Control Data Corporation FE119-A User manual

Popular Card Reader manuals by other brands

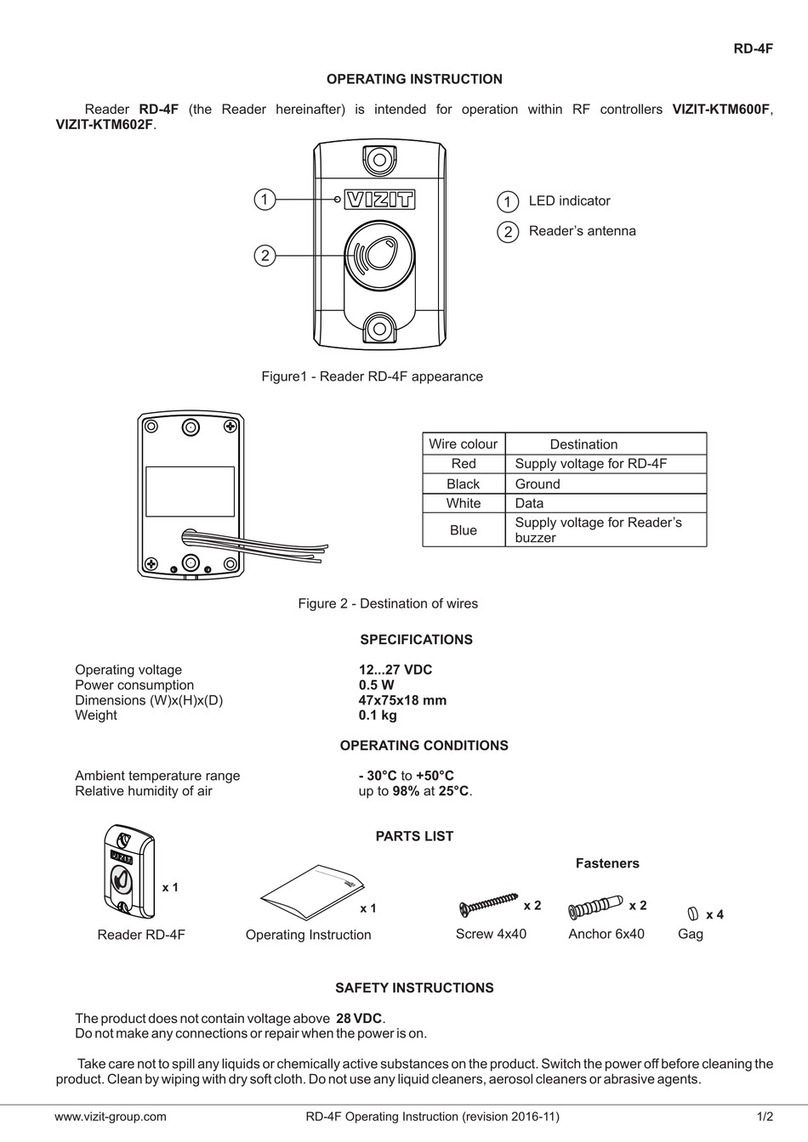

ViziT

ViziT RD-4F operating instructions

Jinmuyu Electronics

Jinmuyu Electronics MR811 Series user manual

Conrad

Conrad PCMCIA operating instructions

Lindy

Lindy 51541 user manual

Diapro T?bbi Ürünler

Diapro T?bbi Ürünler Across System user manual

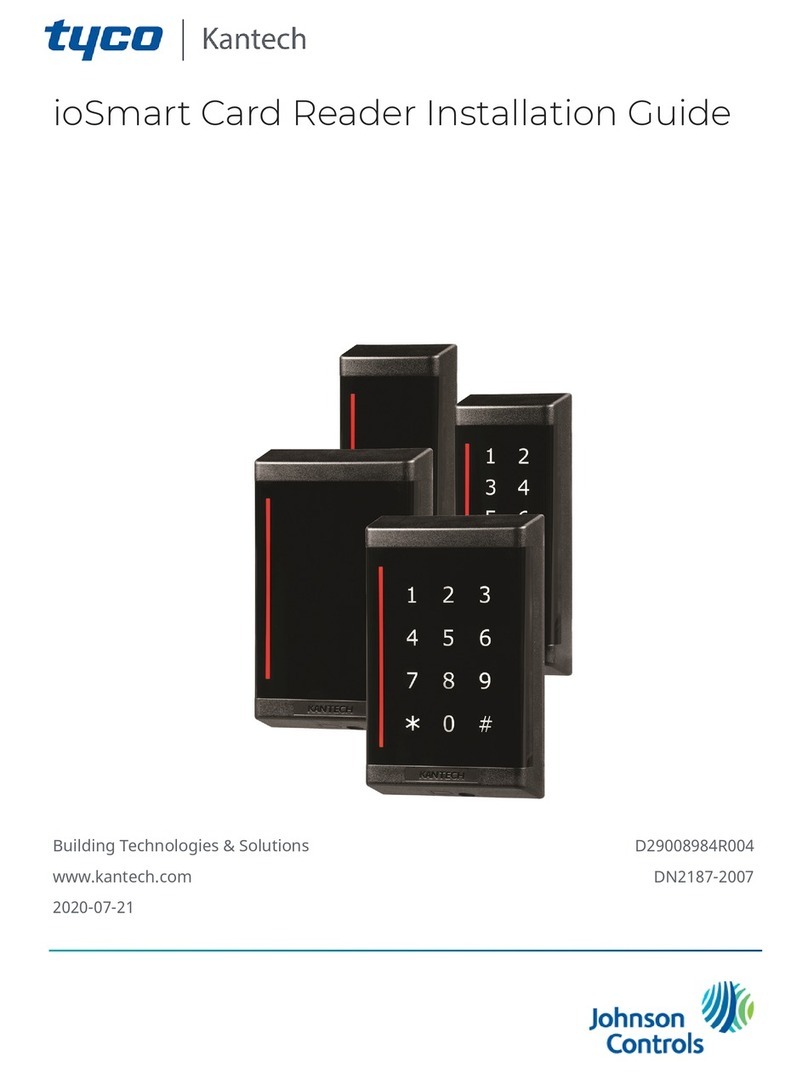

Johnson Controls

Johnson Controls Kantech tyco ioSmart installation guide