Pre-Installation Check of Shutter.

Before installation, carefully check for shipping damage which

may aect the operation of the unit. Concealed damage to the

shutter is possible. If damage is found, le a claim

immediately with the delivering carrier.

DO NOTINSTALL FAN W ITH MOVING PARTS WITHIN 8

FEET OF FLOOR OR GRADE LEVEL W ITHOUT A GUARD

THAT COMPLIES WITH OSHA REGULATIONS. DO NOT

USE UNLESS ELECTRICAL WIRING COMPLIES WITH

ALL APPLICABLE CODES. DO NOT WIRE WITHOUT

PROVIDING FOR A POWER SOURCE DISCONNECT AT

THE FAN ITSELF. DO NOT SERVICE EXCEPT BY A

QUALIFIED MAINTENANCE TECHNICIAN AND ONLY

AFTER DISCONNECTING THE POWER SOURCE.

FAILURE TO OBSERVE THESE PRECAUTIONS CAN

RESULT IN SERIOUS INJURY OR DEATH.

CAUTIONWARNING

Form No. 610-40-12 (June, 2019)

Fan Shutter Spacing.

For improved fan performance and extended fan and shutter

life, a space equal to one-half of the propeller diameter

between the fan and shutter is recommended. If job

conditions will not provide recommended space, the

following minimums should be observed:

S24 - S48 ............................ 5 inches

S54 - S84 .............................7 inches

Installation Procedures.

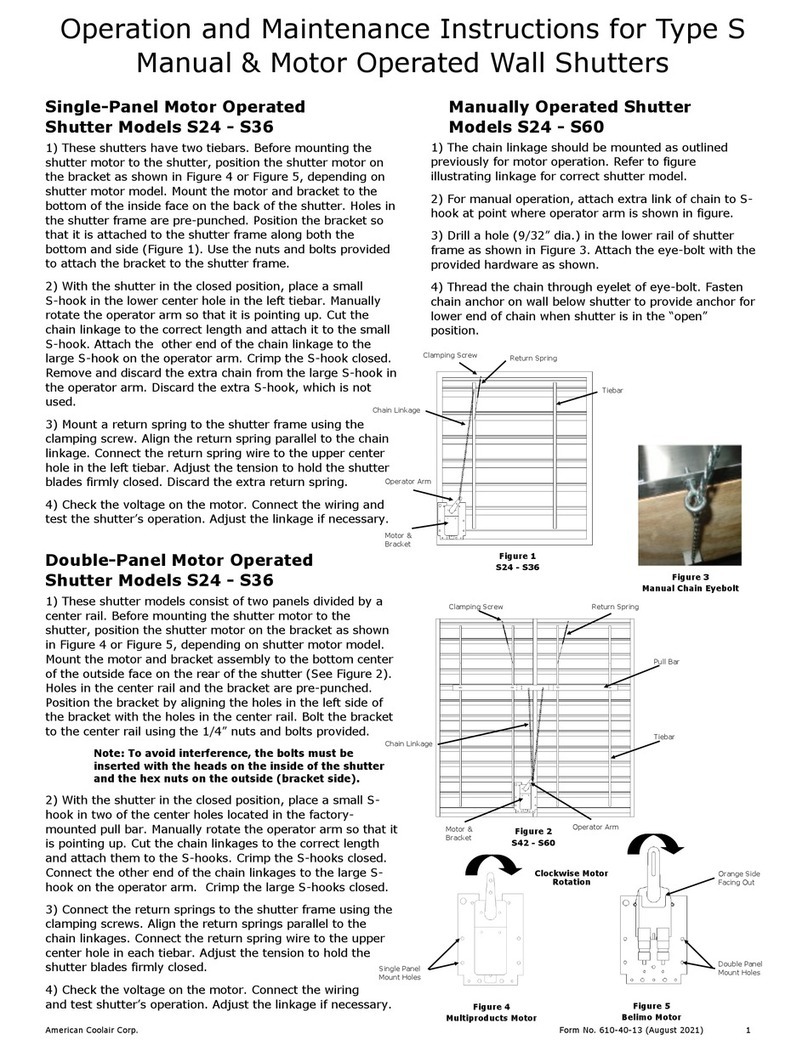

CAUTION: The Type S shutter is made up of many precision

made parts. For the shutter to function properly, care must be

taken when mounting and installing to avoid damage.

a) Do not twist the shutter frame or force shutter when

attaching it to the wall opening.

b) Caulk around the edge of anges and wall to prevent

water leakage.

c) When face-mounting the shutter to a wall, caulk joint of

top ange and shutter frame. See Fig 1 and Detail 1.

d) When ush mounting the shutter, caulk joint of bottom

ange and shutter frame, and also under weep holes

(recommended bead of caulk along the bottom edge of the

shutter frame before ange is attached) see Figure 2 and

Detail 2. After the ange is attached, caulk under weep hole to

avoid leaking behind the ange. Do not block weep holes with

caulk.

Note: When ush mounted, the bottom ange must

be behind the bent edge of the bottom ller strip

(see Detail 2). Wall opening should be a minimum

1/4” larger than the shutter frame.

Alternate Installation Methods.

All shutter models are shipped with anges detached (but in

the same carton as the shutter). This allows the shutter to be

mounted either to the outside face of the wall opening

(Figure 1), or recessed into the wall opening and ush with the

outside wall (Figure 2). The shutter may also be mounted

without the use of anges if desired.

e) If the shutter is mounted without the use of anges, do not

attach to the wall opening through the side of the shutter

frame. Instead, use angle clips and holes through which ange

is normally attached.

f) On 42”- 60”shutters, the center anges (two shortest

anges) need to be mounted to the center frame rail of the

shutter in order to minimize air and water leakage. The rear

center ange, which has 5 holes, mounts to the tiebar (or

blade linkage) side of the shutter. The front center ange,

which has 3 holes, mounts on the opposite side of the shutter.

Note: When attaching the top and bottom anges

to the top and bottom frame rails of the shutter,

make sure that the large hole on the corner of

the ange ts over the rivets on the corner of the

shutter frame. See Detail 2.

Detail 1

Detail 2

P.O. Box 2300 | Jacksonville, FL 32203

Ph 904-389-3646

Fax 904-387-3449 | 904-381-7560

www.americancoolair.com

Member AMCA

/AmericanCoolair

/AmericanCoolair

/Company/American-Coolair-Corp

Notice : Do not return damaged or defective parts to American Coolair Corp

without prior authorization. If repairs under warranty are claimed, see warranty

terms on the reverse. Claims for warranty repairs regarding the motor should be

made directly with the motor manufacturer.

Operation & Maintenance Instructions —Other Side

Installation Instructions

forType S Manual & Motor OperatedWall Shutters

Figure 1 Figure 2

Outside Wall

Outside Wall

Shuer

Shuer

Caulk

Caulk

Caulk

Air

Flow

Air

Flow

Mounng Screws (not

included)

Caulk

Boom

Filler Strip

Weep Hole

Flange Hole over

Corner Rivet