST

- Cabinet Enclosure

- Cyclone reclaimer R-400

- Cartridge Dust Collector DC-1500 (see. Table 2.2.)

STANDARD DELIVERY:

- Quality 800 mm blast gloves with inner fabric lining

- Manual suction blast gun GX

- GXT-8,0 tungsten carbide gun nozzle Ø 8mm

- Reclaimer metering valve

- Pilot regulated blast pressure

- Door safety interlocks

Electrical connection 1,50 kW, 380V, 3 phase, 50Hz

Working chamber size (W x D x H) 1350 x 1100 x 1070

Weight, 450 kg

Noise level, 80 .. 120 dB (2000/14EC)

Standard load capacity, 350 kg

2.1 Package

Table 2.1